display INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 623 of 2395

![INFINITI QX4 2001 Factory Workshop Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

INT/A TEMP SE

[ÉC] or [ÉF]qqIThe intake air temperature determined

by the signal voltage of the intake air

temperature sensor is INFINITI QX4 2001 Factory Workshop Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

INT/A TEMP SE

[ÉC] or [ÉF]qqIThe intake air temperature determined

by the signal voltage of the intake air

temperature sensor is](/img/42/57027/w960_57027-622.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

INT/A TEMP SE

[ÉC] or [ÉF]qqIThe intake air temperature determined

by the signal voltage of the intake air

temperature sensor is indicated.

EVAP SYS PRES [V]qIThe signal voltage of EVAP control sys-

tem pressure sensor is displayed.

ABSOL PRES/SE [V]qIThe signal voltage of the absolute pres-

sure sensor is displayed.

FUEL LEVEL SE [V]qIThe signal voltage of the fuel level sen-

sor is displayed.

START SIGNAL

[ON/OFF]qqIIndicates [ON/OFF] condition from the

starter signal.IAfter starting the engine, [OFF] is dis-

played regardless of the starter signal.

CLSD THL POS

[ON/OFF]qqIIndicates idle position [ON/OFF] com-

puted by ECM according to the throttle

position sensor signal.

CLSD THL/P SW

[ON/OFF]qIIndicates mechanical contact [ON/OFF]

condition of the closed throttle position

switch.

AIR COND SIG

[ON/OFF]qqIIndicates [ON/OFF] condition of the air

conditioner switch as determined by the

air conditioner signal.

P/N POSI SW

[ON/OFF]qqIIndicates [ON/OFF] condition from the

park/neutral position (PNP) switch sig-

nal.

PW/ST SIGNAL

[ON/OFF]qqI[ON/OFF] condition of the power steer-

ing oil pressure switch determined by

the power steering oil pressure signal is

indicated.

LOAD SIGNAL

[ON/OFF]qqIIndicates [ON/OFF] condition from the

electrical load signal and/or lighting

switch.

ON ... rear defogger is operating and/or

lighting switch is on.

OFF ... rear defogger is not operating

and lighting switch is not on.

IGNITION SW

[ON/OFF]qIIndicates [ON/OFF] condition from igni-

tion switch.

SWRL CONT S/V

[ON/OFF]qIThe control condition of the swirl con-

trol valve control solenoid valve (deter-

mined by ECM according to the input

signals) is indicated.

ION ... Swirl control valve is closed.

OFF ... Swirl control valve is opened.

INJ PULSE-B1

[msec]q

IIndicates the actual fuel injection pulse

width compensated by ECM according

to the input signals.IWhen the engine is stopped, a certain

computed value is indicated.

INJ PULSE-B2

[msec]

B/FUEL SCHDL

[msec]qIªBase fuel scheduleº indicates the fuel

injection pulse width programmed into

ECM, prior to any learned on board

correction.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-88

Page 625 of 2395

![INFINITI QX4 2001 Factory Workshop Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

INT/V TIM (B1) [ÉCA]

IIndicate [ÉCA] of intake camshaft

advanced angle.

INT/V TIM (B2) [ÉCA]

INT/V SOL (B1) [%]IThe control con INFINITI QX4 2001 Factory Workshop Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

INT/V TIM (B1) [ÉCA]

IIndicate [ÉCA] of intake camshaft

advanced angle.

INT/V TIM (B2) [ÉCA]

INT/V SOL (B1) [%]IThe control con](/img/42/57027/w960_57027-624.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

INT/V TIM (B1) [ÉCA]

IIndicate [ÉCA] of intake camshaft

advanced angle.

INT/V TIM (B2) [ÉCA]

INT/V SOL (B1) [%]IThe control condition of the intake

valve timing control solenoid valve is

indicated. INT/V SOL (B2) [%]

TRVL AFTER MIL

[km] or [Mile]IDistance traveled while MIL is activated

VIAS S/V

[ON/OFF]IThe control condition of the VIAS con-

trol solenoid valve (determined by ECM

according to the input signal) is indi-

cated.

IOFF ... VIAS control solenoid valve is

not operating.

ON ... VIAS control solenoid valve is

operating.

SWL CON VC SWIIndicates [ON/OFF] condition from the

swirl control valve control vacuum

check switch.

ON ... Swirl control valve is not opera-

tional.

OFF ... Swirl control valve is opera-

tional.

IDL A/V LEANIDisplay the condition of idle air volume

learning

YET ... Idle air volume learning has not

been performed yet.

CMPLT ... Idle air volume learning has

already been performed successfully.

INCMP ... Idle air volume learning has

not been performed successfully.

Voltage [V]IVoltage measured by the voltage

probe.

Frequency

[msec] or [Hz] or [%]IPulse width, frequency or duty cycle

measured by the pulse probe.IOnly ª#º is displayed if item is unable to

be measured.

IFigures with ª#ºs are temporary ones.

They are the same figures as an actual

piece of data which was just previously

measured.

NOTE:

IAny monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

IRegarding R50 model, ª-B1º indicates right bank and ª-B2º indicates left bank.

IBank 1 (-B1 or BK1) includes No. 1 cylinder.

DATA MONITOR (SPEC) MODENBEC0034S11

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

MAS A/F SE-B1 [V]qqIThe signal voltage of the mass air flow sen-

sor specification is displayed.IWhen the engine is running, specifi-

cation range is indicated.

B/FUEL SCHDL

[msec]IªBase fuel scheduleº indicates the fuel injec-

tion pulse width programmed into ECM,

prior to any learned on board correction.IWhen the engine is running, specifi-

cation range is indicated.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-90

Page 626 of 2395

![INFINITI QX4 2001 Factory Workshop Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

A/F ALPHA-B1 [%]q

IIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running INFINITI QX4 2001 Factory Workshop Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

A/F ALPHA-B1 [%]q

IIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running](/img/42/57027/w960_57027-625.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

A/F ALPHA-B1 [%]q

IIndicates the mean value of the air-fuel ratio

feedback correction factor per cycle.IWhen the engine is running, specifi-

cation range is indicated.

IThis data also includes the data for

the air-fuel ratio learning control. A/F ALPHA-B2 [%]q

NOTE:

IAny monitored item that does not match the vehicle being diagnosed is deleted from the display automatically.

IRegarding R50 model, ªB1º indicates bank 1 and ªB2º indicates bank 2.

ACTIVE TEST MODENBEC0034S07

TEST ITEM CONDITION JUDGEMENT CHECK ITEM (REMEDY)

FUEL INJECTIONIEngine: Return to the original

trouble condition

IChange the amount of fuel injec-

tion using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IFuel injectors

IHeated oxygen sensor

IGNITION TIMINGIEngine: Return to the original

trouble condition

ITiming light: Set

IRetard the ignition timing using

CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IAdjust initial ignition timing

IACV-AAC/V

OPENINGIEngine: After warming up, idle

the engine.

IChange the IACV-AAC valve

opening percent using CON-

SULT-II.Engine speed changes according

to the opening percent.IHarness and connector

IIACV-AAC valve

POWER BAL-

ANCEIEngine: After warming up, idle

the engine.

IA/C switch ªOFFº

IShift lever ªNº

ICut off each injector signal one

at a time using CONSULT-II.Engine runs rough or dies.IHarness and connector

ICompression

IInjectors

IPower transistor

ISpark plugs

IIgnition coils

ENG COOLANT

TEMPIEngine: Return to the original

trouble condition

IChange the engine coolant tem-

perature using CONSULT-II.If trouble symptom disappears, see

CHECK ITEM.IHarness and connector

IEngine coolant temperature sen-

sor

IFuel injectors

FUEL PUMP

RELAYIIgnition switch: ON

(Engine stopped)

ITurn the fuel pump relay ªONº

and ªOFFº using CONSULT-II

and listen to operating sound.Fuel pump relay makes the operat-

ing sound.IHarness and connector

IFuel pump relay

VIAS SOL VALVEIIgnition switch: ON

ITurn solenoid valve ªONº and

ªOFFº with CONSULT-II and lis-

ten for operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

SWIRL CONT

S O L VA LV EIIgnition switch: ON

ITurn solenoid valve ªONº and

ªOFFº with CONSULT-II and lis-

ten for operating sound.Solenoid valve makes an operating

sound.IHarness and connector

ISolenoid valve

PURG VOL

CONT/VIEngine: After warming up, run

engine at 1,500 rpm.

IChange the EVAP canister purge

volume control solenoid valve

opening percent using CON-

SULT-II.Engine speed changes according

to the opening percent.IHarness and connector

ISolenoid valve

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-91

Page 628 of 2395

DTC Work Support ModeNBEC0034S0802

Test mode Test item Condition Reference page

EVAPORATIVE SYSTEMEVAP SML LEAK P0440

Refer to corresponding

trouble diagnosis for

DTC.EC-352

EVAP VERY SML LEAK P1441 EC-526

PURG VOL CN/V P1444 EC-541

PURGE FLOW P1447 EC-561

VC CUT/V BP/V P1491 EC-591

HEATED OXYGEN SEN-

SOR 1 (FRONT)HO2S1 (B1) P0130 EC-192

HO2S1 (B1) P0131 EC-202

HO2S1 (B1) P0132 EC-210

HO2S1 (B1) P0133 EC-218

HO2S1 (B2) P0150 EC-192

HO2S1 (B2) P0151 EC-202

HO2S1 (B2) P0152 EC-210

HO2S1 (B2) P0153 EC-218

HEATED OXYGEN SEN-

SOR 2 (REAR)HO2S2 (B1) P0137 EC-247

HO2S2 (B1) P0138 EC-257

HO2S2 (B1) P0139 EC-267

HO2S2 (B2) P0157 EC-247

HO2S2 (B2) P0158 EC-257

HO2S2 (B2) P0159 EC-267

SEF705Y

SEF707X

REAL TIME DIAGNOSIS IN DATA MONITOR MODE

(RECORDING VEHICLE DATA)

NBEC0034S10CONSULT-II has two kinds of triggers and they can be selected by

touching ªSETTINGº in ªDATA MONITORº mode.

1) ªAUTO TRIGº (Automatic trigger):

IThe malfunction will be identified on the CONSULT-II screen in

real time.

In other words, DTC/1st trip DTC and malfunction item will be

displayed if the malfunction is detected by ECM.

At the moment a malfunction is detected by ECM, ªMONITORº

in ªDATA MONITORº screen is changed to ªRecording Data ...

xx%º as shown at left, and the data after the malfunction detec-

tion is recorded. Then when the percentage reached 100%,

ªREAL-TIME DIAGº screen is displayed. If ªSTOPº is touched

on the screen during ª Recording Data ... xx%º, ªREAL-TIME

DIAGº screen is also displayed.

The recording time after the malfunction detection and the

recording speed can be changed by ªTRIGGER POINTº and

ªRecording Speedº. Refer to CONSULT-II OPERATION

MANUAL.

2) ªMANU TRIGº (Manual trigger):

IDTC/1st trip DTC and malfunction item will not be displayed

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-93

Page 629 of 2395

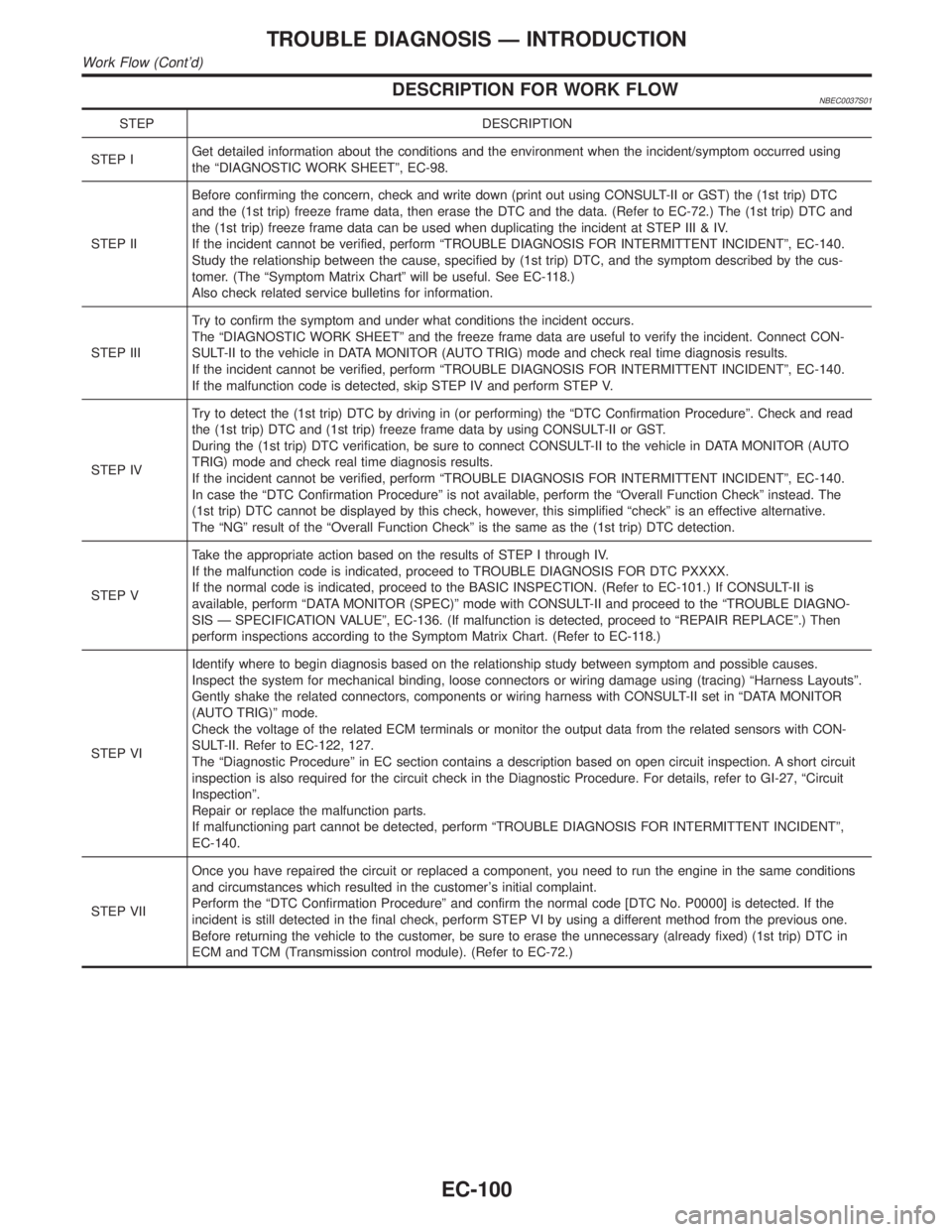

automatically on CONSULT-II screen even though a malfunc-

tion is detected by ECM.

DATA MONITOR can be performed continuously even though

a malfunction is detected.

Use these triggers as follows:

1) ªAUTO TRIGº

IWhile trying to detect the DTC/1st trip DTC by performing the

ªDTC Confirmation Procedureº, be sure to select to ªDATA

MONITOR (AUTO TRIG)º mode. You can confirm the malfunc-

tion at the moment it is detected.

IWhile narrowing down the possible causes, CONSULT-II

should be set in ªDATA MONITOR (AUTO TRIG)º mode, espe-

cially in case the incident is intermittent.

When you are inspecting the circuit by gently shaking (or twist-

ing) the suspicious connectors, components and harness in

the ªDTC Confirmation Procedureº, the moment a malfunction

is found the DTC/1st trip DTC will be displayed. (Refer to

GI-36, ªIncident Simulation Testsº.)

2) ªMANU TRIGº

IIf the malfunction is displayed as soon as ªDATA MONITORº

is selected, reset CONSULT-II to ªMANU TRIGº. By selecting

ªMANU TRIGº you can monitor and store the data. The data

can be utilized for further diagnosis, such as a comparison with

the value for the normal operating condition.

SEF714Y

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-94

Page 635 of 2395

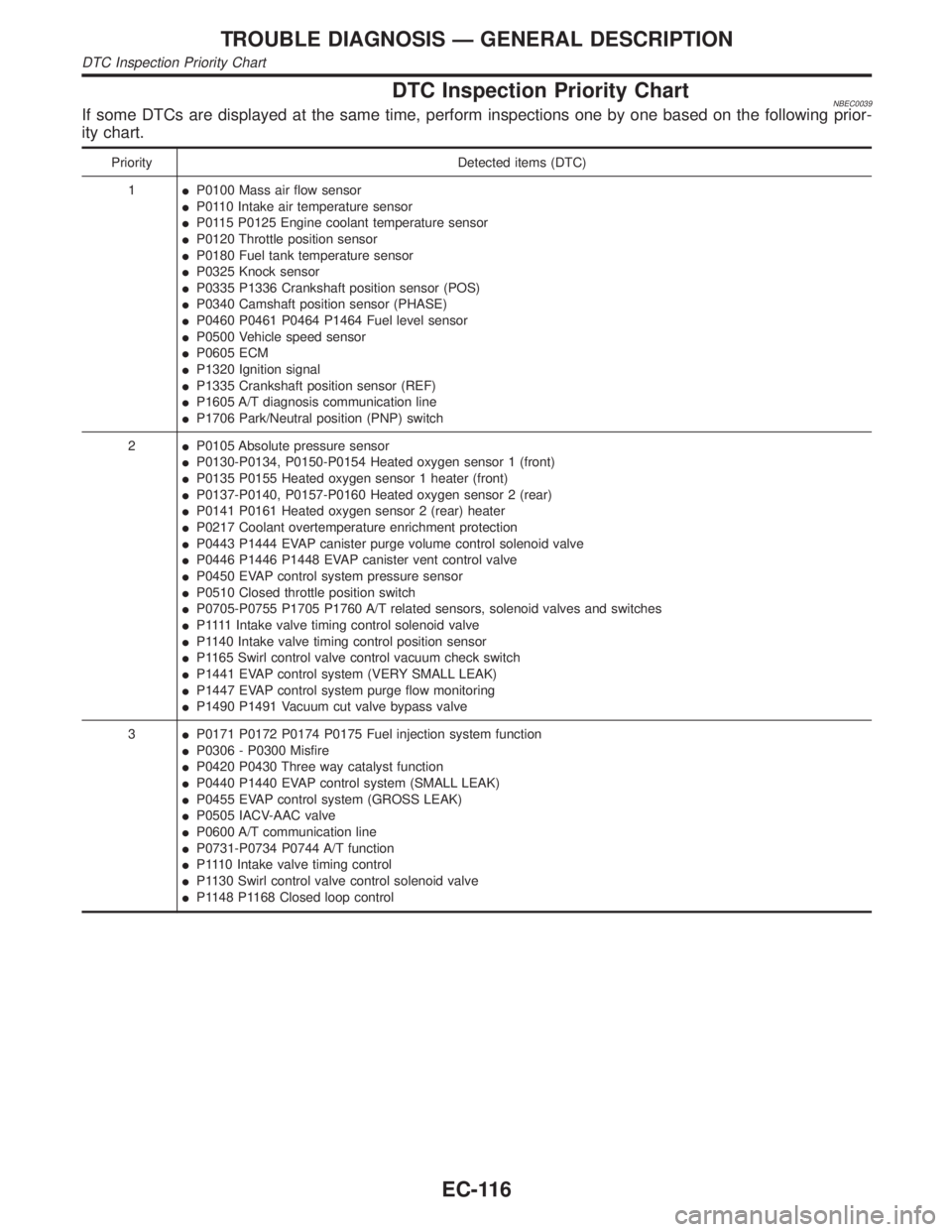

DESCRIPTION FOR WORK FLOWNBEC0037S01

STEP DESCRIPTION

STEP IGet detailed information about the conditions and the environment when the incident/symptom occurred using

the ªDIAGNOSTIC WORK SHEETº, EC-98.

STEP IIBefore confirming the concern, check and write down (print out using CONSULT-II or GST) the (1st trip) DTC

and the (1st trip) freeze frame data, then erase the DTC and the data. (Refer to EC-72.) The (1st trip) DTC and

the (1st trip) freeze frame data can be used when duplicating the incident at STEP III & IV.

If the incident cannot be verified, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

Study the relationship between the cause, specified by (1st trip) DTC, and the symptom described by the cus-

tomer. (The ªSymptom Matrix Chartº will be useful. See EC-118.)

Also check related service bulletins for information.

STEP IIITry to confirm the symptom and under what conditions the incident occurs.

The ªDIAGNOSTIC WORK SHEETº and the freeze frame data are useful to verify the incident. Connect CON-

SULT-II to the vehicle in DATA MONITOR (AUTO TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

If the malfunction code is detected, skip STEP IV and perform STEP V.

STEP IVTry to detect the (1st trip) DTC by driving in (or performing) the ªDTC Confirmation Procedureº. Check and read

the (1st trip) DTC and (1st trip) freeze frame data by using CONSULT-II or GST.

During the (1st trip) DTC verification, be sure to connect CONSULT-II to the vehicle in DATA MONITOR (AUTO

TRIG) mode and check real time diagnosis results.

If the incident cannot be verified, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

In case the ªDTC Confirmation Procedureº is not available, perform the ªOverall Function Checkº instead. The

(1st trip) DTC cannot be displayed by this check, however, this simplified ªcheckº is an effective alternative.

The ªNGº result of the ªOverall Function Checkº is the same as the (1st trip) DTC detection.

STEP VTake the appropriate action based on the results of STEP I through IV.

If the malfunction code is indicated, proceed to TROUBLE DIAGNOSIS FOR DTC PXXXX.

If the normal code is indicated, proceed to the BASIC INSPECTION. (Refer to EC-101.) If CONSULT-II is

available, perform ªDATA MONITOR (SPEC)º mode with CONSULT-II and proceed to the ªTROUBLE DIAGNO-

SIS Ð SPECIFICATION VALUEº, EC-136. (If malfunction is detected, proceed to ªREPAIR REPLACEº.) Then

perform inspections according to the Symptom Matrix Chart. (Refer to EC-118.)

STEP VIIdentify where to begin diagnosis based on the relationship study between symptom and possible causes.

Inspect the system for mechanical binding, loose connectors or wiring damage using (tracing) ªHarness Layoutsº.

Gently shake the related connectors, components or wiring harness with CONSULT-II set in ªDATA MONITOR

(AUTO TRIG)º mode.

Check the voltage of the related ECM terminals or monitor the output data from the related sensors with CON-

SULT-II. Refer to EC-122, 127.

The ªDiagnostic Procedureº in EC section contains a description based on open circuit inspection. A short circuit

inspection is also required for the circuit check in the Diagnostic Procedure. For details, refer to GI-27, ªCircuit

Inspectionº.

Repair or replace the malfunction parts.

If malfunctioning part cannot be detected, perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº,

EC-140.

STEP VIIOnce you have repaired the circuit or replaced a component, you need to run the engine in the same conditions

and circumstances which resulted in the customer's initial complaint.

Perform the ªDTC Confirmation Procedureº and confirm the normal code [DTC No. P0000] is detected. If the

incident is still detected in the final check, perform STEP VI by using a different method from the previous one.

Before returning the vehicle to the customer, be sure to erase the unnecessary (already fixed) (1st trip) DTC in

ECM and TCM (Transmission control module). (Refer to EC-72.)

TROUBLE DIAGNOSIS Ð INTRODUCTION

Work Flow (Cont'd)

EC-100

Page 647 of 2395

19 CHECK (1ST TRIP) DTC

1. Turn ignition switch ªOFFº.

2. Release vacuum from throttle opener.

3. Remove vacuum pump and vacuum hose from throttle opener.

4. Reinstall original vacuum hose to throttle opener securely.

5. Start engine and warm it up to normal operating temperature.

6. Rev (2,000 to 3,000 rpm) two or three times.

7. Make sure no (1st trip) DTC is displayed with CONSULT-II or GST.

OK or NG

OK©GO TO 21.

NG©GO TO 20.

20 REPAIR MALFUNCTION

Repair or replace components as necessary according to corresponding ªDiagnostic Procedureº.

©GO TO 19.

21 CHECK TARGET IDLE SPEED

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªENG SPEEDº in ªDATA MONITORº mode with CONSULT-II.

3. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

OK or NG

OK©GO TO 30.

NG©GO TO 22.

22 PERFORM IDLE AIR VOLUME LEARNING

Refer to ªIdle Air Volume Learningº, EC-57.

Which is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©GO TO 23.

INCMP©1. Follow the construction of ªIdle Air Volume Leaningº.

2. GO TO 22.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection (Cont'd)

EC-112

Page 650 of 2395

31 PERFORM IDLE AIR VOLUME LEARNING

Refer to ªIdle Air Volume Learningº, EC-57.

Which is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©GO TO 32.

INCMP©1. Follow the construction of ªIdle Air volume Learningº.

2. GO TO 31.

32 CHECK TARGET IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªENG SPEEDº in ªDATA MONITORº mode with CONSULT-II.

3. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

OK or NG

OK©GO TO 34.

NG©GO TO 33.

33 CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function.

(ECM may be the cause of a problem, but this is rarely the case.)

2. Perform initialization of NVIS (NATS) system and registration of NVIS (NATS) ignition key IDs. Refer to ªNVIS (NISSAN

VEHICLE IMMOBILIZER SYSTEM Ð NATS)º, EC-74.

©GO TO 31.

34 CHECK IGNITION TIMING AGAIN

Check ignition timing again. Refer to Test No. 30.

OK or NG

OK©GO TO 36.

NG©GO TO 35.

35 CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to EM-29, ªInstallationº.

OK or NG

OK©GO TO 33.

NG©1. Repair the timing chain installation.

2. GO TO 31.

36 ERASE UNNECESSARY DTC

After this inspection, unnecessary DTC No. might be displayed.

Erase the stored memory in ECM and TCM (Transmission control module).

Refer to ªHow to Erase Emission-Related Diagnostic Informationº, EC-72 and AT-35, ªHOW TO ERASE DTCº.

©INSPECTION END

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection (Cont'd)

EC-115

Page 651 of 2395

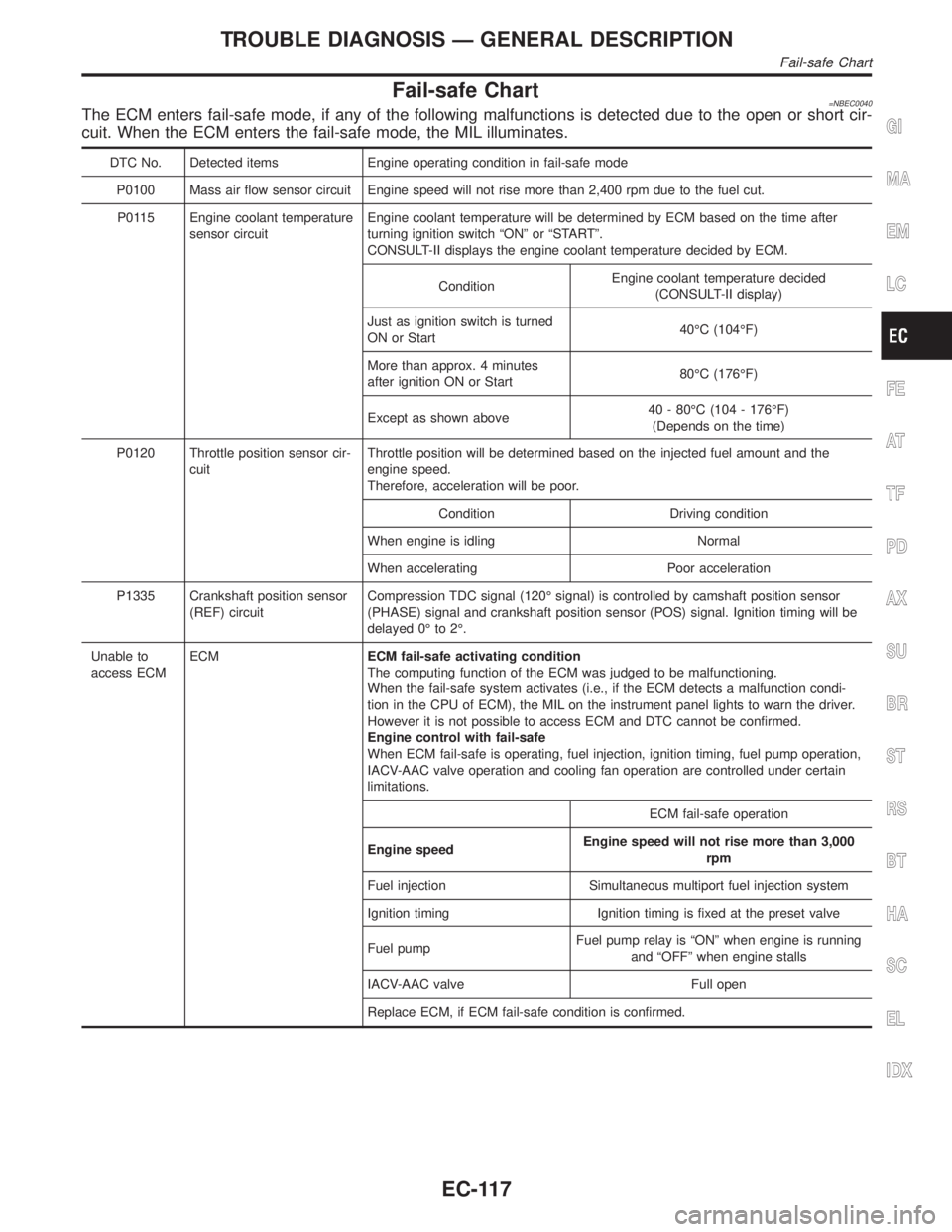

DTC Inspection Priority ChartNBEC0039If some DTCs are displayed at the same time, perform inspections one by one based on the following prior-

ity chart.

Priority Detected items (DTC)

1IP0100 Mass air flow sensor

IP0110 Intake air temperature sensor

IP0115 P0125 Engine coolant temperature sensor

IP0120 Throttle position sensor

IP0180 Fuel tank temperature sensor

IP0325 Knock sensor

IP0335 P1336 Crankshaft position sensor (POS)

IP0340 Camshaft position sensor (PHASE)

IP0460 P0461 P0464 P1464 Fuel level sensor

IP0500 Vehicle speed sensor

IP0605 ECM

IP1320 Ignition signal

IP1335 Crankshaft position sensor (REF)

IP1605 A/T diagnosis communication line

IP1706 Park/Neutral position (PNP) switch

2IP0105 Absolute pressure sensor

IP0130-P0134, P0150-P0154 Heated oxygen sensor 1 (front)

IP0135 P0155 Heated oxygen sensor 1 heater (front)

IP0137-P0140, P0157-P0160 Heated oxygen sensor 2 (rear)

IP0141 P0161 Heated oxygen sensor 2 (rear) heater

IP0217 Coolant overtemperature enrichment protection

IP0443 P1444 EVAP canister purge volume control solenoid valve

IP0446 P1446 P1448 EVAP canister vent control valve

IP0450 EVAP control system pressure sensor

IP0510 Closed throttle position switch

IP0705-P0755 P1705 P1760 A/T related sensors, solenoid valves and switches

IP 1111Intake valve timing control solenoid valve

IP1140 Intake valve timing control position sensor

IP1165 Swirl control valve control vacuum check switch

IP1441 EVAP control system (VERY SMALL LEAK)

IP1447 EVAP control system purge flow monitoring

IP1490 P1491 Vacuum cut valve bypass valve

3IP0171 P0172 P0174 P0175 Fuel injection system function

IP0306 - P0300 Misfire

IP0420 P0430 Three way catalyst function

IP0440 P1440 EVAP control system (SMALL LEAK)

IP0455 EVAP control system (GROSS LEAK)

IP0505 IACV-AAC valve

IP0600 A/T communication line

IP0731-P0734 P0744 A/T function

IP1110 Intake valve timing control

IP1130 Swirl control valve control solenoid valve

IP1148 P1168 Closed loop control

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

DTC Inspection Priority Chart

EC-116

Page 652 of 2395

Fail-safe Chart=NBEC0040The ECM enters fail-safe mode, if any of the following malfunctions is detected due to the open or short cir-

cuit. When the ECM enters the fail-safe mode, the MIL illuminates.

DTC No. Detected items Engine operating condition in fail-safe mode

P0100 Mass air flow sensor circuit Engine speed will not rise more than 2,400 rpm due to the fuel cut.

P0115 Engine coolant temperature

sensor circuitEngine coolant temperature will be determined by ECM based on the time after

turning ignition switch ªONº or ªSTARTº.

CONSULT-II displays the engine coolant temperature decided by ECM.

ConditionEngine coolant temperature decided

(CONSULT-II display)

Just as ignition switch is turned

ON or Start40ÉC (104ÉF)

More than approx. 4 minutes

after ignition ON or Start80ÉC (176ÉF)

Except as shown above40 - 80ÉC (104 - 176ÉF)

(Depends on the time)

P0120 Throttle position sensor cir-

cuitThrottle position will be determined based on the injected fuel amount and the

engine speed.

Therefore, acceleration will be poor.

Condition Driving condition

When engine is idling Normal

When accelerating Poor acceleration

P1335 Crankshaft position sensor

(REF) circuitCompression TDC signal (120É signal) is controlled by camshaft position sensor

(PHASE) signal and crankshaft position sensor (POS) signal. Ignition timing will be

delayed 0É to 2É.

Unable to

access ECMECMECM fail-safe activating condition

The computing function of the ECM was judged to be malfunctioning.

When the fail-safe system activates (i.e., if the ECM detects a malfunction condi-

tion in the CPU of ECM), the MIL on the instrument panel lights to warn the driver.

However it is not possible to access ECM and DTC cannot be confirmed.

Engine control with fail-safe

When ECM fail-safe is operating, fuel injection, ignition timing, fuel pump operation,

IACV-AAC valve operation and cooling fan operation are controlled under certain

limitations.

ECM fail-safe operation

Engine speedEngine speed will not rise more than 3,000

rpm

Fuel injection Simultaneous multiport fuel injection system

Ignition timing Ignition timing is fixed at the preset valve

Fuel pumpFuel pump relay is ªONº when engine is running

and ªOFFº when engine stalls

IACV-AAC valve Full open

Replace ECM, if ECM fail-safe condition is confirmed.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

Fail-safe Chart

EC-117