oil pressure INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 1170 of 2395

Wiring DiagramNBEC0401

MEC977C

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

POWER STEERING OIL PRESSURE SWITCH

Wiring Diagram

EC-635

Page 1171 of 2395

Diagnostic ProcedureNBEC0402

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Start engine.

2. Check ªPW/ST SIGNALº in ªDATA MONITORº mode with CONSULT-II under the following conditions.

SEF228Y

OK or NG

OK©INSPECTION END

NG©GO TO 4.

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Start engine.

2. Check voltage between ECM terminal 47 and ground under the following conditions.

SEF363X

OK or NG

OK©INSPECTION END

NG©GO TO 4.

POWER STEERING OIL PRESSURE SWITCH

Diagnostic Procedure

EC-636

Page 1172 of 2395

4 CHECK POWER STEERING OIL PRESSURE SWITCH GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect power steering oil pressure switch harness connector.

SEF028Z

3. Check harness continuity between power steering oil pressure switch terminal 2 and engine ground. Refer to Wiring

Diagram.

Continuity should exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to power in harness or connectors.

5 CHECK POWER STEERING OIL PRESSURE SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 47 and power steering oil pressure switch terminal 1. Refer to Wiring

Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK POWER STEERING OIL PRESSURE SWITCH

1. Disconnect power steering oil pressure switch harness connector then start engine.

2. Check continuity between power steering oil pressure switch terminals 1 and 2 under the following conditions.

SEF364X

OK or NG

OK©GO TO 7.

NG©Replace power steering oil pressure switch.

GI

MA

EM

LC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

POWER STEERING OIL PRESSURE SWITCH

Diagnostic Procedure (Cont'd)

EC-637

Page 1173 of 2395

7 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-140.

©INSPECTION END

POWER STEERING OIL PRESSURE SWITCH

Diagnostic Procedure (Cont'd)

EC-638

Page 1259 of 2395

SEL350X

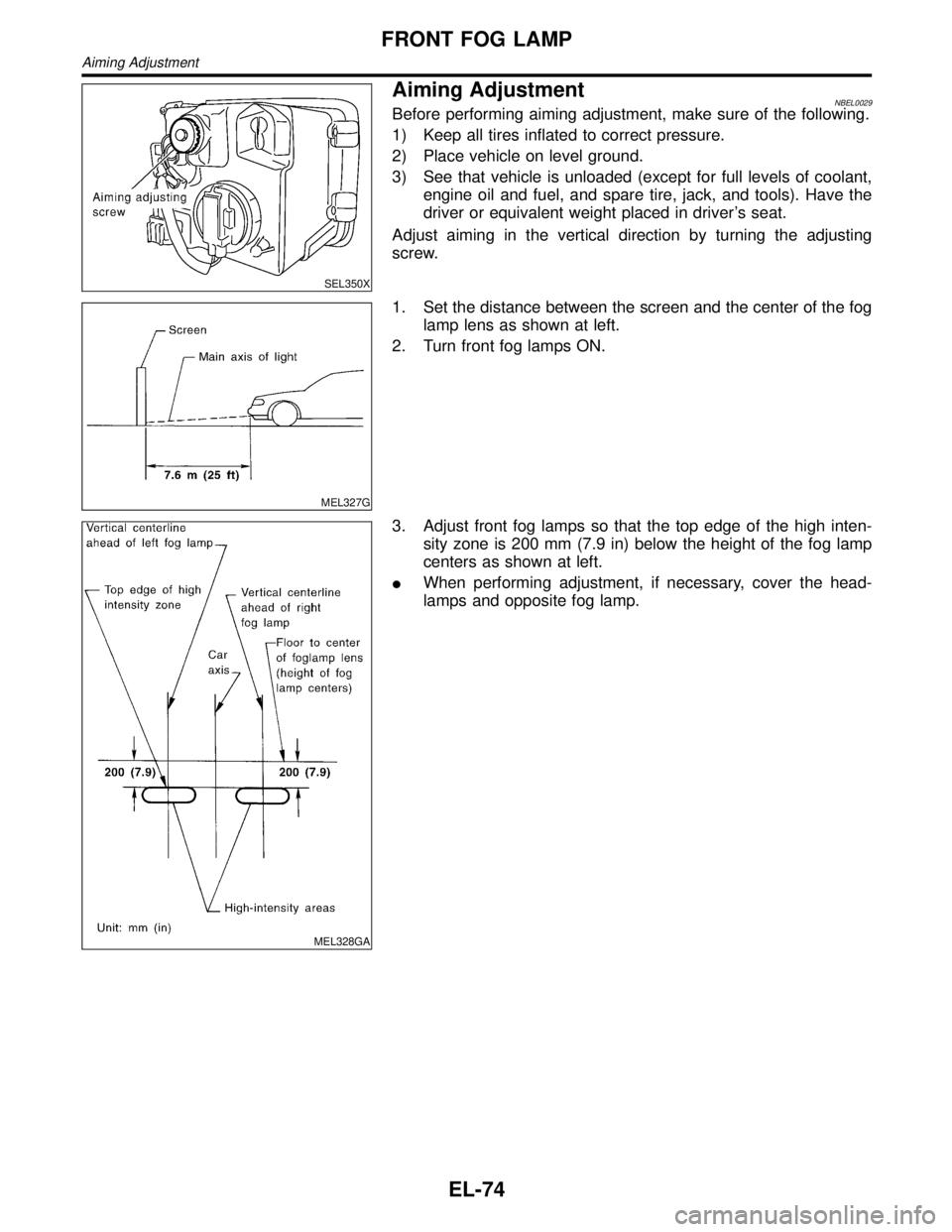

Aiming AdjustmentNBEL0029Before performing aiming adjustment, make sure of the following.

1) Keep all tires inflated to correct pressure.

2) Place vehicle on level ground.

3) See that vehicle is unloaded (except for full levels of coolant,

engine oil and fuel, and spare tire, jack, and tools). Have the

driver or equivalent weight placed in driver's seat.

Adjust aiming in the vertical direction by turning the adjusting

screw.

MEL327G

1. Set the distance between the screen and the center of the fog

lamp lens as shown at left.

2. Turn front fog lamps ON.

MEL328GA

3. Adjust front fog lamps so that the top edge of the high inten-

sity zone is 200 mm (7.9 in) below the height of the fog lamp

centers as shown at left.

IWhen performing adjustment, if necessary, cover the head-

lamps and opposite fog lamp.

FRONT FOG LAMP

Aiming Adjustment

EL-74

Page 1307 of 2395

SEL062WA

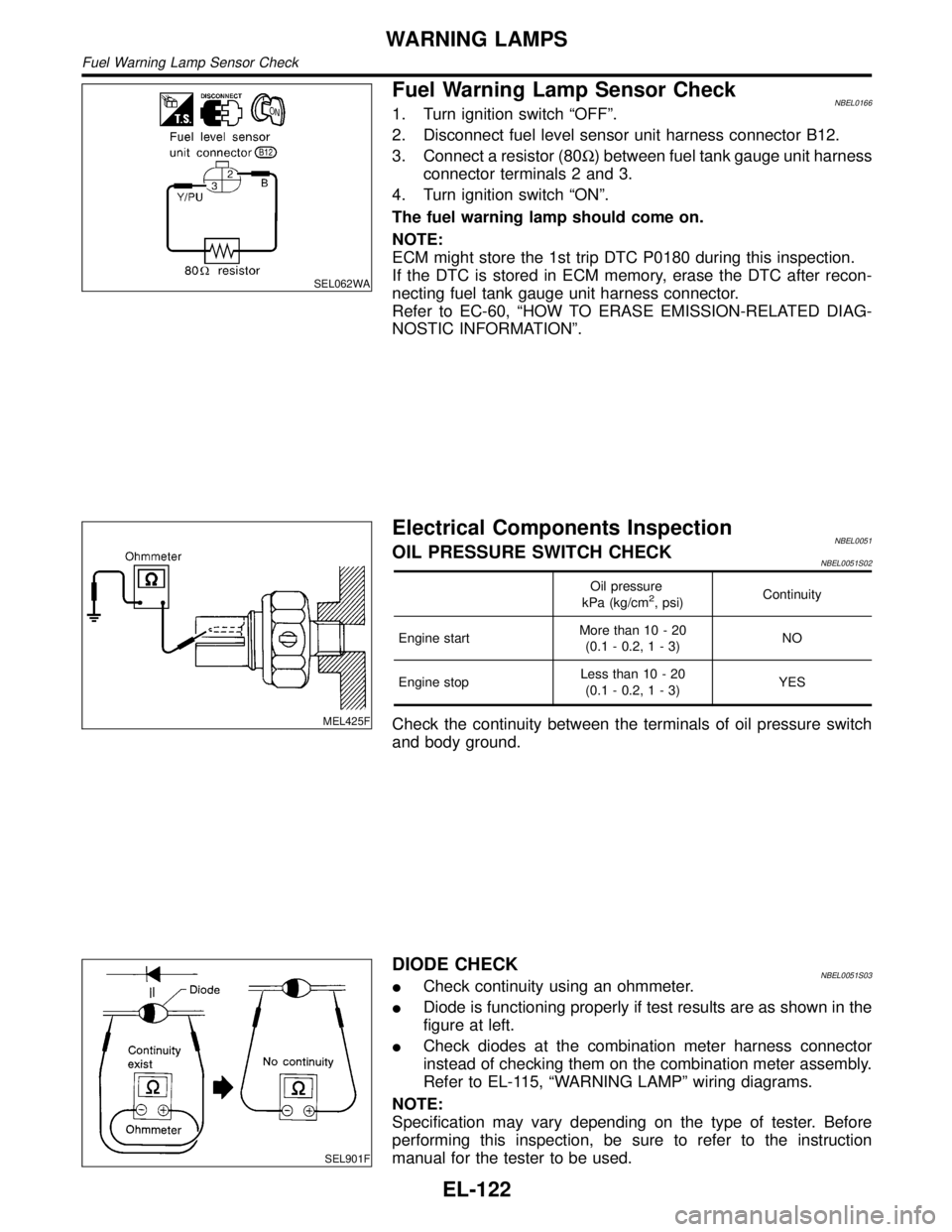

Fuel Warning Lamp Sensor CheckNBEL01661. Turn ignition switch ªOFFº.

2. Disconnect fuel level sensor unit harness connector B12.

3. Connect a resistor (80W) between fuel tank gauge unit harness

connector terminals 2 and 3.

4. Turn ignition switch ªONº.

The fuel warning lamp should come on.

NOTE:

ECM might store the 1st trip DTC P0180 during this inspection.

If the DTC is stored in ECM memory, erase the DTC after recon-

necting fuel tank gauge unit harness connector.

Refer to EC-60, ªHOW TO ERASE EMISSION-RELATED DIAG-

NOSTIC INFORMATIONº.

MEL425F

Electrical Components InspectionNBEL0051OIL PRESSURE SWITCH CHECKNBEL0051S02

Oil pressure

kPa (kg/cm2, psi)Continuity

Engine startMore than 10 - 20

(0.1-0.2,1-3)NO

Engine stopLess than 10 - 20

(0.1-0.2,1-3)YES

Check the continuity between the terminals of oil pressure switch

and body ground.

SEL901F

DIODE CHECKNBEL0051S03ICheck continuity using an ohmmeter.

IDiode is functioning properly if test results are as shown in the

figure at left.

ICheck diodes at the combination meter harness connector

instead of checking them on the combination meter assembly.

Refer to EL-115, ªWARNING LAMPº wiring diagrams.

NOTE:

Specification may vary depending on the type of tester. Before

performing this inspection, be sure to refer to the instruction

manual for the tester to be used.

WARNING LAMPS

Fuel Warning Lamp Sensor Check

EL-122

Page 1642 of 2395

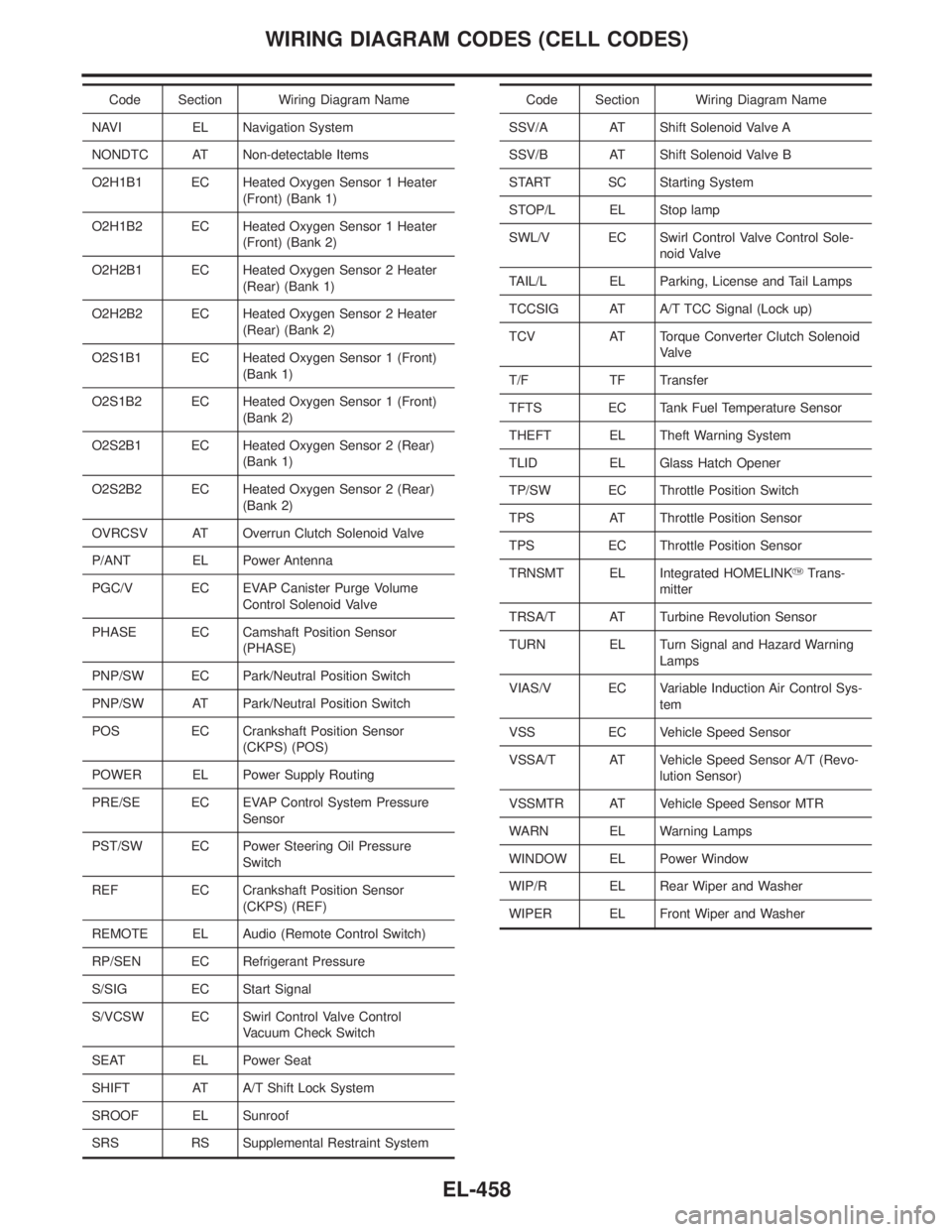

NBEL0145

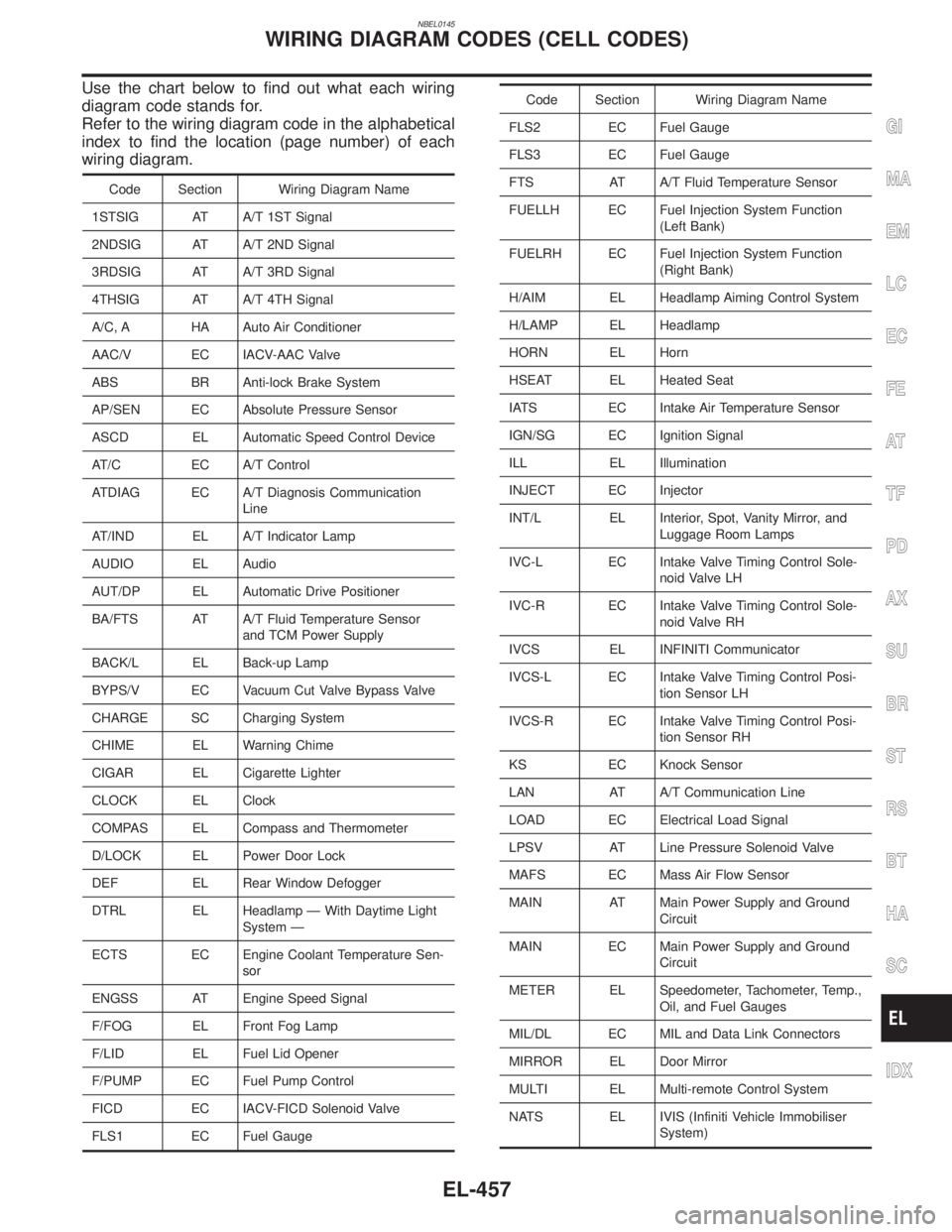

Use the chart below to find out what each wiring

diagram code stands for.

Refer to the wiring diagram code in the alphabetical

index to find the location (page number) of each

wiring diagram.

Code Section Wiring Diagram Name

1STSIG AT A/T 1ST Signal

2NDSIG AT A/T 2ND Signal

3RDSIG AT A/T 3RD Signal

4THSIG AT A/T 4TH Signal

A/C, A HA Auto Air Conditioner

AAC/V EC IACV-AAC Valve

ABS BR Anti-lock Brake System

AP/SEN EC Absolute Pressure Sensor

ASCD EL Automatic Speed Control Device

AT/C EC A/T Control

ATDIAG EC A/T Diagnosis Communication

Line

AT/IND EL A/T Indicator Lamp

AUDIO EL Audio

AUT/DP EL Automatic Drive Positioner

BA/FTS AT A/T Fluid Temperature Sensor

and TCM Power Supply

BACK/L EL Back-up Lamp

BYPS/V EC Vacuum Cut Valve Bypass Valve

CHARGE SC Charging System

CHIME EL Warning Chime

CIGAR EL Cigarette Lighter

CLOCK EL Clock

COMPAS EL Compass and Thermometer

D/LOCK EL Power Door Lock

DEF EL Rear Window Defogger

DTRL EL Headlamp Ð With Daytime Light

System Ð

ECTS EC Engine Coolant Temperature Sen-

sor

ENGSS AT Engine Speed Signal

F/FOG EL Front Fog Lamp

F/LID EL Fuel Lid Opener

F/PUMP EC Fuel Pump Control

FICD EC IACV-FICD Solenoid Valve

FLS1 EC Fuel Gauge

Code Section Wiring Diagram Name

FLS2 EC Fuel Gauge

FLS3 EC Fuel Gauge

FTS AT A/T Fluid Temperature Sensor

FUELLH EC Fuel Injection System Function

(Left Bank)

FUELRH EC Fuel Injection System Function

(Right Bank)

H/AIM EL Headlamp Aiming Control System

H/LAMP EL Headlamp

HORN EL Horn

HSEAT EL Heated Seat

IATS EC Intake Air Temperature Sensor

IGN/SG EC Ignition Signal

ILL EL Illumination

INJECT EC Injector

INT/L EL Interior, Spot, Vanity Mirror, and

Luggage Room Lamps

IVC-L EC Intake Valve Timing Control Sole-

noid Valve LH

IVC-R EC Intake Valve Timing Control Sole-

noid Valve RH

IVCS EL INFINITI Communicator

IVCS-L EC Intake Valve Timing Control Posi-

tion Sensor LH

IVCS-R EC Intake Valve Timing Control Posi-

tion Sensor RH

KS EC Knock Sensor

LAN AT A/T Communication Line

LOAD EC Electrical Load Signal

LPSV AT Line Pressure Solenoid Valve

MAFS EC Mass Air Flow Sensor

MAIN AT Main Power Supply and Ground

Circuit

MAIN EC Main Power Supply and Ground

Circuit

METER EL Speedometer, Tachometer, Temp.,

Oil, and Fuel Gauges

MIL/DL EC MIL and Data Link Connectors

MIRROR EL Door Mirror

MULTI EL Multi-remote Control System

NATS EL IVIS (Infiniti Vehicle Immobiliser

System)

GI

MA

EM

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

IDX

WIRING DIAGRAM CODES (CELL CODES)

EL-457

Page 1643 of 2395

Code Section Wiring Diagram Name

NAVI EL Navigation System

NONDTC AT Non-detectable Items

O2H1B1 EC Heated Oxygen Sensor 1 Heater

(Front) (Bank 1)

O2H1B2 EC Heated Oxygen Sensor 1 Heater

(Front) (Bank 2)

O2H2B1 EC Heated Oxygen Sensor 2 Heater

(Rear) (Bank 1)

O2H2B2 EC Heated Oxygen Sensor 2 Heater

(Rear) (Bank 2)

O2S1B1 EC Heated Oxygen Sensor 1 (Front)

(Bank 1)

O2S1B2 EC Heated Oxygen Sensor 1 (Front)

(Bank 2)

O2S2B1 EC Heated Oxygen Sensor 2 (Rear)

(Bank 1)

O2S2B2 EC Heated Oxygen Sensor 2 (Rear)

(Bank 2)

OVRCSV AT Overrun Clutch Solenoid Valve

P/ANT EL Power Antenna

PGC/V EC EVAP Canister Purge Volume

Control Solenoid Valve

PHASE EC Camshaft Position Sensor

(PHASE)

PNP/SW EC Park/Neutral Position Switch

PNP/SW AT Park/Neutral Position Switch

POS EC Crankshaft Position Sensor

(CKPS) (POS)

POWER EL Power Supply Routing

PRE/SE EC EVAP Control System Pressure

Sensor

PST/SW EC Power Steering Oil Pressure

Switch

REF EC Crankshaft Position Sensor

(CKPS) (REF)

REMOTE EL Audio (Remote Control Switch)

RP/SEN EC Refrigerant Pressure

S/SIG EC Start Signal

S/VCSW EC Swirl Control Valve Control

Vacuum Check Switch

SEAT EL Power Seat

SHIFT AT A/T Shift Lock System

SROOF EL Sunroof

SRS RS Supplemental Restraint SystemCode Section Wiring Diagram Name

SSV/A AT Shift Solenoid Valve A

SSV/B AT Shift Solenoid Valve B

START SC Starting System

STOP/L EL Stop lamp

SWL/V EC Swirl Control Valve Control Sole-

noid Valve

TAIL/L EL Parking, License and Tail Lamps

TCCSIG AT A/T TCC Signal (Lock up)

TCV AT Torque Converter Clutch Solenoid

Valve

T/F TF Transfer

TFTS EC Tank Fuel Temperature Sensor

THEFT EL Theft Warning System

TLID EL Glass Hatch Opener

TP/SW EC Throttle Position Switch

TPS AT Throttle Position Sensor

TPS EC Throttle Position Sensor

TRNSMT EL Integrated HOMELINKYTrans-

mitter

TRSA/T AT Turbine Revolution Sensor

TURN EL Turn Signal and Hazard Warning

Lamps

VIAS/V EC Variable Induction Air Control Sys-

tem

VSS EC Vehicle Speed Sensor

VSSA/T AT Vehicle Speed Sensor A/T (Revo-

lution Sensor)

VSSMTR AT Vehicle Speed Sensor MTR

WARN EL Warning Lamps

WINDOW EL Power Window

WIP/R EL Rear Wiper and Washer

WIPER EL Front Wiper and Washer

WIRING DIAGRAM CODES (CELL CODES)

EL-458

Page 1644 of 2395

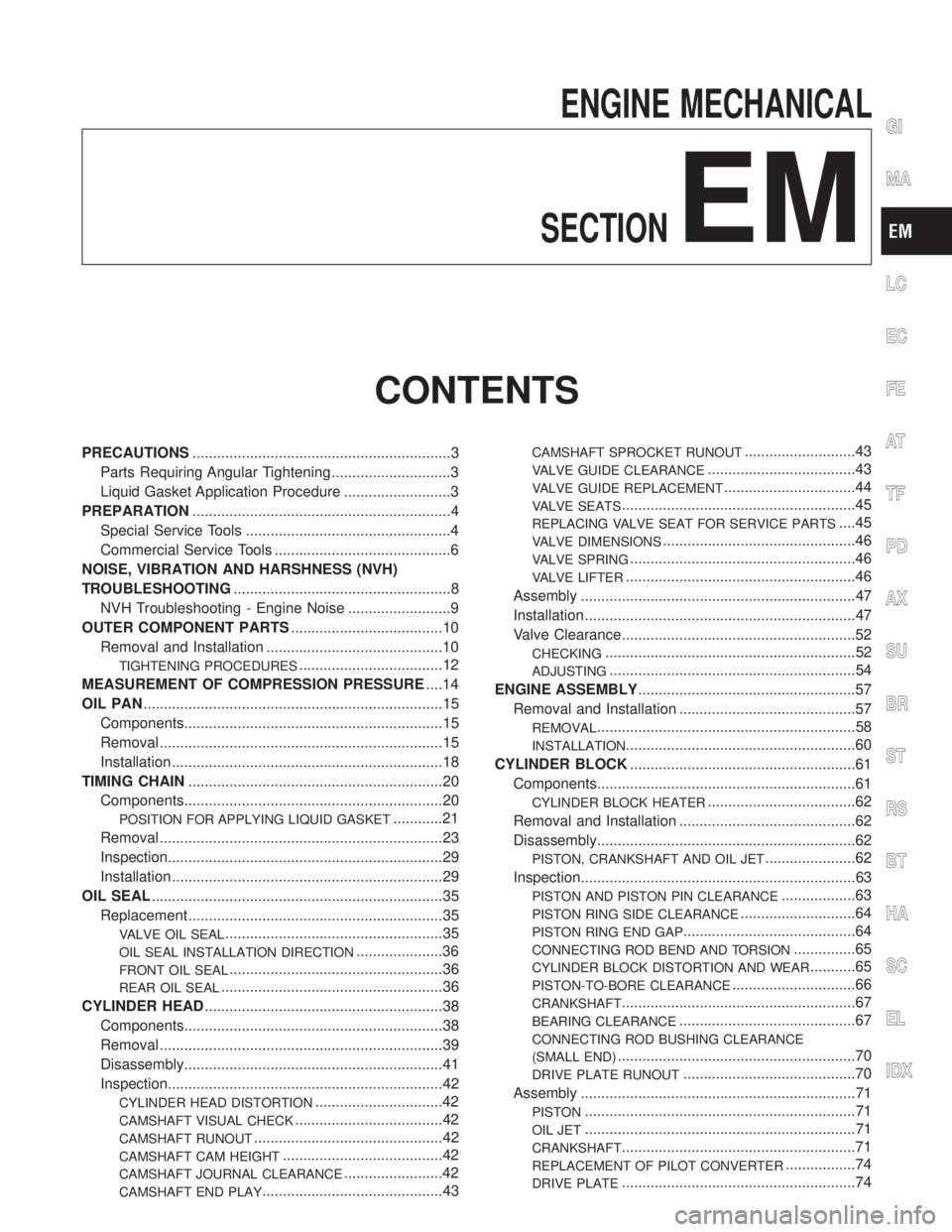

ENGINE MECHANICAL

SECTION

EM

CONTENTS

PRECAUTIONS...............................................................3

Parts Requiring Angular Tightening .............................3

Liquid Gasket Application Procedure ..........................3

PREPARATION...............................................................4

Special Service Tools ..................................................4

Commercial Service Tools ...........................................6

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................8

NVH Troubleshooting - Engine Noise .........................9

OUTER COMPONENT PARTS.....................................10

Removal and Installation ...........................................10

TIGHTENING PROCEDURES...................................12

MEASUREMENT OF COMPRESSION PRESSURE....14

OIL PAN.........................................................................15

Components...............................................................15

Removal .....................................................................15

Installation ..................................................................18

TIMING CHAIN..............................................................20

Components...............................................................20

POSITION FOR APPLYING LIQUID GASKET............21

Removal .....................................................................23

Inspection...................................................................29

Installation ..................................................................29

OIL SEAL.......................................................................35

Replacement ..............................................................35

VALVE OIL SEAL.....................................................35

OIL SEAL INSTALLATION DIRECTION.....................36

FRONT OIL SEAL....................................................36

REAR OIL SEAL......................................................36

CYLINDER HEAD..........................................................38

Components...............................................................38

Removal .....................................................................39

Disassembly...............................................................41

Inspection...................................................................42

CYLINDER HEAD DISTORTION...............................42

CAMSHAFT VISUAL CHECK....................................42

CAMSHAFT RUNOUT..............................................42

CAMSHAFT CAM HEIGHT.......................................42

CAMSHAFT JOURNAL CLEARANCE........................42

CAMSHAFT END PLAY............................................43

CAMSHAFT SPROCKET RUNOUT...........................43

VALVE GUIDE CLEARANCE....................................43

VALVE GUIDE REPLACEMENT................................44

VALVE SEATS.........................................................45

REPLACING VALVE SEAT FOR SERVICE PARTS....45

VALVE DIMENSIONS...............................................46

VALVE SPRING.......................................................46

VALVE LIFTER........................................................46

Assembly ...................................................................47

Installation ..................................................................47

Valve Clearance.........................................................52

CHECKING.............................................................52

ADJUSTING............................................................54

ENGINE ASSEMBLY.....................................................57

Removal and Installation ...........................................57

REMOVAL...............................................................58

INSTALLATION........................................................60

CYLINDER BLOCK.......................................................61

Components...............................................................61

CYLINDER BLOCK HEATER....................................62

Removal and Installation ...........................................62

Disassembly...............................................................62

PISTON, CRANKSHAFT AND OIL JET......................62

Inspection...................................................................63

PISTON AND PISTON PIN CLEARANCE..................63

PISTON RING SIDE CLEARANCE............................64

PISTON RING END GAP..........................................64

CONNECTING ROD BEND AND TORSION...............65

CYLINDER BLOCK DISTORTION AND WEAR...........65

PISTON-TO-BORE CLEARANCE..............................66

CRANKSHAFT.........................................................67

BEARING CLEARANCE...........................................67

CONNECTING ROD BUSHING CLEARANCE

(SMALL END)

..........................................................70

DRIVE PLATE RUNOUT..........................................70

Assembly ...................................................................71

PISTON..................................................................71

OIL JET..................................................................71

CRANKSHAFT.........................................................71

REPLACEMENT OF PILOT CONVERTER.................74

DRIVE PLATE.........................................................74

GI

MA

LC

EC

FE

AT

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

Page 1653 of 2395

Removal and InstallationNBEM0006

SEM483G

1. Intake manifold collector support

2. Lower intake manifold collector

3. Fuel damper and fuel feed hose

assembly

4. Injector

5. Fuel tube assembly6. Fuel pressure regulator

7. Ignition coil with power transistor

8. Upper intake manifold collector

9. Intake manifold

10. Throttle body11. IACV-AAC valve

12. EVAP canister purge volume con-

trol solenoid valve

13. Swirl control valve

14. Variable induction air control valve

control actuator

OUTER COMPONENT PARTS

Removal and Installation

EM-10