EM-29 INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 583 of 2395

9 CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function. (ECM may be the cause of a problem, but this is rarely

the case.)

2. Perform initialization of IVIS (NATS) system and registration of IVIS (NATS) ignition key IDs. Refer to ªIVIS (INFINITI

VEHICLE IMMOBILIZER SYSTEM Ð NATS)º, EC-74.

©GO TO 4.

10 CHECK IGNITION TIMING

1. Start engine and warm it up to normal operating temperature.

2. Check ignition timing at idle using a timing light.

SEF572X

15ɱ5É BTDC (in ªPº or ªNº position)

OK or NG

OK©GO TO 18.

NG©GO TO 11.

11 CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to EM-29, ªInstallationº.

OK or NG

OK©GO TO 9.

NG©1. Repair the timing chain installation.

2. GO TO 4.

12 CHECK IGNITION TIMING

1. Start engine and let it idle.

2. Check ignition timing at idle using a timing light.

SEF572X

15ɱ5É BTDC (in ªPº or ªNº position)

OK or NG

OK©GO TO 18.

NG©GO TO 13.

BASIC SERVICE PROCEDURE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-48

Page 584 of 2395

13 PERFORM IDLE AIR VOLUME LEARNING

Refer to ªIdle Air Volume Learningº, EC-57.

Which is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©GO TO 14.

INCMP©1. Follow the construction of ªIdle Air volume Learningº.

2. GO TO 13.

14 CHECK TARGET IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªENG SPEEDº in ªDATA MONITORº mode with CONSULT-II.

3. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

OK or NG

OK©GO TO 16.

NG©GO TO 15.

15 CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function.

(ECM may be the cause of a problem, but this is rarely the case.)

2. Perform initialization of IVIS (NATS) system and registration of IVIS (NATS) ignition key IDs. Refer to ªIVIS (INFINITI

VEHICLE IMMOBILIZER SYSTEM Ð NATS)º, EC-74.

©GO TO 13.

16 CHECK IGNITION TIMING AGAIN

Check ignition timing again. Refer to Test No. 12.

OK or NG

OK©GO TO 18.

NG©GO TO 17.

17 CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to EM-29, ªInstallationº.

OK or NG

OK©GO TO 15.

NG©1. Repair the timing chain installation.

2. GO TO 13.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

BASIC SERVICE PROCEDURE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-49

Page 649 of 2395

28 CHECK IGNITION TIMING

1. Start engine and warm it up to normal operating temperature.

2. Check ignition timing at idle using a timing light.

SEF572X

Ignition timing:

15ɱ5É BTDC (in ªPº or ªNº position)

OK or NG

OK©GO TO 36.

NG©GO TO 29.

29 CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to EM-29, ªInstallationº.

OK or NG

OK©GO TO 27.

NG©1. Repair the timing chain installation.

2. GO TO 22.

30 CHECK IGNITION TIMING

1. Start engine and let it idle.

2. Check ignition timing at idle using a timing light.

SEF572X

Ignition timing:

15ɱ5É BTDC (in ªPº or ªNº position)

OK or NG

OK©GO TO 36.

NG©GO TO 31.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection (Cont'd)

EC-114

Page 650 of 2395

31 PERFORM IDLE AIR VOLUME LEARNING

Refer to ªIdle Air Volume Learningº, EC-57.

Which is the result CMPLT or INCMP?

CMPLT or INCMP

CMPLT©GO TO 32.

INCMP©1. Follow the construction of ªIdle Air volume Learningº.

2. GO TO 31.

32 CHECK TARGET IDLE SPEED AGAIN

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªENG SPEEDº in ªDATA MONITORº mode with CONSULT-II.

3. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

750±50 rpm (in ªPº or ªNº position)

OK or NG

OK©GO TO 34.

NG©GO TO 33.

33 CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function.

(ECM may be the cause of a problem, but this is rarely the case.)

2. Perform initialization of NVIS (NATS) system and registration of NVIS (NATS) ignition key IDs. Refer to ªNVIS (NISSAN

VEHICLE IMMOBILIZER SYSTEM Ð NATS)º, EC-74.

©GO TO 31.

34 CHECK IGNITION TIMING AGAIN

Check ignition timing again. Refer to Test No. 30.

OK or NG

OK©GO TO 36.

NG©GO TO 35.

35 CHECK TIMING CHAIN INSTALLATION

Check timing chain installation. Refer to EM-29, ªInstallationº.

OK or NG

OK©GO TO 33.

NG©1. Repair the timing chain installation.

2. GO TO 31.

36 ERASE UNNECESSARY DTC

After this inspection, unnecessary DTC No. might be displayed.

Erase the stored memory in ECM and TCM (Transmission control module).

Refer to ªHow to Erase Emission-Related Diagnostic Informationº, EC-72 and AT-35, ªHOW TO ERASE DTCº.

©INSPECTION END

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Basic Inspection (Cont'd)

EC-115

Page 1652 of 2395

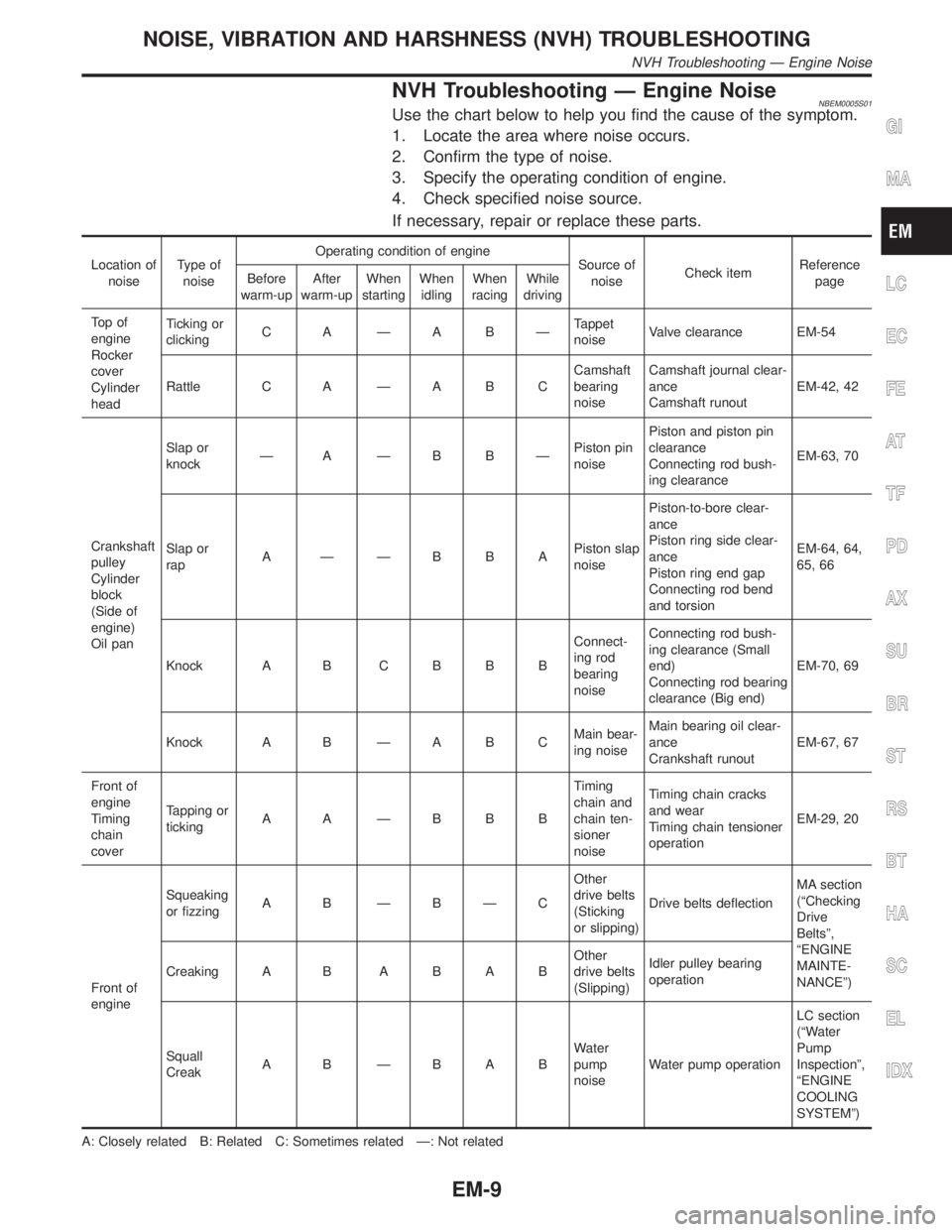

NVH Troubleshooting Ð Engine NoiseNBEM0005S01Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location of

noiseType of

noiseOperating condition of engine

Source of

noiseCheck itemReference

page Before

warm-upAfter

warm-upWhen

startingWhen

idlingWhen

racingWhile

driving

To p o f

engine

Rocker

cover

Cylinder

headTicking or

clickingC A ÐA BÐTappet

noiseValve clearance EM-54

Rattle C A Ð A B CCamshaft

bearing

noiseCamshaft journal clear-

ance

Camshaft runoutEM-42, 42

Crankshaft

pulley

Cylinder

block

(Side of

engine)

Oil panSlap or

knockÐ A ÐB BÐPiston pin

noisePiston and piston pin

clearance

Connecting rod bush-

ing clearanceEM-63, 70

Slap or

rapA ÐÐBBAPiston slap

noisePiston-to-bore clear-

ance

Piston ring side clear-

ance

Piston ring end gap

Connecting rod bend

and torsionEM-64, 64,

65, 66

Knock A B C B B BConnect-

ing rod

bearing

noiseConnecting rod bush-

ing clearance (Small

end)

Connecting rod bearing

clearance (Big end)EM-70, 69

Knock A B Ð A B CMain bear-

ing noiseMain bearing oil clear-

ance

Crankshaft runoutEM-67, 67

Front of

engine

Timing

chain

coverTapping or

tickingA A ÐBBBTiming

chain and

chain ten-

sioner

noiseTiming chain cracks

and wear

Timing chain tensioner

operationEM-29, 20

Front of

engineSqueaking

or fizzingA B ÐBÐCOther

drive belts

(Sticking

or slipping)Drive belts deflectionMA section

(ªChecking

Drive

Beltsº,

ªENGINE

MAINTE-

NANCEº) Creaking A BABABOther

drive belts

(Slipping)Idler pulley bearing

operation

Squall

CreakA B ÐBABWater

pump

noiseWater pump operationLC section

(ªWater

Pump

Inspectionº,

ªENGINE

COOLING

SYSTEMº)

A: Closely related B: Related C: Sometimes related Ð: Not related

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Ð Engine Noise

EM-9

Page 1672 of 2395

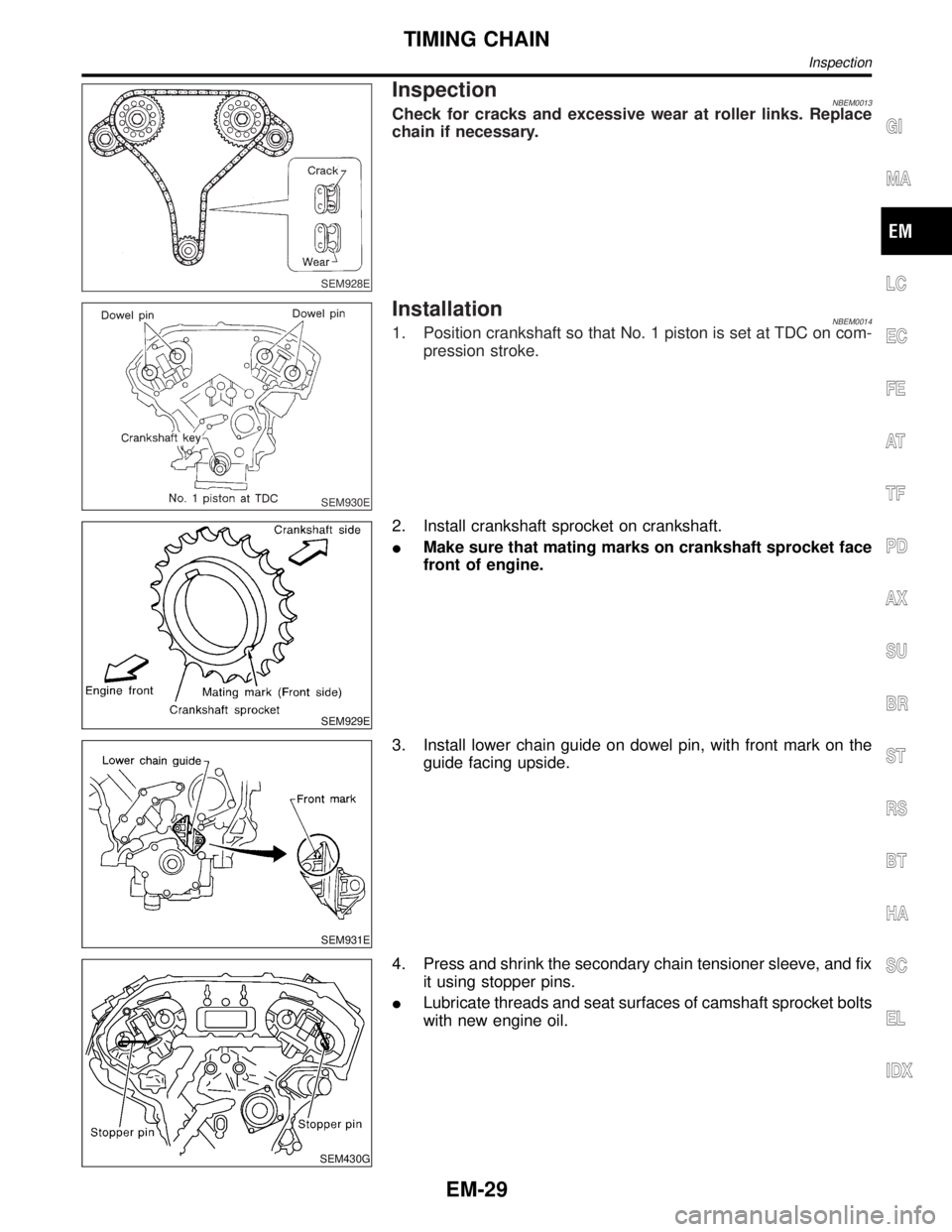

SEM928E

InspectionNBEM0013Check for cracks and excessive wear at roller links. Replace

chain if necessary.

SEM930E

InstallationNBEM00141. Position crankshaft so that No. 1 piston is set at TDC on com-

pression stroke.

SEM929E

2. Install crankshaft sprocket on crankshaft.

IMake sure that mating marks on crankshaft sprocket face

front of engine.

SEM931E

3. Install lower chain guide on dowel pin, with front mark on the

guide facing upside.

SEM430G

4. Press and shrink the secondary chain tensioner sleeve, and fix

it using stopper pins.

ILubricate threads and seat surfaces of camshaft sprocket bolts

with new engine oil.

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TIMING CHAIN

Inspection

EM-29