Transfer INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 26 of 2395

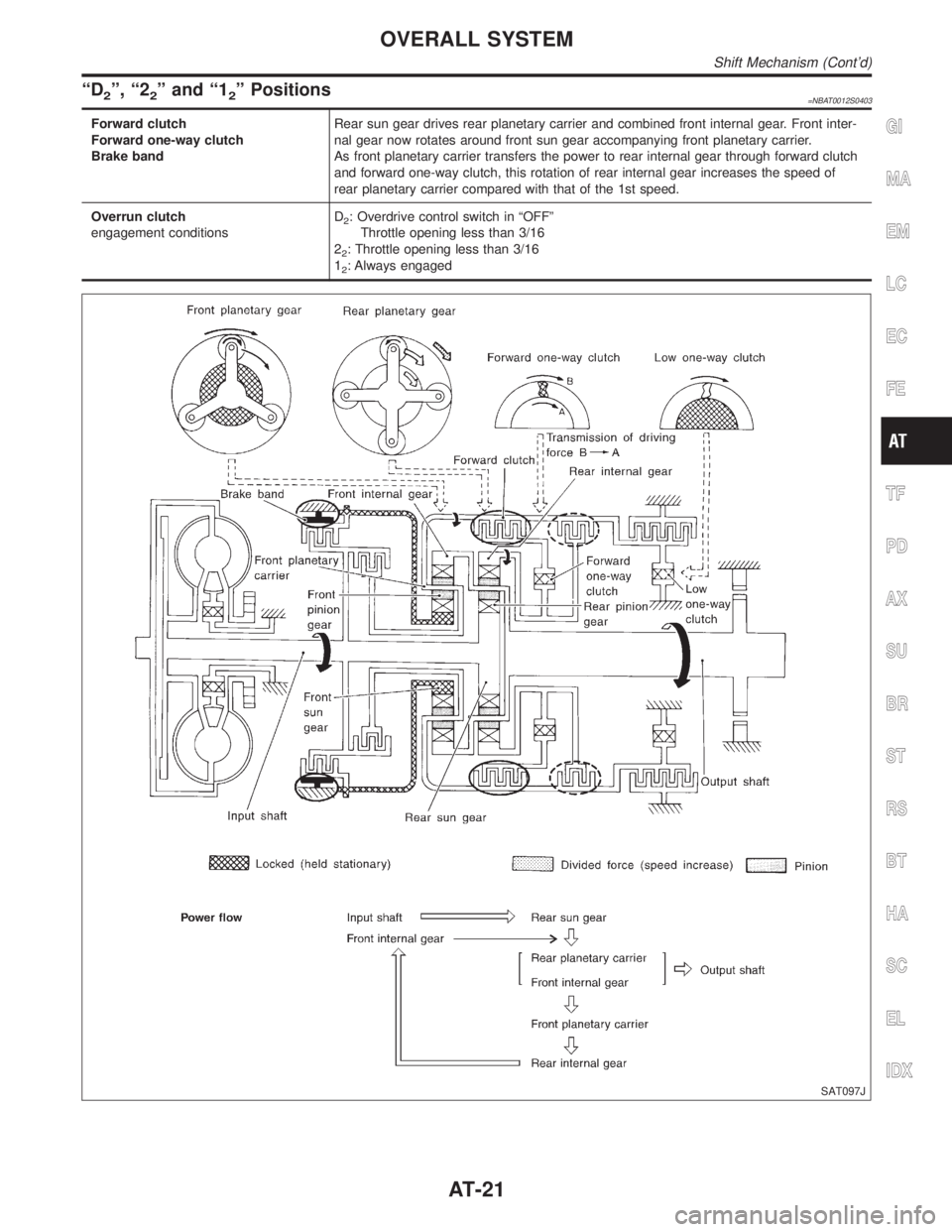

ªD2º, ª22º and ª12º Positions=NBAT0012S0403

Forward clutch

Forward one-way clutch

Brake bandRear sun gear drives rear planetary carrier and combined front internal gear. Front inter-

nal gear now rotates around front sun gear accompanying front planetary carrier.

As front planetary carrier transfers the power to rear internal gear through forward clutch

and forward one-way clutch, this rotation of rear internal gear increases the speed of

rear planetary carrier compared with that of the 1st speed.

Overrun clutch

engagement conditionsD

2: Overdrive control switch in ªOFFº

Throttle opening less than 3/16

2

2: Throttle opening less than 3/16

1

2: Always engaged

SAT097J

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OVERALL SYSTEM

Shift Mechanism (Cont'd)

AT-21

Page 100 of 2395

Terminal

No.Wire color Item ConditionJudgement

standard

(Approx.)

39 W/BEngine speed

signal

Refer to EC-127, ªECM INSPECTION

TABLEº.Ð

40 W/LVehicle speed

sensor

When moving vehicle at 2 to 3 km/h (1 to 2

MPH) for1m(3ft)ormore.Voltage varies

between less

than 1.0V and

more than

4.5V.

41 PThrottle position

sensor

When depressing accelerator pedal slowly

after warming up engine.

(Voltage rises gradually in response to throttle

position.)Fully-closed

throttle:

0.5V - 0.7V

Fully-open

throttle:

4V

42 BThrottle position

sensor

(Ground)Ð0V

45 G/Y Stop lamp switchWhen depressing brake pedalBattery volt-

age

When releasing brake pedal 0V

46 WTransfer control

unitÐÐ

47 RA/T fluid tempera-

ture sensorWhen ATF temperature is 20ÉC (68ÉF). 1.5V

When ATF temperature is 80ÉC (176ÉF). 0.5V

48 B Ground

Ð0V

*1: These terminals are connected to the ECM.

*2: These terminals are connected to the Data link connector for CONSULT-II.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

TCM Terminals and Reference Value (Cont'd)

AT-95

Page 114 of 2395

4 CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assmebly.

3. Check resistance between terminals 8 and 9 when A/T is cold [20ÉC (68ÉF)].

SAT697I

Is resistance approx. 2.5 kW?

Ye s©GO TO 7.

No©GO TO 5.

5 DETECT MALFUNCTIONING ITEM

1. Remove oil pan.

2. Check the following items:

IA/T fluid temperature sensor

Refer to ªComponent Inspectionº, AT-110.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 7.

NG©Repair or replace damaged parts.

6 CHECK INPUT SIGNAL OF A/T FLUID TEMPERATURE SENSOR (WITHOUT CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 47 and ground while warming up A/T.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT518J

OK or NG

OK©GO TO 4.

NG©GO TO 3.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT

Diagnostic Procedure (Cont'd)

AT-109

Page 156 of 2395

Diagnostic ProcedureNBAT0052

1 CHECK VALVE RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assembly.

3. Check resistance between terminal 7 and ground.

SAT156J

Is resistance approx. 10 - 20W?

Ye s©GO TO 3.

No©GO TO 2.

2 CHECK VALVE OPERATION

1. Remove oil pan. Refer to AT-273.

2. Check the following items:

ITorque converter clutch solenoid valve

Refer to ªComponent Inspectionº, AT-152.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal 7 and TCM harness connector terminal 3. Refer to wiring diagram Ð AT Ð TCV.

Continuity should exist.

If OK, check harness for short to ground and short to power.

4. Reinstall any part removed.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-149.

OK or NG

OK©INSPECTION END

NG©GO TO 5.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE

Diagnostic Procedure

AT-151

Page 170 of 2395

Diagnostic ProcedureNBAT0058

1 CHECK VALVE RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assembly.

3. Check resistance between terminal 6 and ground.

SAT162J

Is resistance approx. 2.5 - 5W?

Ye s©GO TO 3.

No©GO TO 2.

2 CHECK VALVE OPERATION

1. Remove control valve assembly.

Refer to AT-273.

2. Check the following items:

ILine pressure solenoid valve

Refer to ªComponent Inspectionº, AT-167.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 3.

NG©Repair or replace damaged parts.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0745 LINE PRESSURE SOLENOID VALVE

Diagnostic Procedure

AT-165

Page 175 of 2395

Diagnostic ProcedureNBAT0061

1 CHECK VALVE RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assembly.

3. Check resistance between terminal 3 and ground.

SAT164J

Is resistance approx. 20 - 40W?

Ye s©GO TO 3.

No©GO TO 2.

2 CHECK VALVE OPERATION

1. Remove control valve assembly.

Refer to AT-273.

2. Check the following items:

IShift solenoid valve A

Refer to ªComponent Inspectionº, AT-171.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 3.

NG©Repair or replace damaged parts.

3 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal 3 and TCM harness connector terminal 11. Refer to wiring diagram Ð AT Ð

SSV/A.

Continuity should exist.

If OK, check harness for short to ground and short to power.

4. Reinstall any part removed.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-168.

OK or NG

OK©INSPECTION END

NG©GO TO 5.

DTC P0750 SHIFT SOLENOID VALVE A

Diagnostic Procedure

AT-170

Page 179 of 2395

Diagnostic ProcedureNBAT0064

1 CHECK VALVE RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assembly.

3. Check resistance between terminal 2 and ground.

SAT166J

Is resistance approx. 20 - 40W?

Ye s©GO TO 3.

No©GO TO 2.

2 CHECK VALVE OPERATION

1. Remove control valve assembly.

Refer to AT-273.

2. Check the following items:

IShift solenoid valve B

Refer to ªComponent Inspectionº, AT-175.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 3.

NG©Repair or replace damaged parts.

3 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal 2 and TCM harness connector terminal 12. Refer to wiring diagram Ð AT Ð

SSV/B.

Continuity should exist.

If OK, check harness for short to ground and short to power.

4. Reinstall any part removed.

Is resistance approx. 0W?

Ye s©GO TO 4.

No©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-172.

OK or NG

OK©INSPECTION END

NG©GO TO 5.

DTC P0755 SHIFT SOLENOID VALVE B

Diagnostic Procedure

AT-174

Page 193 of 2395

Diagnostic ProcedureNBAT0069

1 CHECK VALVE RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assembly.

3. Check resistance between terminal 4 and ground.

SAT170J

Is resistance approx. 20 - 40W?

Ye s©GO TO 3.

No©GO TO 2.

2 CHECK VALVE OPERATION

1. Remove control valve assembly.

Refer to AT-273.

2. Check the following items:

IOverrun clutch solenoid valve

Refer to ªComponent Inspectionº, AT-189.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 3.

NG©Repair or replace damaged parts.

3 CHECK POWER SOURCE CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal 4 and TCM harness connector terminal 20. Refer to wiring diagram Ð AT Ð

OVRCSV.

Continuity should exist.

If OK, check harness for short to ground and short to power.

4. Reinstall any part removed.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-185.

OK or NG

OK©INSPECTION END

NG©GO TO 5.

DTC P1760 OVERRUN CLUTCH SOLENOID VALVE

Diagnostic Procedure

AT-188

Page 199 of 2395

4 CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assmebly.

3. Check resistance between terminals 8 and 9 when A/T is cold [20ÉC (68ÉF)].

SAT697I

Is resistance approx. 2.5 kW?

Ye s©GO TO 7.

No©GO TO 5.

5 DETECT MALFUNCTIONING ITEM

1. Remove oil pan.

2. Check the following items:

IA/T fluid temperature sensor

Refer to ªComponent Inspectionº, AT-110.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 7.

NG©Repair or replace damaged parts.

6 CHECK INPUT SIGNAL OF A/T FLUID TEMPERATURE SENSOR (WITHOUT CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 47 and ground while warming up A/T.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT518J

OK or NG

OK©GO TO 4.

NG©GO TO 3.

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP SENSOR CIRCUIT AND TCM

POWER SOURCE)

Diagnostic Procedure (Cont'd)

AT-194

Page 279 of 2395

SAT360IA

Revolution Sensor ReplacementNBAT0210Ð 4WD MODEL ÐNBAT0210S011. Remove rear engine mounting member from side member

while supporting A/T with transfer case with jack. Tighten rear

engine mounting member to the specified torque. Refer to

EM-59, ªRear Engine Mountingº.

2. Lower A/T with transfer case as much as possible.

3. Remove revolution sensor from A/T.

4. Reinstall any part removed.

IAlways use new sealing parts.

SAT661I

Ð 2WD MODEL ÐNBAT0210S02IRemove revolution sensor from A/T.

IAlways use new sealing parts.

SAT136K

Turbine Revolution Sensor ReplacementNBAT02311. Remove A/T assembly, Refer to ªRemovalº, AT-277.

2. Remove turbine revolution sensor from A/T assembly upper

side.

3. Reinstall any part removed.

IAlways use new sealing parts.

SAT035E

Rear Oil Seal ReplacementNBAT0211Ð 4WD MODEL ÐNBAT0211S011. Remove transfer case from vehicle. Refer to TF-119, ªRemovalº.

2. Remove rear oil seal.

IDo not remove oil seal unless it is to be replaced.

3. Install rear oil seal.

IApply ATF before installing.

4. Reinstall any part removed.

ON-VEHICLE SERVICE

Revolution Sensor Replacement

AT-274