oil temperature INFINITI QX4 2001 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1805 of 2395

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

IWhen the compressor is removed, store it in the same position as it is when mounted on the car.

Failure to do so will cause lubricant to enter the low pressure chamber.

IWhen connecting tubes, always use a torque wrench and a back-up wrench.

IAfter disconnecting tubes, immediately plug all openings to prevent entry of dirt and moisture.

IWhen installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other components until just before required for

connection.

IAllow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

IThoroughly remove moisture from the refrigeration system before charging the refrigerant.

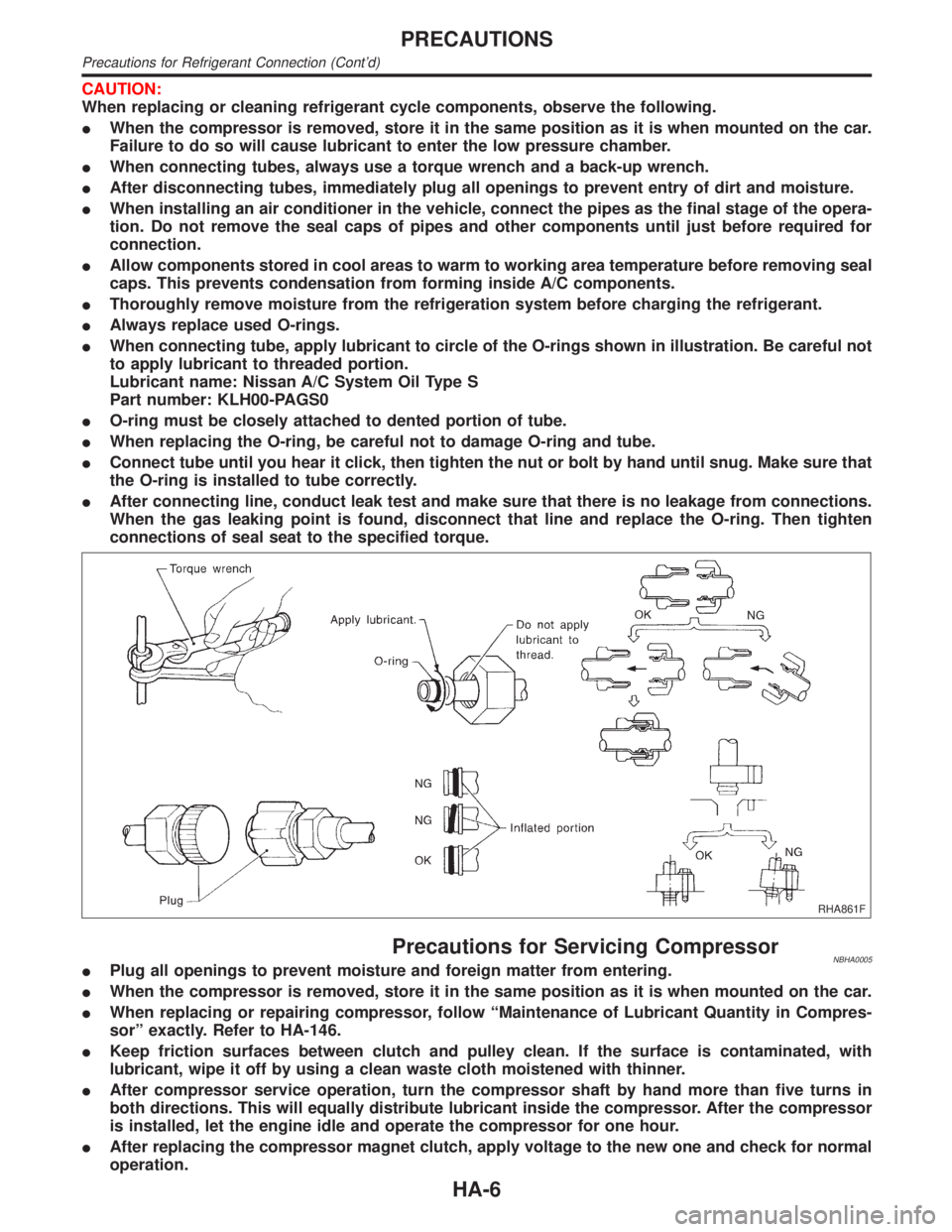

IAlways replace used O-rings.

IWhen connecting tube, apply lubricant to circle of the O-rings shown in illustration. Be careful not

to apply lubricant to threaded portion.

Lubricant name: Nissan A/C System Oil Type S

Part number: KLH00-PAGS0

IO-ring must be closely attached to dented portion of tube.

IWhen replacing the O-ring, be careful not to damage O-ring and tube.

IConnect tube until you hear it click, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

IAfter connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

RHA861F

Precautions for Servicing CompressorNBHA0005IPlug all openings to prevent moisture and foreign matter from entering.

IWhen the compressor is removed, store it in the same position as it is when mounted on the car.

IWhen replacing or repairing compressor, follow ªMaintenance of Lubricant Quantity in Compres-

sorº exactly. Refer to HA-146.

IKeep friction surfaces between clutch and pulley clean. If the surface is contaminated, with

lubricant, wipe it off by using a clean waste cloth moistened with thinner.

IAfter compressor service operation, turn the compressor shaft by hand more than five turns in

both directions. This will equally distribute lubricant inside the compressor. After the compressor

is installed, let the engine idle and operate the compressor for one hour.

IAfter replacing the compressor magnet clutch, apply voltage to the new one and check for normal

operation.

PRECAUTIONS

Precautions for Refrigerant Connection (Cont'd)

HA-6

Page 1813 of 2395

Refrigeration System

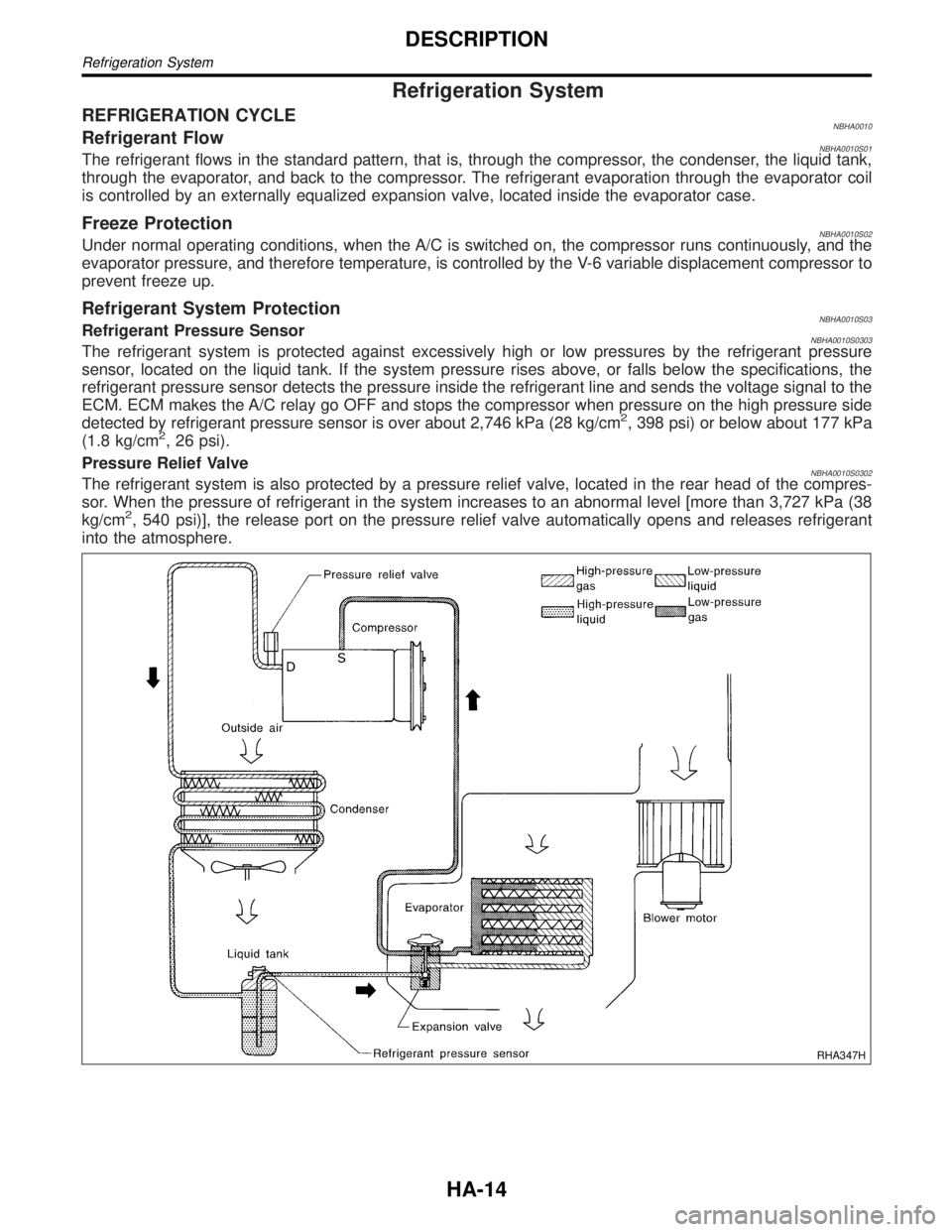

REFRIGERATION CYCLENBHA0010Refrigerant FlowNBHA0010S01The refrigerant flows in the standard pattern, that is, through the compressor, the condenser, the liquid tank,

through the evaporator, and back to the compressor. The refrigerant evaporation through the evaporator coil

is controlled by an externally equalized expansion valve, located inside the evaporator case.

Freeze ProtectionNBHA0010S02Under normal operating conditions, when the A/C is switched on, the compressor runs continuously, and the

evaporator pressure, and therefore temperature, is controlled by the V-6 variable displacement compressor to

prevent freeze up.

Refrigerant System ProtectionNBHA0010S03Refrigerant Pressure SensorNBHA0010S0303The refrigerant system is protected against excessively high or low pressures by the refrigerant pressure

sensor, located on the liquid tank. If the system pressure rises above, or falls below the specifications, the

refrigerant pressure sensor detects the pressure inside the refrigerant line and sends the voltage signal to the

ECM. ECM makes the A/C relay go OFF and stops the compressor when pressure on the high pressure side

detected by refrigerant pressure sensor is over about 2,746 kPa (28 kg/cm

2, 398 psi) or below about 177 kPa

(1.8 kg/cm2, 26 psi).

Pressure Relief Valve

NBHA0010S0302The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compres-

sor. When the pressure of refrigerant in the system increases to an abnormal level [more than 3,727 kPa (38

kg/cm

2, 540 psi)], the release port on the pressure relief valve automatically opens and releases refrigerant

into the atmosphere.

RHA347H

DESCRIPTION

Refrigeration System

HA-14

Page 1905 of 2395

RHA094GB

SYSTEM DESCRIPTION=NBHA0066Auto amplifier controls compressor operation by ambient tempera-

ture and signal from ECM.

Low Temperature Protection ControlNBHA0066S01Auto amplifier will turn the compressor ªONº or ªOFFº as deter-

mined by a signal detected by ambient sensor.

When ambient temperatures are greater than ±2ÉC (28ÉF), the

compressor turns ªONº. The compressor turns ªOFFº when ambi-

ent temperatures are less than þ5ÉC (23ÉF).

RHA877H

DIAGNOSTIC PROCEDURENBHA0067SYMPTOM: Magnet clutch does not engage when AUTO

switch is ON.

1 CHECK POWER SUPPLY FOR COMPRESSOR

Disconnect compressor harness connector. Do approx. 12 volts exist between compressor harness terminal No. 1 and

body ground?

RHA096G

YesorNo

Ye s©Check magnet clutch coil.

1. If NG, replace magnet clutch. Refer to HA-150.

2. Go to self-diagnosis step-by-step procedure (HA-45) and perform self-diagnosis STEP

4.

Confirm that magnet clutch operation is normal.

No©Disconnect A/C relay. And GO TO 2.

TROUBLE DIAGNOSES

Magnet Clutch (Cont'd)

HA-106

Page 1945 of 2395

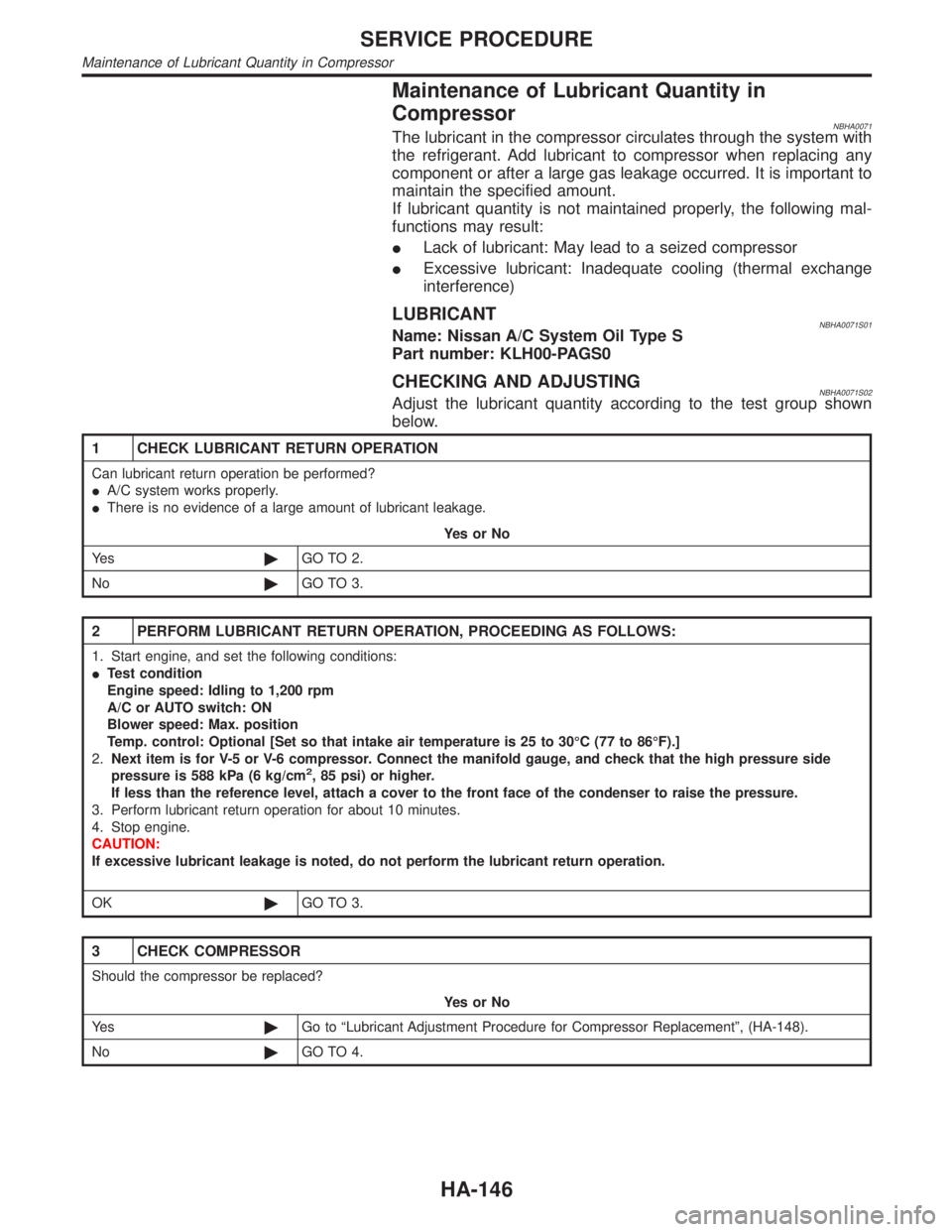

Maintenance of Lubricant Quantity in

Compressor

NBHA0071The lubricant in the compressor circulates through the system with

the refrigerant. Add lubricant to compressor when replacing any

component or after a large gas leakage occurred. It is important to

maintain the specified amount.

If lubricant quantity is not maintained properly, the following mal-

functions may result:

ILack of lubricant: May lead to a seized compressor

IExcessive lubricant: Inadequate cooling (thermal exchange

interference)

LUBRICANTNBHA0071S01Name: Nissan A/C System Oil Type S

Part number: KLH00-PAGS0

CHECKING AND ADJUSTINGNBHA0071S02Adjust the lubricant quantity according to the test group shown

below.

1 CHECK LUBRICANT RETURN OPERATION

Can lubricant return operation be performed?

IA/C system works properly.

IThere is no evidence of a large amount of lubricant leakage.

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

2 PERFORM LUBRICANT RETURN OPERATION, PROCEEDING AS FOLLOWS:

1. Start engine, and set the following conditions:

ITest condition

Engine speed: Idling to 1,200 rpm

A/C or AUTO switch: ON

Blower speed: Max. position

Temp. control: Optional [Set so that intake air temperature is 25 to 30ÉC (77 to 86ÉF).]

2.Next item is for V-5 or V-6 compressor. Connect the manifold gauge, and check that the high pressure side

pressure is 588 kPa (6 kg/cm

2, 85 psi) or higher.

If less than the reference level, attach a cover to the front face of the condenser to raise the pressure.

3. Perform lubricant return operation for about 10 minutes.

4. Stop engine.

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant return operation.

OK©GO TO 3.

3 CHECK COMPRESSOR

Should the compressor be replaced?

YesorNo

Ye s©Go to ªLubricant Adjustment Procedure for Compressor Replacementº, (HA-148).

No©GO TO 4.

SERVICE PROCEDURE

Maintenance of Lubricant Quantity in Compressor

HA-146

Page 1961 of 2395

A

AAC/V - Wiring diagram ...............................EC-425

ABS - Wiring diagram ....................................BR-37

ABS sensor rotor ........................................AX-6, 19

Absolute pressure sensor ............................EC-158

A/C air flow .....................................................HA-25

A/C component layout ....................................HA-19

A/C compressor clutch removal and

installation .................................................HA-150

A/C compressor precaution..............................HA-6

A/C compressor special service tool..............HA-10

A/C control operation (auto A/C) ....................HA-23

A/C diagnostic work flow (auto A/C) ..............HA-65

A/C HFC134a (R134a) system

precaution .....................................................HA-2

A/C HFC134a (R134a) system service

procedure ..................................................HA-144

A/C HFC134a (R134a) system service

tools.............................................................HA-11

A/C HFC134a system service equip-

ment precaution ............................................HA-7

A/C lubricant (R134a)...................................HA-146

A/C operational check ....................................HA-66

A/C performance chart .................................HA-116

A/C performance test diagnoses ..................HA-114

A/C relay .......................................................HA-110

A/C self-diagnoses (auto A/C)........................HA-44

A/C service data specification ......................HA-160

A/C system description (auto A/C) .................HA-23

A/C trouble diagnoses (auto A/C) ..................HA-27

A/C, A - Wiring diagram ...........................HA-31, 36

Accelerator control system ...............................FE-3

Accelerator wire adjustment .............................FE-3

Actuator lever (Transfer) ...............................TF-120

Air bag ............................................................RS-10

Air bag disposal..............................................RS-22

Air bag precautions ...........................................GI-3

Air bleeding for brake system ..........................BR-8

Air cleaner filter replacement .........................MA-17

Air conditioner cut control ..............................EC-31

Air flow meter - See Mass air flow

sensor .......................................................EC-150

Air mix door control linkage adjustment.........HA-85

Air mix. door motor ................................HA-82, 141

Air spoiler, rear................................................BT-35

All - mode 4WD system ..................................TF-10

Alternator ........................................................SC-28

Ambient sensor ............................................HA-129

Angular tightening application..........................EM-3

Antenna - See Power antenna .....................EL-169

Anti-lock brake system - Wiring

diagram .......................................................BR-37

AP/SEN - Wiring diagram ............................EC-160

ASCD (automatic speed control device) ......EL-221

ASCD - Wiring diagram ................................EL-225

A/T - Wiring diagram - AT - FTS ...................AT-107

A/T - Wiring diagram - AT - MAIN ...................AT-96

A/T - Wiring diagram - AT - PNP/SW............AT-101A/T - Wiring diagram - AT - VSS A/T ............AT-113

A/T control ....................................................EC-440

A/T diagnosis communication line................EC-603

A/T fluid temperature sensor .........................AT-110

A/T self-diagnoses...........................................AT-46

A/T shift lock system .....................................AT-265

A/T shift lock system - Wiring diagram .........AT-266

A/T trouble diagnoses .....................................AT-53

A/T Wiring diagram - AT - ENG SS...............AT-117

A/T Wiring diagram AT - 1ST ........................AT-123

A/T Wiring diagram AT - 2ND .......................AT-129

A/T Wiring diagram AT - 3RD .......................AT-135

A/T Wiring diagram AT - 4TH ........................AT-142

A/T Wiring diagram AT - BA/FTS ..................AT-192

A/T Wiring diagram AT - LPSV .....................AT-164

A/T Wiring diagram AT - NONDTC ...............AT-215

A/T Wiring diagram AT - OVRCSV ...............AT-187

A/T Wiring diagram AT - SSV/A ....................AT-169

A/T Wiring diagram AT - SSV/B ....................AT-173

A/T Wiring diagram AT - TCCSIG .................AT-156

A/T Wiring diagram AT - TCV .......................AT-150

A/T Wiring diagram AT - TPS........................AT-179

A/T Wiring diagram AT - VSSMTR................AT-199

AT/C - Wiring diagram ..................................EC-442

ATP switch.....................................................TF-112

ATP warning lamp .........................................TF-102

Audio .............................................................EL-160

AUDIO - Wiring diagram ...............................EL-162

Audio and A/C control removal and

installation - See Instrument panel .............BT-21

AUT/DP - Wiring diagram .............................EL-191

Auto air conditioner - Wiring diagram ......HA-31, 36

Automatic amplifier...................................HA-40, 72

Automatic drive positioner ............................EL-186

Automatic speed control system - See

ASCD ........................................................EL-221

Automatic transmission fluid

replacement ................................................MA-21

Automatic transmission number ......................GI-43

Auxiliary air control (AAC) valve ..................EC-422

Axle housing (rear) .........................................AX-19

B

Back door ........................................................BT-15

Back door opener - See Back door ................BT-15

Back door trim.................................................BT-34

Back-up lamp ..................................................EL-69

BACK/L - Wiring diagram................................EL-69

Ball joint (front) ...............................................SU-12

Base idle air volume initialiging......................EC-57

Basic inspection ...........................................EC-101

Battery ..............................................................SC-4

Battery/Starting/Charging System

Tester ................................................SC-7, 12, 21

Blower motor ..................................................HA-95

Body alignment ...............................................BT-57

Brake booster .................................................BR-19

Brake control valve (Proportioning

valve)...........................................................BR-11

ALPHABETICAL INDEX

IDX-2

Page 1963 of 2395

E

ECM input/output signal ...............................EC-127

ECTS - Wiring diagram ........................EC-171, 189

Electric sun roof ............................................EL-173

Electrical diagnoses.........................................GI-24

Electrical ignition system ................................EC-30

Electrical unit ................................................Foldout

Electrical units location .................................EL-436

Engine compartment .......................................BT-58

Engine control circuit diagram........................EC-24

Engine control component parts

location .......................................................EC-20

Engine control module (ECM) ......................EC-444

Engine control system diagram and

chart ............................................................EC-25

Engine coolant temperature sensor

(ECTS) ..............................................EC-169, 187

Engine fail-safe system ................................EC-117

Engine oil filter replacement ..........................MA-18

Engine oil precautions .......................................GI-8

Engine oil replacement ..................................MA-18

Engine outer component parts ......................EM-10

Engine removal ..............................................EM-57

Engine room - See Engine

compartment................................................BT-58

Engine serial number ......................................GI-43

EVAP canister.................................................EC-33

EVAP canister purge volume control

solenoid valve.............................EC-32, 367, 541

EVAP canister vent control

valve .........................................EC-374, 553, 573

EVAP control system (small leak)

diagnosis ..................................EC-352, 394, 526

EVAP control system pressure sensor.........EC-381

EVAP control system purge flow moni-

toring diagnosis.........................................EC-561

EVAP vapor lines inspection ..........................MA-20

Evaporative emission (EVAP) system ............EC-32

Exhaust system ................................................FE-8

Exhaust system inspection ............................MA-21

Exterior ............................................................BT-35

F

4LO indicator lamp........................................TF-104

4WD shift indicator lamp.................................TF-98

4WD shift switch ............................................TF-111

4WD solenoid valve.......................................TF-111

4WD warning lamp .........................................TF-13

Fan control amp. ............................................HA-98

F/FOG - Wiring diagram .................................EL-72

Final drive disassembly ..................................PD-43

Final drive pre-inspection ...............................PD-43

Final drive removal and installation ...............PD-43

Finisher, interior - See Trim ............................BT-28

F/LID - Wiring diagram .................................EL-180

Fluid temperature sensor (A/T) .....................AT-110Fluids ..............................................................MA-11

Flywheel runout..............................................EM-70

FO2H-L - Wiring diagram .............................EC-243

FO2H-R - Wiring diagram ............................EC-242

Fog lamp, front................................................EL-70

Fog lamp, front, removal and

installation ...................................................BT-12

Forward clutch ...............................................AT-320

F/PUMP - Wiring diagram ............................EC-627

Freeze frame data ..........................................EC-60

FRO2LH - Wiring diagram ...........EC-197, 223, 235

FRO2RH - Wiring diagram...........EC-196, 222, 234

Front axle..........................................................AX-2

Front bumper ..................................................BT-12

Front case (Transfer) ....................................TF-133

Front combination lamp removal and

installation ...................................................BT-12

Front disc brake .............................................BR-22

Front door .......................................................BT-18

Front drive shaft (Transfer) ...........................TF-125

Front final drive disassembly (4WD) ..............PD-18

Front final drive pre-inspection (4WD) ...........PD-18

Front final drive removal and installa-

tion (4WD)...................................................PD-18

Front fog lamp.................................................EL-70

Front fog lamp removal and installation .........BT-12

Front heated oxygen sensor (HO2S)

(Left bank) ................EC-192, 202, 210, 218, 231

Front heated oxygen sensor (HO2S)

(Right bank) .............EC-192, 202, 210, 218, 231

Front heated oxygen sensor heater

(Left bank).................................................EC-240

Front heated oxygen sensor heater

(Right bank) ..............................................EC-240

Front revolution sensor (Transfer) ................TF-112

Front seat ........................................................BT-41

Front seat belt ..................................................RS-4

Front suspension ..............................................SU-2

Front washer .................................................EL-136

Front wiper ....................................................EL-136

Fuel cut control (at no load & high

engine speed) .............................................EC-32

Fuel filler lid.....................................................BT-15

Fuel filter replacement ...................................MA-16

Fuel gauge ......................................................EL-94

Fuel injection system (Left bank) .........EC-294, 302

Fuel injection system (Right bank) ......EC-294, 302

Fuel lid opener, electric.................................EL-180

Fuel line inspection ........................................MA-16

Fuel precautions ................................................GI-8

Fuel pressure check .......................................EC-39

Fuel pressure regulator ..................................EC-40

Fuel pressure release ....................................EC-39

Fuel pump ....................................................EC-625

Fuel system ......................................................FE-4

Fuel tank temperature sensor ......................EC-309

Fuel tank vacuum relief valve ........................EC-33

FUELLH - Wiring diagram....................EC-297, 305

FUELRH - Wiring diagram ...................EC-296, 304

Fuse ................................................................EL-16

Fuse block ....................................................Foldout

ALPHABETICAL INDEX

IDX-4

Page 1973 of 2395

SLC351BA

SLC322B

SLC926

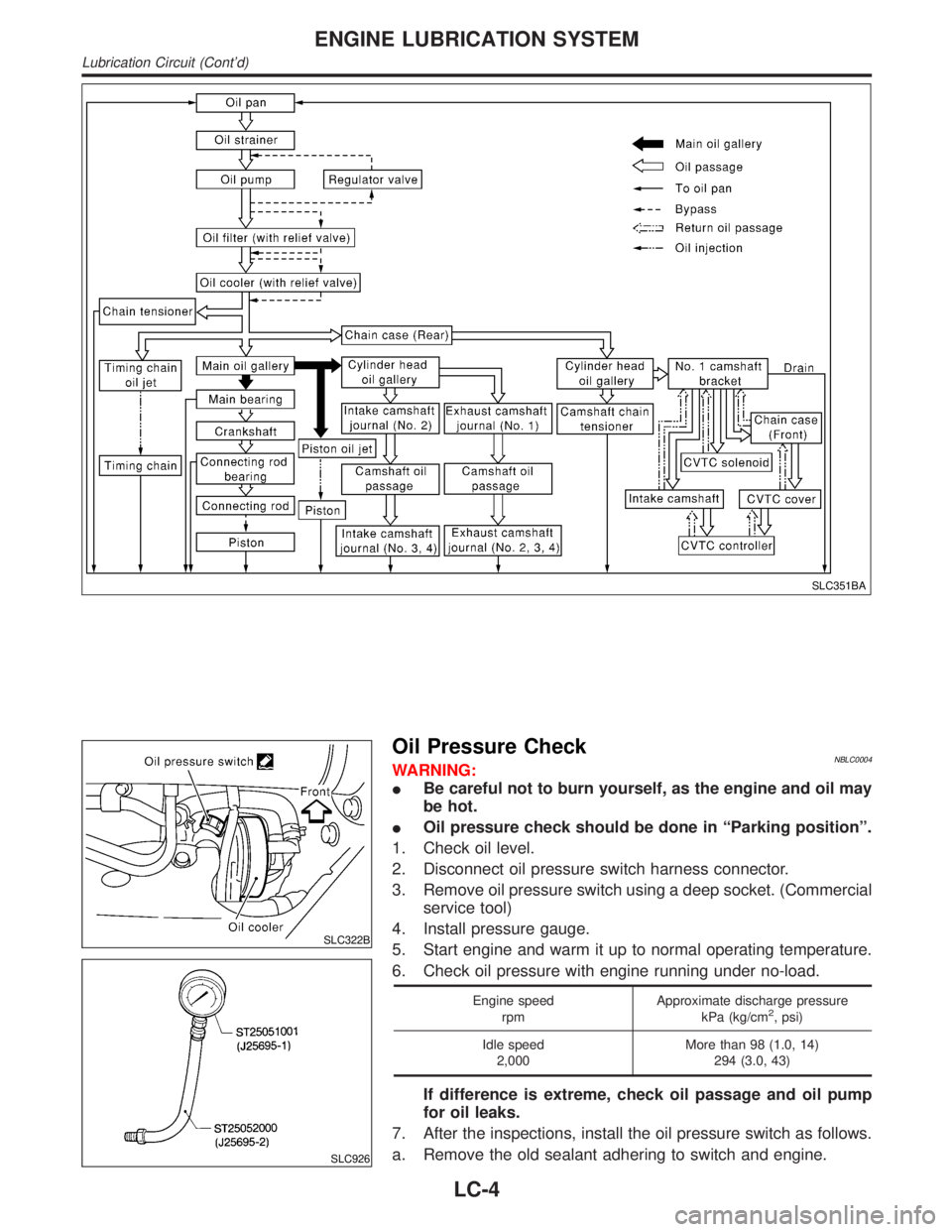

Oil Pressure CheckNBLC0004WARNING:

IBe careful not to burn yourself, as the engine and oil may

be hot.

IOil pressure check should be done in ªParking positionº.

1. Check oil level.

2. Disconnect oil pressure switch harness connector.

3. Remove oil pressure switch using a deep socket. (Commercial

service tool)

4. Install pressure gauge.

5. Start engine and warm it up to normal operating temperature.

6. Check oil pressure with engine running under no-load.

Engine speed

rpmApproximate discharge pressure

kPa (kg/cm2, psi)

Idle speed

2,000More than 98 (1.0, 14)

294 (3.0, 43)

If difference is extreme, check oil passage and oil pump

for oil leaks.

7. After the inspections, install the oil pressure switch as follows.

a. Remove the old sealant adhering to switch and engine.

ENGINE LUBRICATION SYSTEM

Lubrication Circuit (Cont'd)

LC-4

Page 2006 of 2395

NBMA0005

Fluids and LubricantsNBMA0005S01

Capacity (Approximate)

Recommended Fluids/Lubricants

US measure Imp measure Liter

Engine oilDrain and

refillWith oil filter 5-1/4 qt 4-3/8 qt 5.0

IAPI Certification Mark*1

IAPI grade SG/SH, Energy Conserv-

ingI&IIorAPIgrade SJ, Energy

Conserving*1

IILSAC grade GF-I & GF-II*1 Without oil

filter5-1/8 qt 4-1/4 qt 4.8

Dry engine

(Engine overhaul)7-1/4 qt 6 qt 6.8

Cooling system (With reservoir) 9-3/4 qt 8-1/8 qt 9.2Genuine Nissan anti-freeze coolant or

equivalent

All-mode 4WD transfer fluid 3-1/8 qt 2-5/8 qt 3.0Nissan Matic ªDº (Continental U.S. and

Alaska) or Canada NISSAN Automatic

Transmission Fluid*2

Differential

carrier gear

oilFront (4WD) 3-7/8 pt 3-1/4 pt 1.85Standard differential gear: API GL-5*1

Limited-slip differential (LSD) gear:

Use only LSD gear oil API GL-5 and

SAE 80W-90*5 approved for Nissan

LSD*6. Rear 5-7/8 pt 4-7/8 pt 2.8

Automatic transmission fluid2WD

9 qt 7-1/2 qt 8.5Nissan Matic ªDº (Continental U.S. and

Alaska) or Canada NISSAN Automatic

Transmission Fluid*3 4WD

Power steering fluid Ð Ð Ð Genuine NISSAN PSF II or equivalent*7

Brake fluid Ð Ð ÐGenuine Nissan Brake Fluid*4 or

equivalent DOT 3 (U.S. FMVSS No.

116)

Propeller shaft grease Ð Ð ÐNLGI No. 2 (Molybdenum disulphide

lithium soap base)

Multi-purpose grease Ð Ð Ð NLGI No. 2 (Lithium soap base)

*1: For further details, see ªSAE Viscosity Numberº.

*2: Outside the continental United States and Alaska contact an authorized INFINITI dealership for more information regarding suitable

fluids, including recommended brand(s) of DEXRON

TMIII/MERCONTMAutomatic Transmission Fluid.

*3: DEXRONTMIII/MERCONTMor equivalent may also be used. Outside the continental United States and Alaska contact an autho-

rized INFINITI dealership for more information regarding suitable fluids, including recommended brand(s) of DEXRONTMIII/MERCONTM

Automatic Transmission Fluid.

*4: Available in mainland U.S.A. through your INFINITI dealer.

*5: SAE 90 is acceptable in ambient temperatures above þ18ÉC (0ÉF).

*6: Contact an INFINITI dealer for a list of approved oils.

*7: Genuine NISSAN PSF, Canada NISSAN Automatic Transmission Fluid, DEXRON

TMIII/MERCONTMor equivalent ATF may also be

used.

GI

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

RECOMMENDED FLUIDS AND LUBRICANTS

Fluids and Lubricants

MA-11

Page 2007 of 2395

MMA117AA

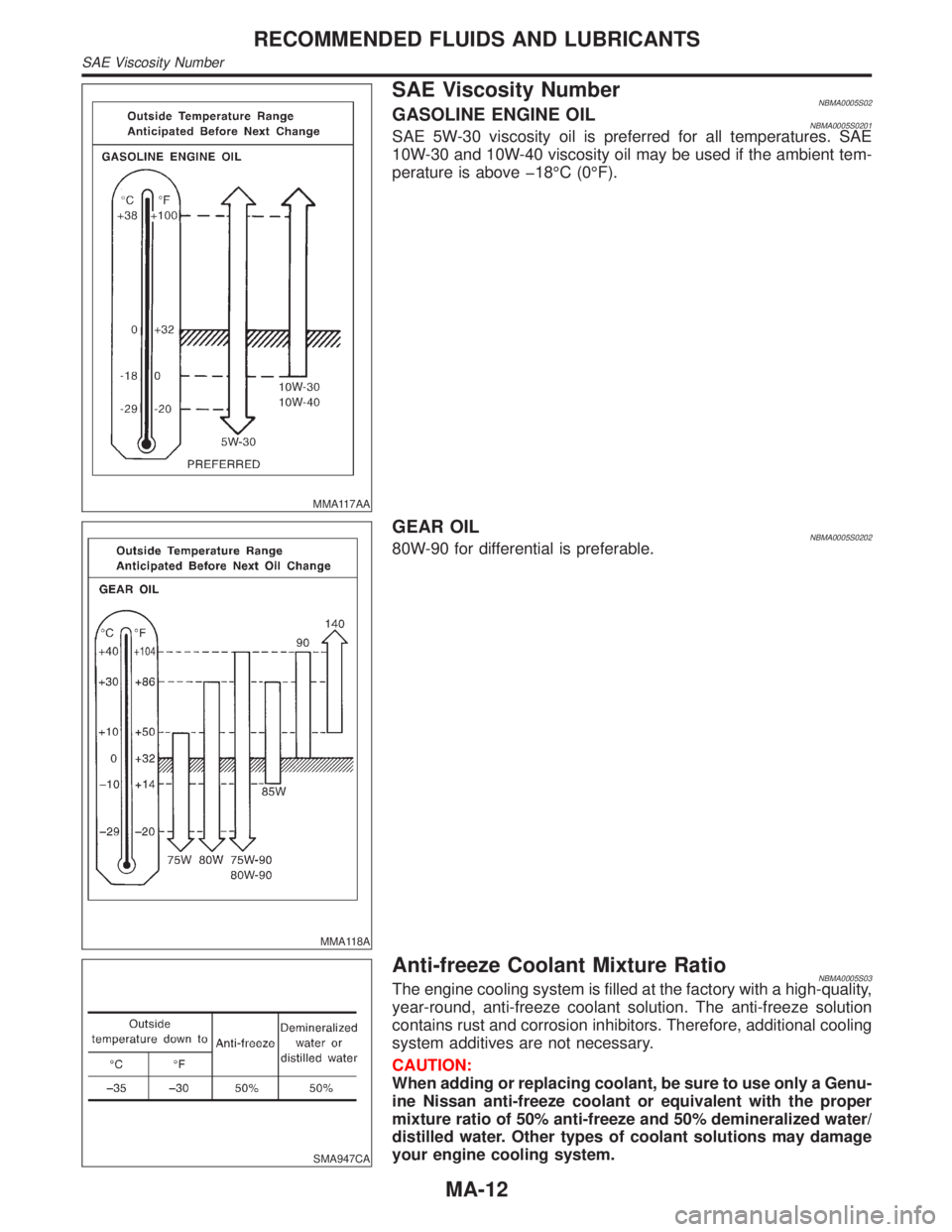

SAE Viscosity NumberNBMA0005S02GASOLINE ENGINE OILNBMA0005S0201SAE 5W-30 viscosity oil is preferred for all temperatures. SAE

10W-30 and 10W-40 viscosity oil may be used if the ambient tem-

perature is above þ18ÉC (0ÉF).

MMA118A

GEAR OILNBMA0005S020280W-90 for differential is preferable.

SMA947CA

Anti-freeze Coolant Mixture RatioNBMA0005S03The engine cooling system is filled at the factory with a high-quality,

year-round, anti-freeze coolant solution. The anti-freeze solution

contains rust and corrosion inhibitors. Therefore, additional cooling

system additives are not necessary.

CAUTION:

When adding or replacing coolant, be sure to use only a Genu-

ine Nissan anti-freeze coolant or equivalent with the proper

mixture ratio of 50% anti-freeze and 50% demineralized water/

distilled water. Other types of coolant solutions may damage

your engine cooling system.

RECOMMENDED FLUIDS AND LUBRICANTS

SAE Viscosity Number

MA-12

Page 2013 of 2395

SMA096D

Changing Engine OilNBMA0015WARNING:

IBe careful not to burn yourself, as the engine oil is hot.

IProlonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com-

ponents.

2. Stop engine and wait for more than 10 minutes.

3. Remove drain plug and oil filler cap.

4. Drain oil and refill with new engine oil.

Oil specification and viscosity

IAPI grade SG or SH, Energy ConservingI&IIorAPIgrade

SJ, Energy Conserving

IAPI Certification Mark

IILSAC grade GF-I & GF-II

ISee ªRECOMMENDED FLUIDS AND LUBRICANTSº, MA-11.

Oil capacity (Approximately):

Unit:(US qt, Imp qt)

Drain and refillWith oil filter change 5.0 (5-1/4, 4-3/8)

Without oil filter change 4.8 (5-1/8, 4-1/4)

Dry engine (engine overhaul) 6.8 (7-1/4, 6)

CAUTION:

IBe sure to clean drain plug and install with new washer.

Oil pan drain plug:

: 29 - 39 N´m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

IThe refill capacity depends on the oil temperature and

drain time. Use these specifications for reference only.

Always use the dipstick to determine when the proper

amount of oil is in the engine.

JMA122D

5. Warm up engine and check area around drain plug and oil fil-

ter for oil leakage.

6. Stop engine and wait for more than 10 minutes.

7. Check oil level.

SMA097D

Changing Oil FilterNBMA00161. Remove oil filter with Tool.

WARNING:

Be careful not to burn yourself, as the engine and engine oil

are hot.

The filter is a full-flow cartridge type and is provided with a relief

valve.

Refer to LC-7, ªOil Filterº.

ENGINE MAINTENANCE

Changing Engine Oil

MA-18