air condition INFINITI QX56 2007 Factory Owners Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 268 of 3061

AT-198

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

1. Turn ignition switch “ON”.

2. Select "ECU INPUT SIGNALS" in "DATA MONITOR" mode for

"A/T" with CONSULT-II.

3. Read out "1 POSITION SW" switch moving selector lever to

each position.

Without CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine)

2. Check voltage between A/T device harness connector terminal

and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK A/T FLUID LEVEL

Check the A/T fluid level. Refer to AT-13, "

Checking Automatic

Transmission Fluid (ATF)".

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4.CHECK CONTROL CABLE

Check the control cable.

• Refer to AT-208, "

Checking of A/T Position".

OK or NG

OK >> GO TO 5.

NG >> Adjust control cable. Refer to AT-208, "

Adjustment of A/

T Position".

5.CHECK A/T FLUID CONDITION

Monitor item Condition Display value

1 POSITION SWWhen setting the selector

lever to "1" position.ON

When setting selector le-

ver to other positions.OFF

LCIA0339E

Item Connector No. Terminal No. ConditionData

(Approx.)

1st position

switchM203 7 - GroundWhen setting

the selector le-

ver to "1" posi-

tion.0V

When setting

selector lever

to other posi-

tions.Battery volt-

age

LCIA0341E

SAT638A

LCIA0345E

Page 269 of 3061

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-199

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

1. Remove oil pan. Refer to AT-210, "Control Valve with TCM and A/T Fluid Temperature Sensor 2".

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before

Trouble Diagnosis".

OK or NG

OK >> GO TO 6.

NG >> GO TO 9.

6.DETECT MALFUNCTIONING ITEM

• Check the malfunction items. If any items are damaged, repair or replace damaged parts. Refer to AT-60,

"Symptom Chart" (Symptom No.17).

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK SYMPTOM

Check again. Refer to AT-58, "

Cruise Test - Part 2".

OK or NG

OK >>INSPECTION END

NG >> GO TO 8.

8.PERFORM TCM INSPECTION

1. Perform TCM input/output signals inspection. Refer to AT-82, "

TCM Input/Output Signal Reference

Va l u e".

2. If NG, recheck A/T assembly harness connector terminals for damage or loose connection with harness

connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

9.DETECT MALFUNCTIONING ITEM

• Check the malfunction items. If any items are damaged, repair or replace damaged parts. Refer to AT-60,

"Symptom Chart" (Symptom No.17).

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

Vehicle Does Not Decelerate By Engine BrakeINFOID:0000000003532468

SYMPTOM:

No engine brake is applied when the gear is shifted from the 22 to 11.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSIS RESULTS

Perform self-diagnosis.

Do the self-diagnosis results indicate PNP switch, ATF pressure switch 5?

YES >> Check the malfunctioning system. Refer to AT- 9 9' AT-154.

NO >> GO TO 2.

2.CHECK 1ST POSITION SWITCH CIRCUIT

With CONSULT-II

SCIA5199E

Page 270 of 3061

AT-200

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

1. Turn ignition switch “ON”.

2. Select "ECU INPUT SIGNALS" in "DATA MONITOR" mode for

"A/T" with CONSULT-II.

3. Read out "1 POSITION SW" moving switch selector lever to

each position.

Without CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine)

2. Check voltage between A/T device harness connector terminal

and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK A/T FLUID LEVEL

Check the A/T fluid level. Refer to AT-13, "

Checking Automatic

Transmission Fluid (ATF)".

OK or NG

OK >> GO TO 4.

NG >> Refill ATF.

4.CHECK CONTROL CABLE

Check the control cable.

• Refer to AT-208, "

Checking of A/T Position".

OK or NG

OK >> GO TO 5.

NG >> Adjust control cable. Refer to AT-208, "

Adjustment of A/

T Position".

5.CHECK A/T FLUID CONDITION

Monitor item Condition Display value

1 POSITION SWWhen setting the selector

lever to "1" position.ON

When setting selector le-

ver to other positions.OFF

LCIA0339E

Item Connector No. Terminal No. ConditionData

(Approx.)

1st position

switchM203 7 - GroundWhen setting

the selector le-

ver to "1" posi-

tion.0V

When setting

selector lever

to other posi-

tions.Battery volt-

age

LCIA0341E

SAT638A

LCIA0345E

Page 271 of 3061

TROUBLE DIAGNOSIS FOR SYMPTOMS

AT-201

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

1. Remove oil pan. Refer to AT-210, "Control Valve with TCM and A/T Fluid Temperature Sensor 2".

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before

Trouble Diagnosis".

OK or NG

OK >> GO TO 6.

NG >> GO TO 9.

6.DETECT MALFUNCTIONING ITEM

• Check the malfunction items. If any items are damaged, repair or replace damaged parts. Refer to AT-60,

"Symptom Chart" (Symptom No.53).

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK SYMPTOM

Check again. Refer to AT-59, "

Cruise Test - Part 3".

OK or NG

OK >>INSPECTION END

NG >> GO TO 8.

8.PERFORM TCM INSPECTION

1. Perform TCM input/output signals inspection. Refer to AT-82, "

TCM Input/Output Signal Reference

Va l u e".

2. If NG, recheck A/T assembly harness connector terminals for damage or loose connection with harness

connector.

OK or NG

OK >>INSPECTION END

NG >> Repair or replace damaged parts.

9.DETECT MALFUNCTIONING ITEM

• Check the malfunction items. If any items are damaged, repair or replace damaged parts. Refer to AT-60,

"Symptom Chart" (Symptom No.53).

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

SCIA5199E

Page 371 of 3061

ATC-1

AIR CONDITIONER

C

DE

F

G H

I

K L

M

SECTION AT C

A

B

AT C

N

O P

CONTENTS

AUTOMATIC AIR CONDITIONER

SERVICE INFORMATION .. ..........................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution for Working with HFC-134a (R-134a) ......3

Contaminated Refrigerant .........................................3

General Refrigerant Precaution ................................4

Precaution for Leak Detection Dye ...........................4

A/C Identification Label .............................................4

Precaution for Refrigerant Connection ......................4

Precaution for Service of Compressor ................ ......9

Precaution for Service Equipment ....................... ......9

PREPARATION ..................................................12

Special Service Tool ........................................... ....12

HFC-134a (R-134a) Service Tool and Equipment ....12

Commercial Service Tool ........................................14

REFRIGERATION SYSTEM ..............................16

Refrigerant Cycle ................................................ ....16

Refrigerant System Protection ................................16

Component Part Location ................................... ....17

OIL ......................................................................20

Maintenance of Oil Quantity in Compressor ....... ....20

AIR CONDITIONER CONTROL .........................22

Description .......................................................... ....22

Operation ................................................................22

Description of Control System .................................23

Control Operation ....................................................24

Discharge Air Flow ..................................................26

System Description (Front) .....................................27

System Description (Rear) .................................. ....28

CAN Communication System Description ...............29

TROUBLE DIAGNOSIS .....................................30

CONSULT-II Function (HVAC) ............................ ....30

CONSULT-II Function (BCM) ..................................31

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ................................................... ....

32

Component Parts and Harness Connector Loca-

tion ...........................................................................

32

Schematic ................................................................36

Wiring Diagram - A/C,A - .........................................37

Front Air Control Terminal and Reference Value ....47

A/C System Self-Diagnosis Function .......................48

Operational Check (Front) ................................... ....50

Operational Check (Rear) ........................................51

Power Supply and Ground Circuit for Front Air

Control ................................................................. ....

52

Mode Door Motor Circuit .........................................54

Air Mix Door Motor Circuit ................................... ....59

Intake Door Motor Circuit .........................................70

Defroster Door Motor Circuit ....................................74

Front Blower Motor Circuit .......................................78

Rear Blower Motor Circuit ................................... ....85

Rear Air Control Circuit ............................................93

Magnet Clutch Circuit ..............................................96

Insufficient Cooling ................................................100

Insufficient Heating ................................................108

Noise .....................................................................109

Self-Diagnosis .......................................................111

Memory Function ...................................................112

Water Valve Circuit ................................................113

Ambient Sensor Circuit ..........................................114

In-vehicle Sensor Circuit ........................................116

Optical Sensor Circuit ............................................119

Intake Sensor Circuit .............................................120

CONTROL UNIT ..............................................123

Removal and Installation .......................................123

AMBIENT SENSOR ........................................124

Removal and Installation .......................................124

IN-VEHICLE SENSOR ....................................125

Removal and Installation .......................................125

OPTICAL SENSOR .........................................126

Page 374 of 3061

ATC-4

< SERVICE INFORMATION >

PRECAUTIONS

not have dedicated recovery equipment, you may contact a local refrigerant product retailer for available ser-

vice. This refrigerant must be disposed of in acco rdance with all federal and local regulations. In addition,

replacement of all refrigerant system components on the vehicle is recommended.

• If the vehicle is within the warranty period, the air conditioner warranty is void. Please contact NISSAN Cus-

tomer Affairs for further assistance.

General Refrigerant PrecautionINFOID:0000000003533220

WARNING:

• Do not release refrigerant into th e air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

• Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

• Do not store or heat refrigerant containers above 52 °C (125 °F).

• Do not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

• Do not intentionally drop, puncture, or incinerate refrigerant containers.

• Keep refrigerant away from open flames: poisonou s gas will be produced if refrigerant burns.

• Refrigerant will displace oxygen, therefore be certa in to work in well ventilated areas to prevent suf-

focation.

• Do not pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air condition-

ing systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a) have

been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause injury or

property damage. Additional heal th and safety information may be obtained from refrigerant manu-

facturers.

Precaution for Leak Detection DyeINFOID:0000000003533221

• The A/C system contains a fluorescent leak detection dye used for locating refrigerant leaks. An ultraviolet

(UV) lamp is required to illuminate the dye when inspecting for leaks.

• Always wear fluorescence enhancing UV safety goggles to protect your eyes and enhance the visibility of

the fluorescent dye.

• The fluorescent dye leak detector is not a replacement for an electronic refrigerant leak detector. The fluo-

rescent dye leak detector should be used in conjuncti on with an electronic refrigerant leak detector (J-

41995).

• For your safety and the customer's satisfaction, r ead and follow all manufacturer's operating instructions and

precautions prior to performing work.

• A compressor shaft seal should not be repaired because of dye seepage. The compressor shaft seal should only be repaired after confirming the leak with an electronic refrigerant leak detector (J-41995).

• Always remove any dye from the leak area after repairs are complete to avoid a misdiagnosis during a future

service.

• Do not allow dye to come into contact with painted body panels or interior components. If dye is spilled,

clean immediately with the approved dye cleaner. Fluoresc ent dye left on a surface for an extended period of

time cannot be removed .

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bottle (1/4 ounce / 7.4 cc) per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R -12) A/C systems are different. Do not use HFC-

134a (R-134a) leak detection dye in CFC-12 (R-12) A/ C systems or CFC-12 (R-12) leak detection dye in

HFC-134a (R-134a) A/C systems or A/C system damage may result.

• The fluorescent properties of the dye will remain for ov er three (3) years unless a compressor failure occurs.

A/C Identification LabelINFOID:0000000003533222

Vehicles with factory installed fluorescent dye have this identification label on the underside of hood.

Precaution for Refrigerant ConnectionINFOID:0000000003533223

A new type refrigerant connection has been introduced to al l refrigerant lines except the following locations.

• Expansion valve to cooling unit

• Evaporator pipes to evaporator (inside cooling unit)

• Refrigerant pressure sensor

FEATURES OF NEW TYPE REFRIGERANT CONNECTION

Page 378 of 3061

ATC-8

< SERVICE INFORMATION >

PRECAUTIONS

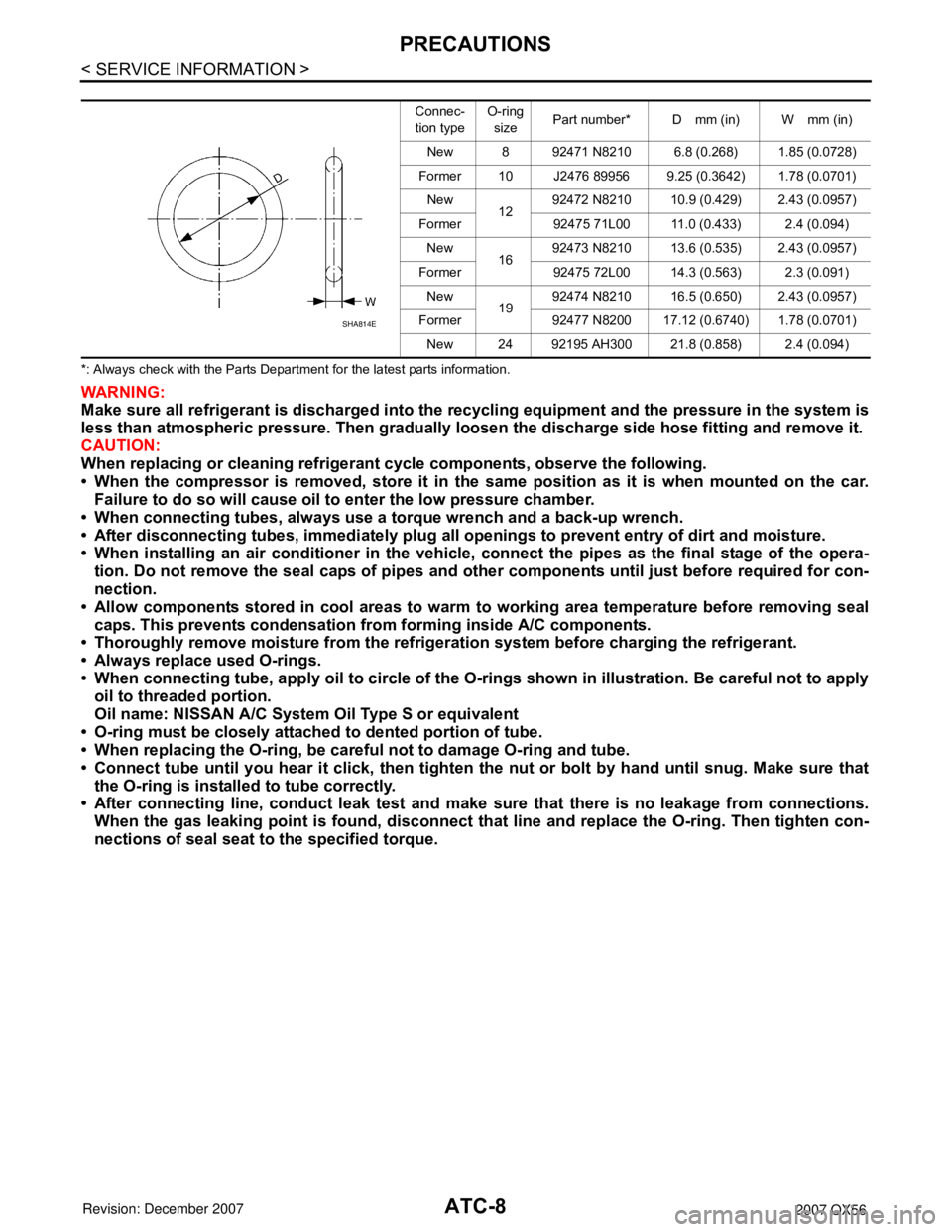

*: Always check with the Parts Department for the latest parts information.

WARNING:

Make sure all refrigerant is discharged into the recycling equipment and the pressure in the system is

less than atmospheric pressure. Then gradually loo sen the discharge side hose fitting and remove it.

CAUTION:

When replacing or cleaning refrigeran t cycle components, observe the following.

• When the compressor is removed, store it in the same position as it is when mounted on the car.

Failure to do so will cause oil to enter the low pressure chamber.

• When connecting tubes, always use a torque wrench and a back-up wrench.

• After disconnecting tubes, immedi ately plug all openings to prevent entry of dirt and moisture.

• When installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and othe r components until just before required for con-

nection.

• Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

• Thoroughly remove moisture from the refrigerat ion system before charging the refrigerant.

• Always replace used O-rings.

• When connecting tube, apply oil to circle of the O-rings shown in illustration. Be careful not to apply

oil to threaded portion.

Oil name: NISSAN A/C System Oil Type S or equivalent

• O-ring must be closely attached to dented portion of tube.

• When replacing the O-ring, be careful not to damage O-ring and tube.

• Connect tube until you hear it cl ick, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

• After connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is foun d, disconnect that line and replace the O-ring. Then tighten con-

nections of seal seat to the specified torque.

Connec-

tion typeO-ring

size Part number* D mm (in) W mm (in)

New 8 92471 N8210 6.8 (0.268) 1.85 (0.0728)

Former 10 J2476 89956 9.25 (0.3642) 1.78 (0.0701) New 1292472 N8210 10.9 (0.429) 2.43 (0.0957)

Former 92475 71L00 11.0 (0.433) 2.4 (0.094) New 1692473 N8210 13.6 (0.535) 2.43 (0.0957)

Former 92475 72L00 14.3 (0.563) 2.3 (0.091) New 1992474 N8210 16.5 (0.650) 2.43 (0.0957)

Former 92477 N8200 17.12 (0.6740) 1.78 (0.0701) New 24 92195 AH300 21.8 (0.858) 2.4 (0.094)

SHA814E

Page 390 of 3061

ATC-20

< SERVICE INFORMATION >

OIL

OIL

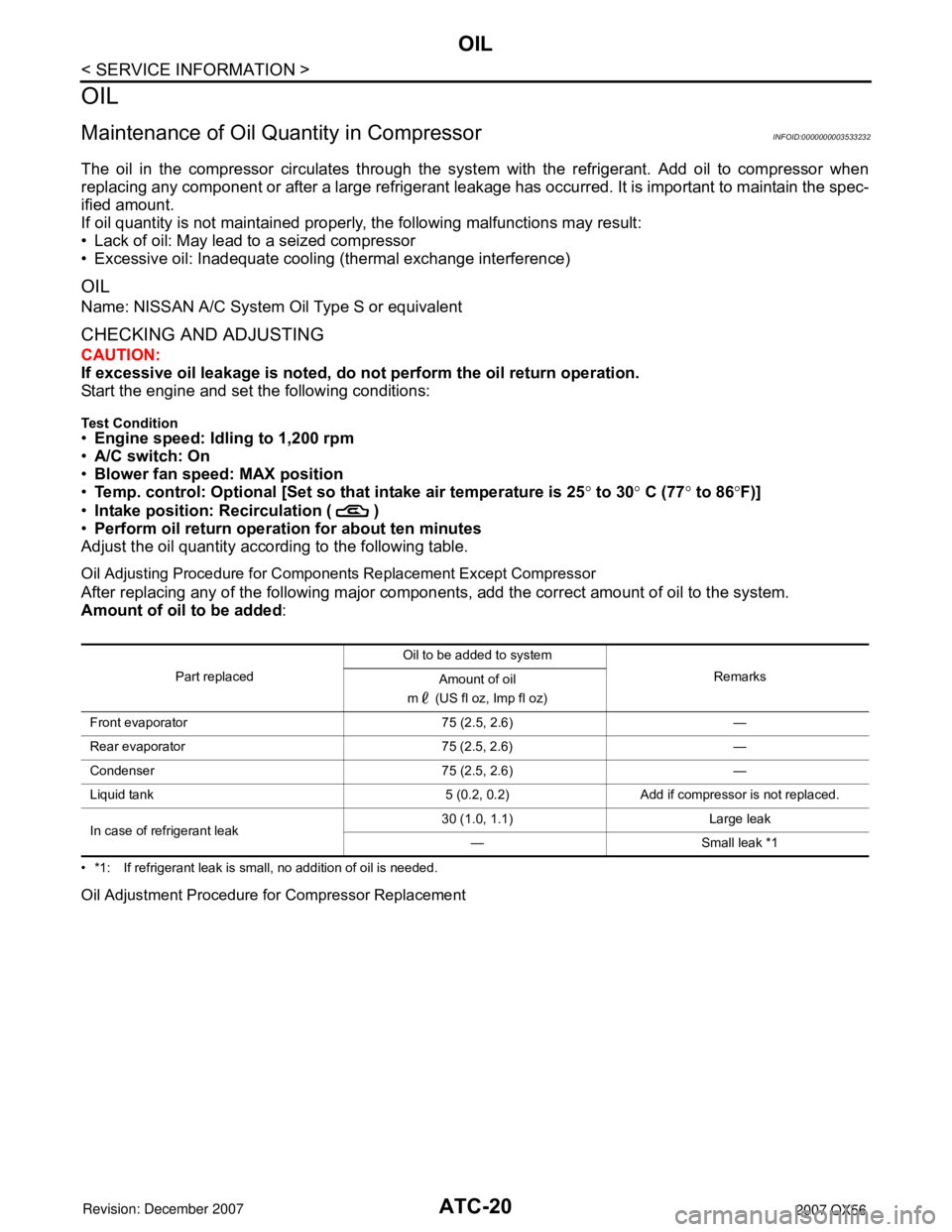

Maintenance of Oil Quantity in CompressorINFOID:0000000003533232

The oil in the compressor circulates through the system with the refrigerant. Add oil to compressor when

replacing any component or after a large refrigerant leakage has occurred. It is important to maintain the spec-

ified amount.

If oil quantity is not maintained properly, the following malfunctions may result:

• Lack of oil: May lead to a seized compressor

• Excessive oil: Inadequate cooling (thermal exchange interference)

OIL

Name: NISSAN A/C System Oil Type S or equivalent

CHECKING AND ADJUSTING

CAUTION:

If excessive oil leakage is noted, do no t perform the oil return operation.

Start the engine and set the following conditions:

Test Condition

• Engine speed: Idling to 1,200 rpm

• A/C switch: On

• Blower fan speed: MAX position

• Temp. control: Optional [Set so that intake air temperature is 25 ° to 30 ° C (77 ° to 86 °F)]

• Intake position: Recirculation ( )

• Perform oil return operation for about ten minutes

Adjust the oil quantity according to the following table.

Oil Adjusting Procedure for Components Replacement Except Compressor

After replacing any of the following major component s, add the correct amount of oil to the system.

Amount of oil to be added :

• *1: If refrigerant leak is small, no addition of oil is needed.

Oil Adjustment Procedure for Compressor Replacement

Part replaced Oil to be added to system

Remarks

Amount of oil

m (US fl oz, Imp fl oz)

Front evaporator 75 (2.5, 2.6) —

Rear evaporator 75 (2.5, 2.6) —

Condenser 75 (2.5, 2.6) —

Liquid tank 5 (0.2, 0.2) Add if compressor is not replaced.

In case of refrigerant leak 30 (1.0, 1.1) Large leak

— Small leak *1

Page 392 of 3061

ATC-22

< SERVICE INFORMATION >

AIR CONDITIONER CONTROL

AIR CONDITIONER CONTROL

DescriptionINFOID:0000000003533233

The front air control provides automatic regulation of the vehicle's interior temperature. The system is based

on the driver's and passenger's selected "set temperat ure", regardless of the outside temperature changes.

This is done by utilizing a microcomputer, also referred to as the front air control, which receives input signals

from the following seven sensors:

• Ambient sensor

• In-vehicle sensor

• Intake sensor

• Optical sensor (providing one input for driver and one input for passenger side)

• PBR (Position Balanced Resistor)

• Vehicle speed sensor (via CAN communication)

• Engine coolant temperature (via CAN communication)

The front air control uses these signals (including the set temperature) to automatically control:

• Outlet air volume

• Air temperature

• Air distribution

The front air control also provides separate regulation of the vehicle's interior temperature for the rear passen-

ger area. The system is based on the temperature and r ear blower settings selected from rear control

switches located on the front air control, or from the temperature and rear blower settings selected from rear

control switches on the rear air control, when the front air control switches are set to the rear position.

The front air control is used to select: • Outlet air volume

• Air temperature/distribution

OperationINFOID:0000000003533234

AIR MIX DOORS CONTROL

The air mix doors are automatically controlled so that in-vehicle temperature is maintained at a predetermined

value by the temperature setting, ambient temper ature, in-vehicle temperature and amount of sunload.

BLOWER SPEED CONTROL

Blower speed is automatically controlled by the temperat ure setting, ambient temperature, in-vehicle tempera-

ture, intake temperature, amount of sunload and air mix door position.

When AUTO switch is pressed, the blower motor starts to gradually increase air flow volume (if required).

When engine coolant temperature is low, the blower moto r operation is delayed to prevent cool air from flow-

ing.

INTAKE DOOR CONTROL

The intake door is automatically controlled by the tem perature setting, ambient temperature, in-vehicle tem-

perature, intake temperature, amount of sunl oad and by the ON-OFF operation of the compressor.

MODE DOOR CONTROL

The mode door is automatically controlled by the temperat ure setting, ambient temperature, in-vehicle temper-

ature, intake temperature and amount of sunload.

DEFROSTER DOOR CONTROL

The defroster door is controlled by: Turning the defroster dial to front defroster.

Page 393 of 3061

AIR CONDITIONER CONTROLATC-23

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

MAGNET CLUTCH CONTROL

When A/C switch or DEF switch is pressed, front air control inputs compressor ON signal to BCM.

BCM sends compressor ON signal to ECM and front air control via CAN communication line.

ECM judges whether compressor can be turned ON, based on each sensor status (refrigerant pressure sen-

sor signal, throttle angle sensor, etc.). If it judges compressor can be turned ON, it sends compressor ON sig-

nal to IPDM E/R, via CAN communication line.

Upon receipt of compressor ON signal from ECM, IPDM E/R turns air conditioner relay ON to operate com-

pressor.

SELF-DIAGNOSTIC SYSTEM

The self-diagnostic system is built into the front air cont rol to quickly locate the cause of symptoms. Refer to

ATC-48, "

A/C System Self-Diagnosis Function"

Description of Control SystemINFOID:0000000003533235

The control system consists of input sensors, swit ches, the front air control (microcomputer) and outputs.

WJIA2144E