fuel pressure INFINITI QX4 2005 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2005, Model line: QX4, Model: INFINITI QX4 2005Pages: 3419, PDF Size: 80.18 MB

Page 1110 of 3419

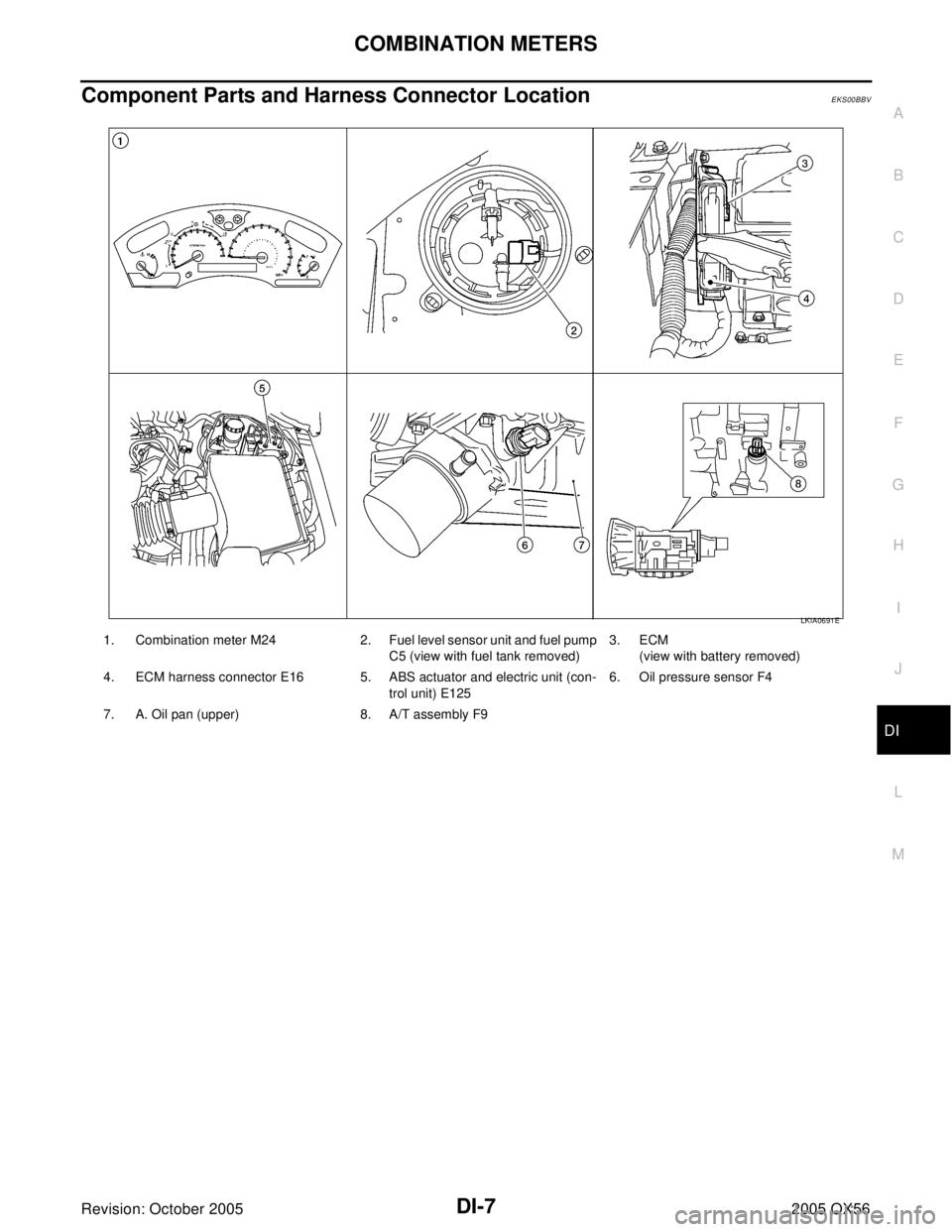

COMBINATION METERS

DI-7

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: October 20052005 QX56

Component Parts and Harness Connector LocationEKS00BBV

1. Combination meter M24 2. Fuel level sensor unit and fuel pump

C5 (view with fuel tank removed)3. ECM

(view with battery removed)

4. ECM harness connector E16 5. ABS actuator and electric unit (con-

trol unit) E1256. Oil pressure sensor F4

7. A. Oil pan (upper) 8. A/T assembly F9

LKIA0691E

Page 1115 of 3419

DI-12

COMBINATION METERS

Revision: October 20052005 QX56

Terminals and Reference Value for Combination MeterEKS00BBZ

Te r m i n a l

No.Wire

colorItemCondition

Reference value (V)

(Approx.) Ignition

switchOperation or condition

1OIgnition switch ACC or

ONACC — Battery voltage

8 Y/R Battery power supply OFF — Battery voltage

11 L C A N - H — — —

12 P CAN-L — — —

15 Y/L Fuel level sensor signal — —Refer to DI-22, "

Fuel Level Sensor

Unit Inspection" .

16 B/PFuel level sensor and oil

pressure sensor groundON — 0V

17 B Ground OFF — 0V

18 BR Illumination control switch — Lighting switch ONRefer to LT-153, "

ILLUMINATION

OPERATION BY LIGHTING

SWITCH" .

20 YOil pressure sensor sig-

nalON — 0 - 5V

22 GR/LOil pressure sensor refer-

ence voltageON — 5V

24 O/LIgnition switch ON or

STARTON — Battery voltage

Page 1117 of 3419

DI-14

COMBINATION METERS

Revision: October 20052005 QX56

Next test requested Sc1XXDisplays 8-bit software

configuration value in Hex

format.Bit Coding

7-3 = reserved for future use

2 = TCS/VDC 0 = not present

1 = present

1 = Shift type 0 = Column shift

1 = Floor shift

0 = ICC 0 = not present

1 = present

Next test requested Sc2XXDisplays 8-bit software

configuration value in Hex

format.Bit coding

7-0 = Reserved for future use

Next test requested EprXXDisplays 8-bit software

configuration value in Hex

format.Bit Coding

7-2 = reserved for future use

1 = A/T Oil Temp (gauge)

0 = not present

1 = present

1 = Odo Units 0 = kilometers

1 = miles

Next test requested 1nFXXDisplays 8-bit market info

value in Hex format.$31 = USA

$2A = Canada

$0E = GCC

Next test requested cYLXXDisplays 8-bit engine con-

figuration value in Hex

format.$08 = 8 cylinder

$06 = 6 cylinder

Next test requested FFXXXXDisplays 16-bit fuel flow

constant "Q" in tenths of

cc/min in Hex format.$0000 - $FFFF

Next test requested tFDisplays 16-bit tire factor

"A" in hundredths in Hex

format.$0000 - $FFFF

Next test requested ot1XXDisplays oil pressure tell-

tale "on" threshold in A/D

counts in Hex format.$00 - $FF

Next test requested ot0XXDisplays oil pressure tell-

tale "off" threshold in A/D

counts in Hex format.$00 - $FF

Next test requested XXXXXRaw uncompensated

english speed value in

hundredths of MPH.

Speedometer indicates

present speed.Will display "-----" if message is

not received. Will display

"99999" if data received is

invalid

Next test requested XXXXXRaw uncompensated

metric speed value in

hundredths of KPH.

Speedometer indicates

present speed.Will display "-----" if message is

not received. Will display

"99999" if data received is

invalid

Next test requested tXXXXTachometer value in

RPM. Tachometer indi-

cates present RPM.Will display "-----" if message is

not received.

Next test requested F1 XXXXPresent ratioed fuel level

A/D input 1 in decimal for-

mat. Fuel gauge indicates

present filtered level.000-009 = Short circuit

010-254 = Normal range

255 = Open circuit

--- = Missing 5 seconds

Next test requested XXXCLast temperature gauge

input value in degrees C.

Temperature gauge indi-

cates present filtered tem-

perature.Will display "---"C if message is

not received.

Will display "999" if data

received is invalid. Event Odometer Display Description of Test/Data Notes:

Page 1122 of 3419

COMBINATION METERS

DI-19

C

D

E

F

G

H

I

J

L

MA

B

DI

Revision: October 20052005 QX56

Symptom ChartEKS00BC4

Vehicle Speed Signal InspectionEKS00BC5

1. CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) SELF-DIAGNOSIS

Refer to BRC-29, "

SELF-DIAGNOSIS" .

OK or NG

OK >> Replace the combination meter. Refer to IP-13, "Combination Meter" .

NG >> Perform the "Diagnostic Procedure" for displayed DTC. Refer to BRC-11, "

TROUBLE DIAGNO-

SIS" .

Engine Oil Pressure Signal Inspection EKS00BC6

1. CHECK OIL PRESSURE SENSOR SIGNAL

1. Turn ignition switch ON.

2. Check voltage between combination meter harness connector

M24 terminal 20 (Y) and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

Trouble phenomenon Possible cause

Improper tachometer indication. Refer to DI-21, "

Engine Speed Signal Inspection" .

Improper water temperature gauge indication. Refer to DI-21, "

Water Temperature Signal Inspection" .

Improper speedometer or odometer. Refer to DI-19, "

Vehicle Speed Signal Inspection" .

Improper fuel gauge indication.

Refer to DI-22, "

Fuel Level Sensor Unit Inspection" .

Fuel warning lamp indication is irregular.

Improper A/T oil temperature gauge indicationRefer to AT-126, "

DTC P1710 A/T FLUID TEMPERATURE SEN-

SOR CIRCUIT" .

Improper voltage gauge indication

Replace combination meter. Refer to IP-13, "

Combination Meter"

.

More than one gauge does not give proper indication.

Improper A/T position indication. Refer to DI-40, "

A/T INDICATOR" .

Illumination control does not operate properly. Refer to LT-152, "

ILLUMINATION" .

Te r m i n a l s

Condition Voltage (V) (+)

(–)

ConnectorTe r m i n a l

(Wire color)

M24 20 (Y) GroundWhen ignition switch is in ON

position. (Engine stopped)Ye s

Engine running. (Idle speed) Yes

WKIA1833E

Page 1192 of 3419

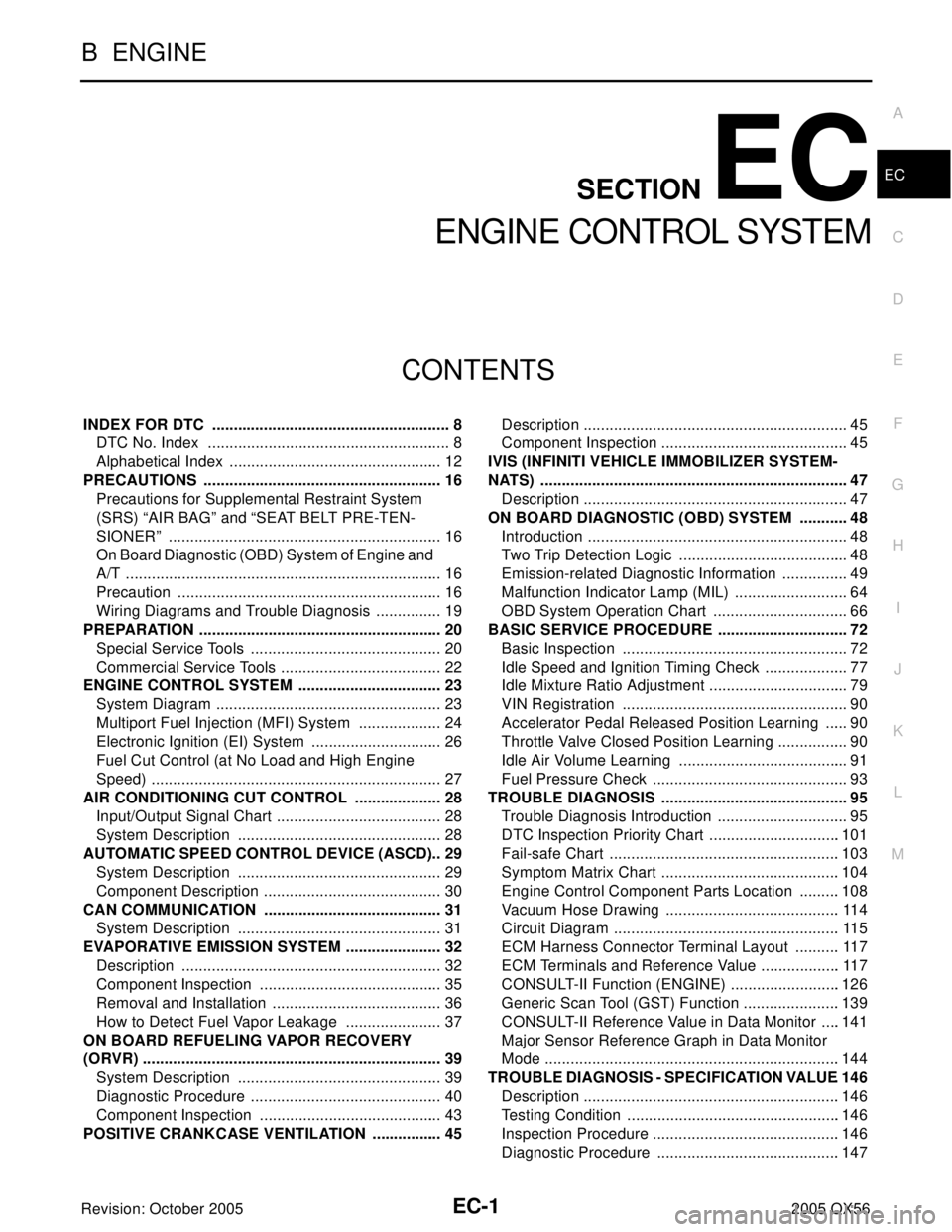

EC-1

ENGINE CONTROL SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION EC

A

EC

Revision: October 20052005 QX56 INDEX FOR DTC ........................................................ 8

DTC No. Index ......................................................... 8

Alphabetical Index .................................................. 12

PRECAUTIONS ........................................................ 16

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” ................................................................ 16

On Board Diagnostic (OBD) System of Engine and

A/T .......................................................................... 16

Precaution .............................................................. 16

Wiring Diagrams and Trouble Diagnosis ................ 19

PREPARATION ......................................................... 20

Special Service Tools ............................................. 20

Commercial Service Tools ...................................... 22

ENGINE CONTROL SYSTEM .................................. 23

System Diagram ..................................................... 23

Multiport Fuel Injection (MFI) System .................... 24

Electronic Ignition (EI) System ............................... 26

Fuel Cut Control (at No Load and High Engine

Speed) .................................................................... 27

AIR CONDITIONING CUT CONTROL ..................... 28

Input/Output Signal Chart ....................................... 28

System Description ................................................ 28

AUTOMATIC SPEED CONTROL DEVICE (ASCD) ... 29

System Description ................................................ 29

Component Description .......................................... 30

CAN COMMUNICATION .......................................... 31

System Description ................................................ 31

EVAPORATIVE EMISSION SYSTEM ....................... 32

Description ............................................................. 32

Component Inspection ........................................... 35

Removal and Installation ........................................ 36

How to Detect Fuel Vapor Leakage ....................... 37

ON BOARD REFUELING VAPOR RECOVERY

(ORVR) ...................................................................... 39

System Description ................................................ 39

Diagnostic Procedure ............................................. 40

Component Inspection ........................................... 43

POSITIVE CRANKCASE VENTILATION ................. 45Description .............................................................. 45

Component Inspection ............................................ 45

IVIS (INFINITI VEHICLE IMMOBILIZER SYSTEM-

NATS) ........................................................................ 47

Description .............................................................. 47

ON BOARD DIAGNOSTIC (OBD) SYSTEM ............ 48

Introduction ............................................................. 48

Two Trip Detection Logic ........................................ 48

Emission-related Diagnostic Information ................ 49

Malfunction Indicator Lamp (MIL) ........................... 64

OBD System Operation Chart ................................ 66

BASIC SERVICE PROCEDURE ............................... 72

Basic Inspection ..................................................... 72

Idle Speed and Ignition Timing Check .................... 77

Idle Mixture Ratio Adjustment ................................. 79

VIN Registration ..................................................... 90

Accelerator Pedal Released Position Learning ...... 90

Throttle Valve Closed Position Learning ................. 90

Idle Air Volume Learning ........................................ 91

Fuel Pressure Check .............................................. 93

TROUBLE DIAGNOSIS ............................................ 95

Trouble Diagnosis Introduction ............................... 95

DTC Inspection Priority Chart ...............................101

Fail-safe Chart ......................................................103

Symptom Matrix Chart ..........................................104

Engine Control Component Parts Location ..........108

Vacuum Hose Drawing .........................................114

Circuit Diagram .....................................................115

ECM Harness Connector Terminal Layout ...........117

ECM Terminals and Reference Value ...................117

CONSULT-II Function (ENGINE) ..........................126

Generic Scan Tool (GST) Function .......................139

CONSULT-II Reference Value in Data Monitor .....141

Major Sensor Reference Graph in Data Monitor

Mode .....................................................................144

TROUBLE DIAGNOSIS - SPECIFICATION VALUE .146

Description ............................................................146

Testing Condition ..................................................146

Inspection Procedure ............................................146

Diagnostic Procedure ...........................................147

Page 1194 of 3419

EC-3

C

D

E

F

G

H

I

J

K

L

M

ECA

Revision: October 20052005 QX56 DTC P0172, P0175 FUEL INJECTION SYSTEM

FUNCTION .............................................................. 245

On Board Diagnosis Logic ................................... 245

DTC Confirmation Procedure ............................... 245

Wiring Diagram .................................................... 247

Diagnostic Procedure ........................................... 249

DTC P0181 FTT SENSOR ...................................... 253

Component Description ........................................ 253

On Board Diagnosis Logic ................................... 253

DTC Confirmation Procedure ............................... 253

Wiring Diagram .................................................... 255

Diagnostic Procedure ........................................... 256

Component Inspection ......................................... 258

Removal and Installation ...................................... 258

DTC P0182, P0183 FTT SENSOR ......................... 259

Component Description ........................................ 259

On Board Diagnosis Logic ................................... 259

DTC Confirmation Procedure ............................... 259

Wiring Diagram .................................................... 260

Diagnostic Procedure ........................................... 261

Component Inspection ......................................... 263

Removal and Installation ...................................... 263

DTC P0222, P0223 TP SENSOR ........................... 264

Component Description ........................................ 264

CONSULT-II Reference Value in Data Monitor Mode

. 264

On Board Diagnosis Logic ................................... 264

DTC Confirmation Procedure ............................... 265

Wiring Diagram .................................................... 266

Diagnostic Procedure ........................................... 267

Component Inspection ......................................... 270

Removal and Installation ...................................... 270

DTC P0300 - P0308 MULTIPLE CYLINDER MIS-

FIRE, NO. 1 - 8 CYLINDER MISFIRE ..................... 271

On Board Diagnosis Logic ................................... 271

DTC Confirmation Procedure ............................... 271

Diagnostic Procedure ........................................... 272

DTC P0327, P0328, P0332, P0333 KS .................. 279

Component Description ........................................ 279

On Board Diagnosis Logic ................................... 279

DTC Confirmation Procedure ............................... 279

Wiring Diagram .................................................... 280

Diagnostic Procedure ........................................... 281

Component Inspection ......................................... 283

Removal and Installation ...................................... 283

DTC P0335 CKP SENSOR (POS) .......................... 284

Component Description ........................................ 284

CONSULT-II Reference Value in Data Monitor Mode

. 284

On Board Diagnosis Logic ................................... 284

DTC Confirmation Procedure ............................... 284

Wiring Diagram .................................................... 286

Diagnostic Procedure ........................................... 287

Component Inspection ......................................... 290

Removal and Installation ...................................... 290

DTC P0340 CMP SENSOR (PHASE) ..................... 291

Component Description ........................................ 291

On Board Diagnosis Logic ................................... 291

DTC Confirmation Procedure ............................... 291Wiring Diagram .....................................................293

Diagnostic Procedure ...........................................294

Component Inspection ..........................................297

Removal and Installation ......................................297

DTC P0420, P0430 THREE WAY CATALYST FUNC-

TION ........................................................................298

On Board Diagnosis Logic ....................................298

DTC Confirmation Procedure ...............................298

Overall Function Check ........................................299

Diagnostic Procedure ...........................................300

DTC P0441 EVAP CONTROL SYSTEM .................304

System Description ...............................................304

On Board Diagnosis Logic ....................................304

DTC Confirmation Procedure ...............................304

Overall Function Check ........................................305

Diagnostic Procedure ...........................................306

DTC P0442 EVAP CONTROL SYSTEM .................309

On Board Diagnosis Logic ....................................309

DTC Confirmation Procedure ...............................310

Diagnostic Procedure ...........................................311

DTC P0444, P0445 EVAP CANISTER PURGE VOL-

UME CONTROL SOLENOID VALVE ......................318

Description ............................................................318

CONSULT-II Reference Value in Data Monitor Mode

.318

On Board Diagnosis Logic ....................................319

DTC Confirmation Procedure ...............................319

Wiring Diagram .....................................................320

Diagnostic Procedure ...........................................322

Component Inspection ..........................................323

Removal and Installation ......................................324

DTC P0447 EVAP CANISTER VENT CONTROL

VALVE .....................................................................325

Component Description ........................................325

CONSULT-II Reference Value in Data Monitor Mode

.325

On Board Diagnosis Logic ....................................325

DTC Confirmation Procedure ...............................326

Wiring Diagram .....................................................327

Diagnostic Procedure ...........................................328

Component Inspection ..........................................330

DTC P0451 EVAP CONTROL SYSTEM PRESSURE

SENSOR .................................................................332

Component Description ........................................332

CONSULT-II Reference Value in Data Monitor Mode

.332

On Board Diagnosis Logic ....................................332

DTC Confirmation Procedure ...............................333

Diagnostic Procedure ...........................................333

Component Inspection ..........................................334

DTC P0452 EVAP CONTROL SYSTEM PRESSURE

SENSOR .................................................................335

Component Description ........................................335

CONSULT-II Reference Value in Data Monitor Mode

.335

On Board Diagnosis Logic ....................................335

DTC Confirmation Procedure ...............................336

Wiring Diagram .....................................................337

Page 1195 of 3419

EC-4Revision: October 20052005 QX56 Diagnostic Procedure ...........................................338

Component Inspection ..........................................340

DTC P0453 EVAP CONTROL SYSTEM PRESSURE

SENSOR ..................................................................341

Component Description ........................................341

CONSULT-II Reference Value in Data Monitor Mode

.341

On Board Diagnosis Logic ....................................341

DTC Confirmation Procedure ...............................342

Wiring Diagram .....................................................343

Diagnostic Procedure ...........................................344

Component Inspection ..........................................348

DTC P0455 EVAP CONTROL SYSTEM .................349

On Board Diagnosis Logic ....................................349

DTC Confirmation Procedure ...............................350

Diagnostic Procedure ...........................................351

DTC P0456 EVAP CONTROL SYSTEM .................357

On Board Diagnosis Logic ....................................357

DTC Confirmation Procedure ...............................358

Overall Function Check ........................................359

Diagnostic Procedure ...........................................360

DTC P0460 FUEL LEVEL SENSOR .......................366

Component Description ........................................366

On Board Diagnosis Logic ....................................366

DTC Confirmation Procedure ...............................366

Diagnostic Procedure ...........................................367

Removal and Installation ......................................367

DTC P0461 FUEL LEVEL SENSOR .......................368

Component Description ........................................368

On Board Diagnosis Logic ....................................368

Overall Function Check ........................................368

Diagnostic Procedure ...........................................369

Removal and Installation ......................................369

DTC P0462, P0463 FUEL LEVEL SENSOR CIR-

CUIT ........................................................................370

Component Description ........................................370

On Board Diagnosis Logic ....................................370

DTC Confirmation Procedure ...............................370

Diagnostic Procedure ...........................................371

Removal and Installation ......................................371

DTC P0500 VSS ......................................................372

Description ............................................................372

On Board Diagnosis Logic ....................................372

DTC Confirmation Procedure ...............................372

Overall Function Check ........................................372

Diagnostic Procedure ...........................................373

DTC P0506 ISC SYSTEM .......................................374

Description ............................................................374

On Board Diagnosis Logic ....................................374

DTC Confirmation Procedure ...............................374

Diagnostic Procedure ...........................................375

DTC P0507 ISC SYSTEM .......................................376

Description ............................................................376

On Board Diagnosis Logic ....................................376

DTC Confirmation Procedure ...............................376

Diagnostic Procedure ...........................................377

DTC P0550 PSP SENSOR ......................................378

Component Description ........................................378

CONSULT-II Reference Value in Data Monitor Mode . 378

On Board Diagnosis Logic .................................... 378

DTC Confirmation Procedure ................................ 378

Wiring Diagram ..................................................... 379

Diagnostic Procedure ............................................ 380

Component Inspection .......................................... 382

Removal and Installation ....................................... 382

DTC P0605 ECM ..................................................... 383

Component Description ........................................ 383

On Board Diagnosis Logic .................................... 383

DTC Confirmation Procedure ................................ 383

Diagnostic Procedure ............................................ 384

DTC P1031, P1032, P1051, P1052 A/F SENSOR 1

HEATER ................................................................... 386

Description ............................................................ 386

CONSULT-II Reference Value in Data Monitor Mode

. 386

On Board Diagnosis Logic .................................... 386

DTC Confirmation Procedure ................................ 386

Wiring Diagram ..................................................... 387

Diagnostic Procedure ............................................ 390

Component Inspection .......................................... 392

Removal and Installation ....................................... 392

DTC P1065 ECM POWER SUPPLY ........................ 393

Component Description ........................................ 393

On Board Diagnosis Logic .................................... 393

DTC Confirmation Procedure ................................ 393

Wiring Diagram ..................................................... 394

Diagnostic Procedure ............................................ 395

DTC P1121 ELECTRIC THROTTLE CONTROL

ACTUATOR ............................................................. 397

Component Description ........................................ 397

On Board Diagnosis Logic .................................... 397

DTC Confirmation Procedure ................................ 397

Diagnostic Procedure ............................................ 398

DTC P1122 ELECTRIC THROTTLE CONTROL

FUNCTION .............................................................. 399

Description ............................................................ 399

On Board Diagnosis Logic .................................... 399

DTC Confirmation Procedure ................................ 399

Wiring Diagram ..................................................... 400

Diagnostic Procedure ............................................ 401

Component Inspection .......................................... 404

Removal and Installation ....................................... 404

DTC P1124, P1126 THROTTLE CONTROL MOTOR

RELAY ..................................................................... 405

Component Description ........................................ 405

CONSULT-II Reference Value in Data Monitor Mode

. 405

On Board Diagnosis Logic .................................... 405

DTC Confirmation Procedure ................................ 405

Wiring Diagram ..................................................... 407

Diagnostic Procedure ............................................ 408

DTC P1128 THROTTLE CONTROL MOTOR ......... 410

Component Description ........................................ 410

On Board Diagnosis Logic .................................... 410

DTC Confirmation Procedure ................................ 410

Wiring Diagram .....................................................411

Diagnostic Procedure ............................................ 412

Page 1198 of 3419

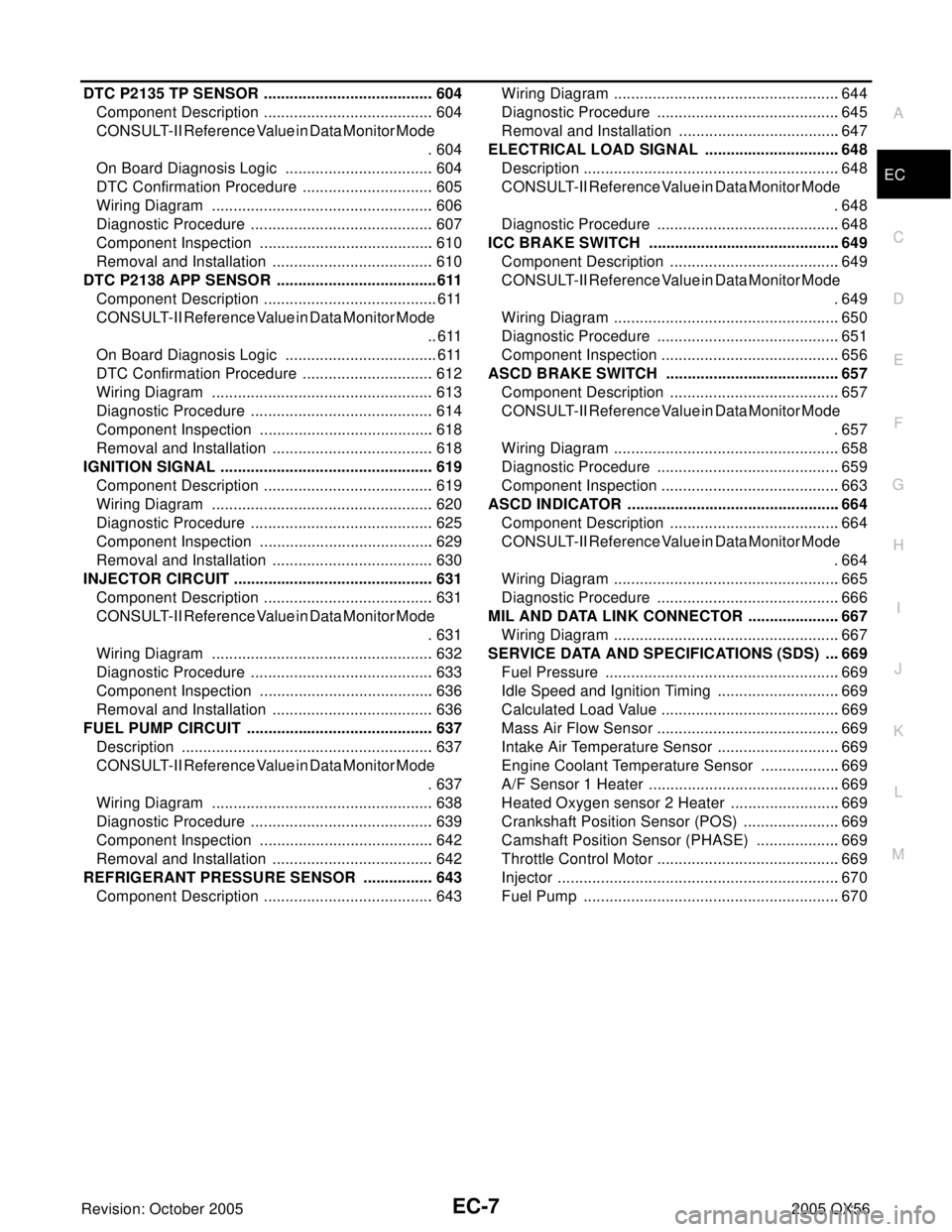

EC-7

C

D

E

F

G

H

I

J

K

L

M

ECA

Revision: October 20052005 QX56 DTC P2135 TP SENSOR ........................................ 604

Component Description ........................................ 604

CONSULT-II Reference Value in Data Monitor Mode

. 604

On Board Diagnosis Logic ................................... 604

DTC Confirmation Procedure ............................... 605

Wiring Diagram .................................................... 606

Diagnostic Procedure ........................................... 607

Component Inspection ......................................... 610

Removal and Installation ...................................... 610

DTC P2138 APP SENSOR ...................................... 611

Component Description ......................................... 611

CONSULT-II Reference Value in Data Monitor Mode

.. 611

On Board Diagnosis Logic .................................... 611

DTC Confirmation Procedure ............................... 612

Wiring Diagram .................................................... 613

Diagnostic Procedure ........................................... 614

Component Inspection ......................................... 618

Removal and Installation ...................................... 618

IGNITION SIGNAL .................................................. 619

Component Description ........................................ 619

Wiring Diagram .................................................... 620

Diagnostic Procedure ........................................... 625

Component Inspection ......................................... 629

Removal and Installation ...................................... 630

INJECTOR CIRCUIT ............................................... 631

Component Description ........................................ 631

CONSULT-II Reference Value in Data Monitor Mode

. 631

Wiring Diagram .................................................... 632

Diagnostic Procedure ........................................... 633

Component Inspection ......................................... 636

Removal and Installation ...................................... 636

FUEL PUMP CIRCUIT ............................................ 637

Description ........................................................... 637

CONSULT-II Reference Value in Data Monitor Mode

. 637

Wiring Diagram .................................................... 638

Diagnostic Procedure ........................................... 639

Component Inspection ......................................... 642

Removal and Installation ...................................... 642

REFRIGERANT PRESSURE SENSOR ................. 643

Component Description ........................................ 643Wiring Diagram .....................................................644

Diagnostic Procedure ...........................................645

Removal and Installation ......................................647

ELECTRICAL LOAD SIGNAL ................................648

Description ............................................................648

CONSULT-II Reference Value in Data Monitor Mode

.648

Diagnostic Procedure ...........................................648

ICC BRAKE SWITCH .............................................649

Component Description ........................................649

CONSULT-II Reference Value in Data Monitor Mode

.649

Wiring Diagram .....................................................650

Diagnostic Procedure ...........................................651

Component Inspection ..........................................656

ASCD BRAKE SWITCH .........................................657

Component Description ........................................657

CONSULT-II Reference Value in Data Monitor Mode

.657

Wiring Diagram .....................................................658

Diagnostic Procedure ...........................................659

Component Inspection ..........................................663

ASCD INDICATOR ..................................................664

Component Description ........................................664

CONSULT-II Reference Value in Data Monitor Mode

.664

Wiring Diagram .....................................................665

Diagnostic Procedure ...........................................666

MIL AND DATA LINK CONNECTOR ......................667

Wiring Diagram .....................................................667

SERVICE DATA AND SPECIFICATIONS (SDS) ....669

Fuel Pressure .......................................................669

Idle Speed and Ignition Timing .............................669

Calculated Load Value ..........................................669

Mass Air Flow Sensor ...........................................669

Intake Air Temperature Sensor .............................669

Engine Coolant Temperature Sensor ...................669

A/F Sensor 1 Heater .............................................669

Heated Oxygen sensor 2 Heater ..........................669

Crankshaft Position Sensor (POS) .......................669

Camshaft Position Sensor (PHASE) ....................669

Throttle Control Motor ...........................................669

Injector ..................................................................670

Fuel Pump ............................................................670

Page 1211 of 3419

EC-20Revision: October 2005

PREPARATION

2005 QX56

PREPARATIONPFP:00002

Special Service ToolsUBS00KZ4

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Tool number

(Kent-Moore No.)

Tool nameDescription

EG17650301

(J-33984-A)

Radiator cap tester

adapterAdapting radiator cap tester to radiator cap and ra-

diator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

KV10117100

(J-36471-A)

Heated oxygen sensor

wrenchLoosening or tightening heated oxygen sensors

with 22 mm (0.87 in) hexagon nut

KV10114400

(J-38365)

Heated oxygen sensor

wrenchLoosening or tightening heated oxygen sensors

a: 22 mm (0.87 in)

(J-44626)

Air fuel ratio (A/F) sen-

sor wrenchLoosening or tightening air fuel ratio (A/F) sensor 1

(J-44321)

Fuel pressure gauge

kitChecking fuel pressure

(J-44321-6)

Fuel pressure adapterConnecting fuel pressure gauge to quick connec-

tor type fuel lines.

(J-45488)

Quick connector re-

leaseRemove fuel tube quick connectors in engine

room.

S-NT564

S-NT379

S-NT636

LEM054

LEC642

LBIA0376E

PBIC0198E

Page 1213 of 3419

EC-22Revision: October 2005

PREPARATION

2005 QX56

Commercial Service ToolsUBS00KZ5

Tool name

(Kent-Moore No.)Description

Leak detector

i.e.: (J-41416)Locating the EVAP leak

EVAP service port

adapter

i.e.: (J-41413-OBD)Applying positive pressure through EVAP service

port

Fuel filler cap adapter

i.e.: (MLR-8382)Checking fuel tank vacuum relief valve opening

pressure

Socket wrench Removing and installing engine coolant tempera-

ture sensor

Oxygen sensor thread

cleaner

i.e.: (J-43897-18)

(J-43897-12)Reconditioning the exhaust system threads before

installing a new oxygen sensor. Use with anti-

seize lubricant shown below.

a: 18 mm diameter with pitch 1.5 mm for Zirco-

nia Oxygen Sensor

b: 12 mm diameter with pitch 1.25 mm for Tita-

nia Oxygen Sensor

Anti-seize lubricant

i.e.: (Permatex

TM

133AR or equivalent

meeting MIL specifica-

tion MIL-A-907)Lubricating oxygen sensor thread cleaning tool

when reconditioning exhaust system threads.

S-NT703

S-NT704

S-NT815

S-NT705

AEM488

S-NT779