02 sensor INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1174 of 2395

SEF029Z

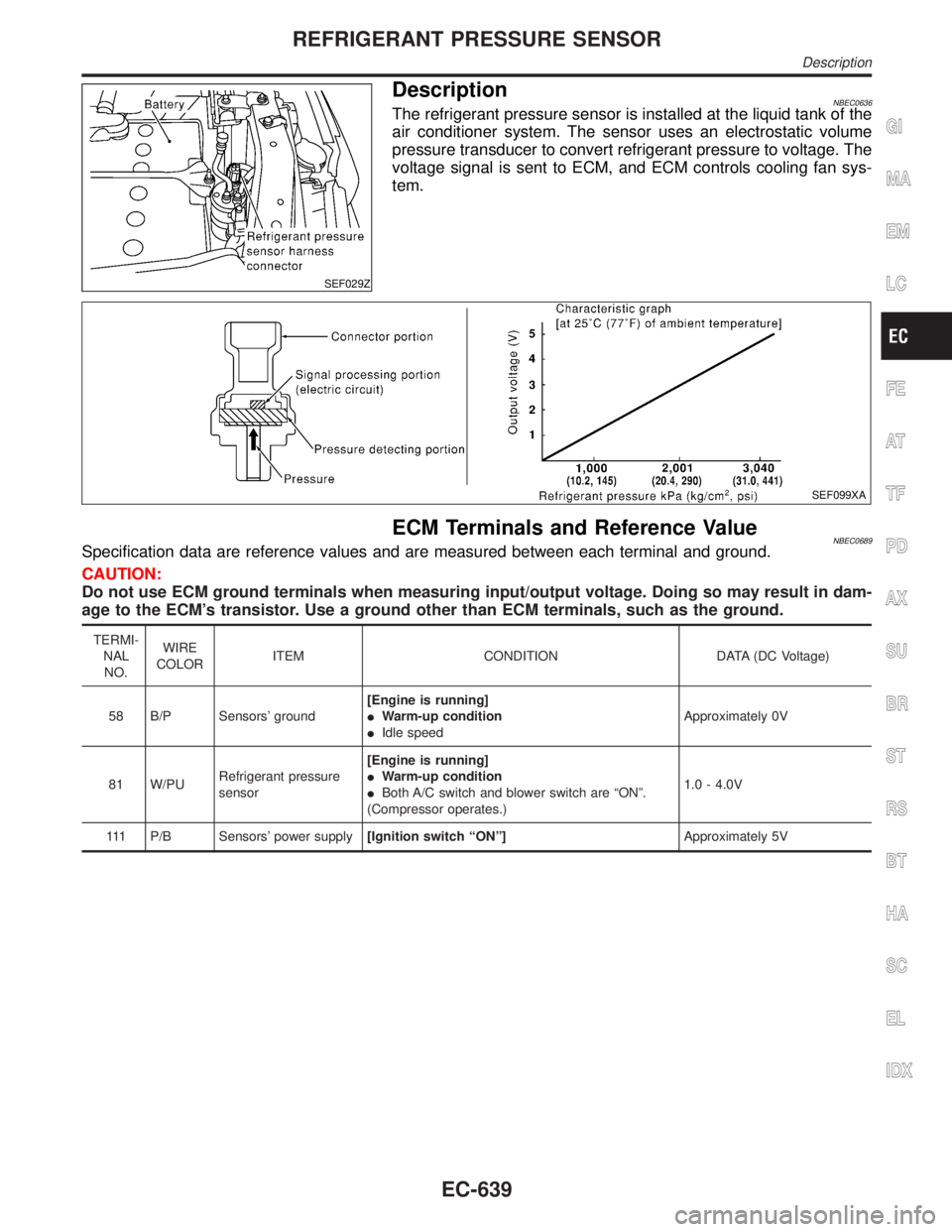

DescriptionNBEC0636The refrigerant pressure sensor is installed at the liquid tank of the

air conditioner system. The sensor uses an electrostatic volume

pressure transducer to convert refrigerant pressure to voltage. The

voltage signal is sent to ECM, and ECM controls cooling fan sys-

tem.

SEF099XA

ECM Terminals and Reference ValueNBEC0689Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

58 B/P Sensors' ground[Engine is running]

IWarm-up condition

IIdle speedApproximately 0V

81 W/PURefrigerant pressure

sensor[Engine is running]

IWarm-up condition

IBoth A/C switch and blower switch are ªONº.

(Compressor operates.)1.0 - 4.0V

111 P/B Sensors' power supply[Ignition switch ªONº]Approximately 5V

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REFRIGERANT PRESSURE SENSOR

Description

EC-639

Page 1175 of 2395

Wiring DiagramNBEC0637

MEC982C

REFRIGERANT PRESSURE SENSOR

Wiring Diagram

EC-640

Page 1176 of 2395

Diagnostic ProcedureNBEC0638

1 CHECK REFRIGERANT PRESSURE SENSOR OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Turn A/C switch and blower switch ªONº.

3. Check voltage between ECM terminal 81 and ground with CONSULT-II or tester.

SEF617XA

OK or NG

OK©INSPECTION END

NG©GO TO 2.

2 CHECK REFRIGERANT PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Turn A/C switch and blower switch ªOFFº.

2. Stop engine.

3. Disconnect refrigerant pressure sensor harness connector.

SEF029Z

4. Turn ignition switch ªONº.

5. Check voltage between refrigerant pressure sensor terminal 1 and ground with CONSULT-II or tester.

SEF030Z

OK or NG

OK©GO TO 4.

NG©GO TO 3.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

REFRIGERANT PRESSURE SENSOR

Diagnostic Procedure

EC-641

Page 1177 of 2395

3 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E1, M1

IHarness for open or short between ECM and refrigerant pressure sensor

©Repair harness or connectors.

4 CHECK REFRIGERANT PRESSURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between refrigerant pressure sensor terminal 1 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E1, M1 and M33, F22

IHarness connectors F23, M32

IHarness for open between ECM and refrigerant pressure sensor

IHarness for open between TCM (Transmission control module) and refrigerant pressure sensor

©Repair open circuit or short to power in harness or connectors.

6 CHECK REFRIGERANT PRESSURE SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 81 and refrigerant pressure sensor terminal 2. Refer to Wiring Dia-

gram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

IHarness connectors E1, M1 and M94, F27

IHarness for open or short between ECM and refrigerant pressure sensor

©Repair open circuit or short to ground or short to power in harness or connectors.

8 CHECK REFRIGERANT PRESSURE SENSOR

Refer to HA-14, ªRefrigerant pressure sensorº.

OK or NG

OK©GO TO 9.

NG©Replace refrigerant pressure sensor.

9 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

REFRIGERANT PRESSURE SENSOR

Diagnostic Procedure (Cont'd)

EC-642

Page 1184 of 2395

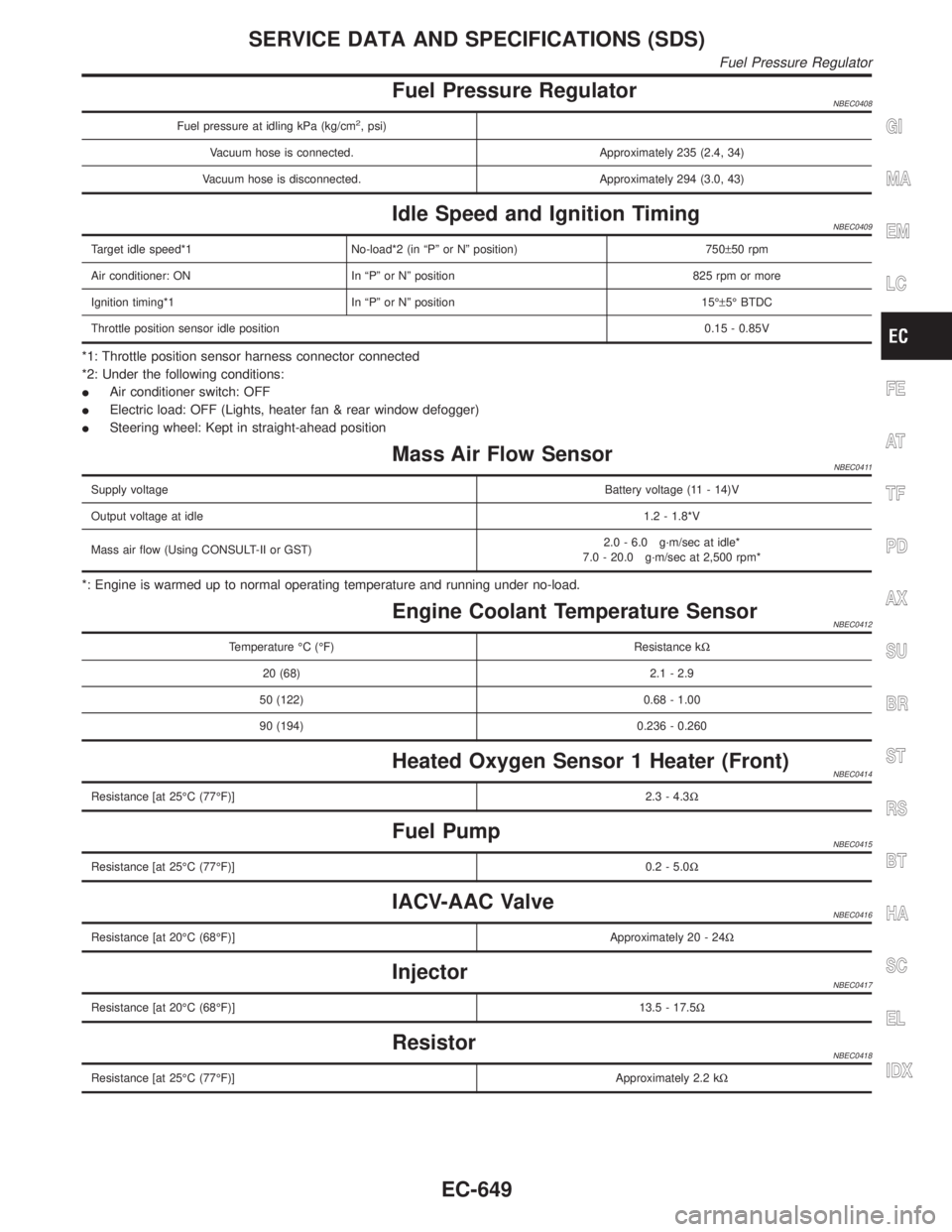

Fuel Pressure RegulatorNBEC0408

Fuel pressure at idling kPa (kg/cm2, psi)

Vacuum hose is connected. Approximately 235 (2.4, 34)

Vacuum hose is disconnected. Approximately 294 (3.0, 43)

Idle Speed and Ignition TimingNBEC0409

Target idle speed*1 No-load*2 (in ªPº or Nº position) 750±50 rpm

Air conditioner: ON In ªPº or Nº position 825 rpm or more

Ignition timing*1 In ªPº or Nº position 15ɱ5É BTDC

Throttle position sensor idle position0.15 - 0.85V

*1: Throttle position sensor harness connector connected

*2: Under the following conditions:

IAir conditioner switch: OFF

IElectric load: OFF (Lights, heater fan & rear window defogger)

ISteering wheel: Kept in straight-ahead position

Mass Air Flow SensorNBEC0411

Supply voltageBattery voltage (11 - 14)V

Output voltage at idle1.2 - 1.8*V

Mass air flow (Using CONSULT-II or GST)2.0 - 6.0 g´m/sec at idle*

7.0 - 20.0 g´m/sec at 2,500 rpm*

*: Engine is warmed up to normal operating temperature and running under no-load.

Engine Coolant Temperature SensorNBEC0412

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

Heated Oxygen Sensor 1 Heater (Front)NBEC0414

Resistance [at 25ÉC (77ÉF)]2.3 - 4.3W

Fuel PumpNBEC0415

Resistance [at 25ÉC (77ÉF)]0.2 - 5.0W

IACV-AAC ValveNBEC0416

Resistance [at 20ÉC (68ÉF)]Approximately 20 - 24W

InjectorNBEC0417

Resistance [at 20ÉC (68ÉF)]13.5 - 17.5W

ResistorNBEC0418

Resistance [at 25ÉC (77ÉF)]Approximately 2.2 kW

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

SERVICE DATA AND SPECIFICATIONS (SDS)

Fuel Pressure Regulator

EC-649

Page 1185 of 2395

Throttle Position SensorNBEC0419

Throttle valve conditionsVoltage

(at normal operating temperature,

engine off, ignition switch ON,

throttle opener disengaged)

Completely closed (a)0.15 - 0.85V

Partially openBetween (a) and (b)

Completely open (b)3.5 - 4.7V

Calculated Load ValueNBEC0420

Calculated load value % (Using CONSULT-II or GST)

At idle14.0 - 33.0

At 2,500 rpm12.0 - 25.0

Intake Air Temperature SensorNBEC0421

Temperature ÉC (ÉF) Resistance kW

20 (68)2.1 - 2.9

80 (176)0.27 - 0.38

Heated Oxygen Sensor 2 Heater (Rear)NBEC0422

Resistance [at 25ÉC (77ÉF)]2.3 - 4.3W

Crankshaft Position Sensor (REF)NBEC0423

Resistance [at 20ÉC (68ÉF)]470 - 570W

Fuel Tank Temperature SensorNBEC0424

Temperature ÉC (ÉF) Resistance kW

20 (68)2.3 - 2.7

50 (122)0.79 - 0.90

Camshaft Position Sensor (PHASE)NBEC0639

Resistance [at 20ÉC (68ÉF)]HITACHI make 1,440 - 1,760W

MITSUBISHI make 2,090 - 2,550W

SERVICE DATA AND SPECIFICATIONS (SDS)

Throttle Position Sensor

EC-650

Page 1187 of 2395

Electrical Components Inspection ...........................108

COMPASS AND THERMOMETER............................. 110

System Description .................................................. 110

Wiring Diagram - COMPAS -................................... 111

Trouble Diagnoses................................................... 112

Calibration Procedure for Compass ........................ 113

WARNING LAMPS...................................................... 114

Schematic ................................................................ 114

Wiring Diagram - WARN - ....................................... 115

Fuel Warning Lamp Sensor Check .........................122

Electrical Components Inspection ...........................122

A/T INDICATOR...........................................................123

Wiring Diagram - AT/IND -.......................................123

WARNING CHIME.......................................................125

Component Parts and Harness Connector

Location ...................................................................125

System Description ..................................................125

Wiring Diagram - CHIME - ......................................127

Trouble Diagnoses...................................................129

FRONT WIPER AND WASHER..................................136

System Description ..................................................136

Wiring Diagram - WIPER - ......................................138

Removal and Installation .........................................139

Washer Nozzle Adjustment .....................................140

Washer Tube Layout ...............................................140

REAR WIPER AND WASHER....................................141

System Description ..................................................141

Wiring Diagram - WIP/R -........................................143

Trouble Diagnoses...................................................145

Removal and Installation .........................................145

Washer Nozzle Adjustment .....................................146

Washer Tube Layout ...............................................146

Check Valve .............................................................146

HORN...........................................................................147

Wiring Diagram - HORN - .......................................147

CIGARETTE LIGHTER................................................148

Wiring Diagram - CIGAR -.......................................148

CLOCK.........................................................................150

Wiring Diagram - CLOCK -......................................150

REAR WINDOW DEFOGGER.....................................151

Component Parts and Harness Connector

Location ...................................................................151

System Description ..................................................151

Wiring Diagram - DEF - ...........................................153

Trouble Diagnoses...................................................155

Electrical Components Inspection ...........................157

Filament Check ........................................................157

Filament Repair .......................................................158

AUDIO..........................................................................160

System Description ..................................................160

Schematic ................................................................161

Wiring Diagram - AUDIO - .......................................162Trouble Diagnoses...................................................166

Inspection.................................................................167

Wiring Diagram - REMOTE -...................................168

AUDIO ANTENNA.......................................................169

System Description ..................................................169

Wiring Diagram - P/ANT - .......................................170

Trouble Diagnoses...................................................171

Location of Antenna .................................................171

Antenna Rod Replacement .....................................171

POWER SUNROOF.....................................................173

System Description ..................................................173

Wiring Diagram - SROOF - .....................................174

Trouble Diagnoses...................................................176

DOOR MIRROR...........................................................177

Wiring Diagram - MIRROR - ...................................177

GLASS HATCH OPENER...........................................178

System Description ..................................................178

Wiring Diagram - TLID - ..........................................179

FUEL FILLER LID OPENER.......................................180

Wiring Diagram - F/LID - .........................................180

POWER SEAT.............................................................181

Wiring Diagram - SEAT - .........................................181

HEATED SEAT............................................................183

Wiring Diagram - HSEAT - ......................................183

Seatback Heating Unit .............................................185

AUTOMATIC DRIVE POSITIONER............................186

Component Parts and Harness Connector

Location ...................................................................186

System Description ..................................................187

Schematic ................................................................190

Wiring Diagram - AUT/DP - .....................................191

On Board Diagnosis ................................................196

Trouble Diagnoses...................................................198

AUTOMATIC SPEED CONTROL DEVICE (ASCD)...221

Component Parts and Harness Connector

Location ...................................................................221

System Description ..................................................222

Schematic ................................................................224

Wiring Diagram - ASCD - ........................................225

Fail-safe System ......................................................229

Trouble Diagnoses...................................................230

Electrical Component Inspection .............................239

ASCD Wire Adjustment ...........................................240

POWER WINDOW.......................................................241

System Description ..................................................241

Schematic ................................................................244

Wiring Diagram - WINDOW - ..................................245

Trouble Diagnoses...................................................250

POWER DOOR LOCK.................................................254

Component Parts and Harness Connector

Location ...................................................................254

System Description ..................................................254

CONTENTS(Cont'd)

EL-2

Page 1189 of 2395

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NBEL0001The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag module (located in the outer side of front seat),

satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring harness,

warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized INFINITI dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Wiring Diagrams and Trouble DiagnosisNBEL0002When you read wiring diagrams, refer to the following:

IGI-11, ªHOW TO READ WIRING DIAGRAMSº

IEL-9, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnosis, refer to the following:

IGI-35, ªHOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSESº

IGI-24, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº

Check for any Service bulletins before servicing the vehicle.

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

EL-4

Page 1273 of 2395

![INFINITI QX4 2001 Factory Service Manual System DescriptionNBEL0038POWER SUPPLY AND GROUNDNBEL0038S06Power is supplied at all times:

Ithrough 7.5A fuse [No. 24, located in the fuse block (J/B)]

Ito key switch terminal 2 and

Ito smart entranc INFINITI QX4 2001 Factory Service Manual System DescriptionNBEL0038POWER SUPPLY AND GROUNDNBEL0038S06Power is supplied at all times:

Ithrough 7.5A fuse [No. 24, located in the fuse block (J/B)]

Ito key switch terminal 2 and

Ito smart entranc](/img/42/57027/w960_57027-1272.png)

System DescriptionNBEL0038POWER SUPPLY AND GROUNDNBEL0038S06Power is supplied at all times:

Ithrough 7.5A fuse [No. 24, located in the fuse block (J/B)]

Ito key switch terminal 2 and

Ito smart entrance control unit terminal 10.

When the key is removed from ignition key cylinder, power is interrupted:

Ithrough key switch terminal 1

Ito smart entrance control unit terminal 32.

With the ignition key switch in the ON or START position, power is supplied:

Ithrough 7.5A fuse [No. 11, located in the fuse block (J/B)]

Ito smart entrance control unit terminal 33.

Ground is supplied:

Ito smart entrance control unit terminal 16

Ithrough body grounds terminals M77 and M111.

When the front driver side door is opened, ground is supplied:

Ithrough body grounds B11, B22 and D210

Ito front door switch (LH) terminal 2

Ifrom front door switch (LH) terminal 1

Ito smart entrance control unit terminal 29.

When the front passenger side door is opened, ground is supplied:

Ithrough case ground of front door switch (RH)

Ifrom front door switch (RH) terminal 1

Ito smart entrance control unit terminal 40.

When any other door (except front door) is opened, ground is supplied to smart entrance control unit termi-

nal 28 in the same manner as the front door switch (front passenger side).

When the front driver side door is unlocked, the smart entrance control unit receives a ground signal:

Ithrough body grounds terminals M77 and M111

Ito front door lock actuator (driver side unlock sensor) terminal 2

Ifrom front door lock actuator (driver side unlock sensor) terminal 4

Ito smart entrance control unit terminal 36.

When a signal, or combination of signals is received by the smart entrance control unit, ground is supplied:

Ithrough smart entrance control unit terminal 8

Ito interior lamp terminal 2.

With power and ground supplied, the interior lamp illuminates.

SWITCH OPERATIONNBEL0038S07When interior lamp switch is ON, ground is supplied:

Ithrough case grounds of interior lamp

Ito interior lamp.

And power is supplied:

Ito interior lamp terminal 1

Ifrom smart entrance control unit terminal 17.

When spot lamp (LH and/or RH) is ON, ground is supplied:

Ithrough body grounds M4, M66 and M147

Ito spot lamp terminal 2.

And power is supplied:

Ito spot lamp terminal 1

Ifrom smart entrance control unit terminal 17.

When vanity mirror illumination (LH and/or RH) is ON, ground is supplied:

Ithrough body grounds M4, M66 and M147

Ito vanity mirror illuminations (LH and RH) terminals 2.

INTERIOR, SPOT, VANITY MIRROR AND LUGGAGE ROOM LAMPS

System Description

EL-88

Page 1274 of 2395

And power is supplied:

Ito vanity mirror illuminations (LH and RH) terminals 1

Ifrom smart entrance control unit terminal 17.

With power and ground supplied, interior lamps turn ON.

INTERIOR LAMP TIMER OPERATIONNBEL0038S08When interior lamp switch is in the ªDOORº position, the smart entrance control unit keeps the interior lamp

illuminated for about 30 seconds when:

Iunlock signal is supplied from driver's door unlock sensor while all doors are closed and key is removed

from ignition key cylinder

Iunlock signal is supplied from multi-remote controller while all doors are closed and driver's door is locked

Ikey is removed from ignition key cylinder while all doors are closed

Idriver's door is opened and then closed while key is removed from the iginition key cylinder. (However, if

the driver's door is closed with the key insered in the ignition key cylinder after the driver's door is opened

with the key removed, the timer is operated.)

The timer is canceled when:

Idriver's door is locked,

Idriver's door is opened, or

Iignition switch is turned ON.

ON-OFF CONTROLNBEL0038S09When the driver side door, front passenger door, rear LH, RH door or back door is opened, the interior room

lamp turns on while the interior room lamp switch is in the ªDOORº position.

BATTERY SAVERNBEL0038S10The lamp turns off automatically when interior lamp, luggage room lamp, spot lamp and/or vanity mirror illu-

mination is illuminated with the ignition key is in OFF position, if the lamp remains lit by the door switch open

signal or if the lamp switch is in ON position for more than 10 minutes.

After lamps turn OFF by the battery saver system, the lamps illuminate again when:

Idriver's door is locked or unlocked,

Idoor is opened or closed,

Ikey is inserted or removed in ignition key cylinder.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

INTERIOR, SPOT, VANITY MIRROR AND LUGGAGE ROOM LAMPS

System Description (Cont'd)

EL-89