belt INFINITI QX4 2001 Factory Manual Online

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 2148 of 2395

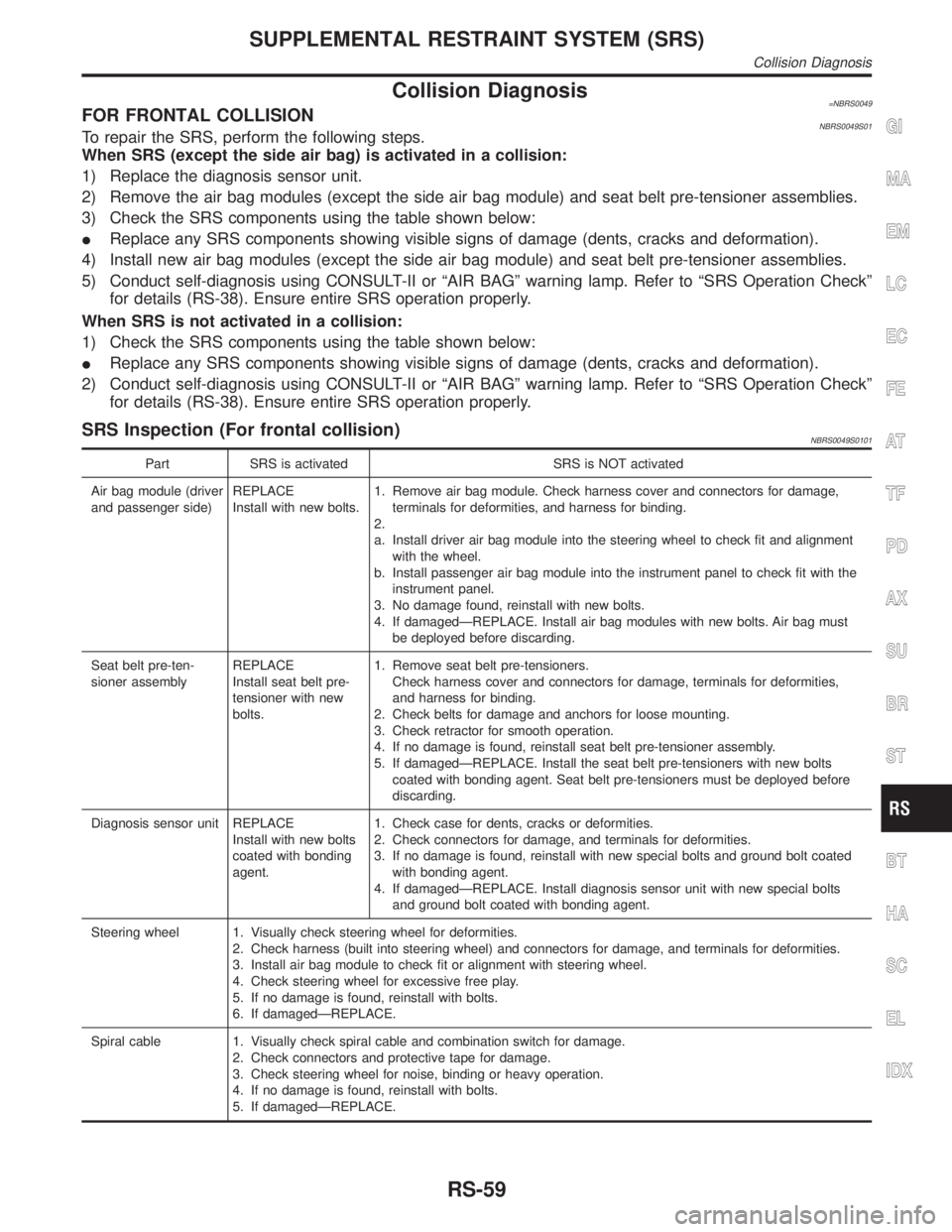

Collision Diagnosis=NBRS0049FOR FRONTAL COLLISIONNBRS0049S01To repair the SRS, perform the following steps.

When SRS (except the side air bag) is activated in a collision:

1) Replace the diagnosis sensor unit.

2) Remove the air bag modules (except the side air bag module) and seat belt pre-tensioner assemblies.

3) Check the SRS components using the table shown below:

IReplace any SRS components showing visible signs of damage (dents, cracks and deformation).

4) Install new air bag modules (except the side air bag module) and seat belt pre-tensioner assemblies.

5) Conduct self-diagnosis using CONSULT-II or ªAIR BAGº warning lamp. Refer to ªSRS Operation Checkº

for details (RS-38). Ensure entire SRS operation properly.

When SRS is not activated in a collision:

1) Check the SRS components using the table shown below:

IReplace any SRS components showing visible signs of damage (dents, cracks and deformation).

2) Conduct self-diagnosis using CONSULT-II or ªAIR BAGº warning lamp. Refer to ªSRS Operation Checkº

for details (RS-38). Ensure entire SRS operation properly.

SRS Inspection (For frontal collision)NBRS0049S0101

Part SRS is activated SRS is NOT activated

Air bag module (driver

and passenger side)REPLACE

Install with new bolts.1. Remove air bag module. Check harness cover and connectors for damage,

terminals for deformities, and harness for binding.

2.

a. Install driver air bag module into the steering wheel to check fit and alignment

with the wheel.

b. Install passenger air bag module into the instrument panel to check fit with the

instrument panel.

3. No damage found, reinstall with new bolts.

4. If damagedÐREPLACE. Install air bag modules with new bolts. Air bag must

be deployed before discarding.

Seat belt pre-ten-

sioner assemblyREPLACE

Install seat belt pre-

tensioner with new

bolts.1. Remove seat belt pre-tensioners.

Check harness cover and connectors for damage, terminals for deformities,

and harness for binding.

2. Check belts for damage and anchors for loose mounting.

3. Check retractor for smooth operation.

4. If no damage is found, reinstall seat belt pre-tensioner assembly.

5. If damagedÐREPLACE. Install the seat belt pre-tensioners with new bolts

coated with bonding agent. Seat belt pre-tensioners must be deployed before

discarding.

Diagnosis sensor unit REPLACE

Install with new bolts

coated with bonding

agent.1. Check case for dents, cracks or deformities.

2. Check connectors for damage, and terminals for deformities.

3. If no damage is found, reinstall with new special bolts and ground bolt coated

with bonding agent.

4. If damagedÐREPLACE. Install diagnosis sensor unit with new special bolts

and ground bolt coated with bonding agent.

Steering wheel 1. Visually check steering wheel for deformities.

2. Check harness (built into steering wheel) and connectors for damage, and terminals for deformities.

3. Install air bag module to check fit or alignment with steering wheel.

4. Check steering wheel for excessive free play.

5. If no damage is found, reinstall with bolts.

6. If damagedÐREPLACE.

Spiral cable 1. Visually check spiral cable and combination switch for damage.

2. Check connectors and protective tape for damage.

3. Check steering wheel for noise, binding or heavy operation.

4. If no damage is found, reinstall with bolts.

5. If damagedÐREPLACE.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Collision Diagnosis

RS-59

Page 2150 of 2395

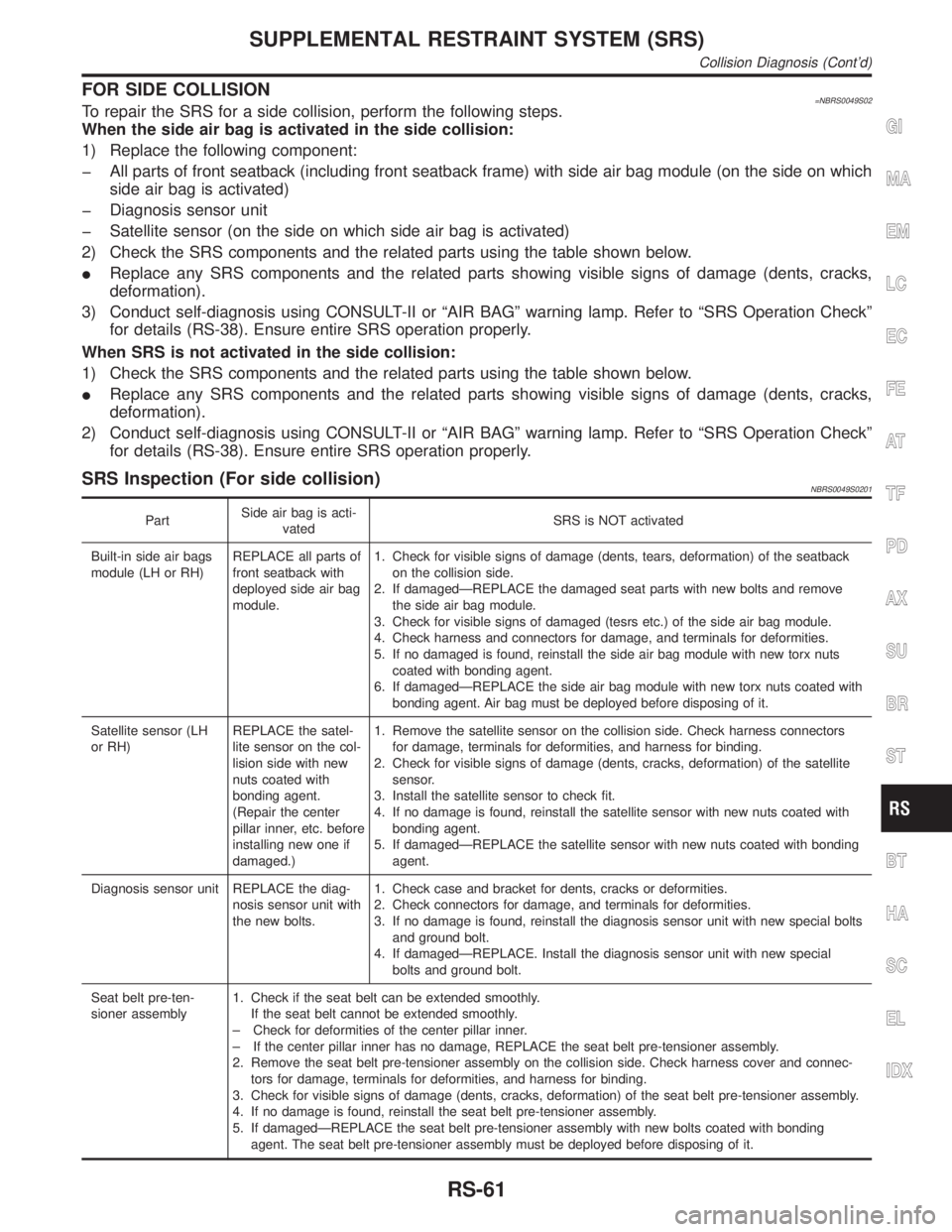

FOR SIDE COLLISION=NBRS0049S02To repair the SRS for a side collision, perform the following steps.

When the side air bag is activated in the side collision:

1) Replace the following component:

þ All parts of front seatback (including front seatback frame) with side air bag module (on the side on which

side air bag is activated)

þ Diagnosis sensor unit

þ Satellite sensor (on the side on which side air bag is activated)

2) Check the SRS components and the related parts using the table shown below.

IReplace any SRS components and the related parts showing visible signs of damage (dents, cracks,

deformation).

3) Conduct self-diagnosis using CONSULT-II or ªAIR BAGº warning lamp. Refer to ªSRS Operation Checkº

for details (RS-38). Ensure entire SRS operation properly.

When SRS is not activated in the side collision:

1) Check the SRS components and the related parts using the table shown below.

IReplace any SRS components and the related parts showing visible signs of damage (dents, cracks,

deformation).

2) Conduct self-diagnosis using CONSULT-II or ªAIR BAGº warning lamp. Refer to ªSRS Operation Checkº

for details (RS-38). Ensure entire SRS operation properly.

SRS Inspection (For side collision)NBRS0049S0201

PartSide air bag is acti-

vatedSRS is NOT activated

Built-in side air bags

module (LH or RH)REPLACE all parts of

front seatback with

deployed side air bag

module.1. Check for visible signs of damage (dents, tears, deformation) of the seatback

on the collision side.

2. If damagedÐREPLACE the damaged seat parts with new bolts and remove

the side air bag module.

3. Check for visible signs of damaged (tesrs etc.) of the side air bag module.

4. Check harness and connectors for damage, and terminals for deformities.

5. If no damaged is found, reinstall the side air bag module with new torx nuts

coated with bonding agent.

6. If damagedÐREPLACE the side air bag module with new torx nuts coated with

bonding agent. Air bag must be deployed before disposing of it.

Satellite sensor (LH

or RH)REPLACE the satel-

lite sensor on the col-

lision side with new

nuts coated with

bonding agent.

(Repair the center

pillar inner, etc. before

installing new one if

damaged.)1. Remove the satellite sensor on the collision side. Check harness connectors

for damage, terminals for deformities, and harness for binding.

2. Check for visible signs of damage (dents, cracks, deformation) of the satellite

sensor.

3. Install the satellite sensor to check fit.

4. If no damage is found, reinstall the satellite sensor with new nuts coated with

bonding agent.

5. If damagedÐREPLACE the satellite sensor with new nuts coated with bonding

agent.

Diagnosis sensor unit REPLACE the diag-

nosis sensor unit with

the new bolts.1. Check case and bracket for dents, cracks or deformities.

2. Check connectors for damage, and terminals for deformities.

3. If no damage is found, reinstall the diagnosis sensor unit with new special bolts

and ground bolt.

4. If damagedÐREPLACE. Install the diagnosis sensor unit with new special

bolts and ground bolt.

Seat belt pre-ten-

sioner assembly1. Check if the seat belt can be extended smoothly.

If the seat belt cannot be extended smoothly.

± Check for deformities of the center pillar inner.

± If the center pillar inner has no damage, REPLACE the seat belt pre-tensioner assembly.

2. Remove the seat belt pre-tensioner assembly on the collision side. Check harness cover and connec-

tors for damage, terminals for deformities, and harness for binding.

3. Check for visible signs of damage (dents, cracks, deformation) of the seat belt pre-tensioner assembly.

4. If no damage is found, reinstall the seat belt pre-tensioner assembly.

5. If damagedÐREPLACE the seat belt pre-tensioner assembly with new bolts coated with bonding

agent. The seat belt pre-tensioner assembly must be deployed before disposing of it.

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

BT

HA

SC

EL

IDX

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Collision Diagnosis (Cont'd)

RS-61

Page 2152 of 2395

STARTING & CHARGING SYSTEM

SECTION

SC

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

Wiring Diagrams and Trouble Diagnosis .....................2

PREPARATION...............................................................3

Special Service Tool ....................................................3

BATTERY.........................................................................4

How to Handle Battery ................................................4

METHODS OF PREVENTING OVER-DISCHARGE......4

CHECKING ELECTROLYTE LEVEL............................4

SPECIFIC GRAVITY CHECK......................................5

CHARGING THE BATTERY........................................6

Trouble Diagnoses with Battery/Starting/Charging

System Tester ..............................................................7

DIAGNOSTIC RESULT ITEM CHART..........................9

STARTING SYSTEM.....................................................10

System Description ....................................................10

Wiring Diagram - START -......................................... 11

Trouble Diagnoses with Battery/Starting/Charging

System Tester ............................................................12

DIAGNOSTIC RESULT ITEM CHART........................13

WORK FLOW..........................................................14

DIAGNOSTIC PROCEDURE 1..................................15

DIAGNOSTIC PROCEDURE 2..................................17

MINIMUM SPECIFICATION OF CRANKING

VOLTAGE REFERENCING COOLANT

TEMPERATURE

......................................................17

Construction ...............................................................18

Removal and Installation ...........................................18

Pinion/Clutch Check ..................................................18

CHARGING SYSTEM....................................................19

System Description ....................................................19

Wiring Diagram - CHARGE -.....................................20

Trouble Diagnoses with Battery/Starting/Charging

System Tester ............................................................21

DIAGNOSTIC RESULT ITEM CHART........................23

WORK FLOW..........................................................24

DIAGNOSTIC PROCEDURE 1..................................25

DIAGNOSTIC PROCEDURE 2..................................26

DIAGNOSTIC PROCEDURE 3..................................27

MALFUNCTION INDICATOR....................................27

Construction ...............................................................28

Removal and Installation ...........................................28

SERVICE DATA AND SPECIFICATIONS (SDS).........29

Battery........................................................................29

Starter ........................................................................29

Alternator ...................................................................29

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

EL

IDX

Page 2153 of 2395

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NBSC0001The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag module (located in the outer side of front seat),

satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring harness,

warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized INFINITI dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Wiring Diagrams and Trouble DiagnosisNBSC0002When you read wiring diagrams, refer to the following:

IGI-11, ªHOW TO READ WIRING DIAGRAMSº

IEL-9, ªPOWER SUPPLY ROUTINGº for power distribution circuit

When you perform trouble diagnosis, refer to the following:

IGI-35, ªHOW TO FOLLOW TEST GROUP IN TROUBLE DIAGNOSISº

IGI-24, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

SC-2

Page 2182 of 2395

STEERING SYSTEM

SECTION

ST

CONTENTS

PRECAUTIONS...............................................................2

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............2

Precautions for Steering System .................................2

PREPARATION...............................................................3

Special Service Tools ..................................................3

Commercial Service Tools ...........................................5

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................6

NVH Troubleshooting Chart.........................................6

ON-VEHICLE SERVICE..................................................7

Checking Steering Wheel Play ....................................7

Checking Neutral Position on Steering Wheel ............7

PRE-CHECKING........................................................7

CHECKING...............................................................7

Front Wheel Turning Angle ..........................................7

Checking Gear Housing Movement ............................8

Adjusting Rack Retainer ..............................................8

Checking and Adjusting Drive Belts ............................8

Checking Fluid Level ...................................................8

Checking Fluid Leakage ..............................................8

Bleeding Hydraulic System..........................................9

Checking Steering Wheel Turning Force ....................9

Checking Hydraulic System.......................................10

STEERING WHEEL AND STEERING COLUMN......... 11

Components............................................................... 11

Removal and Installation ........................................... 11

STEERING WHEEL................................................. 11

STEERING COLUMN...............................................12

Disassembly and Assembly .......................................13

Inspection...................................................................14

TILT MECHANISM...................................................14

STEERING TRANSFER GEAR.....................................15

Removal .....................................................................15

Installation ..................................................................16

Inspection...................................................................16

POWER STEERING GEAR AND LINKAGE................17

Components...............................................................17

Removal and Installation ...........................................18

Disassembly...............................................................19

Inspection...................................................................20

BOOT.....................................................................20

RACK.....................................................................20

PINION ASSEMBLY.................................................20

GEAR HOUSING CYLINDER....................................20

TIE-ROD OUTER AND INNER SOCKETS..................21

Assembly ...................................................................21

Adjustment .................................................................24

POWER STEERING OIL PUMP....................................27

Components...............................................................27

Pre-disassembly Inspection .......................................27

Disassembly...............................................................28

Inspection...................................................................29

Assembly ...................................................................29

SERVICE DATA AND SPECIFICATIONS (SDS).........32

General Specifications ...............................................32

Steering Wheel ..........................................................32

Steering Column ........................................................32

Steering Transfer Gear ..............................................32

Steering Gear and Linkage .......................................33

Power Steering ..........................................................33

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

RS

BT

HA

SC

EL

IDX

Page 2183 of 2395

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

NBST0044The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to INFINITI QX4 is as follows:

IFor a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), seat belt

pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

IFor a side collision

The Supplemental Restraint System consists of side air bag module (located in the outer side of front seat),

satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision), wiring harness,

warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

ITo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be performed

by an authorized INFINITI dealer.

IImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

IDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions for Steering SystemNBST0002IBefore disassembly, thoroughly clean the outside of the unit.

IDisassembly should be done in a clean work area. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

IPlace disassembled parts in order, on a parts rack, for easier and proper assembly.

IUse nylon cloths or paper towels to clean the parts; common shop rags can leave lint that might

interfere with their operation.

IBefore inspection or reassembly, carefully clean all parts with a general purpose, non-flammable

solvent.

IBefore assembly, apply a coat of recommended power steering fluid* to hydraulic parts. Vaseline

may be applied to O-rings and seals. Do not use any grease.

IReplace all gaskets, seals and O-rings. Avoid damaging O-rings, seals and gaskets during instal-

lation. Perform functional tests whenever designated.

*: Genuine Nissan PSF II or equivalent. Refer to MA-11, ªFluids and Lubricantsº.

PRECAUTIONS

Supplemental Restraint System (SRS) ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº

ST-2

Page 2187 of 2395

NBST0043

NVH Troubleshooting ChartNBST0043S01Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference pageST-8

ST-9

ST-21

ST-21

ST-21

ST-8

ST-7

ST-9

MA-13

Ð

ST-13

ST-8

ST-13

ST-13

ST-17

PD-3

PD-3

AX-3

AX-3

SU-3

SU-3

SU-3

BR-6

Possible cause and

SUSPECTED PARTS

Fluid level

Air in hydraulic system

Tie-rod ball joint swinging force

Tie-rod ball joint rotating torque

Tie-rod ball joint end play

Steering gear fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness or tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

DIFFERENTIAL

DRIVE SHAFT

AXLE

SUSPENSION

TIRES

ROAD WHEEL

BRAKES

Symp-

tomSTEERINGNoise´´´´´´´´´ ´´´´´´´´

Shake´´´ ´ ´´´´´´

Vibration´´´´´ ´ ´´´´

Shimmy´´´ ´ ´´´´´

Judder´ ´ ´´´´´

´: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

ST-6

Page 2189 of 2395

SST601C

Checking Gear Housing MovementNBST00081. Check the movement of steering gear housing during station-

ary steering on a dry paved surface.

IApply a force of 49 N (5 kg, 11 lb) to steering wheel to check

the gear housing movement.

Turn off ignition key while checking.

Movement of gear housing:

±2mm(±0.08 in) or less

2. If movement exceeds the limit, replace mount insulator after

confirming proper installation of gear housing clamps.

SST602C

Adjusting Rack RetainerNBST0009IPerform this driving test on a flat road.

a) Check whether vehicle moves in a straight line when steering

wheel is released.

b) Check whether steering wheel returns to neutral position when

steering wheel is released from a slightly turned (approx. 20É)

position.

IIf any abnormality is found, correct it by resetting adjusting

screw.

Checking and Adjusting Drive BeltsNBST0010Refer to MA-13, ªChecking Drive Beltsº.

SST280BA

Checking Fluid LevelNBST0011Check fluid level.

Use the correct range of the dipstick depending on the fluid tem-

perature. Use the ªHOTº range at 50 to 80ÉC (122 to 176ÉF), or the

ªCOLDº range at 0 to 30ÉC (32 to 86ÉF).

CAUTION:

IDo not overfill.

IRecommended fluid is Genuine Nissan PSF II or equiva-

lent. Refer to MA-11, ªFluids and Lubricantsº.

SST458C

Checking Fluid LeakageNBST0012Check the lines for improper attachment and for leaks, cracks,

damage, loose connections, chafing and deterioration.

1. Run engine between idle speed and 1,000 rpm.

Make sure temperature of fluid in oil tank rises to 60 to 80ÉC

(140 to 176ÉF).

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each ªlockº position for five seconds

and carefully check for fluid leakage.

ON-VEHICLE SERVICE

Checking Gear Housing Movement

ST-8

Page 2191 of 2395

6. If rack sliding force is not within specification, overhaul steer-

ing gear assembly.

7. If rack sliding force is OK, inspect steering column. Refer to

ªInspectionº, ªSTEERING WHEEL AND STEERING

COLUMNº, ST-14.

SST834-F

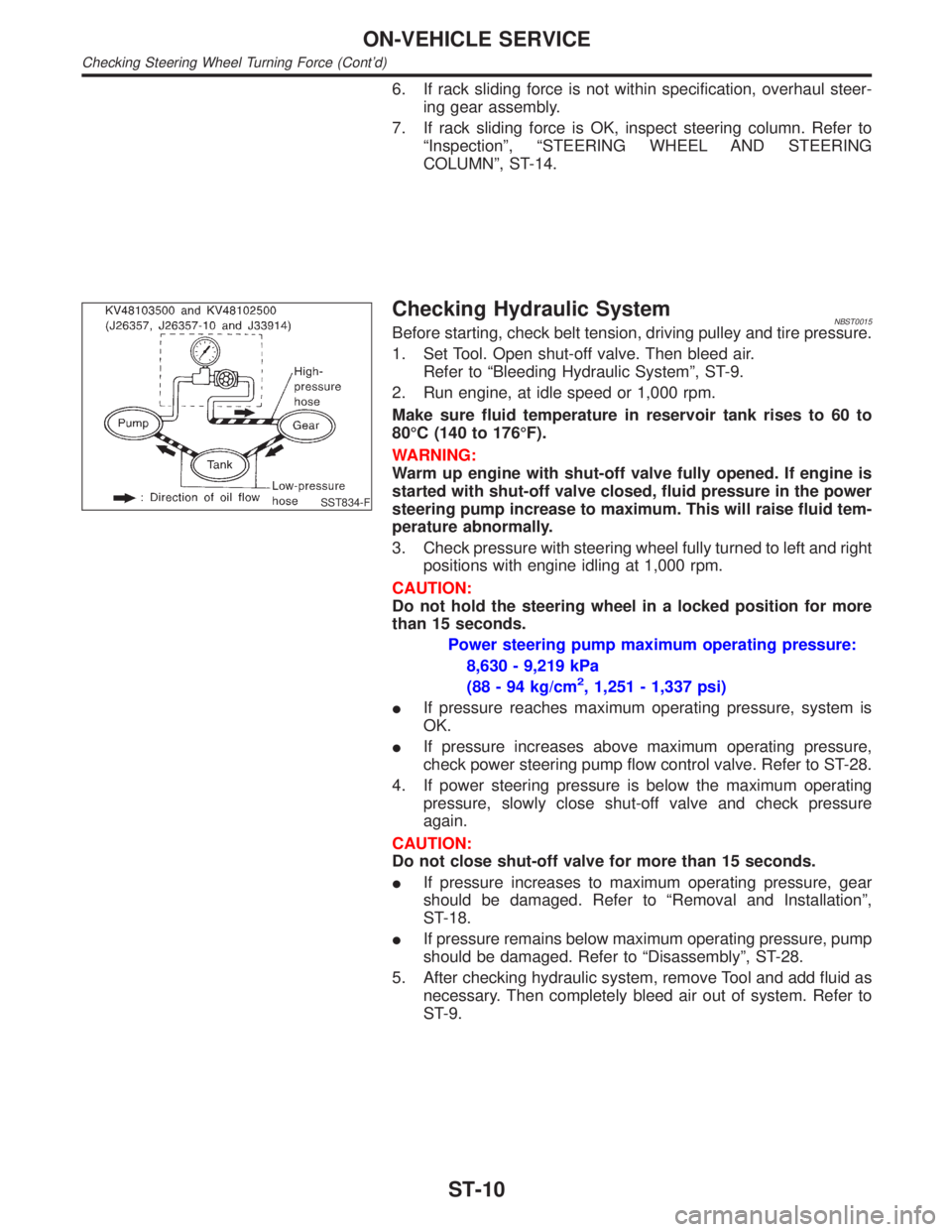

Checking Hydraulic SystemNBST0015Before starting, check belt tension, driving pulley and tire pressure.

1. Set Tool. Open shut-off valve. Then bleed air.

Refer to ªBleeding Hydraulic Systemº, ST-9.

2. Run engine, at idle speed or 1,000 rpm.

Make sure fluid temperature in reservoir tank rises to 60 to

80ÉC (140 to 176ÉF).

WARNING:

Warm up engine with shut-off valve fully opened. If engine is

started with shut-off valve closed, fluid pressure in the power

steering pump increase to maximum. This will raise fluid tem-

perature abnormally.

3. Check pressure with steering wheel fully turned to left and right

positions with engine idling at 1,000 rpm.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 15 seconds.

Power steering pump maximum operating pressure:

8,630 - 9,219 kPa

(88 - 94 kg/cm

2, 1,251 - 1,337 psi)

IIf pressure reaches maximum operating pressure, system is

OK.

IIf pressure increases above maximum operating pressure,

check power steering pump flow control valve. Refer to ST-28.

4. If power steering pressure is below the maximum operating

pressure, slowly close shut-off valve and check pressure

again.

CAUTION:

Do not close shut-off valve for more than 15 seconds.

IIf pressure increases to maximum operating pressure, gear

should be damaged. Refer to ªRemoval and Installationº,

ST-18.

IIf pressure remains below maximum operating pressure, pump

should be damaged. Refer to ªDisassemblyº, ST-28.

5. After checking hydraulic system, remove Tool and add fluid as

necessary. Then completely bleed air out of system. Refer to

ST-9.

ON-VEHICLE SERVICE

Checking Steering Wheel Turning Force (Cont'd)

ST-10

Page 2236 of 2395

TRANSFER

SECTION

TF

CONTENTS

PRECAUTIONS...............................................................3

Supplemental Restraint System (SRS)²AIR

BAG²and²SEAT BELT PRE-TENSIONER²...............3

Precautions ..................................................................3

Service Notice..............................................................4

Wiring Diagrams and Trouble Diagnosis .....................4

PREPARATION...............................................................5

Special Service Tools ..................................................5

Commercial Service Tools ...........................................9

ALL-MODE 4WD SYSTEM...........................................10

Cross-sectional View .................................................10

Control System .......................................................... 11

ALL-MODE 4WD TRANSFER BASIC CONTROL........12

HYDRAULIC CONTROL CIRCUITS...........................12

OUTLINE................................................................12

CONTROL SYSTEM DIAGRAM................................13

INDICATIONS OF 4WD WARNING LAMP..................13

Location of Electrical Parts ........................................14

Description of Electrical Parts ...................................15

TRANSFER MOTOR................................................15

WAIT DETECTION SWITCH.....................................15

2-4WD SHIFT SOLENOID VALVE.............................16

LINE PRESSURE SWITCH.......................................16

Circuit Diagram for Quick Pinpoint Check.................17

Wiring Diagram - TF -................................................18

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................27

Trouble Diagnosis without CONSULT-II ....................27

DESCRIPTION........................................................27

SELF-DIAGNOSTIC PROCEDURE............................28

INDICATIONS OF 4WD WARNING LAMP..................29

Trouble Diagnosis with CONSULT-II .........................30

SELF-DIAGNOSIS...................................................30

SELF-DIAGNOSTIC ITEMS......................................31

DATA MONITOR......................................................33

DATA MONITOR ITEMS...........................................34

REFERENCE VALUE IN DATA MONITOR MODE......36

WORK SUPPORT....................................................38

CLUTCH FORCE RELEASE LIMIT ADJUSTMENT.....39

TROUBLE DIAGNOSIS - INTRODUCTION..................41Introduction ................................................................41

DESCRIPTION........................................................41

DIAGNOSTIC WORKSHEET.....................................41

Work Flow ..................................................................43

HOW TO PERFORM TROUBLE DIAGNOSES FOR

QUICK AND ACCURATE REPAIR

.............................43

TROUBLE DIAGNOSIS - BASIC INSPECTION...........44

Listen to Customer Complaints .................................44

Transfer Fluid Check .................................................44

Road Test...................................................................44

PREPARATION FOR ROAD TEST............................44

1. CHECK BEFORE ENGINE IS STARTED...............45

2. CHECK AT IDLE..................................................47

3. CRUISE TEST.....................................................51

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................54

Transfer Control Unit Terminals and Reference

Value ..........................................................................54

REMOVAL AND INSTALLATION OF TRANSFER

CONTROL UNIT

......................................................54

INSPECTION OF TRANSFER CONTROL UNIT..........54

TRANSFER CONTROL UNIT INSPECTION TABLE....55

VEHICLE SPEED SENSOR (FRONT

REVOLUTION SENSOR)..............................................61

Diagnostic Procedure ................................................61

4WD SOLENOID VALVE...............................................64

Diagnostic Procedure ................................................64

2-4WD SHIFT SOLENOID VALVE AND 4WD

SHIFT SWITCH..............................................................66

Diagnostic Procedure ................................................66

TRANSFER MOTOR AND TRANSFER MOTOR

RELAY...........................................................................70

Diagnostic Procedure ................................................70

TRANSFER FLUID TEMPERATURE SENSOR............73

Diagnostic Procedure ................................................73

ATP SWITCH, WAIT DETECTION SWITCH AND

NEUTRAL-4LO SWITCH...............................................76

Diagnostic Procedure ................................................76

CLUTCH PRESSURE SWITCH....................................80

Diagnostic Procedure ................................................80

GI

MA

EM

LC

EC

FE

AT

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX