check oil INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 8 of 2395

19. A/T Does Not Shift: 22-> 11, When Selector

Lever²2²->²1²Position .........................................255

20. Vehicle Does Not Decelerate By Engine

Brake........................................................................256

21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position Switches

Circuit Checks) ........................................................257

A/T SHIFT LOCK SYSTEM.........................................265

Description ...............................................................265

Wiring Diagram - SHIFT -........................................266

Diagnostic Procedure ..............................................267

KEY INTERLOCK CABLE..........................................271

Components.............................................................271

Removal ...................................................................271

Installation ................................................................272

ON-VEHICLE SERVICE..............................................273

Control Valve Assembly and Accumulators .............273

Revolution Sensor Replacement .............................274

Turbine Revolution Sensor Replacement................274

Rear Oil Seal Replacement .....................................274

Rear Oil Seal and Companion Flange Oil Seal

Replacement ............................................................275

Parking Components Inspection..............................275

Park/Neutral Position Switch Adjustment ................276

Manual Control Linkage Adjustment........................276

REMOVAL AND INSTALLATION...............................277

Removal ...................................................................277

Installation ................................................................278

OVERHAUL.................................................................281

Components.............................................................281

Oil Channel ..............................................................284

Locations of Needle Bearings, Thrust Washers

and Snap Rings .......................................................285

DISASSEMBLY............................................................286

REPAIR FOR COMPONENT PARTS.........................297Oil Pump ..................................................................297

Control Valve Assembly ...........................................301

Control Valve Upper Body .......................................307

Control Valve Lower Body .......................................312

Reverse Clutch ........................................................314

High Clutch ..............................................................317

Forward and Overrun Clutches ...............................320

Low & Reverse Brake..............................................324

Forward Clutch Drum Assembly ..............................328

Rear Internal Gear and Forward Clutch Hub ..........330

Band Servo Piston Assembly ..................................333

Parking Pawl Components ......................................337

ASSEMBLY..................................................................339

Assembly (1) ............................................................339

Adjustment ...............................................................347

Assembly (2) ............................................................349

SERVICE DATA AND SPECIFICATIONS (SDS).......356

General Specifications .............................................356

Shift Schedule..........................................................356

Stall Revolution ........................................................356

Line Pressure...........................................................356

Return Springs .........................................................357

Accumulator O-ring ..................................................358

Clutches and Brakes ...............................................358

Oil Pump and Low One-way Clutch ........................360

Total End Play..........................................................360

Reverse Clutch Drum End Play ..............................361

Removal and Installation .........................................361

Shift Solenoid Valves ...............................................361

Solenoid Valves .......................................................361

A/T Fluid Temperature Sensor.................................361

Turbine Revolution Sensor ......................................361

Revolution Sensor ...................................................362

Dropping Resistor ....................................................362GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS(Cont'd)

AT-3

Page 13 of 2395

IBefore assembly, apply a coat of recommended ATF to all

parts. Apply petroleum jelly to protect O-rings and seals, or

hold bearings and washers in place during assembly. Do not

use grease.

IExtreme care should be taken to avoid damage to O-rings,

seals and gaskets when assembling.

IReplace ATF cooler if excessive foreign material is found in oil

pan or clogging strainer. Refer to ªATF COOLER SERVICEº,

AT-9.

IAfter overhaul, refill the transmission with new ATF.

IWhen the A/T drain plug is removed, only some of the fluid is

drained. Old A/T fluid will remain in torque converter and ATF

cooling system.

Always follow the procedures when changing A/T fluid. Refer

to MA-21, ªChanging A/T Fluidº.

Service Notice or PrecautionsNBAT0004FAIL-SAFENBAT0004S01The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of ª1º, ª2º or ªDº. The

customer may complain of sluggish or poor acceleration.

When the ignition key is turned ªONº following Fail-Safe operation, O/D OFF indicator lamp blinks for about

8 seconds. (For ªTCM SELF-DIAGNOSTIC PROCEDURE (No Tools)º, refer to AT-46.)

Fail-Safe may occur without electrical circuit damage if the vehicle is driven under extreme conditions (such

as excessive wheel spin followed by sudden braking). To recover normal shift pattern, turn the ignition key

ªOFFº for 5 seconds, then ªONº.

The blinking of the O/D OFF indicator lamp for about 8 seconds will appear only once and be cleared. The

customer may resume normal driving conditions.

Always follow the ªWORK FLOWº (Refer to AT-57).

The SELF-DIAGNOSIS results will be as follows:

The first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

During the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

TORQUE CONVERTER SERVICENBAT0004S04The torque converter should be replaced under any of the following conditions:

IExternal leaks in the hub weld area.

IConverter hub is scored or damaged.

IConverter pilot is broken, damaged or fits poorly into crankshaft.

ISteel particles are found after flushing the cooler and cooler lines.

IPump is damaged or steel particles are found in the converter.

IVehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

IConverter is contaminated with engine coolant containing antifreeze.

IInternal failure of stator roller clutch.

IHeavy clutch debris due to overheating (blue converter).

ISteel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged Ð indicates that lining material came from converter.

The torque converter should not be replaced if:

IThe fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

PRECAUTIONS

Precautions (Cont'd)

AT-8

Page 15 of 2395

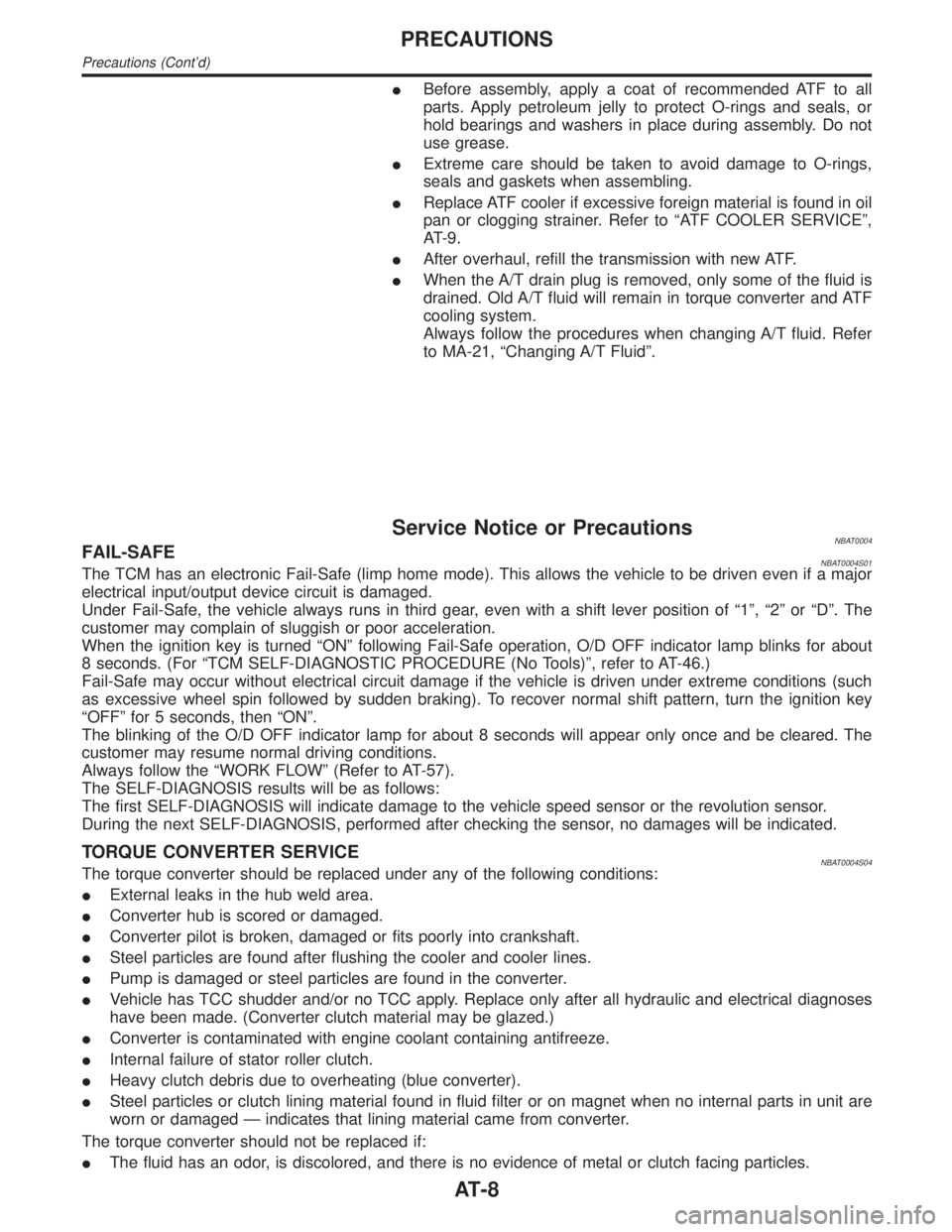

Special Service ToolsNBAT0006The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

ST2505S001

(J34301-C)

Oil pressure gauge set

1 ST25051001

(Ð)

Oil pressure gauge

2 ST25052000

(Ð)

Hose

3 ST25053000

(Ð)

Joint pipe

4 ST25054000

(Ð)

Adapter

5 ST25055000

(Ð)

Adapter

NT097

Measuring line pressure

ST07870000

(J37068)

Transmission case stand

NT421

Disassembling and assembling A/T

a: 182 mm (7.17 in)

b: 282 mm (11.10 in)

c: 230 mm (9.06 in)

d: 100 mm (3.94 in)

KV31102100

(J37065)

Torque converter one-

way clutch check tool

NT098

Checking one-way clutch in torque converter

ST25850000

(J25721-A)

Sliding hammer

NT422

Removing oil pump assembly

a: 179 mm (7.05 in)

b: 70 mm (2.76 in)

c: 40 mm (1.57 in) dia.

d: M12 x 1.75P

KV31102400

(J34285 and J34285-87)

Clutch spring compres-

sor

NT423

Removing and installing clutch return springs

a: 320 mm (12.60 in)

b: 174 mm (6.85 in)

PREPARATION

Special Service Tools

AT-10

Page 64 of 2395

A/T Fluid CheckNBAT0021FLUID LEAKAGE CHECKNBAT0021S011. Clean area suspected of leaking. Ð for example, mating sur-

face of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº posi-

tion and wait a few minutes.

3. Stop engine.

4. Check for fresh leakage.

SAT638A

FLUID CONDITION CHECKNBAT0021S02

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pinkWater contamination Ð Road water

entering through filler tube or breather

Varnished fluid, light to dark brown

and tackyOxidation Ð Over or under filling, Ð

Overheating

FLUID LEVEL CHECKNBAT0021S03Refer to MA-21, ªChecking A/T Fluidº.

SAT647B

Stall TestNBAT0022STALL TEST PROCEDURENBAT0022S011. Check A/T fluid and engine oil levels. If necessary, add fluid

and oil.

2. Drive vehicle for approx. 10 minutes or until fluid and oil reach

operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

SAT513G

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

IIt is good practice to put a mark on point of specified

engine rpm on indicator.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

A/T Fluid Check

AT-59

Page 67 of 2395

SAT209GA

Line Pressure TestNBAT0023ILocation of line pressure test ports.

IAlways replace line pressure plugs as they are self-seal-

ing bolts.

SAT647B

LINE PRESSURE TEST PROCEDURENBAT0023S011. Check A/T fluid and engine oil levels. If necessary, add fluid

and oil.

2. Drive vehicle for approx. 10 minutes or until fluid and oil reach

operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

SAT518GB

SAT519GB

3. Install pressure gauge to corresponding line pressure port.

SAT513G

4. Set parking brake and block wheels.

IContinue to depress brake pedal fully while line pressure

test is being performed at stall speed.

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Line Pressure Test

AT-62

Page 68 of 2395

SAT493G

5. Start engine and measure line pressure at idle and stall speed.

IWhen measuring line pressure at stall speed, follow the

stall test procedure.

Line pressure:

Refer to SDS, AT-356.

JUDGEMENT OF LINE PRESSURE TESTNBAT0023S02

Judgement Suspected parts

At idleLine pressure is low in all posi-

tions.IOil pump wear

IControl piston damage

IPressure regulator valve or plug sticking

ISpring for pressure regulator valve damaged

IFluid pressure leakage between oil strainer and pressure regulator valve

IClogged strainer

Line pressure is low in particu-

lar position.IFluid pressure leakage between manual valve and particular clutch

IFor example, line pressure is:

Ð Low in ªRº and ª1º positions, but

Ð Normal in ªDº and ª2º positions.

Then, fluid leakage exists at or around low and reverse brake circuit.

Refer to ªCLUTCH AND BAND CHARTº, AT-17.

Line pressure is high.IMal-adjustment of throttle position sensor

IFluid temperature sensor damaged

ILine pressure solenoid valve sticking

IShort circuit of line pressure solenoid valve circuit

IPressure modifier valve sticking

IPressure regulator valve or plug sticking

IOpen in dropping resistor circuit

At stall speedLine pressure is low.IMal-adjustment of throttle position sensor

ILine pressure solenoid valve sticking

IShort circuit of line pressure solenoid valve circuit

IPressure regulator valve or plug sticking

IPressure modifier valve sticking

IPilot valve sticking

SAT786A

Road TestNBAT0024DESCRIPTIONNBAT0024S01IThe purpose of the test is to determine overall performance of

A/T and analyze causes of problems.

IThe road test consists of the following three parts:

1. Check before engine is started

2. Check at idle

3. Cruise test

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Line Pressure Test (Cont'd)

AT-63

Page 76 of 2395

Cruise Test Ð Part 1=NBAT0024S0404

1 CHECK STARTING GEAR (D1) POSITION

1. Drive vehicle for approx. 10 minutes to warm engine oil and ATF up to operating temperature.

ATF operating temperature:

50 - 80ÉC (122 - 176ÉF)

2. Park vehicle on flat surface.

3. Set overdrive control switch to ªONº position.

4. Move selector lever to ªPº position.

SAT001J

5. Start engine.

6. Move selector lever to ªDº position.

SAT952I

7. Accelerate vehicle by constantly depressing accelerator pedal halfway.

SAT953I

8. Does vehicle start from D1?

Read gear position.

YesorNo

Ye s©GO TO 2.

No©Go to ª8. Vehicle Cannot Be Started From D

1º, AT-233.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Road Test (Cont'd)

AT-71

Page 114 of 2395

4 CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assmebly.

3. Check resistance between terminals 8 and 9 when A/T is cold [20ÉC (68ÉF)].

SAT697I

Is resistance approx. 2.5 kW?

Ye s©GO TO 7.

No©GO TO 5.

5 DETECT MALFUNCTIONING ITEM

1. Remove oil pan.

2. Check the following items:

IA/T fluid temperature sensor

Refer to ªComponent Inspectionº, AT-110.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 7.

NG©Repair or replace damaged parts.

6 CHECK INPUT SIGNAL OF A/T FLUID TEMPERATURE SENSOR (WITHOUT CONSULT-II)

Without CONSULT-II

1. Start engine.

2. Check voltage between TCM terminal 47 and ground while warming up A/T.

Voltage:

Cold [20ÉC (68ÉF)]®Hot [80ÉC (176ÉF)]:

Approximately 1.5V®0.5V

SAT518J

OK or NG

OK©GO TO 4.

NG©GO TO 3.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0710 A/T FLUID TEMPERATURE SENSOR CIRCUIT

Diagnostic Procedure (Cont'd)

AT-109

Page 123 of 2395

Diagnostic ProcedureNBAT0038

1 CHECK DTC WITH ECM

ICheck P code with CONSULT-II.

Turn ignition switch ªONº and select ªSELF-DIAG RESULTSº mode for ªENGINEº with CONSULT-II.

Refer to EC-74, ªDESCRIPTIONº.

OK or NG

OK (With CONSULT-II)©GO TO 2.

OK (Without CONSULT-

II)©GO TO 4.

NG©Check ignition signal circuit for engine control. Refer to EC-499, ªComponent Descrip-

tionº.

2 CHECK INPUT SIGNAL (WITH CONSULT-II)

With CONSULT-II

1. Start engine.

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªA/Tº with CONSULT-II.

3. Read out the value of ªENGINE SPEEDº.

Check engine speed changes according to throttle position.

SAT645J

Refer toEC-127, ªECM INSPECTION TABLEº.

Ye s©GO TO 5.

No©GO TO 3.

3 DETECT MALFUNCTIONING ITEM

Check the following items:

IHarness for short or open between TCM and ECM

IResistor

IIgnition coil

Refer to EC-499, ªComponent Descriptionº.

OK or NG

OK©GO TO 5.

NG©Repair or replace damaged parts.

DTC P0725 ENGINE SPEED SIGNAL

Diagnostic Procedure

AT-118

Page 156 of 2395

Diagnostic ProcedureNBAT0052

1 CHECK VALVE RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly connector on the right side of transfer assembly.

3. Check resistance between terminal 7 and ground.

SAT156J

Is resistance approx. 10 - 20W?

Ye s©GO TO 3.

No©GO TO 2.

2 CHECK VALVE OPERATION

1. Remove oil pan. Refer to AT-273.

2. Check the following items:

ITorque converter clutch solenoid valve

Refer to ªComponent Inspectionº, AT-152.

IHarness of terminal cord assembly for short or open

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK RESISTANCE

1. Turn ignition switch to ªOFFº position.

2. Disconnect TCM harness connector.

3. Check resistance between terminal 7 and TCM harness connector terminal 3. Refer to wiring diagram Ð AT Ð TCV.

Continuity should exist.

If OK, check harness for short to ground and short to power.

4. Reinstall any part removed.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK DTC

Perform Diagnostic Trouble Code (DTC) confirmation procedure, AT-149.

OK or NG

OK©INSPECTION END

NG©GO TO 5.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P0740 TORQUE CONVERTER CLUTCH SOLENOID VALVE

Diagnostic Procedure

AT-151