check engine INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1582 of 2395

Self-diagnosis ModeNBEL0231APPLICATION ITEMSNBEL0231S01

Mode DescriptionReference

page

Self DiagnosisSelf-diagnosis for display & NAVI control unit, CD-ROM

and GPS antenna connection.EL-398

Confirmation/

adjustmentDisplay Diagnosis Color and gray gradation of display can be checked in

this mode.EL-406

Diagnostic Signals from the Car Several input signals to display & NAVI control unit, can

be monitored in this mode.EL-404

NavigationCheck the map CD-

ROM versionThe version (parts number) of inserted CD-ROM can be

checked in this mode.EL-405

Error history Diagnosis results previously stored in the memory

(before turning ignition switch ON) are displayed in this

mode. Time and location when/where the errors

occurred are also displayed.EL-400

Longitude & Latitude Display the map. Use the joystick to adjust position. Lon-

gitude and latitude will be displayed.EL-407

Adjust the angle Turning angle of the vehicle on the display can be

adjusted in this mode.EL-408

Speed CalibrationUnder ordinary conditions, the navigation system dis-

tance measuring function will automatically compensate

for minute decreases in wheel and tire diameter caused

by tire wear or low pressure. Speed calibration immedi-

ately restores system accuracy in cases such as when

distance calibration is needed because of the use of tire

chains in inclement weather.EL-409

Initialize Location This mode is for initializing the current location. Use

when the vehicle is transported a long distance on a

trailer, etc.EL-433

SEL583X

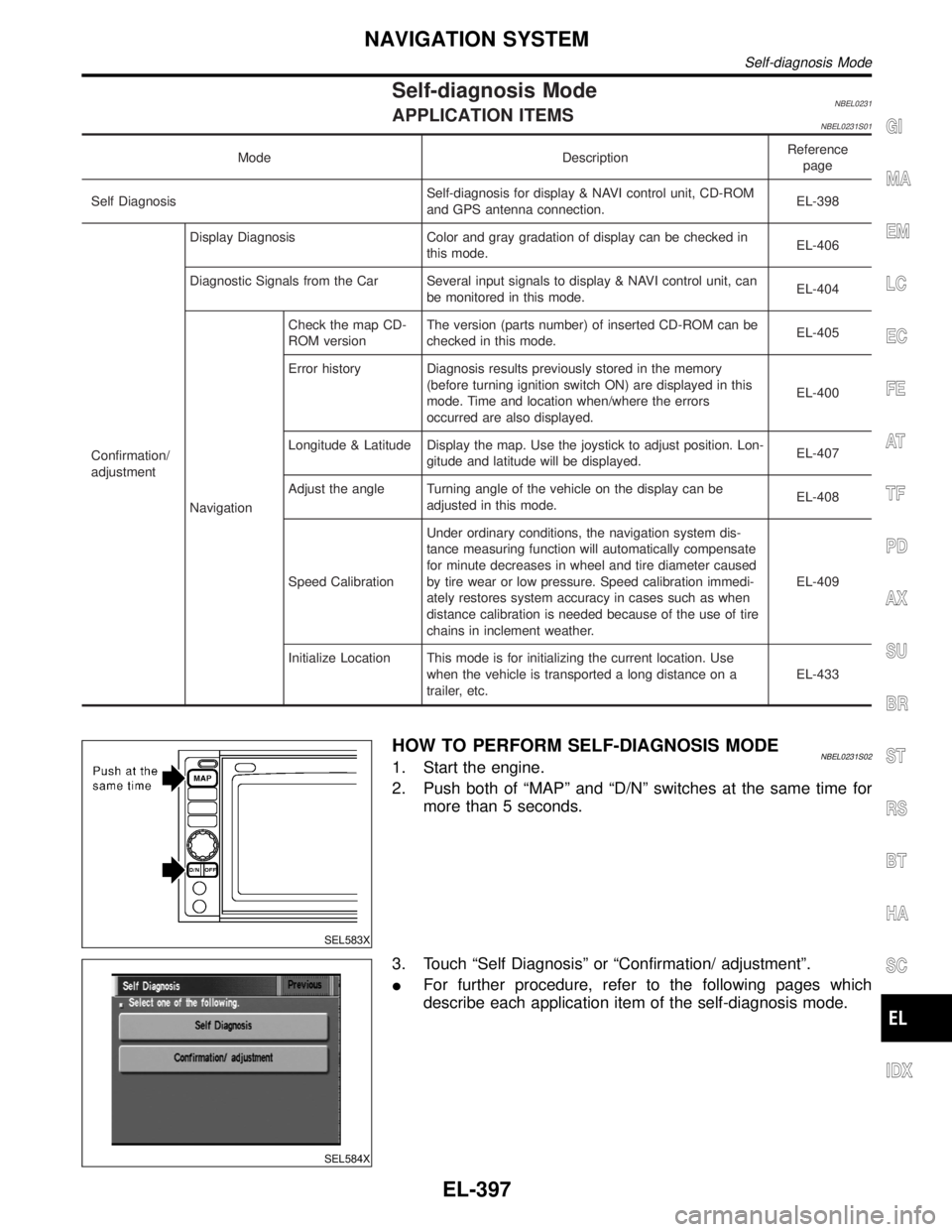

HOW TO PERFORM SELF-DIAGNOSIS MODENBEL0231S021. Start the engine.

2. Push both of ªMAPº and ªD/Nº switches at the same time for

more than 5 seconds.

SEL584X

3. Touch ªSelf Diagnosisº or ªConfirmation/ adjustmentº.

IFor further procedure, refer to the following pages which

describe each application item of the self-diagnosis mode.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

NAVIGATION SYSTEM

Self-diagnosis Mode

EL-397

Page 1589 of 2395

ªDIAGNOSTIC SIGNALS FROM THE CARº MODE=NBEL0232S03DescriptionNBEL0232S0301In ªDiagnostic Signals From the Carº mode, following input signals

to the display & NAVI control unit can be checked on the display.

Item Indication Vehicle condition

Vehicle

Speed*ON Vehicle speed is greater than 0 km/h (0 MPH).

OFF Vehicle speed is 0 km/h (0 MPH).

LightON Lighting switch is in 1st or 2nd position.

OFF Lighting switch is in ªOFFº position.

IGNON Ignition switch is in ªONº position.

OFF Ignition switch is in ªACCº position.

REVERSE*ON Selector/shift lever is in ªReverseº position.

OFFSelector/shift lever is in other than ªReverseº posi-

tion.

*: When ignition switch is in ªACCº position, indication will be changed to ª-º.

SEL584X

How to PerformNBEL0232S03021. Start the engine.

2. Push both ªMAPº and ªD/Nº switches at the same time for more

than 5 seconds.

3. Touch ªConfirmation/ adjustmentº.

SEL588X

4. Touch ªDiagnostic Signals from the Carº.

SEL591X

5. Then ªDiagnostic Signals from the Carº mode is performed.

NAVIGATION SYSTEM

Confirmation/Adjustment Mode (Cont'd)

EL-404

Page 1590 of 2395

SEL584X

ªCHECK THE MAP CD-ROM VERSIONº MODE=NBEL0232S04How to PerformNBEL0232S04011. Start the engine.

2. Push both ªMAPº and ªD/Nº switches at the same time for more

than 5 seconds.

3. Touch ªConfirmation/ adjustmentº.

SEL588X

4. Touch ªNavigationº.

SEL589X

5. Touch ªCheck the map CD-ROM versionº.

SEL592X

6. The version (parts number) of CD-ROM loaded to the display

and NAVI control unit will be displayed.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

NAVIGATION SYSTEM

Confirmation/Adjustment Mode (Cont'd)

EL-405

Page 1591 of 2395

ªDISPLAY DIAGNOSISº MODE=NBEL0232S05DescriptionNBEL0232S0501Use the ªDiagnosis Displayº mode to check the display color bright-

ness and shading. The display & NAVI control unit must be

replaced if the color brightness and shading are abnormal.

SEL584X

How to PerformNBEL0232S05021. Start the engine.

2. Push both ªMAPº and ªD/Nº switches at the same time for more

than 5 seconds.

3. Touch ªConfirmation/ adjustmentº.

SEL588X

4. Touch ªDisplay Diagnosisº.

SEL593X

5. Touch ªDisplay color spectrum barº or ªDisplay gradation barº.

6. Then color bar/gray scale will be displayed.

SEL594X

NAVIGATION SYSTEM

Confirmation/Adjustment Mode (Cont'd)

EL-406

Page 1593 of 2395

ªADJUST THE ANGLEº MODE=NBEL0232S07DescriptionNBEL0232S0701If the display indicates a larger or smaller turning angle than the

actual turning angle, the gyro (angular speed sensor) sensing val-

ues must be checked.

In case that the vehicle on the display makes larger angle turn than

reality, touch ªþº. In case that the vehicle on the display makes

smaller angle turn than reality, touch ª+º.

SEL584X

How to PerformNBEL0232S07021. Start the engine.

2. Push both ªMAPº and ªD/Nº switches at the same time for more

than 5 seconds.

3. Touch ªConfirmation/ adjustmentº.

SEL588X

4. Touch ªNavigationº.

SEL589X

5. Touch ªAdjust the angleº.

SEL596X

6. Touch ªLeft Turnº to adjust the angle to the left. Touch ªRight

Turnº to adjust the angle to the right.

7. Touch ª+º to increase the angle change coefficient or ªþº to

reduce the angle change coefficient.

8. Touch ªSetº to save the changed values in memory.

9. Then the vehicle turning angle on the display has adjusted.

NAVIGATION SYSTEM

Confirmation/Adjustment Mode (Cont'd)

EL-408

Page 1611 of 2395

Possible cause Drive condition Service procedure

Opera-

tionDriving immediately after starting engine.The gyro (angular velocity sensor)

needs about 15 seconds after the

engine is started to precisely sense

the angular velocity. Directional

sensing errors will occur if the

vehicle is moved immediately after

starting the engine. The position

marker may indicate inaccurate

position.Wait a few moments between

starting the engine and actually

driving the vehicle.

Continuous driving for long distances (non-stop)When the vehicle is driven continu-

ously without stopping over a long

distance, errors in directional sens-

ing may occur. The position marker

may indicate inaccurate position.Stop the vehicle. Perform

ªSPEED CALIBRATIONº (EL-

409).

Rough or violent drivingWheel spinning (peeling out) or simi-

lar rough driving techniques can

adversely affect sensing accuracy.

The position marker may indicate

inaccurate position.If the position marker does not

move to the correct position

even after the vehicle has been

driven approximately 10 km (6

miles), perform ªADJUST CUR-

RENT LOCATIONº (EL-411).

Posi-

tional

calibra-

tion pro-

ceduresPositional calibration precision

SEL701V

If current vehicle location is roughly

set, the system may be unable to

locate the road that the vehicle is

traveling on. (This is especially true

in an area where there are many

roads.)Perform ªADJUST CURRENT

LOCATIONº (EL-411) within a

precision standard of 1 mm

(0.04 in) on the display.

Note: During calibration, use

the most detailed map pos-

sible.

Position calibration direction

SEL702V

When calibrating the position, check

the vehicle direction. If the vehicle

direction is not correct, subsequent

precision of current location will be

affected.Perform ªADJUST CURRENT

LOCATIONº, refer to EL-411.

NAVIGATION SYSTEM

This Condition is Not Abnormal (Cont'd)

EL-426

Page 1644 of 2395

ENGINE MECHANICAL

SECTION

EM

CONTENTS

PRECAUTIONS...............................................................3

Parts Requiring Angular Tightening .............................3

Liquid Gasket Application Procedure ..........................3

PREPARATION...............................................................4

Special Service Tools ..................................................4

Commercial Service Tools ...........................................6

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................8

NVH Troubleshooting - Engine Noise .........................9

OUTER COMPONENT PARTS.....................................10

Removal and Installation ...........................................10

TIGHTENING PROCEDURES...................................12

MEASUREMENT OF COMPRESSION PRESSURE....14

OIL PAN.........................................................................15

Components...............................................................15

Removal .....................................................................15

Installation ..................................................................18

TIMING CHAIN..............................................................20

Components...............................................................20

POSITION FOR APPLYING LIQUID GASKET............21

Removal .....................................................................23

Inspection...................................................................29

Installation ..................................................................29

OIL SEAL.......................................................................35

Replacement ..............................................................35

VALVE OIL SEAL.....................................................35

OIL SEAL INSTALLATION DIRECTION.....................36

FRONT OIL SEAL....................................................36

REAR OIL SEAL......................................................36

CYLINDER HEAD..........................................................38

Components...............................................................38

Removal .....................................................................39

Disassembly...............................................................41

Inspection...................................................................42

CYLINDER HEAD DISTORTION...............................42

CAMSHAFT VISUAL CHECK....................................42

CAMSHAFT RUNOUT..............................................42

CAMSHAFT CAM HEIGHT.......................................42

CAMSHAFT JOURNAL CLEARANCE........................42

CAMSHAFT END PLAY............................................43

CAMSHAFT SPROCKET RUNOUT...........................43

VALVE GUIDE CLEARANCE....................................43

VALVE GUIDE REPLACEMENT................................44

VALVE SEATS.........................................................45

REPLACING VALVE SEAT FOR SERVICE PARTS....45

VALVE DIMENSIONS...............................................46

VALVE SPRING.......................................................46

VALVE LIFTER........................................................46

Assembly ...................................................................47

Installation ..................................................................47

Valve Clearance.........................................................52

CHECKING.............................................................52

ADJUSTING............................................................54

ENGINE ASSEMBLY.....................................................57

Removal and Installation ...........................................57

REMOVAL...............................................................58

INSTALLATION........................................................60

CYLINDER BLOCK.......................................................61

Components...............................................................61

CYLINDER BLOCK HEATER....................................62

Removal and Installation ...........................................62

Disassembly...............................................................62

PISTON, CRANKSHAFT AND OIL JET......................62

Inspection...................................................................63

PISTON AND PISTON PIN CLEARANCE..................63

PISTON RING SIDE CLEARANCE............................64

PISTON RING END GAP..........................................64

CONNECTING ROD BEND AND TORSION...............65

CYLINDER BLOCK DISTORTION AND WEAR...........65

PISTON-TO-BORE CLEARANCE..............................66

CRANKSHAFT.........................................................67

BEARING CLEARANCE...........................................67

CONNECTING ROD BUSHING CLEARANCE

(SMALL END)

..........................................................70

DRIVE PLATE RUNOUT..........................................70

Assembly ...................................................................71

PISTON..................................................................71

OIL JET..................................................................71

CRANKSHAFT.........................................................71

REPLACEMENT OF PILOT CONVERTER.................74

DRIVE PLATE.........................................................74

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 1652 of 2395

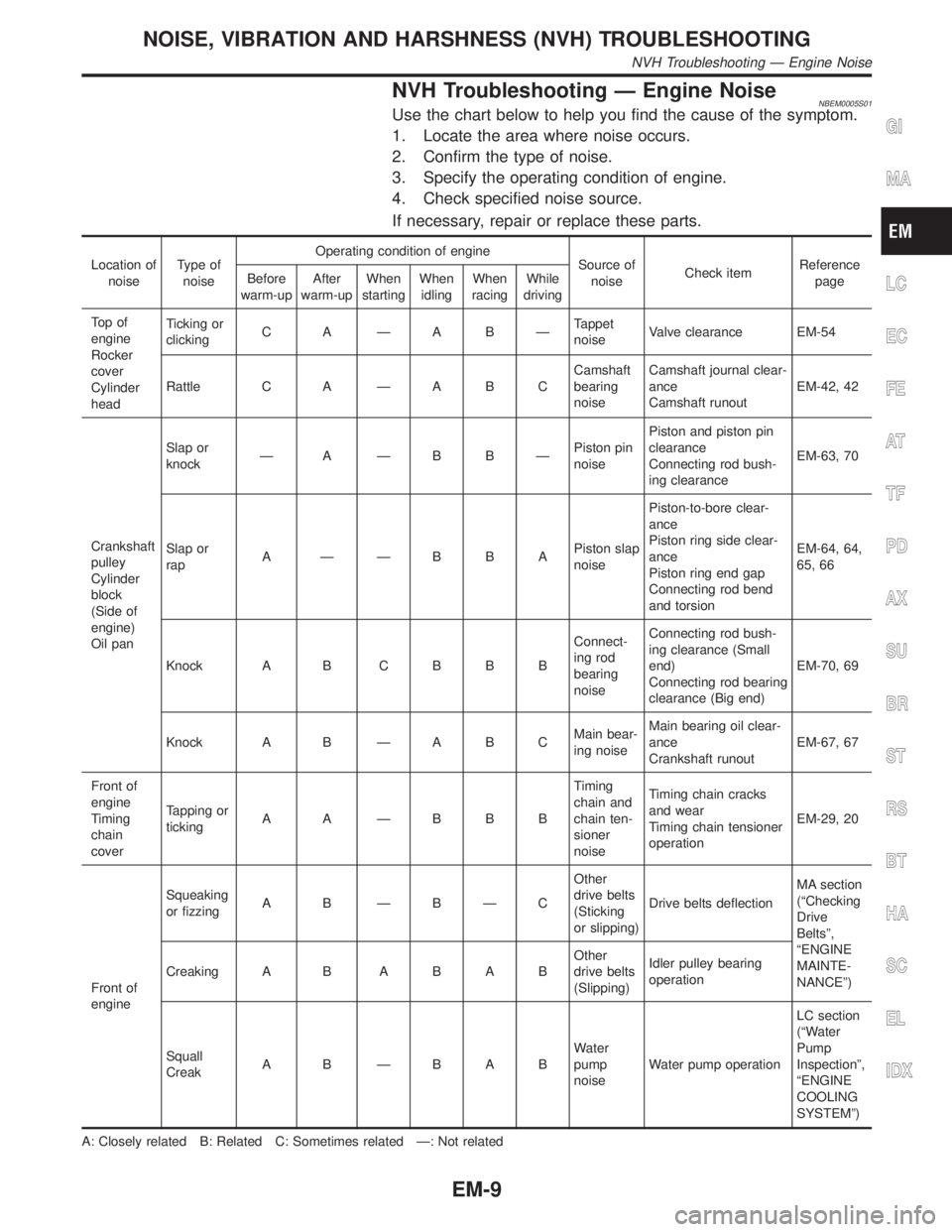

NVH Troubleshooting Ð Engine NoiseNBEM0005S01Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location of

noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemReference

page Before

warm-upAfter

warm-upWhen

startingWhen

idlingWhen

racingWhile

driving

To p o f

engine

Rocker

cover

Cylinder

headTicking or

clickingC A ÐA BÐTappet

noiseValve clearance EM-54

Rattle C A Ð A B CCamshaft

bearing

noiseCamshaft journal clear-

ance

Camshaft runoutEM-42, 42

Crankshaft

pulley

Cylinder

block

(Side of

engine)

Oil panSlap or

knockÐ A ÐB BÐPiston pin

noisePiston and piston pin

clearance

Connecting rod bush-

ing clearanceEM-63, 70

Slap or

rapA ÐÐBBAPiston slap

noisePiston-to-bore clear-

ance

Piston ring side clear-

ance

Piston ring end gap

Connecting rod bend

and torsionEM-64, 64,

65, 66

Knock A B C B B BConnect-

ing rod

bearing

noiseConnecting rod bush-

ing clearance (Small

end)

Connecting rod bearing

clearance (Big end)EM-70, 69

Knock A B Ð A B CMain bear-

ing noiseMain bearing oil clear-

ance

Crankshaft runoutEM-67, 67

Front of

engine

Timing

chain

coverTapping or

tickingA A ÐBBBTiming

chain and

chain ten-

sioner

noiseTiming chain cracks

and wear

Timing chain tensioner

operationEM-29, 20

Front of

engineSqueaking

or fizzingA B ÐBÐCOther

drive belts

(Sticking

or slipping)Drive belts deflectionMA section

(ªChecking

Drive

Beltsº,

ªENGINE

MAINTE-

NANCEº) Creaking A BABABOther

drive belts

(Slipping)Idler pulley bearing

operation

Squall

CreakA B ÐBABWater

pump

noiseWater pump operationLC section

(ªWater

Pump

Inspectionº,

ªENGINE

COOLING

SYSTEMº)

A: Closely related B: Related C: Sometimes related Ð: Not related

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Ð Engine Noise

EM-9

Page 1657 of 2395

NBEM0007

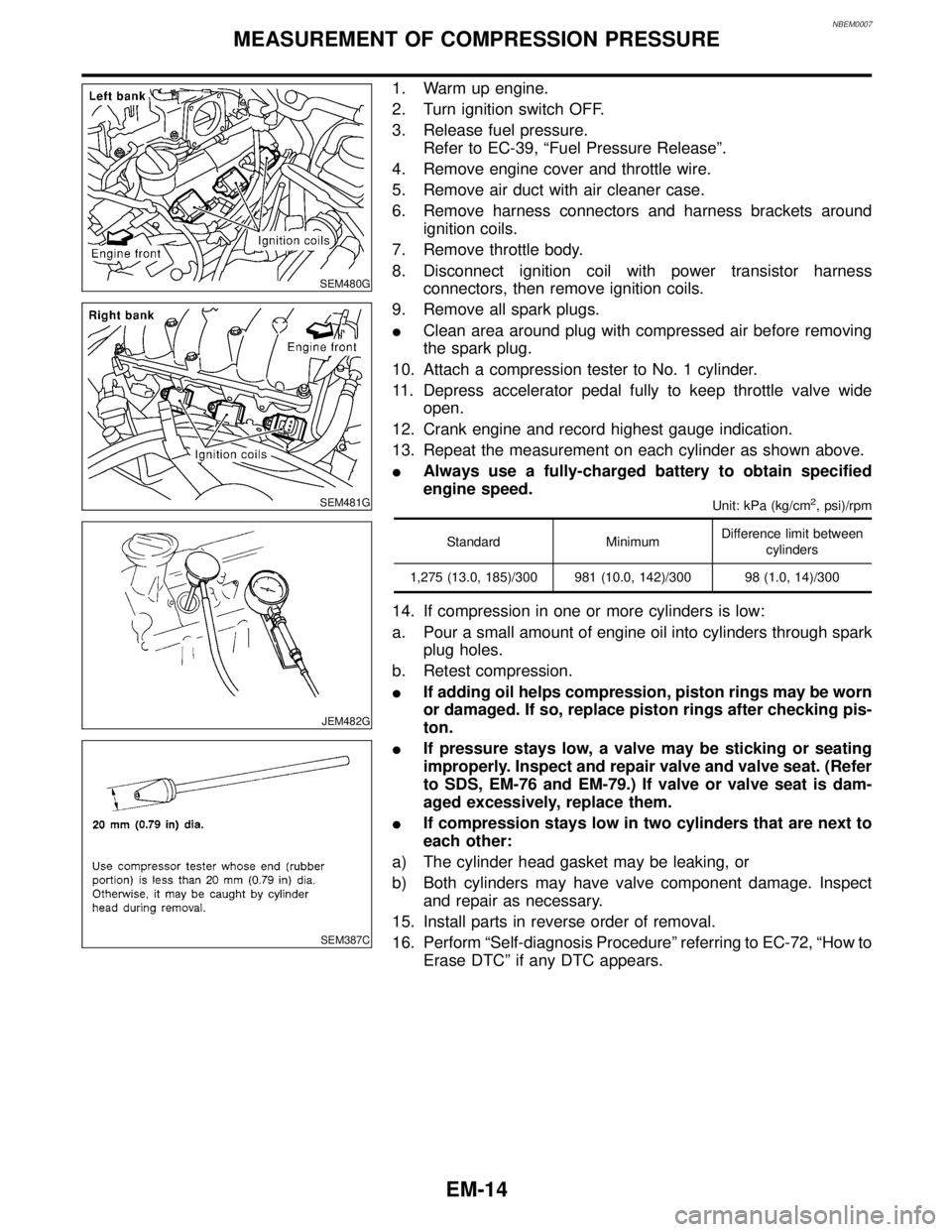

SEM480G

SEM481G

JEM482G

SEM387C

1. Warm up engine.

2. Turn ignition switch OFF.

3. Release fuel pressure.

Refer to EC-39, ªFuel Pressure Releaseº.

4. Remove engine cover and throttle wire.

5. Remove air duct with air cleaner case.

6. Remove harness connectors and harness brackets around

ignition coils.

7. Remove throttle body.

8. Disconnect ignition coil with power transistor harness

connectors, then remove ignition coils.

9. Remove all spark plugs.

IClean area around plug with compressed air before removing

the spark plug.

10. Attach a compression tester to No. 1 cylinder.

11. Depress accelerator pedal fully to keep throttle valve wide

open.

12. Crank engine and record highest gauge indication.

13. Repeat the measurement on each cylinder as shown above.

IAlways use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (kg/cm2, psi)/rpm

Standard MinimumDifference limit between

cylinders

1,275 (13.0, 185)/300 981 (10.0, 142)/300 98 (1.0, 14)/300

14. If compression in one or more cylinders is low:

a. Pour a small amount of engine oil into cylinders through spark

plug holes.

b. Retest compression.

IIf adding oil helps compression, piston rings may be worn

or damaged. If so, replace piston rings after checking pis-

ton.

IIf pressure stays low, a valve may be sticking or seating

improperly. Inspect and repair valve and valve seat. (Refer

to SDS, EM-76 and EM-79.) If valve or valve seat is dam-

aged excessively, replace them.

IIf compression stays low in two cylinders that are next to

each other:

a) The cylinder head gasket may be leaking, or

b) Both cylinders may have valve component damage. Inspect

and repair as necessary.

15. Install parts in reverse order of removal.

16. Perform ªSelf-diagnosis Procedureº referring to EC-72, ªHow to

Erase DTCº if any DTC appears.

MEASUREMENT OF COMPRESSION PRESSURE

EM-14

Page 1672 of 2395

SEM928E

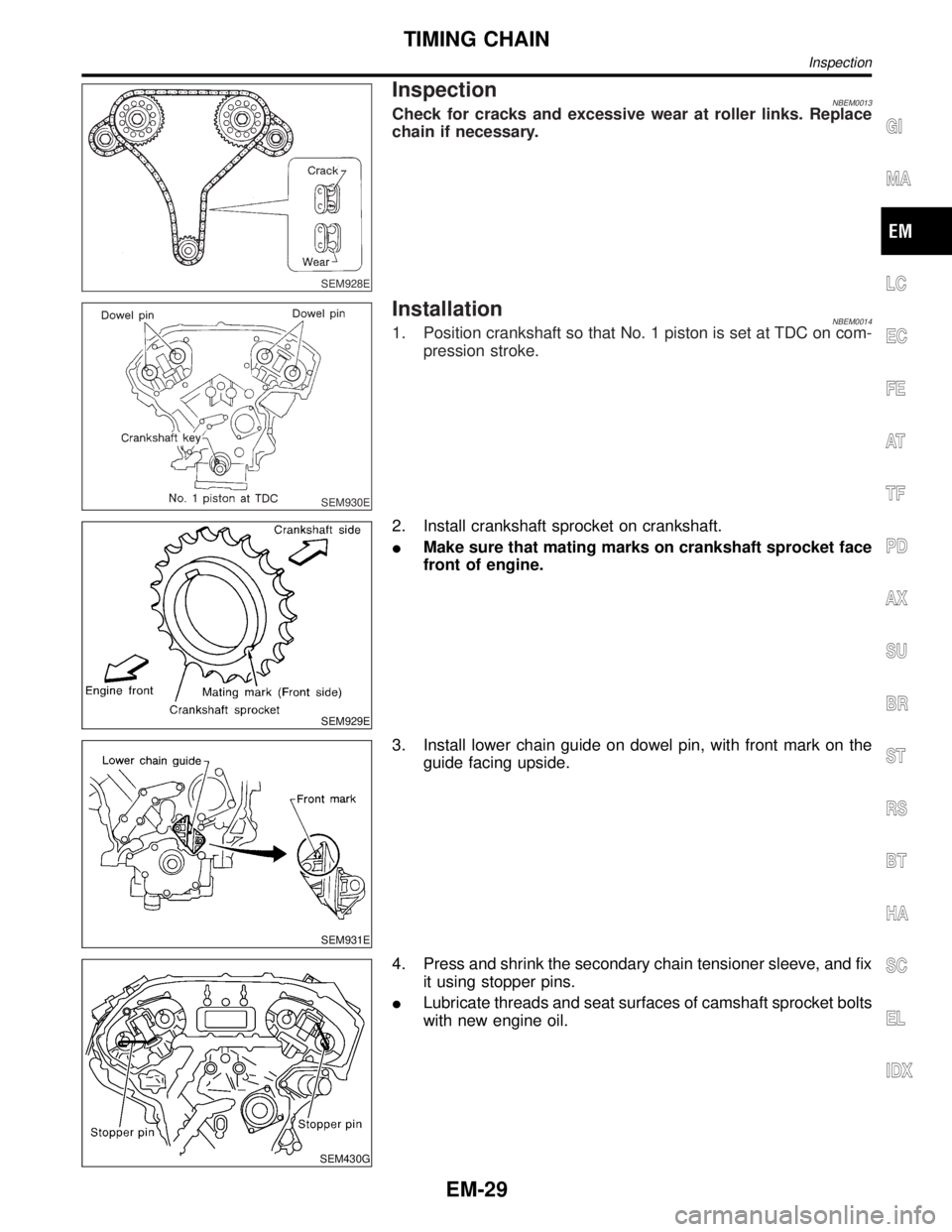

InspectionNBEM0013Check for cracks and excessive wear at roller links. Replace

chain if necessary.

SEM930E

InstallationNBEM00141. Position crankshaft so that No. 1 piston is set at TDC on com-

pression stroke.

SEM929E

2. Install crankshaft sprocket on crankshaft.

IMake sure that mating marks on crankshaft sprocket face

front of engine.

SEM931E

3. Install lower chain guide on dowel pin, with front mark on the

guide facing upside.

SEM430G

4. Press and shrink the secondary chain tensioner sleeve, and fix

it using stopper pins.

ILubricate threads and seat surfaces of camshaft sprocket bolts

with new engine oil.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAIN

Inspection

EM-29