clutch INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 7 of 2395

Component Inspection .............................................131

DTC P0733 IMPROPER SHIFTING TO 3RD GEAR

POSITION....................................................................132

Description ...............................................................132

Wiring Diagram - AT - 3RD......................................135

Diagnostic Procedure ..............................................136

Component Inspection .............................................137

DTC P0734 IMPROPER SHIFTING TO 4TH GEAR

POSITION....................................................................138

Description ...............................................................138

Wiring Diagram - AT - 4TH ......................................142

Diagnostic Procedure ..............................................143

Component Inspection .............................................147

DTC P0740 TORQUE CONVERTER CLUTCH

SOLENOID VALVE......................................................148

Description ...............................................................148

Wiring Diagram - AT - TCV......................................150

Diagnostic Procedure ..............................................151

Component Inspection .............................................152

DTC P0744 IMPROPER LOCK-UP OPERATION......153

Description ...............................................................153

Wiring Diagram - AT - TCCSIG ...............................156

Diagnostic Procedure ..............................................157

Component Inspection .............................................161

DTC P0745 LINE PRESSURE SOLENOID VALVE...162

Description ...............................................................162

Wiring Diagram - AT - LPSV....................................164

Diagnostic Procedure ..............................................165

Component Inspection .............................................167

DTC P0750 SHIFT SOLENOID VALVE A..................168

Description ...............................................................168

Wiring Diagram - AT - SSV/A ..................................169

Diagnostic Procedure ..............................................170

Component Inspection .............................................171

DTC P0755 SHIFT SOLENOID VALVE B..................172

Description ...............................................................172

Wiring Diagram - AT - SSV/B ..................................173

Diagnostic Procedure ..............................................174

Component Inspection .............................................175

DTC P1705 THROTTLE POSITION SENSOR...........176

Description ...............................................................176

Wiring Diagram - AT - TPS ......................................179

Diagnostic Procedure ..............................................180

Component Inspection .............................................184

DTC P1760 OVERRUN CLUTCH SOLENOID

VALVE..........................................................................185

Description ...............................................................185

Wiring Diagram - AT - OVRCSV..............................187

Diagnostic Procedure ..............................................188

Component Inspection .............................................189

DTC BATT/FLUID TEMP SEN (A/T FLUID TEMP

SENSOR CIRCUIT AND TCM POWER SOURCE)....190Description ...............................................................190

Wiring Diagram - AT - BA/FTS ................................192

Diagnostic Procedure ..............................................193

Component Inspection .............................................196

DTC VEHICLE SPEED SENSOR.MTR.......................197

Description ...............................................................197

Wiring Diagram - AT - VSSMTR ..............................199

Diagnostic Procedure ..............................................200

DTC TURBINE REVOLUTION SENSOR....................202

Description ...............................................................202

Wiring Diagram - AT - TRSA/T ................................204

Diagnostic Procedure ..............................................205

Component Inspection .............................................206

DTC A/T COMMUNICATION LINE.............................207

Description ...............................................................207

Wiring Diagram - AT - LAN ......................................209

Diagnostic Procedure ..............................................210

DTC CONTROL UNIT (RAM), CONTROL UNIT

(ROM)........................................................................... 211

Description ............................................................... 211

Diagnostic Procedure ..............................................212

DTC CONTROL UNIT (EEP ROM).............................213

Description ...............................................................213

Diagnostic Procedure ..............................................214

TROUBLE DIAGNOSES FOR SYMPTOMS...............215

Wiring Diagram - AT - NONDTC .............................215

1. O/D OFF Indicator Lamp Does Not Come On....218

2. Engine Cannot Be Started In²P²and²N²

Position ....................................................................221

3. In²P²Position, Vehicle Moves Forward Or

Backward When Pushed .........................................222

4. In²N²Position, Vehicle Moves ...........................223

5. Large Shock.²N²->²R²Position .......................225

6. Vehicle Does Not Creep Backward In²R²

Position ....................................................................227

7. Vehicle Does Not Creep Forward In²D²,²2²

Or²1²Position .........................................................230

8. Vehicle Cannot Be Started From D

1...................233

9. A/T Does Not Shift: D

1-> D2Or Does Not

Kickdown: D

4-> D2..................................................236

10. A/T Does Not Shift: D

2-> D3.............................239

11. A/T Does Not Shift: D

3-> D4.............................242

12. A/T Does Not Perform Lock-up .........................245

13. A/T Does Not Hold Lock-up Condition ..............247

14. Lock-up Is Not Released ...................................249

15. Engine Speed Does Not Return To Idle (Light

Braking D

4-> D3).....................................................250

16. Vehicle Does Not Start From D

1.......................252

17. A/T Does Not Shift: D

4-> D3, When

Overdrive Control Switch²ON²->²OFF²...............253

18. A/T Does Not Shift: D

3-> 22, When Selector

Lever²D²->²2²Position.........................................254

CONTENTS(Cont'd)

AT-2

Page 8 of 2395

19. A/T Does Not Shift: 22-> 11, When Selector

Lever²2²->²1²Position .........................................255

20. Vehicle Does Not Decelerate By Engine

Brake........................................................................256

21. TCM Self-diagnosis Does Not Activate (PNP,

Overdrive Control and Throttle Position Switches

Circuit Checks) ........................................................257

A/T SHIFT LOCK SYSTEM.........................................265

Description ...............................................................265

Wiring Diagram - SHIFT -........................................266

Diagnostic Procedure ..............................................267

KEY INTERLOCK CABLE..........................................271

Components.............................................................271

Removal ...................................................................271

Installation ................................................................272

ON-VEHICLE SERVICE..............................................273

Control Valve Assembly and Accumulators .............273

Revolution Sensor Replacement .............................274

Turbine Revolution Sensor Replacement................274

Rear Oil Seal Replacement .....................................274

Rear Oil Seal and Companion Flange Oil Seal

Replacement ............................................................275

Parking Components Inspection..............................275

Park/Neutral Position Switch Adjustment ................276

Manual Control Linkage Adjustment........................276

REMOVAL AND INSTALLATION...............................277

Removal ...................................................................277

Installation ................................................................278

OVERHAUL.................................................................281

Components.............................................................281

Oil Channel ..............................................................284

Locations of Needle Bearings, Thrust Washers

and Snap Rings .......................................................285

DISASSEMBLY............................................................286

REPAIR FOR COMPONENT PARTS.........................297Oil Pump ..................................................................297

Control Valve Assembly ...........................................301

Control Valve Upper Body .......................................307

Control Valve Lower Body .......................................312

Reverse Clutch ........................................................314

High Clutch ..............................................................317

Forward and Overrun Clutches ...............................320

Low & Reverse Brake..............................................324

Forward Clutch Drum Assembly ..............................328

Rear Internal Gear and Forward Clutch Hub ..........330

Band Servo Piston Assembly ..................................333

Parking Pawl Components ......................................337

ASSEMBLY..................................................................339

Assembly (1) ............................................................339

Adjustment ...............................................................347

Assembly (2) ............................................................349

SERVICE DATA AND SPECIFICATIONS (SDS).......356

General Specifications .............................................356

Shift Schedule..........................................................356

Stall Revolution ........................................................356

Line Pressure...........................................................356

Return Springs .........................................................357

Accumulator O-ring ..................................................358

Clutches and Brakes ...............................................358

Oil Pump and Low One-way Clutch ........................360

Total End Play..........................................................360

Reverse Clutch Drum End Play ..............................361

Removal and Installation .........................................361

Shift Solenoid Valves ...............................................361

Solenoid Valves .......................................................361

A/T Fluid Temperature Sensor.................................361

Turbine Revolution Sensor ......................................361

Revolution Sensor ...................................................362

Dropping Resistor ....................................................362GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS(Cont'd)

AT-3

Page 13 of 2395

IBefore assembly, apply a coat of recommended ATF to all

parts. Apply petroleum jelly to protect O-rings and seals, or

hold bearings and washers in place during assembly. Do not

use grease.

IExtreme care should be taken to avoid damage to O-rings,

seals and gaskets when assembling.

IReplace ATF cooler if excessive foreign material is found in oil

pan or clogging strainer. Refer to ªATF COOLER SERVICEº,

AT-9.

IAfter overhaul, refill the transmission with new ATF.

IWhen the A/T drain plug is removed, only some of the fluid is

drained. Old A/T fluid will remain in torque converter and ATF

cooling system.

Always follow the procedures when changing A/T fluid. Refer

to MA-21, ªChanging A/T Fluidº.

Service Notice or PrecautionsNBAT0004FAIL-SAFENBAT0004S01The TCM has an electronic Fail-Safe (limp home mode). This allows the vehicle to be driven even if a major

electrical input/output device circuit is damaged.

Under Fail-Safe, the vehicle always runs in third gear, even with a shift lever position of ª1º, ª2º or ªDº. The

customer may complain of sluggish or poor acceleration.

When the ignition key is turned ªONº following Fail-Safe operation, O/D OFF indicator lamp blinks for about

8 seconds. (For ªTCM SELF-DIAGNOSTIC PROCEDURE (No Tools)º, refer to AT-46.)

Fail-Safe may occur without electrical circuit damage if the vehicle is driven under extreme conditions (such

as excessive wheel spin followed by sudden braking). To recover normal shift pattern, turn the ignition key

ªOFFº for 5 seconds, then ªONº.

The blinking of the O/D OFF indicator lamp for about 8 seconds will appear only once and be cleared. The

customer may resume normal driving conditions.

Always follow the ªWORK FLOWº (Refer to AT-57).

The SELF-DIAGNOSIS results will be as follows:

The first SELF-DIAGNOSIS will indicate damage to the vehicle speed sensor or the revolution sensor.

During the next SELF-DIAGNOSIS, performed after checking the sensor, no damages will be indicated.

TORQUE CONVERTER SERVICENBAT0004S04The torque converter should be replaced under any of the following conditions:

IExternal leaks in the hub weld area.

IConverter hub is scored or damaged.

IConverter pilot is broken, damaged or fits poorly into crankshaft.

ISteel particles are found after flushing the cooler and cooler lines.

IPump is damaged or steel particles are found in the converter.

IVehicle has TCC shudder and/or no TCC apply. Replace only after all hydraulic and electrical diagnoses

have been made. (Converter clutch material may be glazed.)

IConverter is contaminated with engine coolant containing antifreeze.

IInternal failure of stator roller clutch.

IHeavy clutch debris due to overheating (blue converter).

ISteel particles or clutch lining material found in fluid filter or on magnet when no internal parts in unit are

worn or damaged Ð indicates that lining material came from converter.

The torque converter should not be replaced if:

IThe fluid has an odor, is discolored, and there is no evidence of metal or clutch facing particles.

PRECAUTIONS

Precautions (Cont'd)

AT-8

Page 14 of 2395

IThe threads in one or more of the converter bolt holes are damaged.

ITransmission failure did not display evidence of damaged or worn internal parts, steel particles or clutch

plate lining material in unit and inside the fluid filter.

IVehicle has been exposed to high mileage (only). The exception may be where the torque converter clutch

dampener plate lining has seen excess wear by vehicles operated in heavy and/or constant traffic, such

as taxi, delivery or police use.

ATF COOLER SERVICENBAT0004S02Replace ATF cooler if excessive foreign material is found in oil pan or clogging strainer.

Replace radiator lower tank (which includes ATF cooler) with a new one and flush cooler line using cleaning

solvent and compressed air. Refer to LC-19, ªREMOVAL AND INSTALLATIONº.

OBD-II SELF-DIAGNOSISNBAT0004S03IA/T self-diagnosis is performed by the TCM in combination with the ECM. The results can be read through

the blinking pattern of the O/D OFF indicator or the malfunction indicator lamp (MIL). Refer to the table on

AT-38 for the indicator used to display each self-diagnostic result.

IThe self-diagnostic results indicated by the MIL are automatically stored in both the ECM and TCM

memories.

Always perform the procedure ªHOW TO ERASE DTCº on AT-35 to complete the repair and avoid

unnecessary blinking of the MIL.

IThe following self-diagnostic items can be detected using ECM self-diagnostic results mode* only when

the O/D OFF indicator lamp does not indicate any malfunctions.

þ PNP switch

þ A/T 1st, 2nd, 3rd, or 4th gear function

þ A/T TCC S/V function (lock-up)

*: For details of OBD-II, refer to EC-59, ªIntroductionº.

ICertain systems and components, especially those related to OBD, may use the new style slide-

locking type harness connector. For description and how to disconnect, refer to EL-5, ªDescrip-

tionº.

Wiring Diagrams and Trouble DiagnosisNBAT0005When you read wiring diagrams, refer to the following:

IGI-11, ªHOW TO READ WIRING DIAGRAMSº.

IEL-9, ªPOWER SUPPLY ROUTINGº for power distribution circuit.

When you perform trouble diagnosis, refer to the following:

IGI-35, ªHOW TO FOLLOW TEST GROUP IN TROUBLE DIAGNOSISº.

IGI-24, ªHOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRICAL INCIDENTº.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Service Notice or Precautions (Cont'd)

AT-9

Page 15 of 2395

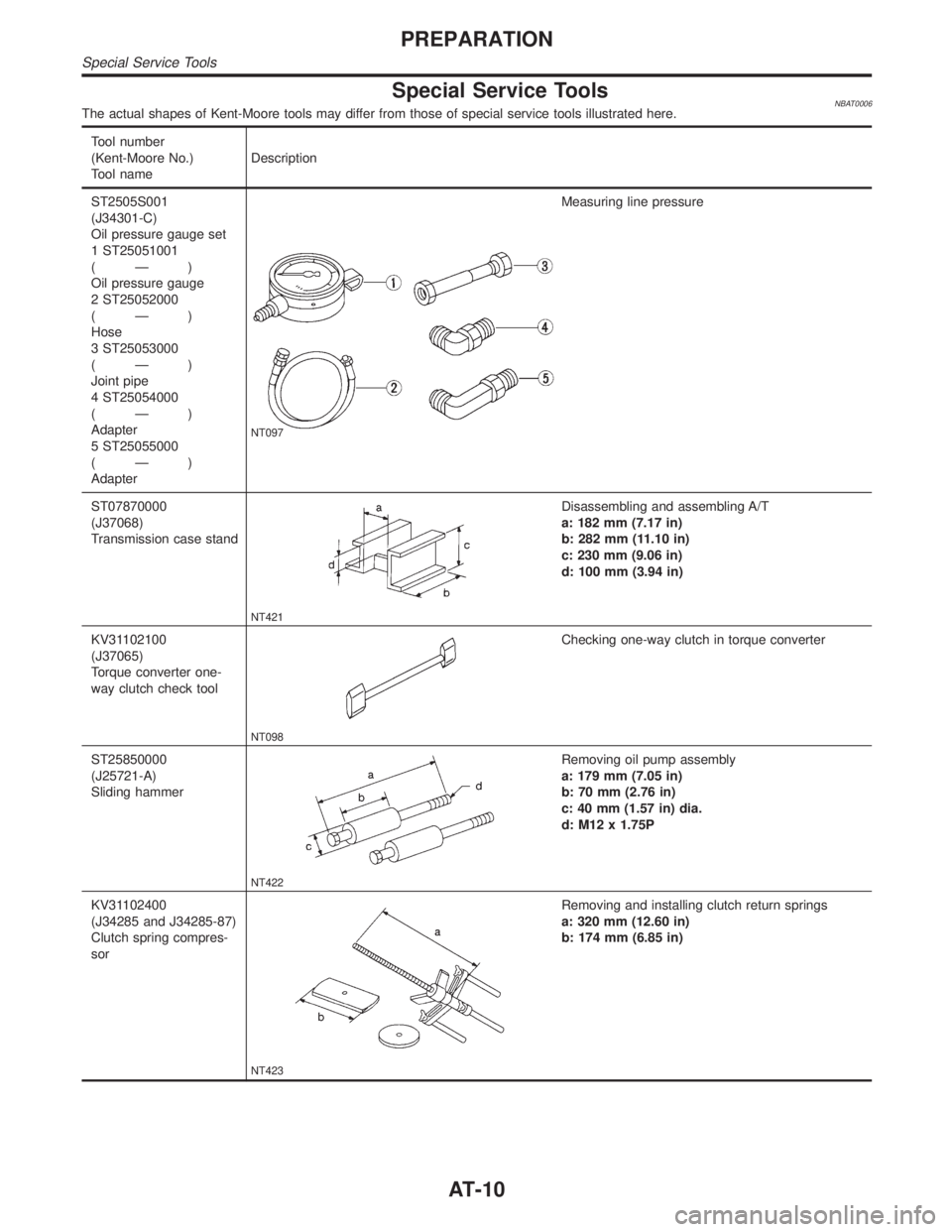

Special Service ToolsNBAT0006The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

ST2505S001

(J34301-C)

Oil pressure gauge set

1 ST25051001

(Ð)

Oil pressure gauge

2 ST25052000

(Ð)

Hose

3 ST25053000

(Ð)

Joint pipe

4 ST25054000

(Ð)

Adapter

5 ST25055000

(Ð)

Adapter

NT097

Measuring line pressure

ST07870000

(J37068)

Transmission case stand

NT421

Disassembling and assembling A/T

a: 182 mm (7.17 in)

b: 282 mm (11.10 in)

c: 230 mm (9.06 in)

d: 100 mm (3.94 in)

KV31102100

(J37065)

Torque converter one-

way clutch check tool

NT098

Checking one-way clutch in torque converter

ST25850000

(J25721-A)

Sliding hammer

NT422

Removing oil pump assembly

a: 179 mm (7.05 in)

b: 70 mm (2.76 in)

c: 40 mm (1.57 in) dia.

d: M12 x 1.75P

KV31102400

(J34285 and J34285-87)

Clutch spring compres-

sor

NT423

Removing and installing clutch return springs

a: 320 mm (12.60 in)

b: 174 mm (6.85 in)

PREPARATION

Special Service Tools

AT-10

Page 21 of 2395

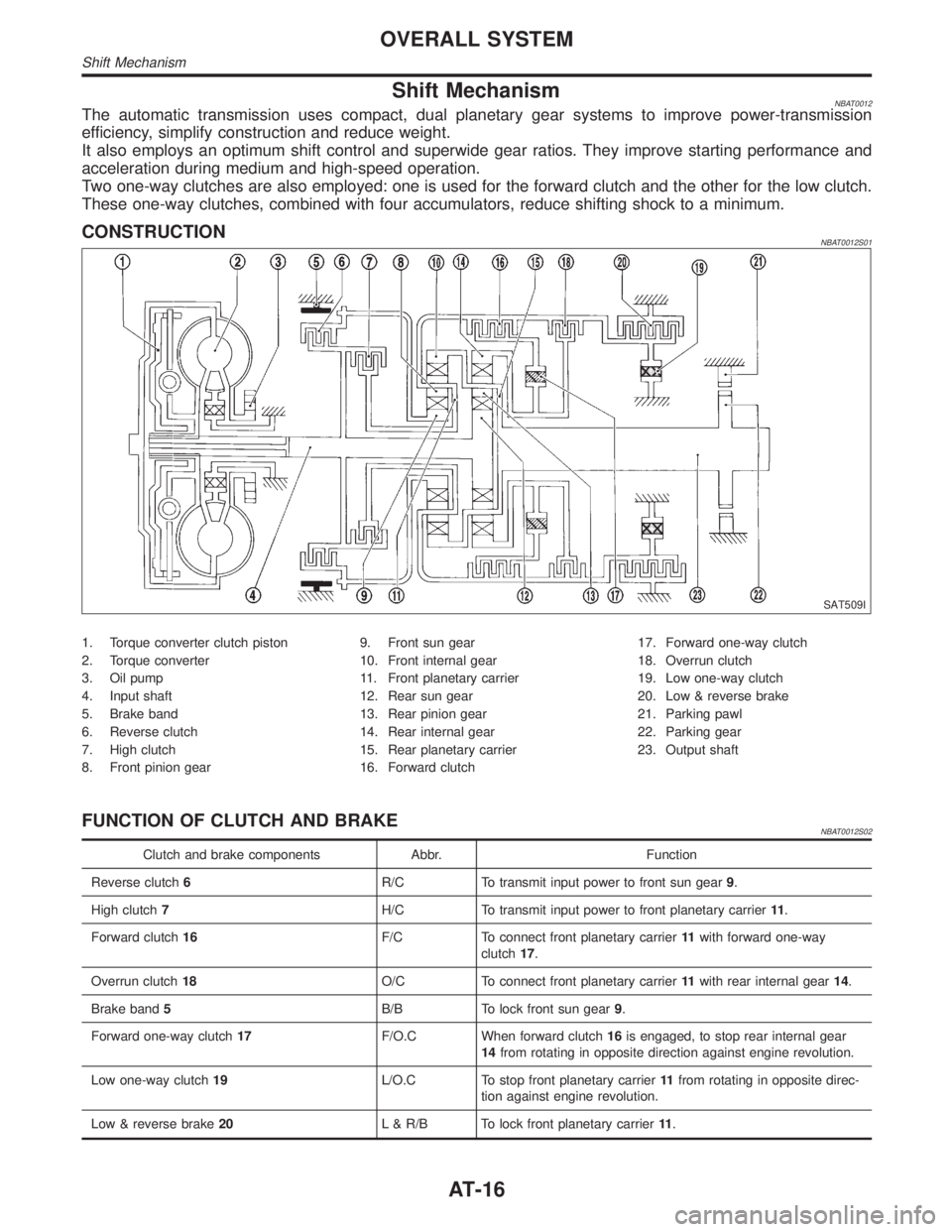

Shift MechanismNBAT0012The automatic transmission uses compact, dual planetary gear systems to improve power-transmission

efficiency, simplify construction and reduce weight.

It also employs an optimum shift control and superwide gear ratios. They improve starting performance and

acceleration during medium and high-speed operation.

Two one-way clutches are also employed: one is used for the forward clutch and the other for the low clutch.

These one-way clutches, combined with four accumulators, reduce shifting shock to a minimum.

CONSTRUCTIONNBAT0012S01

SAT509I

1. Torque converter clutch piston

2. Torque converter

3. Oil pump

4. Input shaft

5. Brake band

6. Reverse clutch

7. High clutch

8. Front pinion gear9. Front sun gear

10. Front internal gear

11. Front planetary carrier

12. Rear sun gear

13. Rear pinion gear

14. Rear internal gear

15. Rear planetary carrier

16. Forward clutch17. Forward one-way clutch

18. Overrun clutch

19. Low one-way clutch

20. Low & reverse brake

21. Parking pawl

22. Parking gear

23. Output shaft

FUNCTION OF CLUTCH AND BRAKENBAT0012S02

Clutch and brake components Abbr. Function

Reverse clutch6R/C To transmit input power to front sun gear9.

High clutch7H/C To transmit input power to front planetary carrier11.

Forward clutch16F/C To connect front planetary carrier11with forward one-way

clutch17.

Overrun clutch18O/C To connect front planetary carrier11with rear internal gear14.

Brake band5B/B To lock front sun gear9.

Forward one-way clutch17F/O.C When forward clutch16is engaged, to stop rear internal gear

14from rotating in opposite direction against engine revolution.

Low one-way clutch19L/O.C To stop front planetary carrier11from rotating in opposite direc-

tion against engine revolution.

Low & reverse brake20L & R/B To lock front planetary carrier11.

OVERALL SYSTEM

Shift Mechanism

AT-16

Page 22 of 2395

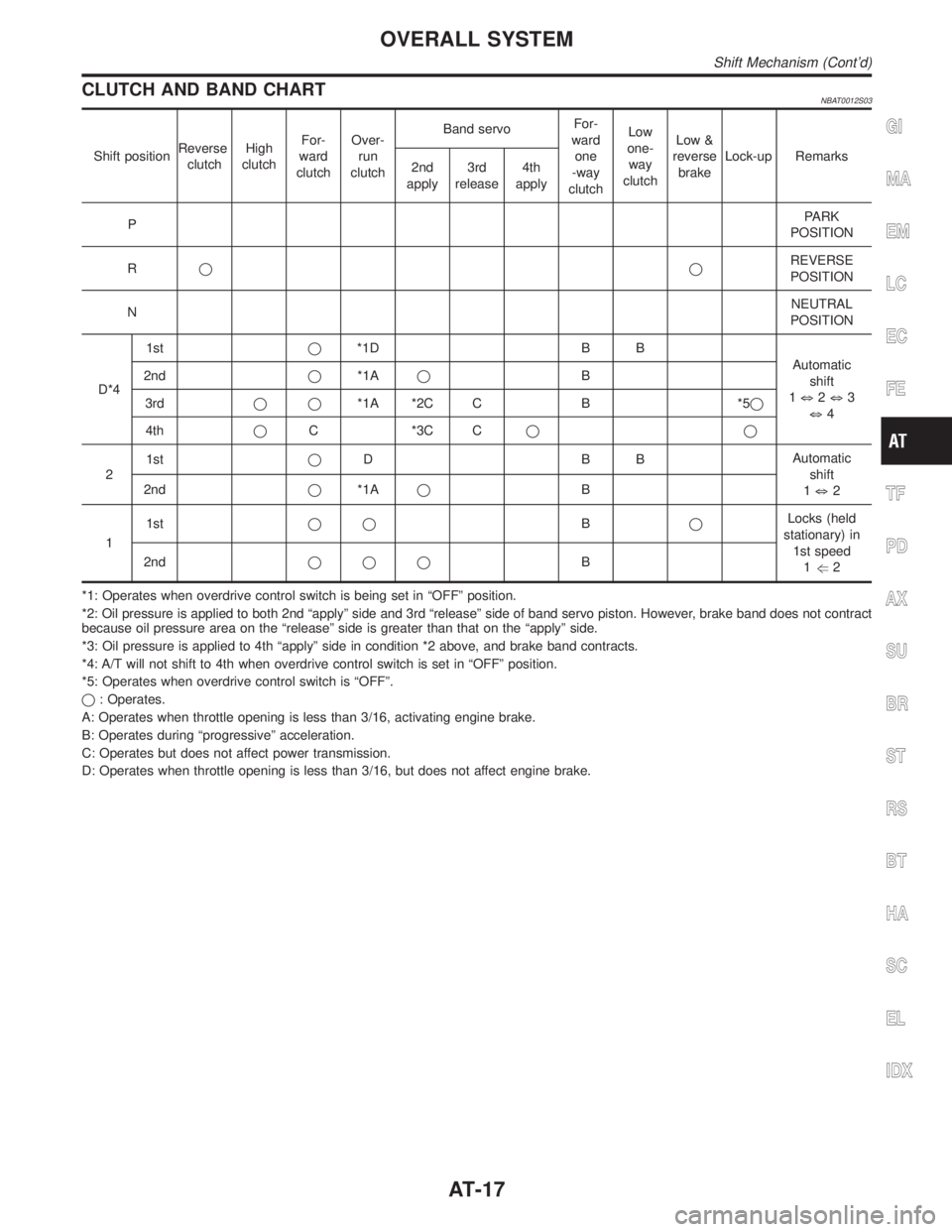

CLUTCH AND BAND CHARTNBAT0012S03

Shift positionReverse

clutchHigh

clutchFor-

ward

clutchOver-

run

clutchBand servoFor-

ward

one

-way

clutchLow

one-

way

clutchLow &

reverse

brakeLock-up Remarks

2nd

apply3rd

release4th

apply

PPARK

POSITION

RqqREVERSE

POSITION

NNEUTRAL

POSITION

D*41stq*1D B B

Automatic

shift

1k2k3

k4 2ndq*1AqB

3rdqq*1A *2C C B *5q

4thqC *3C Cqq

21stqDBBAutomatic

shift

1k2 2ndq*1AqB

11stqqBqLocks (held

stationary) in

1st speed

1g2 2ndqqqB

*1: Operates when overdrive control switch is being set in ªOFFº position.

*2: Oil pressure is applied to both 2nd ªapplyº side and 3rd ªreleaseº side of band servo piston. However, brake band does not contract

because oil pressure area on the ªreleaseº side is greater than that on the ªapplyº side.

*3: Oil pressure is applied to 4th ªapplyº side in condition *2 above, and brake band contracts.

*4: A/T will not shift to 4th when overdrive control switch is set in ªOFFº position.

*5: Operates when overdrive control switch is ªOFFº.

q: Operates.

A: Operates when throttle opening is less than 3/16, activating engine brake.

B: Operates during ªprogressiveº acceleration.

C: Operates but does not affect power transmission.

D: Operates when throttle opening is less than 3/16, but does not affect engine brake.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OVERALL SYSTEM

Shift Mechanism (Cont'd)

AT-17

Page 23 of 2395

POWER TRANSMISSION=NBAT0012S04ªNº and ªPº PositionsNBAT0012S0401IªNº position

No control members operate. Power from the input shaft is not transmitted to the output shaft since the

clutch does not operate.

IªPº position

Similar to the ªNº position, no control members operate. The parking pawl interconnected with the select

lever engages with the parking gear to mechanically hold the output shaft so that the power train is locked.

SAT039J

OVERALL SYSTEM

Shift Mechanism (Cont'd)

AT-18

Page 24 of 2395

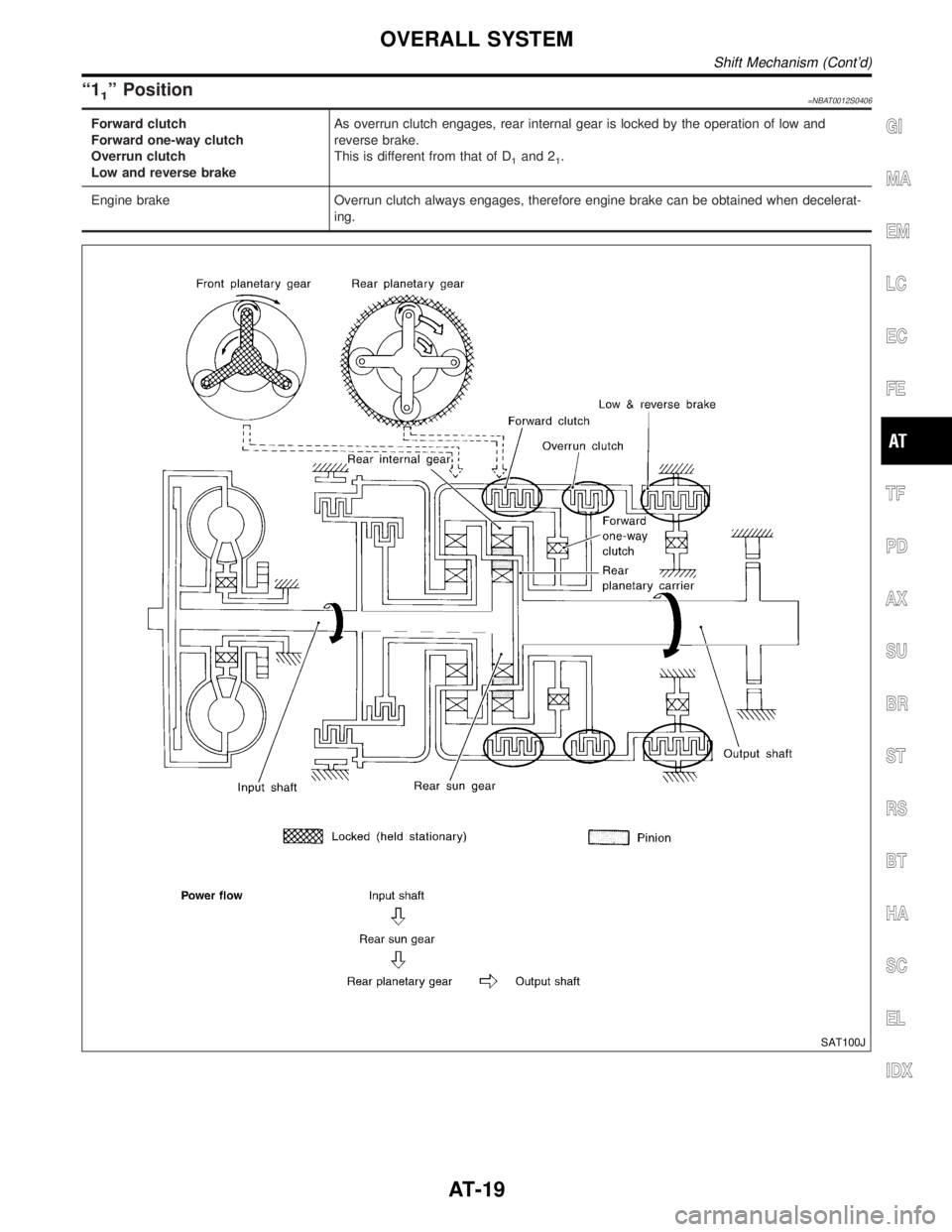

ª11º Position=NBAT0012S0406

Forward clutch

Forward one-way clutch

Overrun clutch

Low and reverse brakeAs overrun clutch engages, rear internal gear is locked by the operation of low and

reverse brake.

This is different from that of D

1and 21.

Engine brake Overrun clutch always engages, therefore engine brake can be obtained when decelerat-

ing.

SAT100J

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

OVERALL SYSTEM

Shift Mechanism (Cont'd)

AT-19

Page 25 of 2395

ªD1º and ª21º Positions=NBAT0012S0402

Forward one-way clutch

Forward clutch

Low one-way clutchRear internal gear is locked to rotate counterclockwise because of the functioning of

these three clutches. (Start-up at D

1)

Overrun clutch

engagement conditions

(Engine brake)D

1: Overdrive control switch in ªOFFº

Throttle opening less than 3/16

2

1: Throttle opening less than 3/16

At D

1and 21positions, engine brake is not activated due to free turning of low one-way

clutch.

SAT096J

OVERALL SYSTEM

Shift Mechanism (Cont'd)

AT-20