Electrical INFINITI QX4 2001 Factory Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1801 of 2395

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NBHA0001The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring

harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized INFINITI dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for Working with HFC-134a

(R-134a)

NBHA0002WARNING:

ICFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. If the refrigerants

are mixed and compressor failure is likely to occur, refer to ªCONTAMINATED REFRIGERANTº

below. To determine the purity of HFC-134a (R-134a) in the vehicle and recovery tank, use Refrig-

erant Recovery/Recycling Recharging equipment (ACR4) (J-39500-INF) and Refrigerant Identifier.

IUse only specified lubricant for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) compo-

nents. If lubricant other than that specified is used, compressor failure is likely to occur.

IThe specified HFC-134a (R-134a) lubricant rapidly absorbs moisture from the atmosphere. The fol-

lowing handling precautions must be observed:

a) When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

b) When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as pos-

sible to minimize the entry of moisture into system.

c) Only use the specified lubricant from a sealed container. Immediately reseal containers of lubri-

cant. Without proper sealing, lubricant will become moisture saturated and should not be used.

d) Avoid breathing A/C refrigerant and lubricant vapor or mist. Exposure may irritate eyes, nose and

throat. Remove R-134a from the A/C system, using certified service equipment meeting require-

ments of SAE J2210 (R-134a recycling equipment), or J2209 (R-134a recovery equipment). If acci-

dental system discharge occurs, ventilate work area before resuming service. Additional health and

safety information may be obtained from refrigerant and lubricant manufacturers.

e) Do not allow lubricant (Nissan A/C System Oil Type S) to come in contact with styrofoam parts.

Damage may result.

CONTAMINATED REFRIGERANTNBHA0002S01If a refrigerant other than pure R-134a is identified in a vehicle, your options are:

IExplain to the customer that environmental regulations prohibit the release of contaminated refrigerant into

the atmosphere.

IExplain that recovery of the contaminated refrigerant could damage your service equipment and refriger-

ant supply.

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

HA-2

Page 1808 of 2395

Wiring Diagrams and Trouble DiagnosesNBHA0007When you read wiring diagrams, refer to the following:

IGI-11, ªHOW TO READ WIRING DIAGRAMSº

IEL-10, ªWiring Diagram Ð POWER к for power distribution

circuit

When you perform trouble diagnoses, refer to the following:

IGI-34, ªHOW TO FOLLOW TROUBLE DIAGNOSESº

IGI-24, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENTºGI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

PRECAUTIONS

Wiring Diagrams and Trouble Diagnoses

HA-9

Page 1810 of 2395

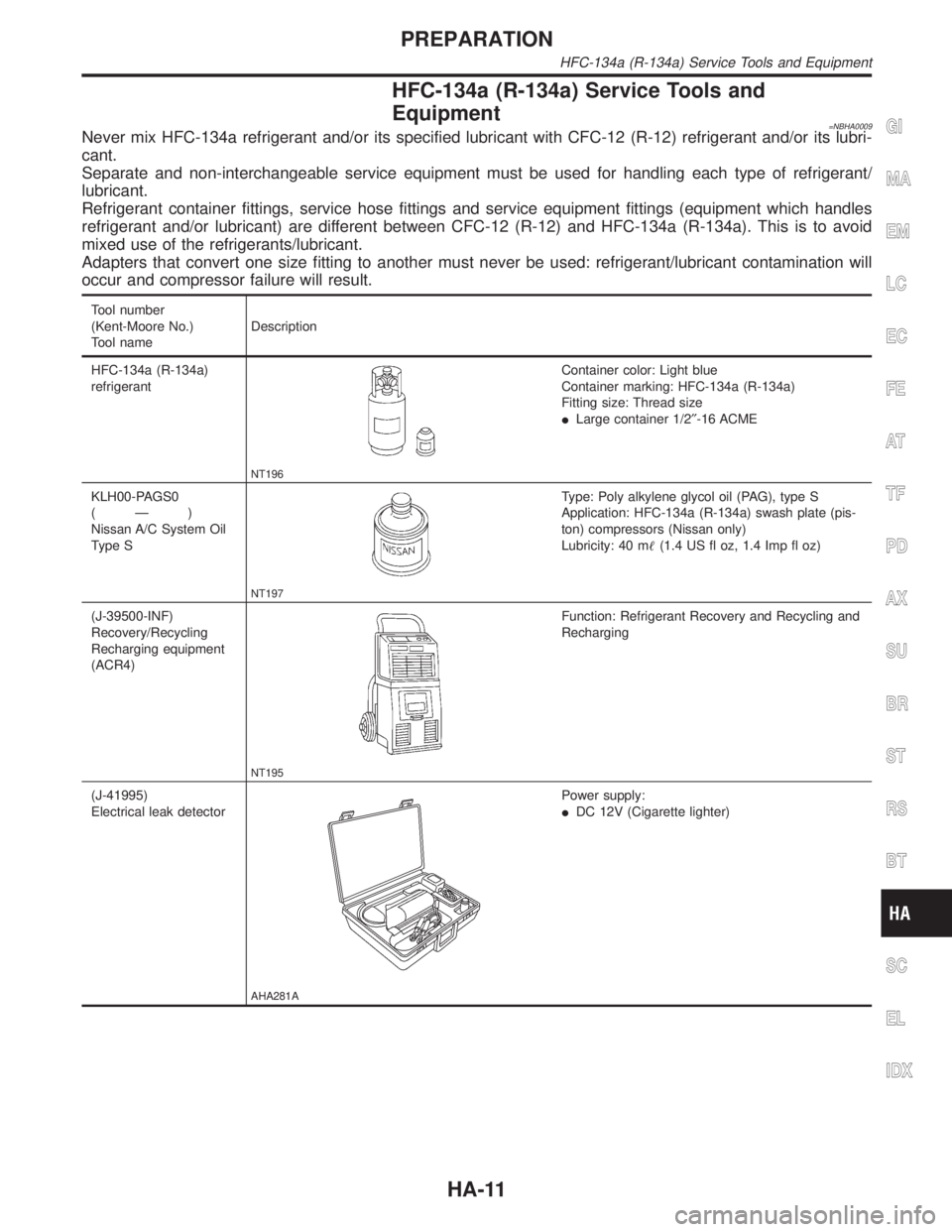

HFC-134a (R-134a) Service Tools and

Equipment

=NBHA0009Never mix HFC-134a refrigerant and/or its specified lubricant with CFC-12 (R-12) refrigerant and/or its lubri-

cant.

Separate and non-interchangeable service equipment must be used for handling each type of refrigerant/

lubricant.

Refrigerant container fittings, service hose fittings and service equipment fittings (equipment which handles

refrigerant and/or lubricant) are different between CFC-12 (R-12) and HFC-134a (R-134a). This is to avoid

mixed use of the refrigerants/lubricant.

Adapters that convert one size fitting to another must never be used: refrigerant/lubricant contamination will

occur and compressor failure will result.

Tool number

(Kent-Moore No.)

Tool nameDescription

HFC-134a (R-134a)

refrigerant

NT196

Container color: Light blue

Container marking: HFC-134a (R-134a)

Fitting size: Thread size

ILarge container 1/2²-16 ACME

KLH00-PAGS0

(Ð)

Nissan A/C System Oil

Type S

NT197

Type: Poly alkylene glycol oil (PAG), type S

Application: HFC-134a (R-134a) swash plate (pis-

ton) compressors (Nissan only)

Lubricity: 40 m(1.4 US fl oz, 1.4 Imp fl oz)

(J-39500-INF)

Recovery/Recycling

Recharging equipment

(ACR4)

NT195

Function: Refrigerant Recovery and Recycling and

Recharging

(J-41995)

Electrical leak detector

AHA281A

Power supply:

IDC 12V (Cigarette lighter)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

PREPARATION

HFC-134a (R-134a) Service Tools and Equipment

HA-11

Page 1820 of 2395

RHA441GA

Transmission Data and Transmission OrderNBHA0014S0802Amplifier data is transmitted consecutively to each of the door motors following the form shown in figure below.

Start: Initial compulsory signal sent to each of the door motors.

Address: Data sent from the auto amplifier is selected according to data-based decisions made by the air mix

door motor and mode door motor.

If the addresses are identical, the opening angle data and error check signals are received by the door motor

LCUs. The LCUs then make the appropriate error decision. If the opening angle data is normal, door control

begins.

If an error exists, the received data is rejected and corrected data received. Finally, door control is based upon

the corrected opening angle data.

Opening angle: Data that shows the indicated door opening angle of each door motor.

Error check: Procedure by which sent and received data is checked for errors. Error data is then compiled.

The error check prevents corrupted data from being used by the air mix door motor and mode door motor.

Error data can be related to the following problems.

IAbnormal electrical frequency

IPoor electrical connections

ISignal leakage from transmission lines

ISignal level fluctuation

Stop signal: At the end of each transmission, a stop operation, in-operation, or internal problem message is

delivered to the auto amplifier. This completes one data transmission and control cycle.

RHA442G

Air Mix Door Control (Automatic Temperature Control)NBHA0014S0803The air mix door is automatically controlled so that in-vehicle temperature is maintained at a predetermined

value by: The temperature setting, ambient temperature, in-vehicle temperature and amount of sunload.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

SC

EL

IDX

DESCRIPTION

Features (Cont'd)

HA-21

Page 1963 of 2395

E

ECM input/output signal ...............................EC-127

ECTS - Wiring diagram ........................EC-171, 189

Electric sun roof ............................................EL-173

Electrical diagnoses.........................................GI-24

Electrical ignition system ................................EC-30

Electrical unit ................................................Foldout

Electrical units location .................................EL-436

Engine compartment .......................................BT-58

Engine control circuit diagram........................EC-24

Engine control component parts

location .......................................................EC-20

Engine control module (ECM) ......................EC-444

Engine control system diagram and

chart ............................................................EC-25

Engine coolant temperature sensor

(ECTS) ..............................................EC-169, 187

Engine fail-safe system ................................EC-117

Engine oil filter replacement ..........................MA-18

Engine oil precautions .......................................GI-8

Engine oil replacement ..................................MA-18

Engine outer component parts ......................EM-10

Engine removal ..............................................EM-57

Engine room - See Engine

compartment................................................BT-58

Engine serial number ......................................GI-43

EVAP canister.................................................EC-33

EVAP canister purge volume control

solenoid valve.............................EC-32, 367, 541

EVAP canister vent control

valve .........................................EC-374, 553, 573

EVAP control system (small leak)

diagnosis ..................................EC-352, 394, 526

EVAP control system pressure sensor.........EC-381

EVAP control system purge flow moni-

toring diagnosis.........................................EC-561

EVAP vapor lines inspection ..........................MA-20

Evaporative emission (EVAP) system ............EC-32

Exhaust system ................................................FE-8

Exhaust system inspection ............................MA-21

Exterior ............................................................BT-35

F

4LO indicator lamp........................................TF-104

4WD shift indicator lamp.................................TF-98

4WD shift switch ............................................TF-111

4WD solenoid valve.......................................TF-111

4WD warning lamp .........................................TF-13

Fan control amp. ............................................HA-98

F/FOG - Wiring diagram .................................EL-72

Final drive disassembly ..................................PD-43

Final drive pre-inspection ...............................PD-43

Final drive removal and installation ...............PD-43

Finisher, interior - See Trim ............................BT-28

F/LID - Wiring diagram .................................EL-180

Fluid temperature sensor (A/T) .....................AT-110Fluids ..............................................................MA-11

Flywheel runout..............................................EM-70

FO2H-L - Wiring diagram .............................EC-243

FO2H-R - Wiring diagram ............................EC-242

Fog lamp, front................................................EL-70

Fog lamp, front, removal and

installation ...................................................BT-12

Forward clutch ...............................................AT-320

F/PUMP - Wiring diagram ............................EC-627

Freeze frame data ..........................................EC-60

FRO2LH - Wiring diagram ...........EC-197, 223, 235

FRO2RH - Wiring diagram...........EC-196, 222, 234

Front axle..........................................................AX-2

Front bumper ..................................................BT-12

Front case (Transfer) ....................................TF-133

Front combination lamp removal and

installation ...................................................BT-12

Front disc brake .............................................BR-22

Front door .......................................................BT-18

Front drive shaft (Transfer) ...........................TF-125

Front final drive disassembly (4WD) ..............PD-18

Front final drive pre-inspection (4WD) ...........PD-18

Front final drive removal and installa-

tion (4WD)...................................................PD-18

Front fog lamp.................................................EL-70

Front fog lamp removal and installation .........BT-12

Front heated oxygen sensor (HO2S)

(Left bank) ................EC-192, 202, 210, 218, 231

Front heated oxygen sensor (HO2S)

(Right bank) .............EC-192, 202, 210, 218, 231

Front heated oxygen sensor heater

(Left bank).................................................EC-240

Front heated oxygen sensor heater

(Right bank) ..............................................EC-240

Front revolution sensor (Transfer) ................TF-112

Front seat ........................................................BT-41

Front seat belt ..................................................RS-4

Front suspension ..............................................SU-2

Front washer .................................................EL-136

Front wiper ....................................................EL-136

Fuel cut control (at no load & high

engine speed) .............................................EC-32

Fuel filler lid.....................................................BT-15

Fuel filter replacement ...................................MA-16

Fuel gauge ......................................................EL-94

Fuel injection system (Left bank) .........EC-294, 302

Fuel injection system (Right bank) ......EC-294, 302

Fuel lid opener, electric.................................EL-180

Fuel line inspection ........................................MA-16

Fuel precautions ................................................GI-8

Fuel pressure check .......................................EC-39

Fuel pressure regulator ..................................EC-40

Fuel pressure release ....................................EC-39

Fuel pump ....................................................EC-625

Fuel system ......................................................FE-4

Fuel tank temperature sensor ......................EC-309

Fuel tank vacuum relief valve ........................EC-33

FUELLH - Wiring diagram....................EC-297, 305

FUELRH - Wiring diagram ...................EC-296, 304

Fuse ................................................................EL-16

Fuse block ....................................................Foldout

ALPHABETICAL INDEX

IDX-4

Page 1964 of 2395

Fusible link ......................................................EL-16

G

Garage jack and safety stand .........................GI-46

Gauges............................................................EL-94

Generator - See Alternator .............................SC-28

Generic scan tool (GST) ................................EC-95

Glass ...............................................................BT-18

Glass hatch opener, electric .........................EL-178

Grease ............................................................MA-11

Ground distribution..........................................EL-17

H

Harness connector ............................................EL-5

Harness connector inspection .........................GI-21

Harness layout ..............................................EL-440

Hazard warning lamp ......................................EL-75

Headlamp ........................................................EL-31

Headlamp aiming control ................................EL-59

Headlining - See Roof trim .............................BT-32

Heated seat .......................................BT-43, EL-183

Height (Dimensions) ........................................GI-43

HFC134a (R134a) system precaution .............HA-2

HFC134a (R134a) system service

procedure ..................................................HA-144

HFC134a (R134a) system service tools ........HA-11

HFC134a system service equipment

precaution .....................................................HA-7

High clutch.....................................................AT-317

H/LAMP - Wiring diagram ...............................EL-36

Hood................................................................BT-12

Horn ..............................................................EL-147

HORN - Wiring diagram................................EL-147

How to erase DTC for OBD system...............EC-72

HSEAT - Wiring diagram...............................EL-183

I

IACV-AAC valve ...........................................EC-422

IATS - Wiring diagram ..................................EC-166

Identification .....................................................HA-4

Identification plate............................................GI-42

Idle air control valve (IACV) .........................EC-422

Idle mixture ratio.............................................EC-43

Idle speed .......................................................EC-43

IGN/SG - Wiring diagram .............................EC-501

Ignition control system .................................EC-499

Ignition timing .................................................EC-43

ILL - Wiring diagram .......................................EL-83

Illumination ......................................................EL-80

In vehicle sensor ..........................................HA-132

INFINITI COMMUNICATOR..........................EL-348

Infiniti communicator (IVCS) .........................EL-348

INJECT - Wiring diagram .............................EC-617

Injector ..........................................................EC-616Injector removal and installation ....................EC-41

Instrument panel .............................................BT-21

INT/L - Wiring diagram....................................EL-91

Intake air temparature sensor ......................EC-164

Intake door control linkage adjustment ..........HA-94

Intake door motor ...........................................HA-87

Intake manifold...............................................EM-12

Intake sensor ................................................HA-139

Integrated homelink transmitter ....................EL-325

Interior .............................................................BT-28

Interior lamp ....................................................EL-88

Interior lamp on-off control ..............................EL-89

Internal gear (Transfer) .................................TF-134

IVC-L - Wiring diagram.................................EC-453

IVC-R - Wiring diagram ................................EC-453

IVCS - Wiring diagram ..................................EL-359

IVCS-L - Wiring diagram ..............................EC-485

IVCS-R - Wiring diagram .............................EC-485

IVIS (Infiniti vehicle immobilizer

system) ......................................................EL-328

IVIS (Infiniti vehicle immobilizer sys-

tem) precautions ............................................GI-3

J

Jacking points ..................................................GI-45

Journal bearing assembly (propeller

shaft) .............................................................PD-9

Journal bearing disassembly (propeller

shaft) .............................................................PD-8

Junction box (J/B).........................................Foldout

K

Keyless entry system - See Multi-re-

mote control system ..................................EL-270

Knock sensor (KS) .......................................EC-328

Knuckle spindle ................................................AX-9

KS - Wiring diagram .....................................EC-330

L

Length (Dimensions) .......................................GI-43

License lamp ...................................................EL-61

Lifting points ....................................................GI-47

Limited slip diff. adjustment ............................PD-50

Limited slip diff. assembly ..............................PD-51

Limited slip diff. disassembly..........................PD-48

Limited slip diff. inspection .............................PD-49

Line pressure solenoid valve ........AT-147, 161, 167

Line pressure switch (Transfer) .....................TF-111

Line pressure test (A/T) ..................................AT-62

Liquid gasket application .................................EM-3

LOAD - Wiring diagram ................................EC-643

Location of electrical units ............................EL-436

Lock, door .......................................................BT-18

Low and reverse brake .................................AT-324

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

ALPHABETICAL INDEX

IDX-5

Page 1997 of 2395

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NBMA0001The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag module (located in the outer side of front seat),

satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring harness,

warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized INFINITI dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

MA-2

Page 2092 of 2395

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

NBRS0001The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag module (located in the outer side of front seat),

satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring harness,

warning lamp (one of components of air bags for a frontal collision).

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized INFINITI dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTION FOR SEAT BELT SERVICENBRS0002CAUTION:

IBefore removing the seat belt pre-tensioner assembly, turn the ignition switch off, disconnect both

battery cables and wait at least 3 minutes.

IDo not use electrical test equipment for seat belt pre-tensioner connector.

IAfter replacing or reinstalling seat belt pre-tensioner assembly, or reconnecting seat belt pre-ten-

sioner connector, check the system function. Refer to ªSRS Operation Checkº (RS-38) for details.

IDo not use disassemble buckle or seat belt assembly.

IReplace anchor bolts if they are deformed or worn out.

INever oil tongue and buckle.

IIf any component of seat belt assembly is questionable, do not repair. Replace the whole seat belt

assembly.

IIf webbing is cut, frayed, or damaged, replace seat belt assembly.

IWhen replacing seat belt assembly, use a genuine seat belt assembly.

After A CollisionNBRS0002S01WARNING:

Inspect all seat belt assemblies including retractors and attaching hardware after any collision.

NISSAN recommends that all seat belt assemblies in use during a collision be replaced unless the

collision was minor and the belts show no damage and continue to operate properly. Failure to do so

could result in serious personal injury in an accident. Seat belt assemblies not in use during a colli-

sion should also be replaced if either damage or improper operation is noted. Seat belt pre-tensioner

should be replaced even if the seat belts are not in use during a frontal collision in which the air bags

are deployed.

Replace any seat belt assembly if:

IThe seat belt was in use at the time of a collision (except for minor collisions and the belts, retractors and

buckles show no damage and continue to operate properly).

IThe seat belt was damaged in an accident. (i.e. torn webbing, bent retractor or guide, etc.)

IThe seat belt attaching point was damaged in an accident. Inspect the seat belt attaching area for dam-

age or distortion and repair as necessary before installing a new seat belt assembly.

IAnchor bolts are deformed or worn out.

IThe seat belt pre-tensioner should be replaced even if the seat belts are not in use during the collision in

which the air bags are deployed.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SEAT BELTS

Precautions

RS-3

Page 2099 of 2395

Precautions

SUPPLEMENTAL RESTRAINT SYSTEM (SRS) ªAIR BAGº AND ªSEAT BELT

PRE-TENSIONERº

NBRS0005The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS composition which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag module (located in the outer side of front seat),

satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring harness,

warning lamp (one of components of air bags for a frontal collision).

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized INFINITI dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS FOR SRS ªAIR BAGº AND ªSEAT BELT PRE-TENSIONERº SERVICENBRS0006IDo not use electrical test equipment to check SRS circuits unless instructed to in this Service Manual.

IBefore servicing the SRS, turn ignition switch ªOFFº, disconnect both battery cables and wait at least 3

minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

IDiagnosis sensor unit must always be installed with their arrow marks ªgº pointing towards the front of

the vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before

installation and replace as required.

IThe spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

IHandle air bag module carefully. Always place driver and passenger air bag modules with the pad side

facing upward and side air bag module (built-in type) standing with the stud bolt side setting bottom.

IConduct self-diagnosis to check entire SRS for proper function after replacing any components.

IAfter air bag inflates, the front instrument panel assembly should be replaced if damaged.

WIRING DIAGRAMS AND TROUBLE DIAGNOSISNBRS0007When you read wiring diagrams, refer to the following:

IGI-11, ªHOW TO READ WIRING DIAGRAMSº

IEL-9, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnosis, refer to the following:

IGI-35, ªHOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSESº

IGI-24, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Precautions

RS-10

Page 2103 of 2395

SRS797-A

Maintenance ItemsNBRS0011CAUTION:

Do not use electrical test equipment to check SRS circuit.

1. Check operation of ªAIR BAGº warning lamp.

After turning ignition key to ªONº position, air bag warning lamp

illuminates. The ªAIR BAGº warning lamp will go off after about

7 seconds if no malfunction is detected. If any of the following

warning lamp conditions occur, immediately check the air bag

or seat belt pre-tensioner system. Refer to RS-38 for details.

IThe ªAIR BAGº warning lamp does not illuminate when the

ignition switch is turned ªONº.

IThe ªAIR BAGº warning lamp does not go off about 7 seconds

after the ignition switch is turned ªONº.

IThe ªAIR BAGº warning lamp blinks after about 7 seconds after

the ignition switch is turned ªONº.

2. Visually check SRS components.

1) Diagnosis sensor unit

ICheck diagnosis sensor unit and bracket for dents, cracks and

deformities.

ICheck connectors for damage, and terminals for deformities.

2) Air bag module and steering wheel

IRemove air bag module from steering wheel, instrument panel

or seatback. Check harness cover and connectors for damage,

terminals for deformities, and harness for binding.

IInstall driver air bag module to steering wheel to check fit or

alignment with the wheel.

ICheck steering wheel for excessive free play.

IInstall passenger air bag module to instrument panel to check

fit or alignment with the instrument panel.

IInstall side air bag module to seatback to check fit and align-

ment with the seat.

3) Spiral cable

ICheck spiral cable for dents, cracks, or deformities.

ICheck connectors and protective tape for damage.

ICheck steering wheel for noise, binding or heavy operation.

4) Main harness, air bag harness, body harness, side air bag

module sub-harness

ICheck connectors for poor connections, damage, and termi-

nals for deformities.

ICheck harnesses for binding, chafing or cut.

5) Seat belt pre-tensioner

ICheck harness cover and connectors for damage, terminals

for deformities, and harness for binding.

ICheck belts for damage and anchors for loose mounting.

ICheck retractor for smooth operation.

IPerform self-diagnosis for seat belt pre-tensioner using air bag

warning lamp or CONSULT-II. Refer to ªSRS Operation Checkº

for details. (RS-38)

6) Satellite sensor

ICheck satellite sensor (including bracket portion) for dents,

cracks or deformities.

ICheck connectors for damage, and terminals for deformities.

CAUTION:

Replace previously used special bolts and ground bolt with

new ones.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Maintenance Items

RS-14