heater INFINITI QX4 2001 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 5 of 2395

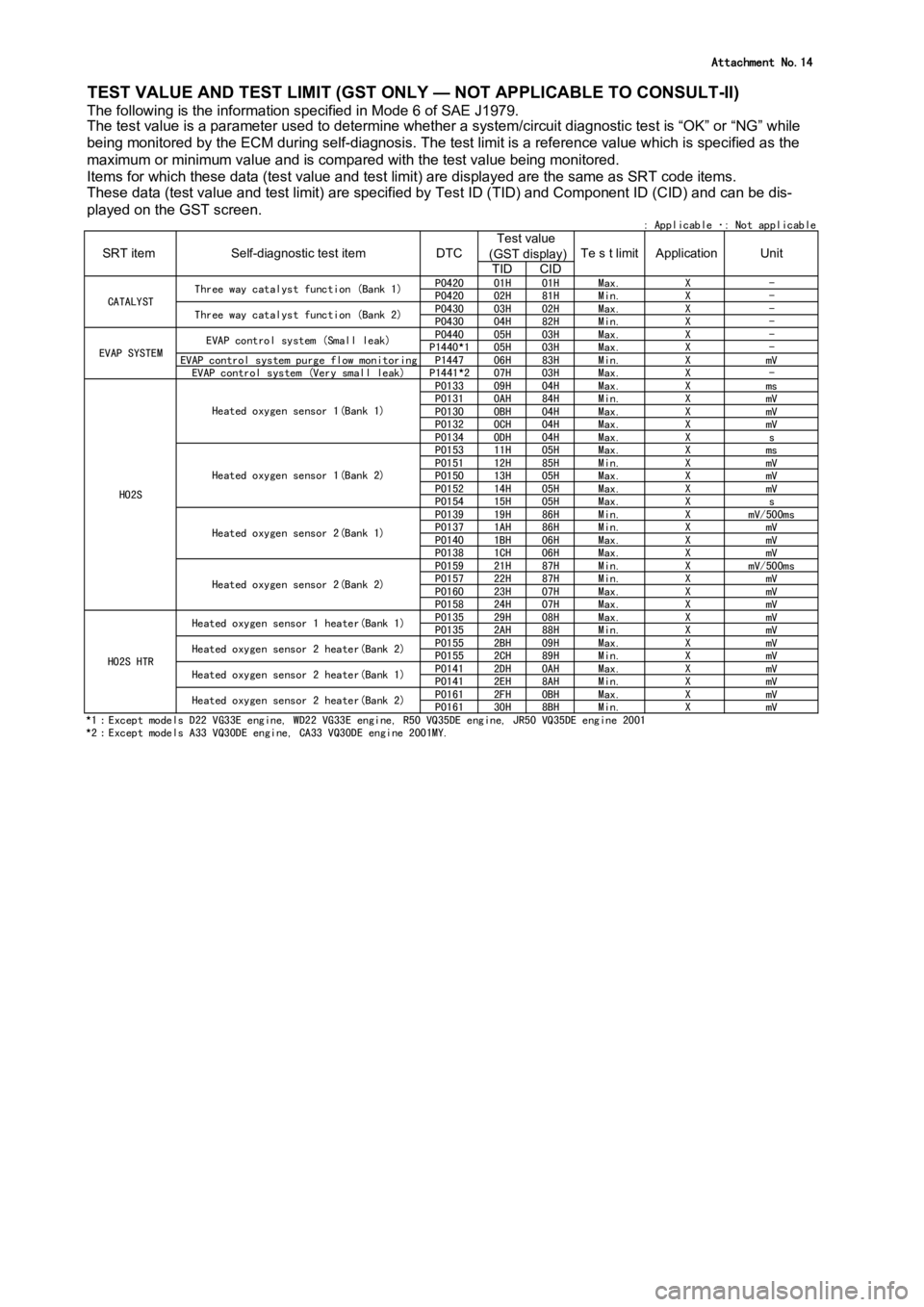

Attachment No.14

TID CID

P0420 01H 01H Max. X -

P0420 02H 81H Min. X -

P0430 03H 02H Max. X -

P0430 04H 82H Min. X -

P0440 05H 03H Max. X -

P1440

★1 05H 03H Max. X -

EVAP control system purge flow monitoring P1447 06H 83H Min. X mV

EVAP control system (Very small leak) P1441

★2 07H 03H Max. X -

P0133 09H 04H Max. X ms

P0131 0AH 84H Min. X mV

P0130 0BH 04H Max. X mV

P0132 0CH 04H Max. X mV

P0134 0DH 04H Max. X s

P0153 11H 05H Max. X ms

P0151 12H 85H Min. X mV

P0150 13H 05H Max. X mV

P0152 14H 05H Max. X mV

P0154 15H 05H Max. X s

P0139 19H 86H Min. X mV/500ms

P0137 1AH 86H Min. X mV

P0140 1BH 06H Max. X mV

P0138 1CH 06H Max. X mV

P0159 21H 87H Min. X mV/500ms

P0157 22H 87H Min. X mV

P0160 23H 07H Max. X mV

P0158 24H 07H Max. X mV

P0135 29H 08H Max. X mV

P0135 2AH 88H Min. X mV

P0155 2BH 09H Max. X mV

P0155 2CH 89H Min. X mV

P0141 2DH 0AH Max. X mV

P0141 2EH 8AH Min. X mV

P0161 2FH 0BH Max. X mV

P0161 30H 8BH Min. X mV

TEST VALUE AND TEST LIMIT (GST ONLY — NOT APPLICABLE TO CONSULT-II)

The following is the information specified in Mode 6 of SAE J1979.

The test value is a parameter used to determine whether a system/circuit diagnostic test is “OK” or “NG” while

being monitored by the ECM during self-diagnosis. The test limit is a reference value which is specified as the

maximum or minimum value and is compared with the test value being monitored.

Items for which these data (test value and test limit) are displayed are the same as SRT code items.

These data (test value and test limit) are specified by Test ID (TID) and Component ID (CID) and can be dis-

played on the GST screen.

: Applicable ・: Not applicable

SRT item Self-diagnostic test item DTCTest value

(GST display)Te s t limit Application Unit

CATALYSTThree way catalyst function (Bank 1)

Three way catalyst function (Bank 2)

EVAP SYSTEMEVAP control system (Small leak)

HO2SHeated oxygen sensor 1(Bank 1)

Heated oxygen sensor 1(Bank 2)

Heated oxygen sensor 2(Bank 1)

Heated oxygen sensor 2(Bank 2)

HO2S HTRHeated oxygen sensor 1 heater(Bank 1)

Heated oxygen sensor 2 heater(Bank 2)

Heated oxygen sensor 2 heater(Bank 1)

Heated oxygen sensor 2 heater(Bank 2)

★<021103d60225025802430245025002540200024d024f02440245024c0253020002240212021202000236022702130213022502000245024e02470249024e0245020c0200023702240212021202000236022702130213022502000245024e02470249024e02

45020c02000232021502100200023602310213021502240225> engine, JR50 VQ35DE engine 2001★<021203d60225025802430245025002540200024d024f02440245024c02530200022102130213020002360231021302100224022502000245024e02470249024e0245020c02000223022102130213020002360231021302100224022502000245024e024702

49024e024502000212021002100211022d0239020e>

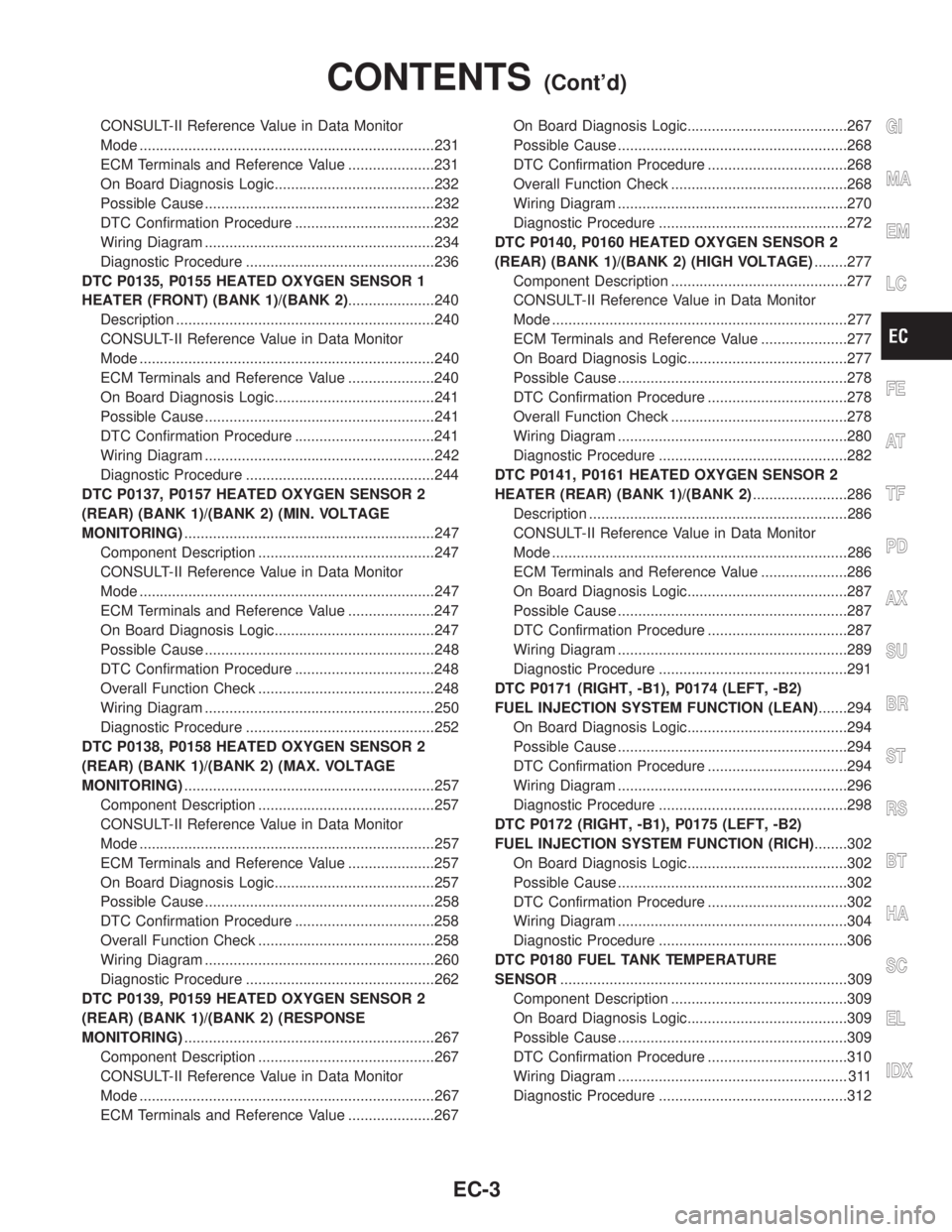

Page 538 of 2395

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................231

ECM Terminals and Reference Value .....................231

On Board Diagnosis Logic.......................................232

Possible Cause ........................................................232

DTC Confirmation Procedure ..................................232

Wiring Diagram ........................................................234

Diagnostic Procedure ..............................................236

DTC P0135, P0155 HEATED OXYGEN SENSOR 1

HEATER (FRONT) (BANK 1)/(BANK 2).....................240

Description ...............................................................240

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................240

ECM Terminals and Reference Value .....................240

On Board Diagnosis Logic.......................................241

Possible Cause ........................................................241

DTC Confirmation Procedure ..................................241

Wiring Diagram ........................................................242

Diagnostic Procedure ..............................................244

DTC P0137, P0157 HEATED OXYGEN SENSOR 2

(REAR) (BANK 1)/(BANK 2) (MIN. VOLTAGE

MONITORING).............................................................247

Component Description ...........................................247

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................247

ECM Terminals and Reference Value .....................247

On Board Diagnosis Logic.......................................247

Possible Cause ........................................................248

DTC Confirmation Procedure ..................................248

Overall Function Check ...........................................248

Wiring Diagram ........................................................250

Diagnostic Procedure ..............................................252

DTC P0138, P0158 HEATED OXYGEN SENSOR 2

(REAR) (BANK 1)/(BANK 2) (MAX. VOLTAGE

MONITORING).............................................................257

Component Description ...........................................257

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................257

ECM Terminals and Reference Value .....................257

On Board Diagnosis Logic.......................................257

Possible Cause ........................................................258

DTC Confirmation Procedure ..................................258

Overall Function Check ...........................................258

Wiring Diagram ........................................................260

Diagnostic Procedure ..............................................262

DTC P0139, P0159 HEATED OXYGEN SENSOR 2

(REAR) (BANK 1)/(BANK 2) (RESPONSE

MONITORING).............................................................267

Component Description ...........................................267

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................267

ECM Terminals and Reference Value .....................267On Board Diagnosis Logic.......................................267

Possible Cause ........................................................268

DTC Confirmation Procedure ..................................268

Overall Function Check ...........................................268

Wiring Diagram ........................................................270

Diagnostic Procedure ..............................................272

DTC P0140, P0160 HEATED OXYGEN SENSOR 2

(REAR) (BANK 1)/(BANK 2) (HIGH VOLTAGE)........277

Component Description ...........................................277

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................277

ECM Terminals and Reference Value .....................277

On Board Diagnosis Logic.......................................277

Possible Cause ........................................................278

DTC Confirmation Procedure ..................................278

Overall Function Check ...........................................278

Wiring Diagram ........................................................280

Diagnostic Procedure ..............................................282

DTC P0141, P0161 HEATED OXYGEN SENSOR 2

HEATER (REAR) (BANK 1)/(BANK 2).......................286

Description ...............................................................286

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................286

ECM Terminals and Reference Value .....................286

On Board Diagnosis Logic.......................................287

Possible Cause ........................................................287

DTC Confirmation Procedure ..................................287

Wiring Diagram ........................................................289

Diagnostic Procedure ..............................................291

DTC P0171 (RIGHT, -B1), P0174 (LEFT, -B2)

FUEL INJECTION SYSTEM FUNCTION (LEAN).......294

On Board Diagnosis Logic.......................................294

Possible Cause ........................................................294

DTC Confirmation Procedure ..................................294

Wiring Diagram ........................................................296

Diagnostic Procedure ..............................................298

DTC P0172 (RIGHT, -B1), P0175 (LEFT, -B2)

FUEL INJECTION SYSTEM FUNCTION (RICH)........302

On Board Diagnosis Logic.......................................302

Possible Cause ........................................................302

DTC Confirmation Procedure ..................................302

Wiring Diagram ........................................................304

Diagnostic Procedure ..............................................306

DTC P0180 FUEL TANK TEMPERATURE

SENSOR......................................................................309

Component Description ...........................................309

On Board Diagnosis Logic.......................................309

Possible Cause ........................................................309

DTC Confirmation Procedure ..................................310

Wiring Diagram ........................................................ 311

Diagnostic Procedure ..............................................312GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS(Cont'd)

EC-3

Page 542 of 2395

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................585

ECM Terminals and Reference Value .....................585

On Board Diagnosis Logic.......................................586

Possible Cause ........................................................586

DTC Confirmation Procedure ..................................586

Wiring Diagram ........................................................587

Diagnostic Procedure ..............................................588

DTC P1491 VACUUM CUT VALVE BYPASS

VALVE..........................................................................591

Description ...............................................................591

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................591

ECM Terminals and Reference Value .....................591

On Board Diagnosis Logic.......................................592

Possible Cause ........................................................592

DTC Confirmation Procedure ..................................592

Overall Function Check ...........................................593

Wiring Diagram ........................................................594

Diagnostic Procedure ..............................................595

DTC P1605 A/T DIAGNOSIS COMMUNICATION

LINE.............................................................................603

Component Description ...........................................603

On Board Diagnosis Logic.......................................603

Possible Cause ........................................................603

DTC Confirmation Procedure ..................................603

DTC P1706 PARK/NEUTRAL POSITION (PNP)

SWITCH.......................................................................604

Component Description ...........................................604

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................604

ECM Terminals and Reference Value .....................604

On Board Diagnosis Logic.......................................604

Possible Cause ........................................................604

DTC Confirmation Procedure ..................................605

Overall Function Check ...........................................606

Wiring Diagram ........................................................607

Diagnostic Procedure ..............................................608

VARIABLE INDUCTION AIR CONTROL SYSTEM

(VIAS)...........................................................................610

Description ...............................................................610

ECM Terminals and Reference Value ..................... 611

Wiring Diagram ........................................................612

Diagnostic Procedure ..............................................613

INJECTOR...................................................................616

Component Description ...........................................616

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................616

ECM Terminals and Reference Value .....................616

Wiring Diagram ........................................................617Diagnostic Procedure ..............................................618

START SIGNAL...........................................................621

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................621

ECM Terminals and Reference Value .....................621

Wiring Diagram ........................................................622

Diagnostic Procedure ..............................................623

FUEL PUMP.................................................................625

System Description ..................................................625

Component Description ...........................................625

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................625

ECM Terminals and Reference Value .....................626

Wiring Diagram ........................................................627

Diagnostic Procedure ..............................................628

POWER STEERING OIL PRESSURE SWITCH.........634

Component Description ...........................................634

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................634

ECM Terminals and Reference Value .....................634

Wiring Diagram ........................................................635

Diagnostic Procedure ..............................................636

REFRIGERANT PRESSURE SENSOR......................639

Description ...............................................................639

ECM Terminals and Reference Value .....................639

Wiring Diagram ........................................................640

Diagnostic Procedure ..............................................641

ELECTRICAL LOAD SIGNAL.....................................643

ECM Terminals and Reference Value .....................643

Wiring Diagram ........................................................644

Diagnostic Procedure ..............................................645

MIL & DATA LINK CONNECTORS............................648

Wiring Diagram ........................................................648

SERVICE DATA AND SPECIFICATIONS (SDS).......649

Fuel Pressure Regulator..........................................649

Idle Speed and Ignition Timing ................................649

Mass Air Flow Sensor..............................................649

Engine Coolant Temperature Sensor ......................649

Heated Oxygen Sensor 1 Heater (Front) ................649

Fuel Pump ...............................................................649

IACV-AAC Valve ......................................................649

Injector .....................................................................649

Resistor ....................................................................649

Throttle Position Sensor ..........................................650

Calculated Load Value.............................................650

Intake Air Temperature Sensor ................................650

Heated Oxygen Sensor 2 Heater (Rear).................650

Crankshaft Position Sensor (REF) ..........................650

Fuel Tank Temperature Sensor ...............................650

Camshaft Position Sensor (PHASE) .......................650GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

CONTENTS(Cont'd)

EC-7

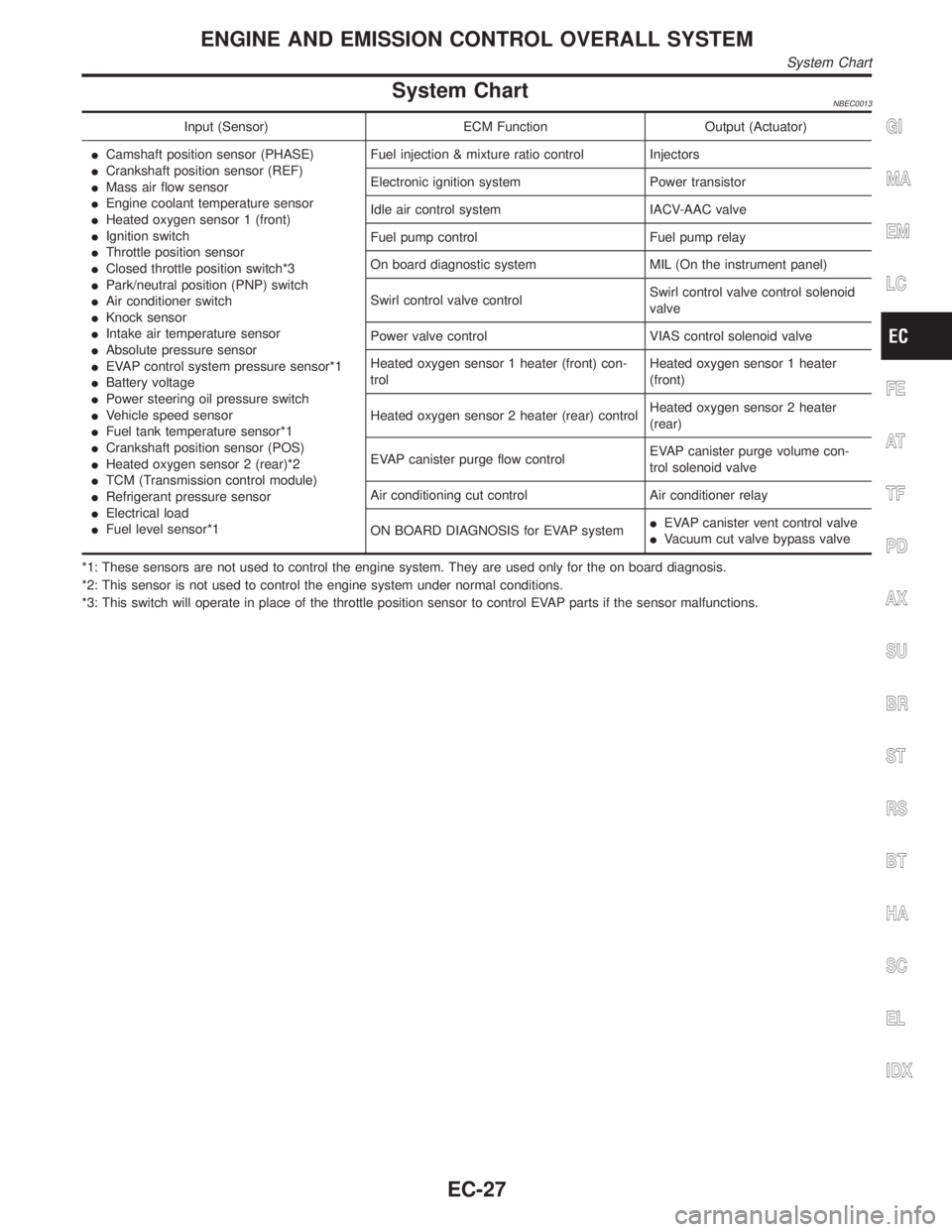

Page 562 of 2395

System ChartNBEC0013

Input (Sensor) ECM Function Output (Actuator)

ICamshaft position sensor (PHASE)

ICrankshaft position sensor (REF)

IMass air flow sensor

IEngine coolant temperature sensor

IHeated oxygen sensor 1 (front)

IIgnition switch

IThrottle position sensor

IClosed throttle position switch*3

IPark/neutral position (PNP) switch

IAir conditioner switch

IKnock sensor

IIntake air temperature sensor

IAbsolute pressure sensor

IEVAP control system pressure sensor*1

IBattery voltage

IPower steering oil pressure switch

IVehicle speed sensor

IFuel tank temperature sensor*1

ICrankshaft position sensor (POS)

IHeated oxygen sensor 2 (rear)*2

ITCM (Transmission control module)

IRefrigerant pressure sensor

IElectrical load

IFuel level sensor*1Fuel injection & mixture ratio control Injectors

Electronic ignition system Power transistor

Idle air control system IACV-AAC valve

Fuel pump control Fuel pump relay

On board diagnostic system MIL (On the instrument panel)

Swirl control valve controlSwirl control valve control solenoid

valve

Power valve control VIAS control solenoid valve

Heated oxygen sensor 1 heater (front) con-

trolHeated oxygen sensor 1 heater

(front)

Heated oxygen sensor 2 heater (rear) controlHeated oxygen sensor 2 heater

(rear)

EVAP canister purge flow controlEVAP canister purge volume con-

trol solenoid valve

Air conditioning cut control Air conditioner relay

ON BOARD DIAGNOSIS for EVAP systemIEVAP canister vent control valve

IVacuum cut valve bypass valve

*1: These sensors are not used to control the engine system. They are used only for the on board diagnosis.

*2: This sensor is not used to control the engine system under normal conditions.

*3: This switch will operate in place of the throttle position sensor to control EVAP parts if the sensor malfunctions.GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

System Chart

EC-27

Page 579 of 2395

IAir intake system

(Oil filler cap, oil level gauge, etc.)

IFuel pressure

IEngine compression

IThrottle valve

IEvaporative emission system

2) On air conditioner equipped models, checks should be carried out while the air conditioner is ªOFFº.

3) On automatic transmission equipped models, when checking idle rpm, ignition timing and mixture ratio,

checks should be carried out while shift lever is in ªNº position.

4) When measuring ªCOº percentage, insert probe more than 40 cm (15.7 in) into tail pipe.

5) Turn off headlamps, heater blower, rear defogger.

6) Keep front wheels pointed straight ahead.

7) Make the check after the cooling fan has stopped.

BASIC SERVICE PROCEDURE

Idle Speed/Ignition Timing/Idle Mixture Ratio Adjustment (Cont'd)

EC-44

Page 597 of 2395

SRT Item=NBEC0031S0310The table below shows required self-diagnostic items to set the SRT to ªCMPLTº.

SRT item

(CONSULT-II indica-

tion)Perfor-

mance Pri-

ority*Required self-diagnostic items to set the SRT to ªCMPLTºCorresponding

DTC No.

CATALYST 3 Three way catalyst function P0420, P0430

EVAP SYSTEM 2 EVAP control system (small leak) (negative pressure) P0440

3 EVAP control system (very small leak) (negative pressure)/

(positive pressure)P1441

3 EVAP control system purge flow monitoring P1447

O2 SENSOR 3 Heated oxygen sensor 1 (front) (circuit) P0130, P0150

Heated oxygen sensor 1 (front) (lean shift monitoring) P0131, P0151

Heated oxygen sensor 1 (front) (rich shift monitoring) P0132, P0152

Heated oxygen sensor 1 (front) (response monitoring) P0133, P0153

Heated oxygen sensor 1 (front) (high voltage) P0134, P0154

Heated oxygen sensor 2 (rear) (min. voltage monitoring) P0137, P0157

Heated oxygen sensor 2 (rear) (max. voltage monitoring) P0138, P0158

Heated oxygen sensor 2 (rear) (response monitoring) P0139, P0159

Heated oxygen sensor 2 (rear) (high voltage) P0140, P0160

O2 SEN HEATER 3 Heated oxygen sensor 1 heater (front) P0135, P0155

Heated oxygen sensor 2 heater (rear) P0141, P0161

*: If completion of several SRTs is required, perform driving patterns (DTC confirmation procedure), one by one based on the priority

for models with CONSULT-II.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Emission-related Diagnostic Information (Cont'd)

EC-62

Page 604 of 2395

SRT item Self-diagnostic test itemTest value (GST display)

Test limit Application

TID CID

O2 SENSORHeated oxygen sensor 1 (front)

(bank 1)09H 04H Max. X

0AH 84H Min. X

0BH 04H Max. X

0CH 04H Max. X

0DH 04H Max. X

Heated oxygen sensor 1 (front)

(bank 2)11H 05H Max. X

12H 85H Min. X

13H 05H Max. X

14H 05H Max. X

15H 05H Max. X

Heated oxygen sensor 2 (rear)

(bank 1)19H 86H Min. X

1AH 86H Min. X

1BH 06H Max. X

1CH 06H Max. X

Heated oxygen sensor 2 (rear)

(bank 2)21H 87H Min. X

22H 87H Min. X

23H 07H Max. X

24H 07H Max. X

O2 SENSOR HEATERHeated oxygen sensor 1 (front) heater

(bank 1)29H 08H Max. X

2AH 88H Min. X

Heated oxygen sensor 1 (front) heater

(bank 2)2BH 09H Max. X

2CH 89H Min. X

Heated oxygen sensor 2 (rear) heater

(bank 1)2DH 0AH Max. X

2EH 8AH Min. X

Heated oxygen sensor 2 (rear) heater

(bank 2)2FH 0BH Max. X

30H 8BH Min. X

EMISSION-RELATED DIAGNOSTIC INFORMATION ITEMSNBEC0031S05X: Applicable Ð: Not applicable

Items

(CONSULT-II screen terms)DTC*1 SRT codeTest value/ Test

limit

(GST only)1st trip DTC*1 Reference page

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.P0000ÐÐÐÐ

MAF SEN/CIRCUIT P0100 Ð Ð X EC-150

ABSL PRES SEN/CIRC P0105 Ð Ð X EC-158

AIR TEMP SEN/CIRC P0110 Ð Ð X EC-164

COOLANT T SEN/CIRC P0115 Ð Ð X EC-169

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

Emission-related Diagnostic Information (Cont'd)

EC-69

Page 618 of 2395

ItemDIAGNOSTIC TEST MODE

WORK

SUP-

PORTSELF-DIAGNOSTIC

RESULTS

D ATA

MONI-

TORD ATA

MONI-

TOR

(SPEC)ACTIVE

TESTDTC & SRT

CONFIRMATION

DTC*1FREEZE

FRAME

DATA*2SRT

STATUSDTC

WORK

SUP-

PORT

ENGINE CONTROL COMPONENT PARTS

OUTPUT

Injectors X X X

Power transistor (Ignition timing)X

(Ignition

signal)XXX

IACV-AAC valve X X X X

EVAP canister purge volume

control solenoid valveX XXX X

Air conditioner relay X X

Fuel pump relay X X X X

Heated oxygen sensor 1 (front)

heaterXXXX

Heated oxygen sensor 2 (rear)

heaterXXXX

EVAP canister vent control valve X X X X

Vacuum cut valve bypass valve X X X X X

Swirl control valve control sole-

noid valveX XXX

VIAS control solenoid valve X X X

Intake valve timing control sole-

noid valveX XXX

Calculated load value X X X

X: Applicable

*1: This item includes 1st trip DTCs.

*2: This mode includes 1st trip freeze frame data or freeze frame data. The items appear on CONSULT-II screen in freeze frame data

mode only if a 1st trip DTC or DTC is detected. For details, refer to EC-60.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-83

Page 624 of 2395

![INFINITI QX4 2001 Factory Service Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

IGN TIMING [BTDC]qIIndicates the ignition timing computed

by ECM according to the input signals.IWhen the engine is stopped, a cer INFINITI QX4 2001 Factory Service Manual Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

IGN TIMING [BTDC]qIIndicates the ignition timing computed

by ECM according to the input signals.IWhen the engine is stopped, a cer](/img/42/57027/w960_57027-623.png)

Monitored item [Unit]ECM

input

signalsMain

signalsDescription Remarks

IGN TIMING [BTDC]qIIndicates the ignition timing computed

by ECM according to the input signals.IWhen the engine is stopped, a certain

value is indicated.

IACV-AAC/V [step]qIIndicates the IACV-AAC valve control

value computed by ECM according to

the input signals.

PURG VOL C/V [%]IIndicates the EVAP canister purge vol-

ume control solenoid valve control

value computed by the ECM according

to the input signals.

IThe opening becomes larger as the

value increases.

A/F ALPHA-B1 [%]q

IThe mean value of the air-fuel ratio

feedback correction factor per cycle is

indicated.IWhen the engine is stopped, a certain

value is indicated.

IThis data also includes the data for the

air-fuel ratio learning control. A/F ALPHA-B2 [%]q

AIR COND RLY

[ON/OFF]qIThe air conditioner relay control condi-

tion (determined by ECM according to

the input signal) is indicated.

FUEL PUMP RLY

[ON/OFF]qIIndicates the fuel pump relay control

condition determined by ECM accord-

ing to the input signals.

VENT CONT/V

[ON/OFF]IThe control condition of the EVAP can-

ister vent control valve (determined by

ECM according to the input signal) is

indicated.

ION ... Closed

OFF ... Open

HO2S1 HTR (B1)

[ON/OFF]IIndicates [ON/OFF] condition of front

heated oxygen sensor heater deter-

mined by ECM according to the input

signals. HO2S1 HTR (B2)

[ON/OFF]

HO2S2 HTR (B1)

[ON/OFF]IIndicates [ON/OFF] condition of rear

heated oxygen sensor heater deter-

mined by ECM according to the input

signals. HO2S2 HTR (B2)

[ON/OFF]

VC/V BYPASS/V

[ON/OFF]IThe control condition of the vacuum cut

valve bypass valve (determined by

ECM according to the input signal) is

indicated.

ION ... Open

OFF ... Closed

CAL/LD VALUE [%]IªCalculated load valueº indicates the

value of the current airflow divided by

peak airflow.

ABSOL TH´P/S [%]IªAbsolute throttle position sensorº indi-

cates the throttle opening computed by

ECM according to the signal voltage of

the throttle position sensor.

MASS AIRFLOW

[g´m/s]IIndicates the mass airflow computed by

ECM according to the signal voltage of

the mass airflow sensor.GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTION

CONSULT-II (Cont'd)

EC-89

Page 651 of 2395

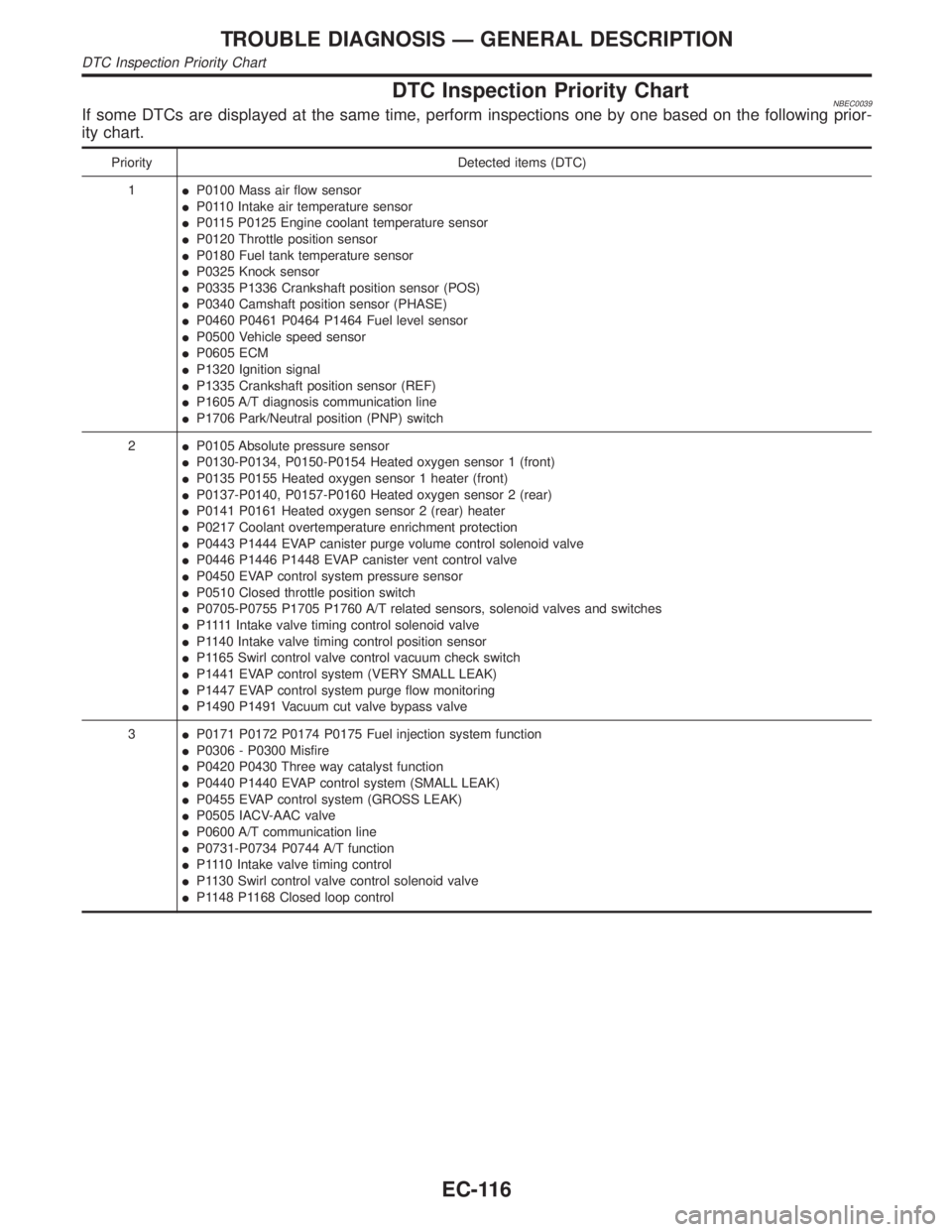

DTC Inspection Priority ChartNBEC0039If some DTCs are displayed at the same time, perform inspections one by one based on the following prior-

ity chart.

Priority Detected items (DTC)

1IP0100 Mass air flow sensor

IP0110 Intake air temperature sensor

IP0115 P0125 Engine coolant temperature sensor

IP0120 Throttle position sensor

IP0180 Fuel tank temperature sensor

IP0325 Knock sensor

IP0335 P1336 Crankshaft position sensor (POS)

IP0340 Camshaft position sensor (PHASE)

IP0460 P0461 P0464 P1464 Fuel level sensor

IP0500 Vehicle speed sensor

IP0605 ECM

IP1320 Ignition signal

IP1335 Crankshaft position sensor (REF)

IP1605 A/T diagnosis communication line

IP1706 Park/Neutral position (PNP) switch

2IP0105 Absolute pressure sensor

IP0130-P0134, P0150-P0154 Heated oxygen sensor 1 (front)

IP0135 P0155 Heated oxygen sensor 1 heater (front)

IP0137-P0140, P0157-P0160 Heated oxygen sensor 2 (rear)

IP0141 P0161 Heated oxygen sensor 2 (rear) heater

IP0217 Coolant overtemperature enrichment protection

IP0443 P1444 EVAP canister purge volume control solenoid valve

IP0446 P1446 P1448 EVAP canister vent control valve

IP0450 EVAP control system pressure sensor

IP0510 Closed throttle position switch

IP0705-P0755 P1705 P1760 A/T related sensors, solenoid valves and switches

IP 1111Intake valve timing control solenoid valve

IP1140 Intake valve timing control position sensor

IP1165 Swirl control valve control vacuum check switch

IP1441 EVAP control system (VERY SMALL LEAK)

IP1447 EVAP control system purge flow monitoring

IP1490 P1491 Vacuum cut valve bypass valve

3IP0171 P0172 P0174 P0175 Fuel injection system function

IP0306 - P0300 Misfire

IP0420 P0430 Three way catalyst function

IP0440 P1440 EVAP control system (SMALL LEAK)

IP0455 EVAP control system (GROSS LEAK)

IP0505 IACV-AAC valve

IP0600 A/T communication line

IP0731-P0734 P0744 A/T function

IP1110 Intake valve timing control

IP1130 Swirl control valve control solenoid valve

IP1148 P1168 Closed loop control

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTION

DTC Inspection Priority Chart

EC-116