IDX INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 846 of 2395

Wiring DiagramNBEC0180

MEC957C

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0180 FUEL TANK TEMPERATURE SENSOR

Wiring Diagram

EC-311

Page 848 of 2395

4 CHECK FUEL TANK TEMPERATURE SENSOR

1. Remove fuel level sensor unit.

2. Check resistance between fuel level sensor unit and fuel pump terminals 1 and 2 by heating with hot water or heat gun

as shown in the figure.

SEF974Y

OK or NG

OK©GO TO 5.

NG©Replace fuel level sensor unit.

5 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0180 FUEL TANK TEMPERATURE SENSOR

Diagnostic Procedure (Cont'd)

EC-313

Page 850 of 2395

of 2 liters per minute like pouring coolant from a kettle. Be sure

to use coolant with the proper mixture ratio. Refer to MA-12,

ªAnti-freeze Coolant Mixture Ratioº.

b) After refilling coolant, run engine to ensure that no water-flow

noise is emitted.

c) After checking or replacing coolant, go to step 3 below.

2) Ask the customer if engine coolant has been added. If it has

been added, go to ªDiagnostic Procedureº, EC-316. After

repair, go to the next step.

3) Start engine and let it idle.

4) Make sure that A/C switch is ªOFFº and air conditioner is not

operating. If NG, check air conditioner circuit. Refer to HA-30

or HA-35, ªTROUBLE DIAGNOSESº. After repair, go to the

next step.

5) Check for blocked coolant passage.

a) Warm up engine to normal operating temperature, then grasp

radiator upper hose and lower hose and make sure that cool-

ant flows.

If NG, go to ªDiagnostic Procedureº, EC-316. After repair, go

to the next step.

Be extremely careful not to touch any moving or adjacent

parts.

6) Check for blocked radiator air passage.

a) When market fog lamps have been installed, check for dam-

aged fans and clogging in the condenser and radiator.

b) Check the front end for clogging caused by insects or debris.

c) Check for improper fitting of front-end cover, damaged radia-

tor grille or bumper, damaged vehicle front.

If NG, take appropriate action and then go to the next step.

7) Check function of ECT sensor.

Refer to step 7 of ªDiagnostic Procedureº, EC-316.

If NG, replace ECT sensor and go to the next step.

8) Check ignition timing. Refer to basic inspection, EC-101.

Make sure that ignition timing is 15ɱ5É at idle.

If NG, adjust ignition timing and then recheck.

WITH GSTNBEC0612S021) Check the coolant level and mixture ratio (using coolant tester)

in the reservoir tank and radiator.

Allow engine to cool before checking coolant level and

mixture ratio.

IIf the coolant level in the reservoir and/or radiator is below the

proper range, and go to ªDiagnostic Procedureº, EC-316.

IIf the coolant mixture ratio is out of the range of 45 to 55%,

replace the coolant in the following procedure MA-14, ªChang-

ing Engine Coolantº.

a) Fill radiator with coolant up to specified level with a filling speed

of 2 liters per minute like pouring coolant from a kettle. Be sure

to use coolant with the proper mixture ratio. Refer to MA-12,

ªAnti-freeze Coolant Mixture Ratioº.

b) After refilling coolant, run engine to ensure that no water-flow

noise is emitted.

c) After checking or replacing coolant, go to step 3 below.

2) Ask the customer if engine coolant has been added. If it has

been added, go to ªDiagnostic Procedureº, EC-316. After

repair, go to the next step.

3) Start engine and let it idle.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

Overall Function Check (Cont'd)

EC-315

Page 852 of 2395

2 DETECT MALFUNCTIONING PART

Check the following for leak.

IHose

IRadiator

IWater pump (Refer to LC-12, ªWater Pumpº.)

©Repair or replace.

3 CHECK RADIATOR CAP

Apply pressure to cap with a tester and check radiator cap relief pressure.

SLC755A

Radiator cap relief pressure:

59 - 98 kPa (0.6 - 1.0 kg/cm2,9-14psi)

OK or NG

OK©GO TO 4.

NG©Replace radiator cap.

4 CHECK THERMOSTAT

1. Remove thermostat.

2. Check valve seating condition at normal room temperatures.

It should seat tightly.

3. Check valve opening temperature and valve lift.

SLC343

Valve opening temperature:

76.5ÉC (170ÉF) [standard]

Valve lift:

More than 8.6 mm/90ÉC (0.339 in/194ÉF)

4. Check if valve is closed at 5ÉC (9ÉF) below valve opening temperature. For details, refer to LC-16, ªThermostatº.

OK or NG

OK©GO TO 5.

NG©Replace thermostat

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

Diagnostic Procedure (Cont'd)

EC-317

Page 854 of 2395

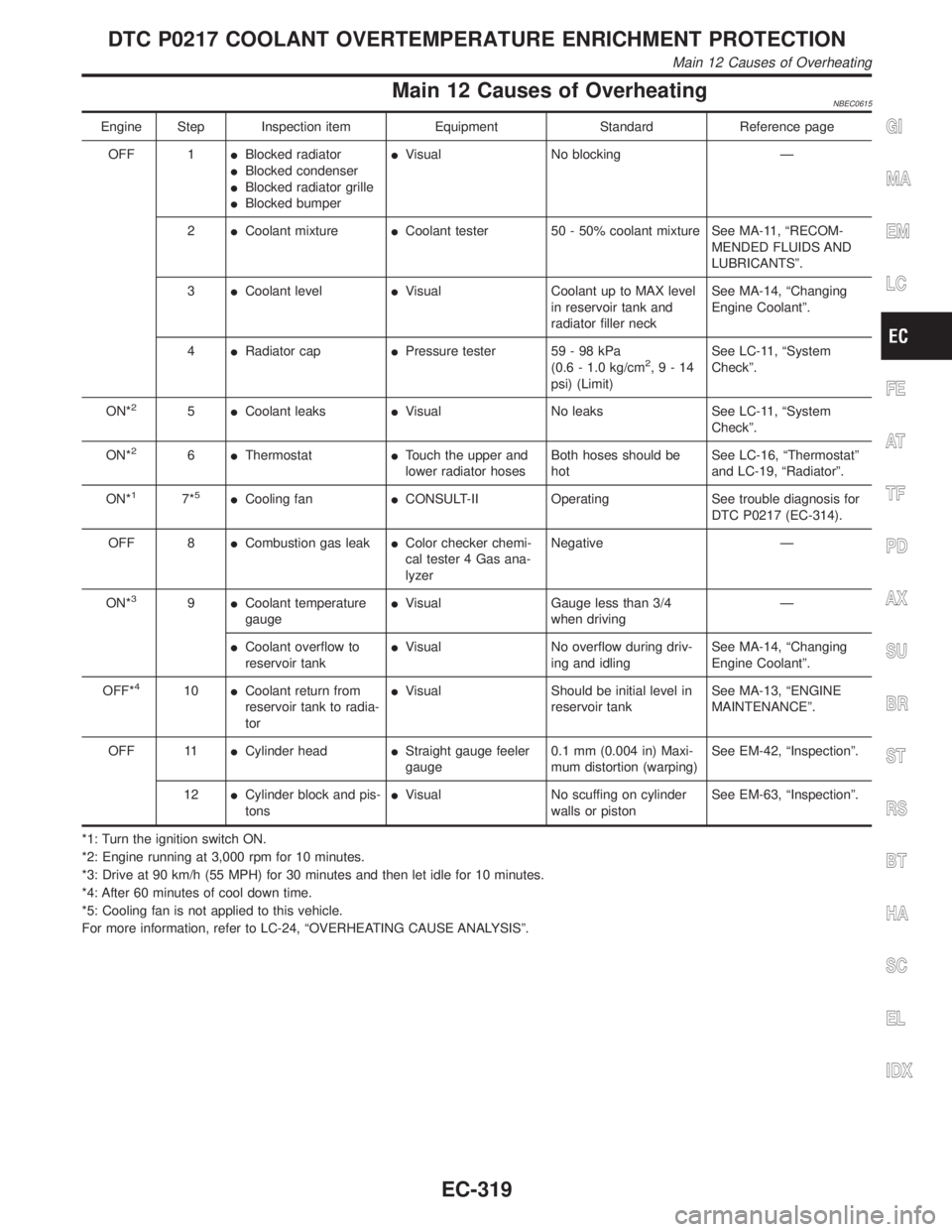

Main 12 Causes of OverheatingNBEC0615

Engine Step Inspection item Equipment Standard Reference page

OFF 1IBlocked radiator

IBlocked condenser

IBlocked radiator grille

IBlocked bumperIVisual No blocking Ð

2ICoolant mixtureICoolant tester 50 - 50% coolant mixture See MA-11, ªRECOM-

MENDED FLUIDS AND

LUBRICANTSº.

3ICoolant levelIVisual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee MA-14, ªChanging

Engine Coolantº.

4IRadiator capIPressure tester 59 - 98 kPa

(0.6 - 1.0 kg/cm

2,9-14

psi) (Limit)See LC-11, ªSystem

Checkº.

ON*

25ICoolant leaksIVisual No leaks See LC-11, ªSystem

Checkº.

ON*

26IThermostatITouch the upper and

lower radiator hosesBoth hoses should be

hotSee LC-16, ªThermostatº

and LC-19, ªRadiatorº.

ON*

17*5ICooling fanICONSULT-II Operating See trouble diagnosis for

DTC P0217 (EC-314).

OFF 8ICombustion gas leakIColor checker chemi-

cal tester 4 Gas ana-

lyzerNegative Ð

ON*

39ICoolant temperature

gaugeIVisual Gauge less than 3/4

when drivingÐ

ICoolant overflow to

reservoir tankIVisual No overflow during driv-

ing and idlingSee MA-14, ªChanging

Engine Coolantº.

OFF*

410ICoolant return from

reservoir tank to radia-

torIVisual Should be initial level in

reservoir tankSee MA-13, ªENGINE

MAINTENANCEº.

OFF 11ICylinder headIStraight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See EM-42, ªInspectionº.

12ICylinder block and pis-

tonsIVisual No scuffing on cylinder

walls or pistonSee EM-63, ªInspectionº.

*1: Turn the ignition switch ON.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

*5: Cooling fan is not applied to this vehicle.

For more information, refer to LC-24, ªOVERHEATING CAUSE ANALYSISº.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0217 COOLANT OVERTEMPERATURE ENRICHMENT PROTECTION

Main 12 Causes of Overheating

EC-319

Page 856 of 2395

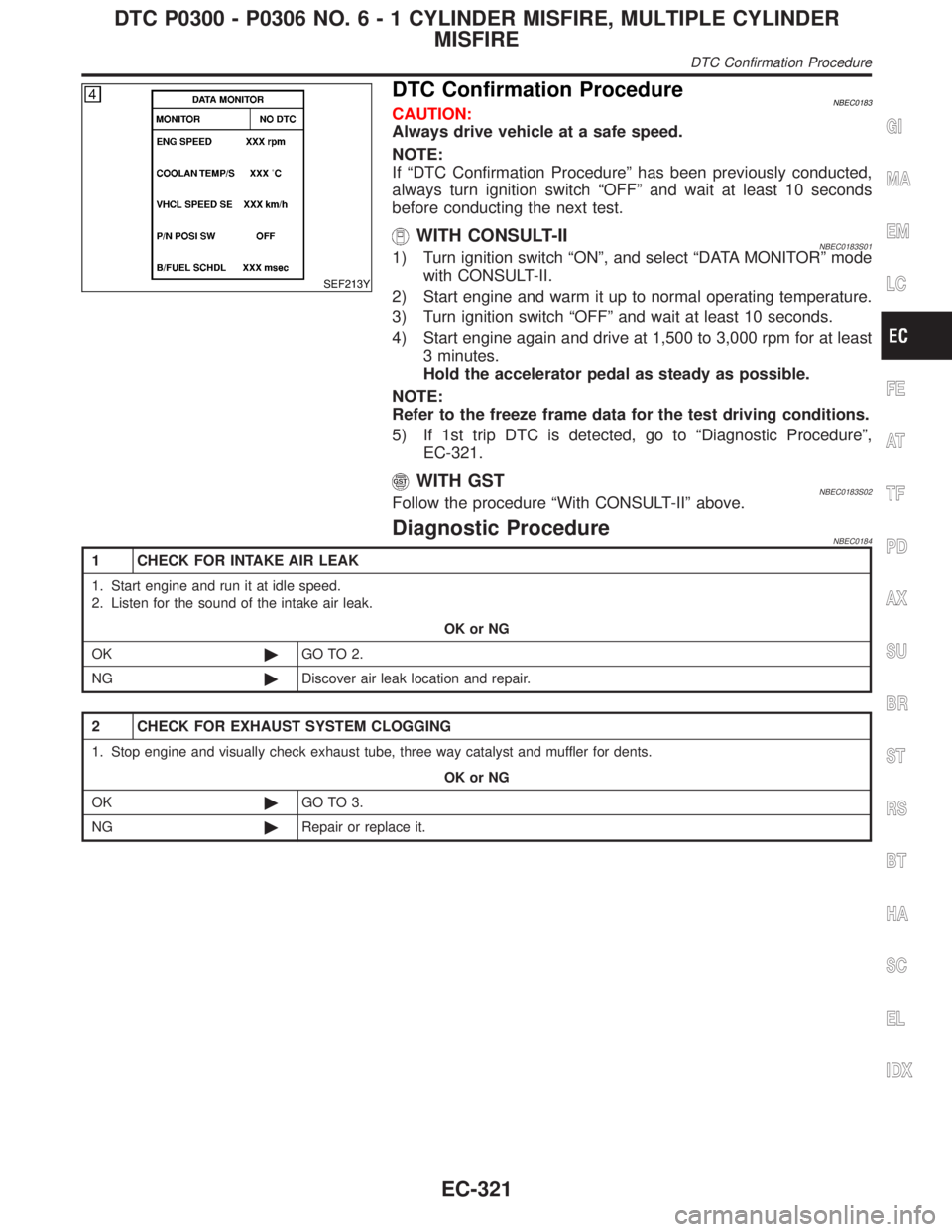

SEF213Y

DTC Confirmation ProcedureNBEC0183CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 10 seconds

before conducting the next test.

WITH CONSULT-IINBEC0183S011) Turn ignition switch ªONº, and select ªDATA MONITORº mode

with CONSULT-II.

2) Start engine and warm it up to normal operating temperature.

3) Turn ignition switch ªOFFº and wait at least 10 seconds.

4) Start engine again and drive at 1,500 to 3,000 rpm for at least

3 minutes.

Hold the accelerator pedal as steady as possible.

NOTE:

Refer to the freeze frame data for the test driving conditions.

5) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-321.

WITH GSTNBEC0183S02Follow the procedure ªWith CONSULT-IIº above.

Diagnostic ProcedureNBEC0184

1 CHECK FOR INTAKE AIR LEAK

1. Start engine and run it at idle speed.

2. Listen for the sound of the intake air leak.

OK or NG

OK©GO TO 2.

NG©Discover air leak location and repair.

2 CHECK FOR EXHAUST SYSTEM CLOGGING

1. Stop engine and visually check exhaust tube, three way catalyst and muffler for dents.

OK or NG

OK©GO TO 3.

NG©Repair or replace it.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0300 - P0306 NO.6-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

DTC Confirmation Procedure

EC-321

Page 858 of 2395

5 CHECK IGNITION SPARK

1. Disconnect ignition wire from spark plug.

2. Connect a known good spark plug to the ignition wire.

3. Place end of spark plug against a suitable ground and crank engine.

4. Check for spark.

SEF575Q

OK or NG

OK©GO TO 6.

NG©Check ignition coil, power transistor and their circuits. Refer to ªDTC P1320 IGNITION

SIGNALº, EC-499

6 CHECK SPARK PLUGS

Remove the spark plugs and check for fouling, etc.

SEF156I

OK or NG

OK©GO TO 7.

NG©Repair or replace spark plug(s) with standard type one(s). For spark plug type, refer to

MA-13, ªENGINE MAINTENANCEº.

7 CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM-14, ªMeasurement of Compression Pressureº.

Standard:

1,275 kPa (13.0 kg/cm

2, 185 psi)/300 rpm

Minimum:

981 kPa (10.0 kg/cm

2, 142 psi)/300 rpm

Difference between each cylinder:

98 kPa (1.0 kg/cm

2, 14 psi)/300 rpm

OK or NG

OK©GO TO 8.

NG©Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0300 - P0306 NO.6-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

Diagnostic Procedure (Cont'd)

EC-323

Page 860 of 2395

11 CHECK HEATED OXYGEN SENSOR 1 (FRONT)

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªMANU TRIGº and ªHI SPEEDº in ªDATA MONITORº mode with CONSULT-II, and select ªHO2S1 (B1)/(B2)º and

ªHO2S1 MNTR (B1)/(B2)º.

3. Hold engine speed at 2,000 rpm under no load during the following steps.

4. Touch ªRECORDº on CONSULT-II screen.

SEF967Y

5. Check the following.

IªHO2S1 MNTR (B1)/(B2)º in ªDATA MONITORº mode changes from ªRICHº to ªLEANº to ªRICHº 5 times in 10 seconds.

5 times (cycles) are counted as shown left:

SEF647Y

IªHO2S1 (B1)/(B2)º voltage goes above 0.6V at least once.

IªHO2S1 (B1)/(B2)º voltage goes below 0.3V at least once.

IªHO2S1 (B1)/(B2)º voltage never exceeds 1.0V.

SEF648Y

CAUTION:

Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

OK or NG

OK©GO TO 14.

NG©GO TO 13.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0300 - P0306 NO.6-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

Diagnostic Procedure (Cont'd)

EC-325

Page 862 of 2395

14 CHECK MASS AIR FLOW SENSOR

With CONSULT-II

Check mass air flow sensor signal in ªDATA MONITORº mode with CONSULT-II.

2.0 - 6.0 g´m/sec: at idling

7.0 - 20.0 g´m/sec: at 2,500 rpm

With GST

Check mass air flow sensor signal in MODE 1 with GST.

2.0 - 6.0 g´m/sec: at idling

7.0 - 20.0 g´m/sec: at 2,500 rpm

OK or NG

OK©GO TO 15.

NG©Check connectors for rusted terminals or loose connections in the mass air flow sensor

circuit or engine grounds. Refer to EC-150.

15 CHECK SYMPTOM MATRIX CHART

Check items on the rough idle symptom in ªSymptom Matrix Chartº, EC-118.

OK or NG

OK©GO TO 16.

NG©Repair or replace.

16 ERASE THE 1ST TRIP DTC

Erase the 1st trip DTC from the ECM memory after performing the tests. Refer to EC-72.

Some tests may cause a 1st trip DTC to be set.

©GO TO 17.

17 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0300 - P0306 NO.6-1CYLINDER MISFIRE, MULTIPLE CYLINDER

MISFIRE

Diagnostic Procedure (Cont'd)

EC-327

Page 864 of 2395

WITH CONSULT-IINBEC0188S011) Turn ignition switch ªONº and select ªDATA MONITORº mode

with CONSULT-II

2) Start engine and run it for at least 5 seconds at idle speed.

3) If DTC is detected, go to ªDiagnostic Procedureº, EC-331.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0325 KNOCK SENSOR (KS)

DTC Confirmation Procedure (Cont'd)

EC-329