stop start INFINITI QX4 2001 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 937 of 2395

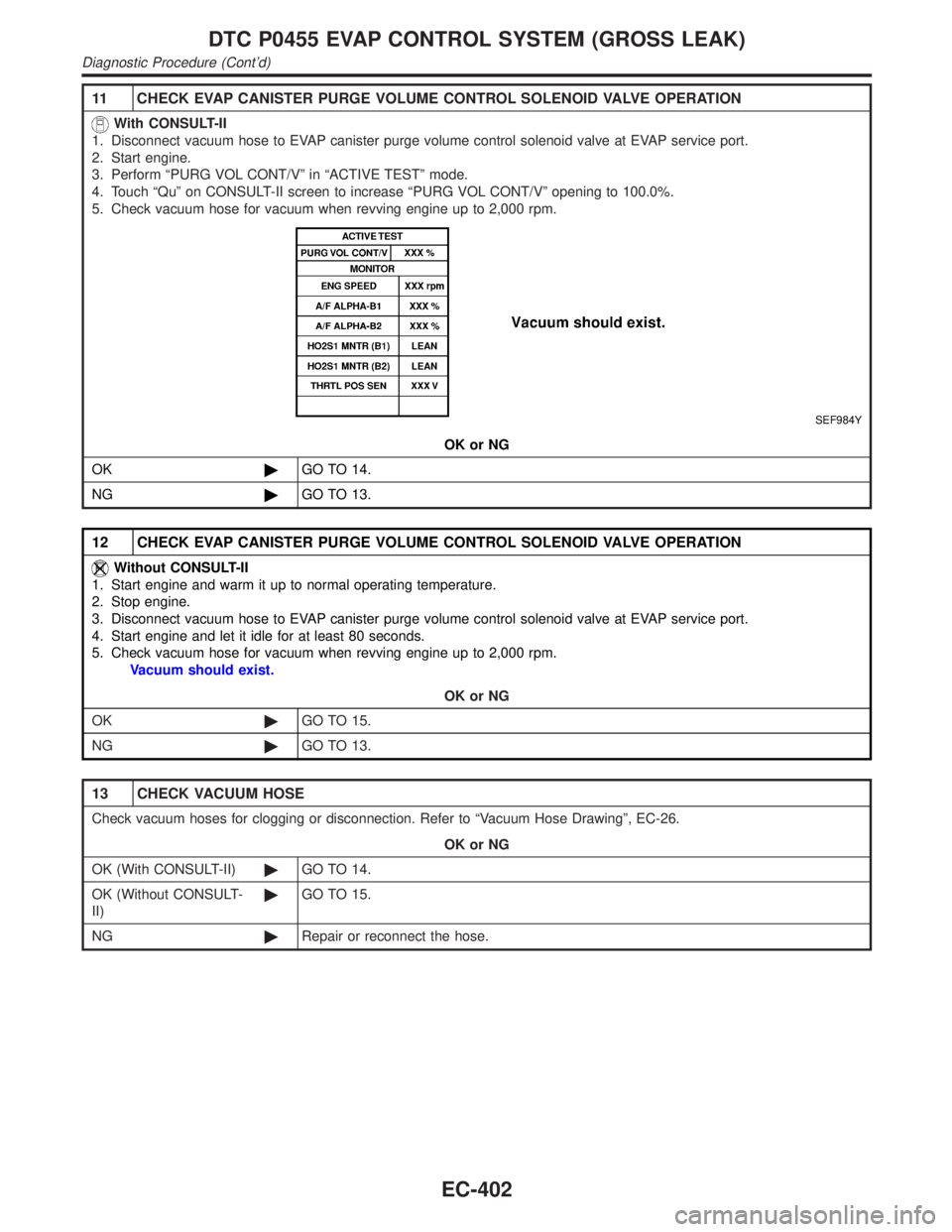

11 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

With CONSULT-II

1. Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

2. Start engine.

3. Perform ªPURG VOL CONT/Vº in ªACTIVE TESTº mode.

4. Touch ªQuº on CONSULT-II screen to increase ªPURG VOL CONT/Vº opening to 100.0%.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

SEF984Y

OK or NG

OK©GO TO 14.

NG©GO TO 13.

12 CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE OPERATION

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Disconnect vacuum hose to EVAP canister purge volume control solenoid valve at EVAP service port.

4. Start engine and let it idle for at least 80 seconds.

5. Check vacuum hose for vacuum when revving engine up to 2,000 rpm.

Vacuum should exist.

OK or NG

OK©GO TO 15.

NG©GO TO 13.

13 CHECK VACUUM HOSE

Check vacuum hoses for clogging or disconnection. Refer to ªVacuum Hose Drawingº, EC-26.

OK or NG

OK (With CONSULT-II)©GO TO 14.

OK (Without CONSULT-

II)©GO TO 15.

NG©Repair or reconnect the hose.

DTC P0455 EVAP CONTROL SYSTEM (GROSS LEAK)

Diagnostic Procedure (Cont'd)

EC-402

Page 947 of 2395

5) Turn ignition switch ªOFFº and wait at least 10 seconds then

turn ªONº.

6) Select ªFUEL LEVEL SEº in ªDATA MONITORº mode with

CONSULT-II.

7) Check ªFUEL LEVEL SEº output voltage and note it.

8) Select ªFUEL PUMPº in ªACTIVE TESTº mode with CON-

SULT-II.

9) Touch ªONº and drain fuel approximately 30(7-7/8 US gal,

6-5/8 Imp gal) and stop it.

10) Fill fuel into the fuel tank for 30(7-7/8 US gal, 6-5/8 Imp gal).

11) Check ªFUEL LEVEL SEº output voltage and note it.

12) Check ªFUEL LEVEL SEº output voltage and confirm whether

the voltage changes more than 0.03V during step 7 to 11.

If NG, check the fuel level sensor, refer to EL-108, ªFUEL

LEVEL SENSOR UNIT CHECKº.

SEF615X

WITH GSTNBEC0625S02NOTE:

Start from step 11, if it is possible to confirm that the fuel

cannot be drained by 30(7-7/8 US gal, 6-5/8 Imp gal) in

advance.

1) Prepare a fuel container and a spare hose.

2) Release fuel pressure from fuel line, refer to ªFuel Pressure

Releaseº, EC-39.

3) Remove the fuel feed hose on the fuel level sensor unit.

4) Connect a spare fuel hose where the fuel feed hose was

removed.

5) Turn ignition switch ªOFFº.

6) Set voltmeters probe between ECM terminal 83 (fuel level

sensor signal) and ground.

7) Turn ignition switch ªONº.

8) Check voltage between ECM terminal 83 and ground and note

it.

9) Drain fuel by 30(7-7/8 US gal, 6-5/8 Imp gal) from the fuel

tank using proper equipment.

10) Fill fuel into the fuel tank for 30(7-7/8 US gal, 6-5/8 Imp gal).

11) Confirm that the voltage between ECM terminal 83 and ground

changes more than 0.03V during step8-10.

If NG, check component of fuel level sensor, refer to EL-108,

ªFUEL LEVEL SENSOR UNIT CHECKº.

DTC P0461 FUEL LEVEL SENSOR FUNCTION

Overall Function Check (Cont'd)

EC-412

Page 965 of 2395

10 CHECK IACV-AAC VALVE-II

1. Reconnect IACV-AAC valve harness connector and ECM harness connector.

2. Turn ignition switch ªONº and ªOFFº, and ensure the IACV-AAC valve makes operating sound according to the ignition

switch position.

SEF997Y

OK or NG

OK©GO TO 12.

NG©GO TO 11.

11 REPLACE IACV-AAC VALVE

1. Replace IACV-AAC valve assembly.

2. Perform ªIdle Air Volume Learningº, EC-57.

Is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©INSPECTION END

INCMP©Follow the construction of ªIdle Air Volume Learningº.

12 CHECK TARGET IDLE SPEED

1. Turn ignition switch ªOFFº.

2. Reconnect all harness connectors and vacuum hoses.

3. Start engine and warm it up to normal operating temperature.

4. Also warm up transmission to normal operating temperature.

IFor A/T models with CONSULT-II, drive vehicle until ªFLUID TEMP SEº in ªDATA MONITORº mode of ªA/Tº system indi-

cates less than 0.9V.

IFor A/T models without CONSULT-II, drive vehicle for 10 minutes.

5. Stop vehicle with engine running.

6. Check target idle speed.

A/T: 750±50 rpm (in ªPº or ªNº position)

OK or NG

OK©GO TO 13.

NG©Perform ªIdle Air Volume Learningº, EC-57.

13 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

DTC P0505 IDLE AIR CONTROL VALVE (IACV) Ð AUXILIARY AIR CONTROL

(AAC) VALVE

Diagnostic Procedure (Cont'd)

EC-430

Page 973 of 2395

7 ADJUST THROTTLE POSITION SWITCH

Check the following items. Refer to ªBasic Inspectionº, EC-101.

MTBL0655

Is it possible to adjust closed throttle position switch?

YesorNo

Yes (With CONSULT-II)©GO TO 9.

Yes (Without CONSULT-

II)©GO TO 9.

No©Replace throttle position switch.

8 CHECK THROTTLE POSITION SENSOR

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine (ignition switch OFF).

3. Remove the vacuum hose connected to the throttle opener.

4. Connect suitable vacuum hose to the vacuum pump and the opener.

5. Apply vacuum [more than þ40.0 kPa (þ300 mmHg, þ11.81 inHg)] until the throttle drum becomes free from the rod of

the throttle opener.

SEF793W

6. Turn ignition switch ON.

7. Select ªDATA MONITORº mode with CONSULT-II.

8. Check voltage of ªTHRTL POS SENº under the following conditins.

Voltage measurement must be made with throttle position sensor installed in vehicle.

MTBL0230

OK or NG

OK©GO TO 10.

NG©Replace throttle position sensor.

DTC P0510 CLOSED THROTTLE POSITION SWITCH

Diagnostic Procedure (Cont'd)

EC-438

Page 974 of 2395

9 CHECK THROTTLE POSITION SENSOR

1. Start engine and warm it up to normal operating temperature.

2. Stop engine (ignition switch OFF).

3. Remove the vacuum hose connected to the throttle opener.

4. Connect suitable vacuum hose to the vacuum pump and the opener.

5. Apply vacuum [more than þ40.0 kPa (þ300 mmHg, þ11.81 inHg)] until the throttle drum becomes free from the rod of

the throttle opener.

SEF793W

6. Turn ignition switch ON.

7. Check voltage between ECM terminal 91 (Throttle position sensor signal) and ground.

Voltage measurement must be made with throttle position sensor installed in vehicle.

SEF348X

OK or NG

OK©GO TO 10.

NG©Replace throttle position sensor.

10 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0510 CLOSED THROTTLE POSITION SWITCH

Diagnostic Procedure (Cont'd)

EC-439

Page 996 of 2395

SEF174Y

PROCEDURE FOR MALFUNCTION BNBEC0528S02TESTING CONDITION:

IFor best results, perform the test at a temperature above

5ÉC (41ÉF).

IBefore performing the following procedure, confirm that

battery voltage is more than 10V at idle, then stop engine

immediately.

With CONSULT-IINBEC0528S02011) Turn ignition switch ªOFFº and wait at least 10 seconds.

2) Turn ignition switch ªONº.

3) Check ªCOOLAN TEMP/Sº in ªDATA MONITORº mode with

CONSULT-II.

4) Confirm COOLAN TEMP/S value is 40ÉC (104ÉF) or less.

If the value is more than 40ÉC (104ÉF), park the vehicle in a

cool place and retry from step 1.

5) Start engine and wait until COOLAN TEMP/S value increases

to more than 55ÉC (131ÉF).

If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-463.

With GSTNBEC0528S0202Follow the procedure ªWith CONSULT-IIº above.

SEF174Y

PROCEDURE FOR MALFUNCTION CNBEC0528S03TESTING CONDITION:

IFor best results, perform the test at a temperature above

5ÉC (41ÉF).

IBefore performing the following procedure, confirm that

battery voltage is more than 10V at idle.

With CONSULT-IINBEC0528S03011) Start engine and warm it up to normal operating temperature.

2) Turn ignition switch ªOFFº and wait at least 10 seconds.

3) Turn ignition switch ªONº again and select ªDATA MONITORº

mode with CONSULT-II.

4) Start engine and let it idle for at least 20 seconds. If 1st trip

DTC is detected, go to ªDiagnostic Procedureº, EC-463.

With GSTNBEC0528S0302Follow the procedure ªWith CONSULT-IIº above.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1130 SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

DTC Confirmation Procedure (Cont'd)

EC-461

Page 1007 of 2395

11 CHECK THROTTLE POSITION SENSOR

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine (ignition switch OFF).

3. Remove the vacuum hose connected to the throttle opener.

4. Connect suitable vacuum hose to the vacuum pump and the opener.

5. Apply vacuum [more than þ40.0 kPa (þ300 mmHg, þ11.81 inHg)] until the throttle drum becomes free from the rod of

the throttle opener.

SEF793W

6. Turn ignition switch ON.

7. Select ªDATA MONITORº mode with CONSULT-II.

8. Check voltage of ªTHRTL POS SENº under the following conditions.

Voltage measurement must be made with throttle position sensor installed in vehicle.

SEF062Y

OK or NG

OK©GO TO 14.

NG©GO TO 13.

DTC P1130 SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

Diagnostic Procedure (Cont'd)

EC-472

Page 1008 of 2395

12 CHECK THROTTLE POSITION SENSOR

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine (ignition switch OFF).

3. Remove the vacuum hose connected to the throttle opener.

4. Connect suitable vacuum hose to the vacuum pump and the opener.

5. Apply vacuum [more than þ40.0 kPa (þ300 mmHg, þ11.81 inHg)] until the throttle drum becomes free from the rod of

the throttle opener.

SEF793W

6. Turn ignition switch ON.

7. Check voltage between ECM terminal 91 (Throttle position sensor signal) and ground.

Voltage measurement must be made with throttle position sensor installed in vehicle.

MTBL0231

OK or NG

OK©GO TO 14.

NG©GO TO 13.

13 ADJUST CLOSED THROTTLE POSITION SWITCH

Adjust closed throttle position switch. Refer to ªBasic Inspectionº, EC-101.

MTBL0655

OK or NG

OK©GO TO 14.

NG©Replace throttle position sensor. To adjust it, perform ªBasic Inspectionº, EC-101.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1130 SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

Diagnostic Procedure (Cont'd)

EC-473

Page 1015 of 2395

11 CHECK THROTTLE POSITION SENSOR

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine (ignition switch OFF).

3. Remove the vacuum hose connected to the throttle opener.

4. Connect suitable vacuum hose to the vacuum pump and the opener.

5. Apply vacuum [more than þ40.0 kPa (þ300 mmHg, þ11.81 inHg)] until the throttle drum becomes free from the rod of

the throttle opener.

SEF793W

6. Turn ignition switch ON.

7. Select ªDATA MONITORº mode with CONSULT-II.

8. Check voltage of ªTHRTL POS SENº under the following conditions.

Voltage measurement must be made with throttle position sensor installed in vehicle.

SEF062Y

OK or NG

OK©GO TO 14.

NG©GO TO 13.

DTC P1130 SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

Diagnostic Procedure (Cont'd)

EC-480

Page 1016 of 2395

12 CHECK THROTTLE POSITION SENSOR

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Stop engine (ignition switch OFF).

3. Remove the vacuum hose connected to the throttle opener.

4. Connect suitable vacuum hose to the vacuum pump and the opener.

5. Apply vacuum [more than þ40.0 kPa (þ300 mmHg, þ11.81 inHg)] until the throttle drum becomes free from the rod of

the throttle opener.

SEF793W

6. Turn ignition switch ON.

7. Check voltage between ECM terminal 91 (Throttle position sensor signal) and ground.

Voltage measurement must be made with throttle position sensor installed in vehicle.

MTBL0231

OK or NG

OK©GO TO 14.

NG©GO TO 13.

13 ADJUST CLOSED THROTTLE POSITION SWITCH

Adjust closed throttle position switch. Refer to ªBasic Inspectionº, EC-101.

MTBL0655

OK or NG

OK©GO TO 14.

NG©Replace throttle position sensor. To adjust it, perform ªBasic Inspectionº, EC-101.

14 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1130 SWIRL CONTROL VALVE CONTROL SOLENOID VALVE

Diagnostic Procedure (Cont'd)

EC-481