Oil sensor INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1642 of 2395

NBEL0145

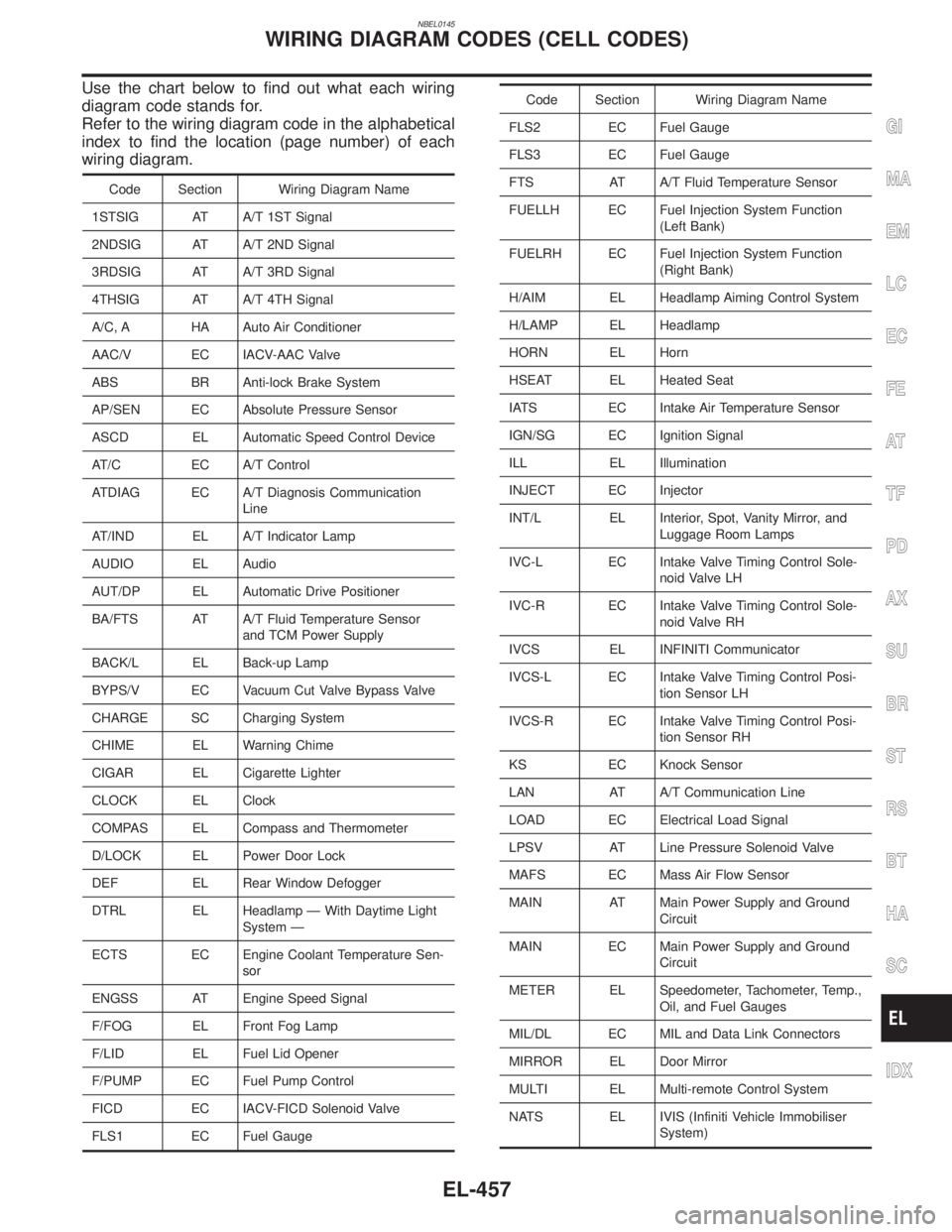

Use the chart below to find out what each wiring

diagram code stands for.

Refer to the wiring diagram code in the alphabetical

index to find the location (page number) of each

wiring diagram.

Code Section Wiring Diagram Name

1STSIG AT A/T 1ST Signal

2NDSIG AT A/T 2ND Signal

3RDSIG AT A/T 3RD Signal

4THSIG AT A/T 4TH Signal

A/C, A HA Auto Air Conditioner

AAC/V EC IACV-AAC Valve

ABS BR Anti-lock Brake System

AP/SEN EC Absolute Pressure Sensor

ASCD EL Automatic Speed Control Device

AT/C EC A/T Control

ATDIAG EC A/T Diagnosis Communication

Line

AT/IND EL A/T Indicator Lamp

AUDIO EL Audio

AUT/DP EL Automatic Drive Positioner

BA/FTS AT A/T Fluid Temperature Sensor

and TCM Power Supply

BACK/L EL Back-up Lamp

BYPS/V EC Vacuum Cut Valve Bypass Valve

CHARGE SC Charging System

CHIME EL Warning Chime

CIGAR EL Cigarette Lighter

CLOCK EL Clock

COMPAS EL Compass and Thermometer

D/LOCK EL Power Door Lock

DEF EL Rear Window Defogger

DTRL EL Headlamp Ð With Daytime Light

System Ð

ECTS EC Engine Coolant Temperature Sen-

sor

ENGSS AT Engine Speed Signal

F/FOG EL Front Fog Lamp

F/LID EL Fuel Lid Opener

F/PUMP EC Fuel Pump Control

FICD EC IACV-FICD Solenoid Valve

FLS1 EC Fuel Gauge

Code Section Wiring Diagram Name

FLS2 EC Fuel Gauge

FLS3 EC Fuel Gauge

FTS AT A/T Fluid Temperature Sensor

FUELLH EC Fuel Injection System Function

(Left Bank)

FUELRH EC Fuel Injection System Function

(Right Bank)

H/AIM EL Headlamp Aiming Control System

H/LAMP EL Headlamp

HORN EL Horn

HSEAT EL Heated Seat

IATS EC Intake Air Temperature Sensor

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INT/L EL Interior, Spot, Vanity Mirror, and

Luggage Room Lamps

IVC-L EC Intake Valve Timing Control Sole-

noid Valve LH

IVC-R EC Intake Valve Timing Control Sole-

noid Valve RH

IVCS EL INFINITI Communicator

IVCS-L EC Intake Valve Timing Control Posi-

tion Sensor LH

IVCS-R EC Intake Valve Timing Control Posi-

tion Sensor RH

KS EC Knock Sensor

LAN AT A/T Communication Line

LOAD EC Electrical Load Signal

LPSV AT Line Pressure Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground

Circuit

MAIN EC Main Power Supply and Ground

Circuit

METER EL Speedometer, Tachometer, Temp.,

Oil, and Fuel Gauges

MIL/DL EC MIL and Data Link Connectors

MIRROR EL Door Mirror

MULTI EL Multi-remote Control System

NATS EL IVIS (Infiniti Vehicle Immobiliser

System)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

WIRING DIAGRAM CODES (CELL CODES)

EL-457

Page 1643 of 2395

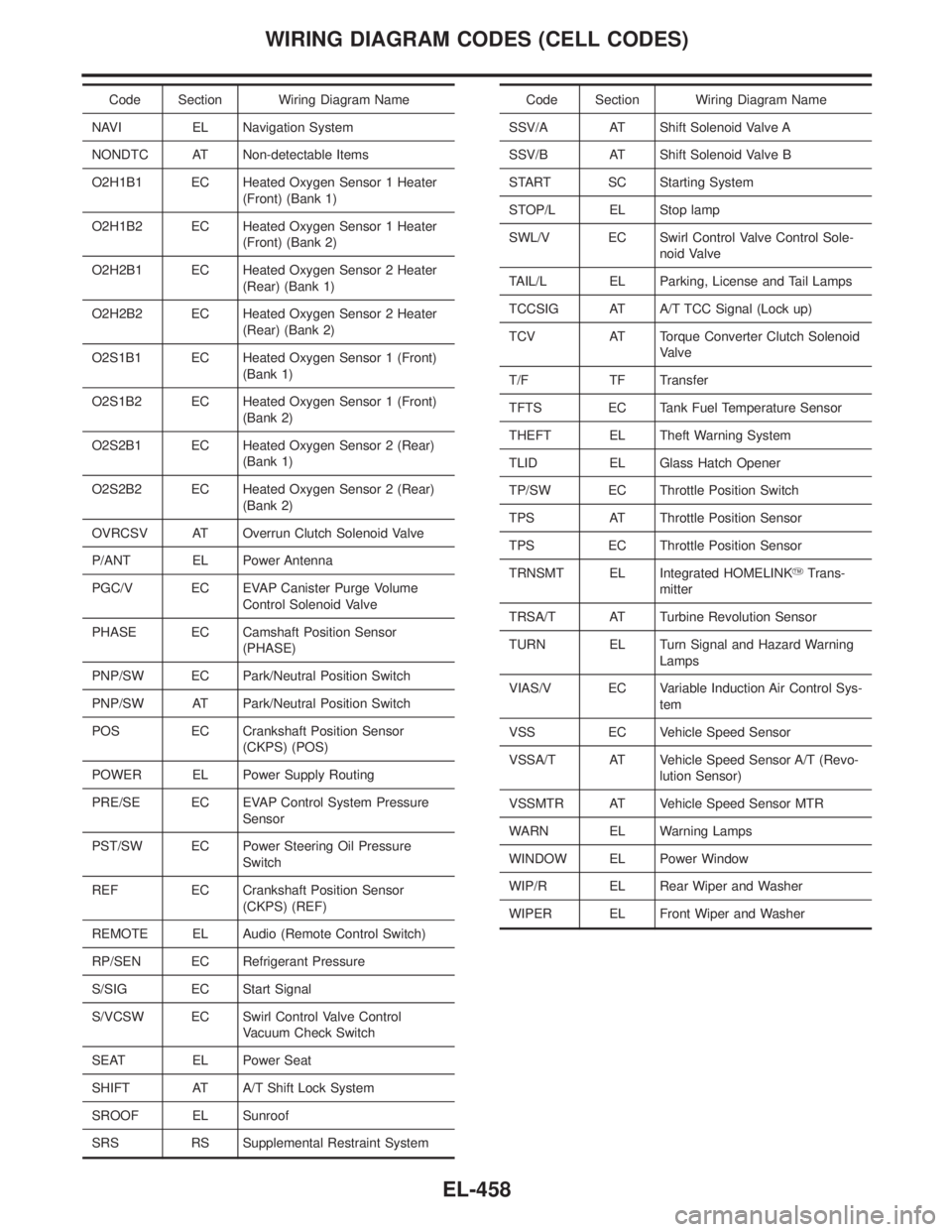

Code Section Wiring Diagram Name

NAVI EL Navigation System

NONDTC AT Non-detectable Items

O2H1B1 EC Heated Oxygen Sensor 1 Heater

(Front) (Bank 1)

O2H1B2 EC Heated Oxygen Sensor 1 Heater

(Front) (Bank 2)

O2H2B1 EC Heated Oxygen Sensor 2 Heater

(Rear) (Bank 1)

O2H2B2 EC Heated Oxygen Sensor 2 Heater

(Rear) (Bank 2)

O2S1B1 EC Heated Oxygen Sensor 1 (Front)

(Bank 1)

O2S1B2 EC Heated Oxygen Sensor 1 (Front)

(Bank 2)

O2S2B1 EC Heated Oxygen Sensor 2 (Rear)

(Bank 1)

O2S2B2 EC Heated Oxygen Sensor 2 (Rear)

(Bank 2)

OVRCSV AT Overrun Clutch Solenoid Valve

P/ANT EL Power Antenna

PGC/V EC EVAP Canister Purge Volume

Control Solenoid Valve

PHASE EC Camshaft Position Sensor

(PHASE)

PNP/SW EC Park/Neutral Position Switch

PNP/SW AT Park/Neutral Position Switch

POS EC Crankshaft Position Sensor

(CKPS) (POS)

POWER EL Power Supply Routing

PRE/SE EC EVAP Control System Pressure

Sensor

PST/SW EC Power Steering Oil Pressure

Switch

REF EC Crankshaft Position Sensor

(CKPS) (REF)

REMOTE EL Audio (Remote Control Switch)

RP/SEN EC Refrigerant Pressure

S/SIG EC Start Signal

S/VCSW EC Swirl Control Valve Control

Vacuum Check Switch

SEAT EL Power Seat

SHIFT AT A/T Shift Lock System

SROOF EL Sunroof

SRS RS Supplemental Restraint SystemCode Section Wiring Diagram Name

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

START SC Starting System

STOP/L EL Stop lamp

SWL/V EC Swirl Control Valve Control Sole-

noid Valve

TAIL/L EL Parking, License and Tail Lamps

TCCSIG AT A/T TCC Signal (Lock up)

TCV AT Torque Converter Clutch Solenoid

Valve

T/F TF Transfer

TFTS EC Tank Fuel Temperature Sensor

THEFT EL Theft Warning System

TLID EL Glass Hatch Opener

TP/SW EC Throttle Position Switch

TPS AT Throttle Position Sensor

TPS EC Throttle Position Sensor

TRNSMT EL Integrated HOMELINKYTrans-

mitter

TRSA/T AT Turbine Revolution Sensor

TURN EL Turn Signal and Hazard Warning

Lamps

VIAS/V EC Variable Induction Air Control Sys-

tem

VSS EC Vehicle Speed Sensor

VSSA/T AT Vehicle Speed Sensor A/T (Revo-

lution Sensor)

VSSMTR AT Vehicle Speed Sensor MTR

WARN EL Warning Lamps

WINDOW EL Power Window

WIP/R EL Rear Wiper and Washer

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-458

Page 1658 of 2395

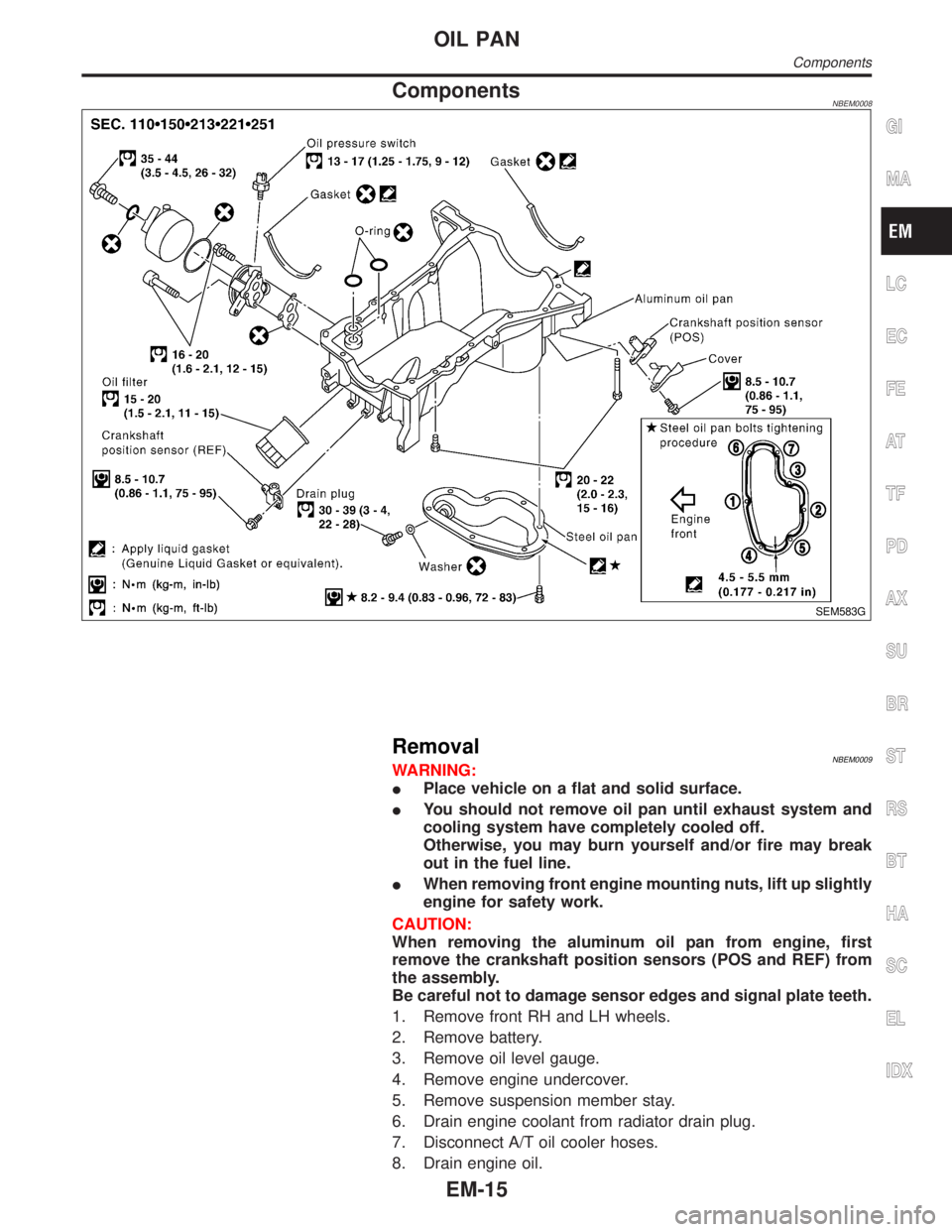

ComponentsNBEM0008

SEM583G

RemovalNBEM0009WARNING:

IPlace vehicle on a flat and solid surface.

IYou should not remove oil pan until exhaust system and

cooling system have completely cooled off.

Otherwise, you may burn yourself and/or fire may break

out in the fuel line.

IWhen removing front engine mounting nuts, lift up slightly

engine for safety work.

CAUTION:

When removing the aluminum oil pan from engine, first

remove the crankshaft position sensors (POS and REF) from

the assembly.

Be careful not to damage sensor edges and signal plate teeth.

1. Remove front RH and LH wheels.

2. Remove battery.

3. Remove oil level gauge.

4. Remove engine undercover.

5. Remove suspension member stay.

6. Drain engine coolant from radiator drain plug.

7. Disconnect A/T oil cooler hoses.

8. Drain engine oil.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OIL PAN

Components

EM-15

Page 1659 of 2395

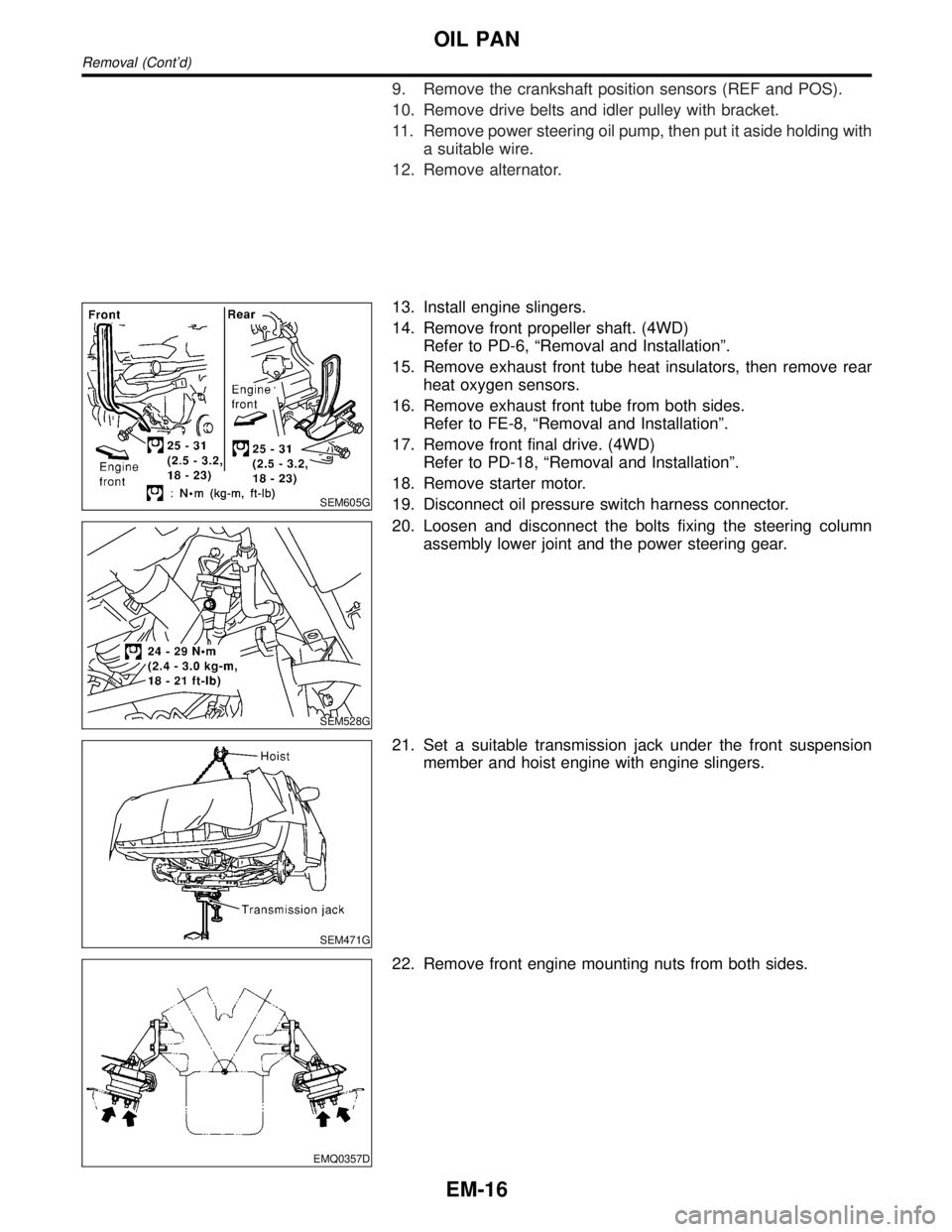

9. Remove the crankshaft position sensors (REF and POS).

10. Remove drive belts and idler pulley with bracket.

11. Remove power steering oil pump, then put it aside holding with

a suitable wire.

12. Remove alternator.

SEM605G

13. Install engine slingers.

14. Remove front propeller shaft. (4WD)

Refer to PD-6, ªRemoval and Installationº.

15. Remove exhaust front tube heat insulators, then remove rear

heat oxygen sensors.

16. Remove exhaust front tube from both sides.

Refer to FE-8, ªRemoval and Installationº.

17. Remove front final drive. (4WD)

Refer to PD-18, ªRemoval and Installationº.

18. Remove starter motor.

19. Disconnect oil pressure switch harness connector.

SEM528G

20. Loosen and disconnect the bolts fixing the steering column

assembly lower joint and the power steering gear.

SEM471G

21. Set a suitable transmission jack under the front suspension

member and hoist engine with engine slingers.

EMQ0357D

22. Remove front engine mounting nuts from both sides.

OIL PAN

Removal (Cont'd)

EM-16

Page 1666 of 2395

CAUTION:

IAfter removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

IWhen installing camshafts, chain tensioners, oil seals, or

other sliding parts, lubricate contacting surfaces with new

engine oil.

IApply new engine oil to bolt threads and seat surfaces

when installing camshaft sprockets and crankshaft pulley.

IBefore disconnecting fuel hose, release fuel pressure.

Refer to EC-39, ªFuel Pressure Releaseº.

IBe careful not to damage sensor edges.

IDo not spill engine coolant on drive belts.

RemovalNBEM00121. Release fuel pressure.

Refer to EC-39, ªFuel Pressure Releaseº.

2. Remove battery.

3. Remove radiator.

Refer to LC-19, ªREMOVAL AND INSTALLATIONº.

4. Drain engine oil.

5. Remove drive belts and idler pulley with brackets.

6. Remove cooling fan with bracket.

7. Remove engine cover.

8. Remove air duct with air cleaner case, collector, blow-by hose,

vacuum hoses, fuel hoses, water hoses, wires, harnesses,

connectors and so on.

9. Remove the air compressor, and tie it down using rope or the

like to keep it from interfering.

10. Remove the power steering oil pump and reservoir tank. Tie

them down using rope or the like to keep them from interfer-

ing.

11. Remove alternator.

12. Remove the following.

IVacuum gallery

IWater bypass pipe

IBrackets

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAIN

Components (Cont'd)

EM-23

Page 1676 of 2395

SEM439G

SEM440G

17. Install RH and LH rocker covers.

Rocker cover tightening procedure:

ITighten in numerical order as shown in the figure.

a. Tighten bolts 1 to 10 in that order to 6.9 to 8.8 N´m (0.7 to 0.9

kg-m, 61 to 78 in-lb).

b. Then tighten bolts 1 to 10 as indicated in figure to 6.9 to 8.8

N´m (0.7 to 0.9 kg-m, 61 to 78 in-lb).

18. Hang engine using the right and left side engine slingers with

a suitable hoist.

19. Set a suitable transmission jack under the suspension mem-

ber.

20. Remove right and left side engine mounting nuts.

21. Remove right and left side suspension member bolts.

22. Install aluminum oil pan. Refer to EM-18, ªInstallationº.

23. Set ring gear stopper using the mounting bolt hole.

IBe careful not to damage the signal plate teeth.

SEM417G

24. Install crankshaft pulley to crankshaft.

IAlign pointer with TDC mark on crankshaft pulley.

SEM531G

25. Install crankshaft pulley bolt.

ILubricate thread and seat surface of the bolt with new

engine oil.

a. Tighten to 39 to 49 N´m (4.0 to 5.0 kg-m, 29 to 36 ft-lb).

b. Put a paint mark on the crankshaft pulley.

SEM963E

c. Again tighten by turning 60É to 66É, about the angle from one

hexagon bolt head corner to another.

26. Install camshaft position sensor (PHASE), crankshaft position

sensors (REF)/(POS) and CVTC sensors.

27. Reinstall removed parts in the reverse order of removal.

IWhen installing fuel tube and intake manifold collectors, refer

to EM-12, ªTIGHTENING PROCEDURESº.

IAfter starting engine, keep idling for three minutes. Then

rev engine up to 3,000 rpm under no load to purge air from

the high-pressure chamber of the chain tensioners. The

engine may produce a rattling noise. This indicates that

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAIN

Installation (Cont'd)

EM-33

Page 1678 of 2395

SEM948E

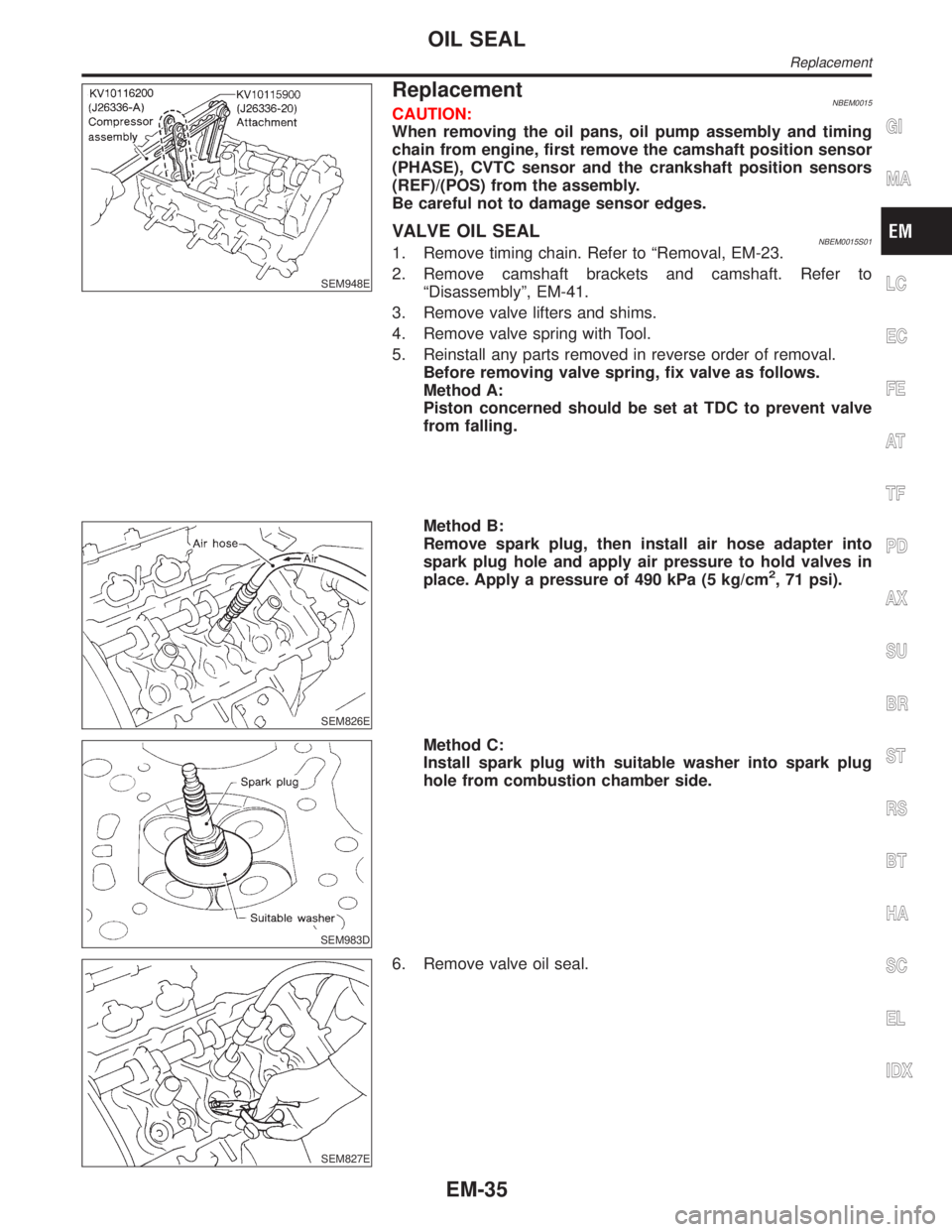

ReplacementNBEM0015CAUTION:

When removing the oil pans, oil pump assembly and timing

chain from engine, first remove the camshaft position sensor

(PHASE), CVTC sensor and the crankshaft position sensors

(REF)/(POS) from the assembly.

Be careful not to damage sensor edges.

VALVE OIL SEALNBEM0015S011. Remove timing chain. Refer to ªRemoval, EM-23.

2. Remove camshaft brackets and camshaft. Refer to

ªDisassemblyº, EM-41.

3. Remove valve lifters and shims.

4. Remove valve spring with Tool.

5. Reinstall any parts removed in reverse order of removal.

Before removing valve spring, fix valve as follows.

Method A:

Piston concerned should be set at TDC to prevent valve

from falling.

SEM826E

Method B:

Remove spark plug, then install air hose adapter into

spark plug hole and apply air pressure to hold valves in

place. Apply a pressure of 490 kPa (5 kg/cm

2, 71 psi).

SEM983D

Method C:

Install spark plug with suitable washer into spark plug

hole from combustion chamber side.

SEM827E

6. Remove valve oil seal.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OIL SEAL

Replacement

EM-35

Page 1679 of 2395

SEM828E

7. Apply engine oil to new valve oil seal and install it with Tool.

SEM715A

OIL SEAL INSTALLATION DIRECTIONNBEM0015S02IInstall new oil seal in the direction shown in the figure.

FRONT OIL SEALNBEM0015S031. Remove the following parts:

IEngine undercover

ISuspension member stay

IDrive belts

ICrankshaft position sensor (REF)

Be careful not to damage sensor edge.

ICrankshaft pulley

IRadiator

ICooling fan

SEM829E

2. Remove front oil seal using a suitable tool.

Be careful not to scratch front cover.

3. Apply engine oil to new oil seal and install it using a suitable

tool.

SEM830E

REAR OIL SEALNBEM0015S041. Remove transmission. Refer to AT-277, ªRemovalº.

2. Remove drive plate.

3. Remove oil pan. Refer to EM-15.

4. Remove rear oil seal retainer.

OIL SEAL

Replacement (Cont'd)

EM-36

Page 1702 of 2395

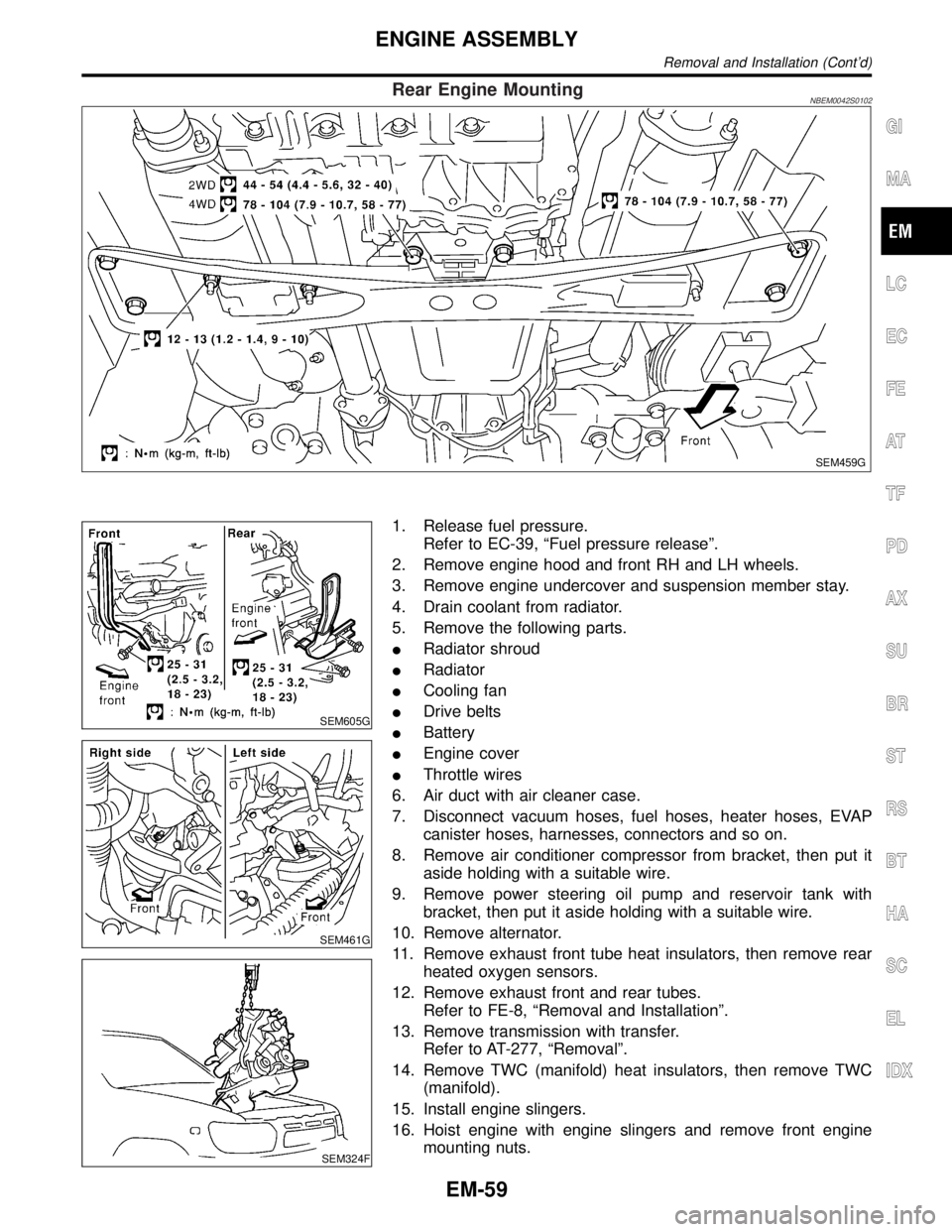

Rear Engine MountingNBEM0042S0102

SEM459G

SEM605G

SEM461G

SEM324F

1. Release fuel pressure.

Refer to EC-39, ªFuel pressure releaseº.

2. Remove engine hood and front RH and LH wheels.

3. Remove engine undercover and suspension member stay.

4. Drain coolant from radiator.

5. Remove the following parts.

IRadiator shroud

IRadiator

ICooling fan

IDrive belts

IBattery

IEngine cover

IThrottle wires

6. Air duct with air cleaner case.

7. Disconnect vacuum hoses, fuel hoses, heater hoses, EVAP

canister hoses, harnesses, connectors and so on.

8. Remove air conditioner compressor from bracket, then put it

aside holding with a suitable wire.

9. Remove power steering oil pump and reservoir tank with

bracket, then put it aside holding with a suitable wire.

10. Remove alternator.

11. Remove exhaust front tube heat insulators, then remove rear

heated oxygen sensors.

12. Remove exhaust front and rear tubes.

Refer to FE-8, ªRemoval and Installationº.

13. Remove transmission with transfer.

Refer to AT-277, ªRemovalº.

14. Remove TWC (manifold) heat insulators, then remove TWC

(manifold).

15. Install engine slingers.

16. Hoist engine with engine slingers and remove front engine

mounting nuts.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE ASSEMBLY

Removal and Installation (Cont'd)

EM-59

Page 1704 of 2395

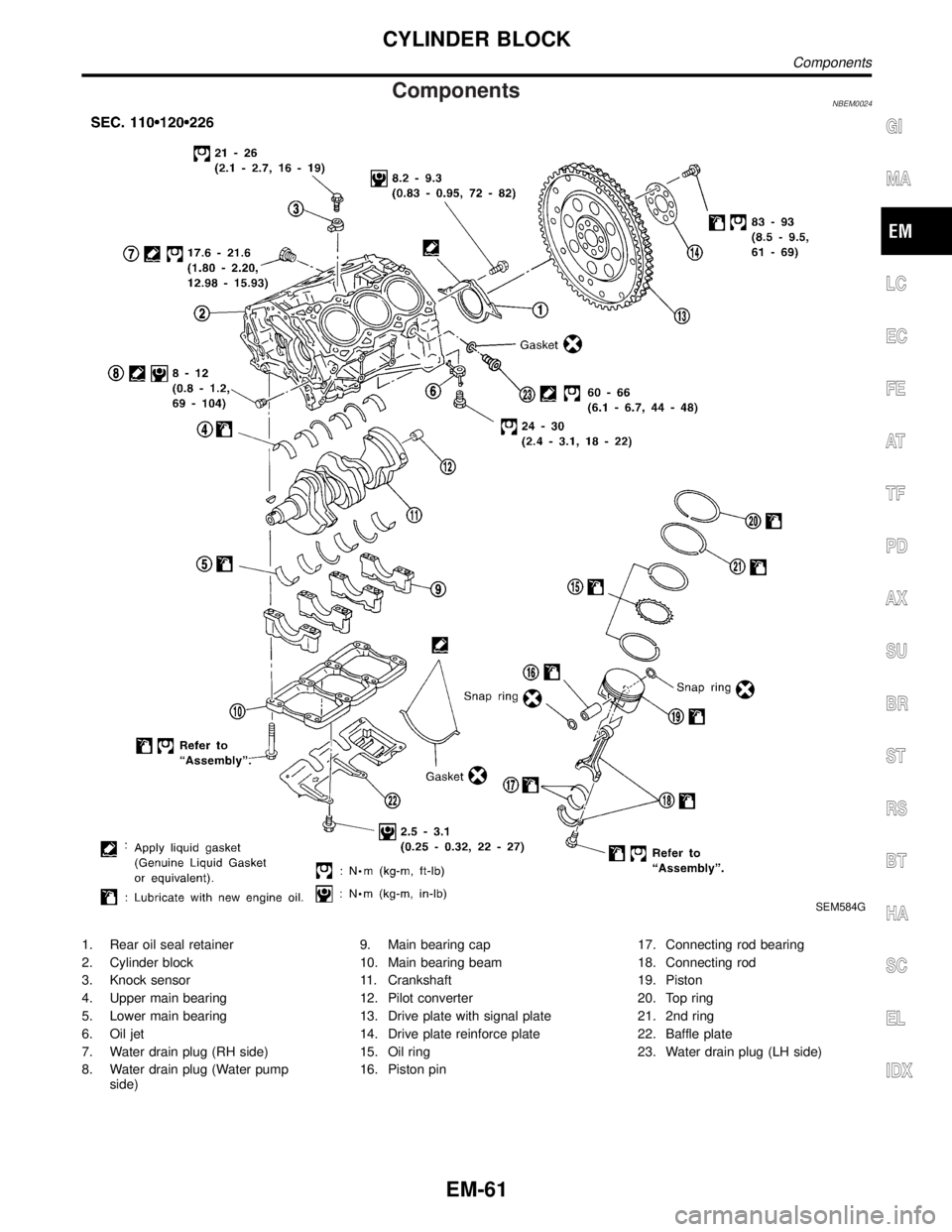

ComponentsNBEM0024

SEM584G

1. Rear oil seal retainer

2. Cylinder block

3. Knock sensor

4. Upper main bearing

5. Lower main bearing

6. Oil jet

7. Water drain plug (RH side)

8. Water drain plug (Water pump

side)9. Main bearing cap

10. Main bearing beam

11. Crankshaft

12. Pilot converter

13. Drive plate with signal plate

14. Drive plate reinforce plate

15. Oil ring

16. Piston pin17. Connecting rod bearing

18. Connecting rod

19. Piston

20. Top ring

21. 2nd ring

22. Baffle plate

23. Water drain plug (LH side)

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CYLINDER BLOCK

Components

EM-61