steering INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2179 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-48

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

NOTE:

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

Tire pressure signal T R R

Turn indica INFINITI QX56 2007 Factory Service Manual LAN-48

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

NOTE:

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

Tire pressure signal T R R

Turn indica](/img/42/57029/w960_57029-2178.png)

LAN-48

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

NOTE:

CAN data of the air bag diagnosis sensor unit is not used by usual service work, thus it is omitted.

Tire pressure signal T R R

Turn indicator signal T R

A/C switch/indicator signalTR

RT

1st position switch signal R T

4th position switch signal R T

Distance to empty signal R T

Fuel level low warning signal R T

Fuel level sensor signal R T

Parking brake switch signal R T

Stop lamp switch signal R T

Tow mode switch signal R T

Vehicle speed signalRR R T

RRR RRR T

Steering angle sensor signalTR

ABS malfunction signal R T

ABS warning lamp signalRT

Brake pressure sensor signal R T

Brake warning lamp signalRT

SLIP indicator lamp signalRT

TCS malfunction signal R T

VDC malfunction signal R T

VDC OFF indicator lamp signal R R T

VDC operation signal R T

Front wiper stop position signal R T

High beam status signal RT

Hood switch signal R T

Low beam status signal RT

Rear window defogger control signal R R TSignal name/Connecting unit

ECM

TCM

LASER

ICC

ADP

BCM

DISP

HVAC

M&A

STRG

4WD

ABS

IPDM-E

Page 2192 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-61

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Component Parts LocationINFOID:0000000003533637

Harness LayoutINFOID:0000000003533638

Refer to PG-39, "Harness La INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-61

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Component Parts LocationINFOID:0000000003533637

Harness LayoutINFOID:0000000003533638

Refer to PG-39, "Harness La](/img/42/57029/w960_57029-2191.png)

TROUBLE DIAGNOSIS

LAN-61

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Component Parts LocationINFOID:0000000003533637

Harness LayoutINFOID:0000000003533638

Refer to PG-39, "Harness Layout".

Malfunction Area ChartINFOID:0000000003533639

MAIN LINE

BRANCH LINE

1. ECM E16 2. IPDM E/R E122 3. ICC sensor E42

4. Display control unit M95 5. Combination meter M24 6. ABS actuator and electric unit (con-

trol unit) E125

7. BCM M18 8. Data link connector M22 9. Steering angle sensor M47

10. Driver seat control unit P2 11. ICC unit B13 12. Air bag diagnosis sensor unit M35

13. A/T assembly F9 14. Front air control M50 15. Transfer control unit E142

BKIA0189E

Malfunction Area Reference

Main line between TCM and driver seat control unitLAN-62, "

Main Line Between TCM and Driver Seat Control Unit"

Main line between TCM and ICC sensorLAN-63, "Main Line Between TCM and ICC Sensor"

Main line between ICC sensor and ICC unitLAN-64, "Main Line Between ICC Sensor and ICC Unit"

Main line between ICC unit and driver seat control unitLAN-65, "Main Line Between ICC Unit and Driver Seat Control

Unit"

Main line between driver seat control unit and data link connectorLAN-65, "Main Line Between Driver Seat Control Unit and Data

Link Connector"

Main line between data link connector and ABS actuator and

electric unit (control unit)LAN-66, "Main Line Between Data Link Connector and ABS Ac-

tuator and Electric Unit (Control Unit)"

Malfunction Area Reference

ECM branch line circuit LAN-67, "

ECM Branch Line Circuit"

TCM branch line circuit LAN-67, "TCM Branch Line Circuit"

ICC sensor branch line circuit LAN-68, "ICC Sensor Branch Line Circuit"

ICC unit branch line circuit LAN-69, "ICC Unit Branch Line Circuit"

Driver seat control unit branch line circuitLAN-69, "Driver Seat Control Unit Branch Line Circuit"

Page 2193 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-62

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

SHORT CIRCUIT

Main Line Between TCM and Driver Seat Control UnitINFOID:0000000003533640

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignitio INFINITI QX56 2007 Factory Service Manual LAN-62

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

SHORT CIRCUIT

Main Line Between TCM and Driver Seat Control UnitINFOID:0000000003533640

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignitio](/img/42/57029/w960_57029-2192.png)

LAN-62

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

SHORT CIRCUIT

Main Line Between TCM and Driver Seat Control UnitINFOID:0000000003533640

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (connector side

and harness side).

- Harness connector F14

- Harness connector E5

- Harness connector E34

- Harness connector B40

OK or NG

OK >> GO TO 2.

NG >> Repair the terminal and connector.

2.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the connector of A/T assembly and the harness connectors F14 and E5.

2. Check the continuity between the A/T assembly harness connector and the harness connector.

OK or NG

OK >> GO TO 3.

NG >> Repair the main line between the A/T assembly and the harness connector F14.

3.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the harness connectors E34 and B40.

2. Check the continuity between harness connectors.

BCM branch line circuit LAN-70, "BCM Branch Line Circuit"

Display control unit branch line circuit LAN-70, "Display Control Unit Branch Line Circuit"

Data link connector branch line circuit LAN-71, "Data Link Connector Branch Line Circuit"

Front air control branch line circuitLAN-71, "Front Air Control Branch Line Circuit"

Combination meter branch line circuit LAN-72, "Combination Meter Branch Line Circuit"

Steering angle sensor branch line circuit LAN-72, "Steering Angle Sensor Branch Line Circuit"

Transfer control unit branch line circuitLAN-73, "Transfer Control Unit Branch Line Circuit"

ABS actuator and electric unit (control unit) branch line circuit LAN-74, "ABS Actuator and Electric Unit (Control Unit) Branch

Line Circuit"

IPDM E/R branch line circuit LAN-74, "IPDM E/R Branch Line Circuit"

Malfunction Area Reference

Malfunction Area Reference

CAN communication circuitLAN-75, "

CAN Communication Circuit"

A/T assembly harness connector Harness connector

Continuity

Connector No. Terminal No. Connector No. Terminal No.

F93

F145Yes

815Yes

Harness connector Harness connector

Continuity

Connector No. Terminal No. Connector No. Terminal No.

Page 2203 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-72

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of front air control.

2. Check the resistance between the front air control harness c INFINITI QX56 2007 Factory Service Manual LAN-72

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of front air control.

2. Check the resistance between the front air control harness c](/img/42/57029/w960_57029-2202.png)

LAN-72

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of front air control.

2. Check the resistance between the front air control harness connector terminals.

OK or NG

OK >> GO TO 3.

NG >> Repair the front air control branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the front air control. Refer to ATC-36, "

Schematic".

OK or NG

OK >> • Present error: Replace the front air control. Refer to ATC-123, "Removal and Installation".

• Past error: Error was detected in the front air control branch line.

NG >> Repair the power supply and the ground circuit.

Combination Meter Branch Line CircuitINFOID:0000000003533655

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the combination meter for damage, bend and loose connection

(unit side and connector side).

OK or NG

OK >> GO TO 2.

NG >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of combination meter.

2. Check the resistance between the combination meter harness connector terminals.

OK or NG

OK >> GO TO 3.

NG >> Repair the combination meter branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the combination meter. Refer to DI-9, "

Wiring Diagram -

METER -".

OK or NG

OK >> • Present error: Replace the combination meter. Refer to IP-10, "Removal and Installation".

• Past error: Error was detected in the combination meter branch line.

NG >> Repair the power supply and the ground circuit.

Steering Angle Sensor Branch Line CircuitINFOID:0000000003533656

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

Front air control harness connector

Resistance (Ω)

Connector No. Terminal No.

M50 34 35 Approx. 54 – 66

Combination meter harness connector

Resistance (Ω)

Connector No. Terminal No.

M24 11 12 Approx. 54 – 66

Page 2204 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-73

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the steering INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-73

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the steering](/img/42/57029/w960_57029-2203.png)

TROUBLE DIAGNOSIS

LAN-73

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the steering angle sensor for damage, bend and loose connection

(unit side and connector side).

OK or NG

OK >> GO TO 2.

NG >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of steering angle sensor.

2. Check the resistance between the steering angle sensor harness connector terminals.

OK or NG

OK >> GO TO 3.

NG >> Repair the steering angle sensor branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the steering angle sensor. Refer to BRC-15, "

Schematic".

OK or NG

OK >> • Present error: Replace the steering angle sensor. Refer to BRC-60, "Removal and Installation".

• Past error: Error was detected in the steering angle sensor branch line.

NG >> Repair the power supply and the ground circuit.

Transfer Control Unit Branch Line CircuitINFOID:0000000003533657

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the transfer control unit for damage, bend and loose connection

(unit side and connector side).

OK or NG

OK >> GO TO 2.

NG >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of transfer control unit.

2. Check the resistance between the transfer control unit harness connector terminals.

OK or NG

OK >> GO TO 3.

NG >> Repair the transfer control unit branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the transfer control unit. Refer to TF-23, "

Circuit Diagram".

OK or NG

OK >> • Present error: Replace the transfer control unit. Refer to TF-115, "Removal and Installation".

• Past error: Error was detected in the transfer control unit branch line.

NG >> Repair the power supply and the ground circuit.

Steering angle sensor harness connector

Resistance (Ω)

Connector No. Terminal No.

M47 3 4 Approx. 54 – 66

Transfer control unit harness connector

Resistance (Ω)

Connector No. Terminal No.

E142 7 8 Approx. 54 – 66

Page 2277 of 3061

LT-70

< SERVICE INFORMATION >

LIGHTING AND TURN SIGNAL SWITCH

LIGHTING AND TURN SIGNAL SWITCH

Removal and InstallationINFOID:0000000003533419

Removal

1. Remove steering column cover.

2. While pressing tabs, pull lighting and turn signal switch toward

driver door and disconnect from the base.

Installation

Installation is in the reverse order of removal.

LKIA0013E

Page 2301 of 3061

LT-94

< SERVICE INFORMATION >

TRAILER TOW

TRAILER TOW

Component Parts and Harness Connector LocationINFOID:0000000003533451

System DescriptionINFOID:0000000003533452

Power is supplied at all times

• to ignition relay, located in the IPDM E/R (intelligent power distribution module engine room),

• through 50A fusible link (letter f , located in the fuse and fusible link box)

• to BCM (body control module) terminal 70,

• through 10A fuse (No. 32, located in the IPDM E/R)

• through IPDM E/R terminal 61

1. Fuse and fusible link box 2. IPDM E/R fuse layout 3. Fuse and relay box

4. IPDM E/R E118, E119, E120, E121,

E122, E123, E1245. A. Steering column

B. Data link connector M22

C. BCM M18, M19, M20

(view with instrument lower panel LH

removed)6. A. Trailer turn relay LH E156

B. Battery

C. Trailer tow relay 2 E140

D. Trailer turn relay RH E157

7. A. Trailer tow relay 1 M51

B. Electric brake (pre-wiring) M76

(view with instrument lower panel LH

removed)8. Trailer connector C2 9. Combination switch (lighting switch)

M28

WKIA4616E

Page 2363 of 3061

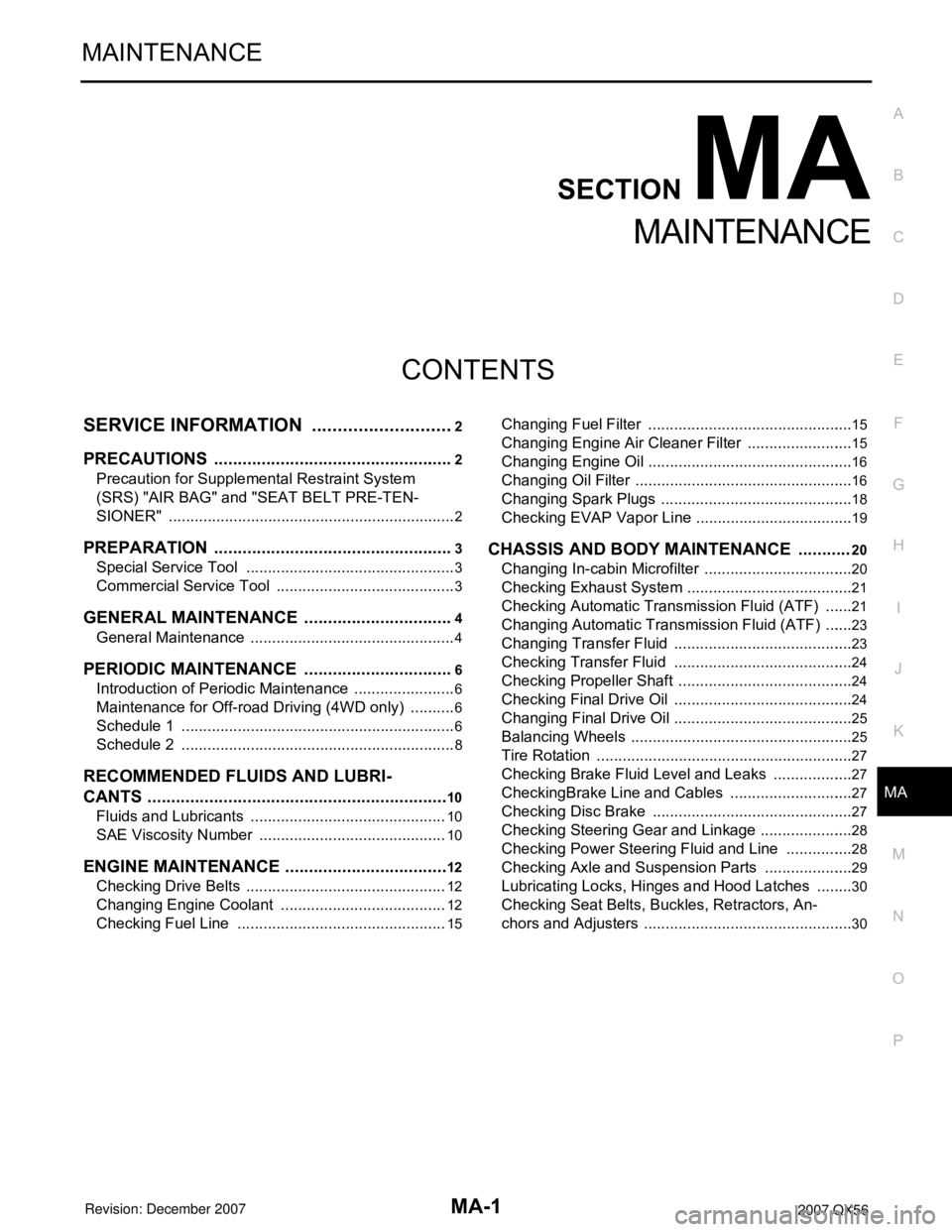

MA-1

MAINTENANCE

C

D

E

F

G

H

I

J

K

M

SECTION MA

A

B

MA

N

O

P

CONTENTS

MAINTENANCE

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................3

GENERAL MAINTENANCE ................................4

General Maintenance ................................................4

PERIODIC MAINTENANCE ................................6

Introduction of Periodic Maintenance ........................6

Maintenance for Off-road Driving (4WD only) ...........6

Schedule 1 ................................................................6

Schedule 2 ................................................................8

RECOMMENDED FLUIDS AND LUBRI-

CANTS ................................................................

10

Fluids and Lubricants ..............................................10

SAE Viscosity Number ............................................10

ENGINE MAINTENANCE ...................................12

Checking Drive Belts ...............................................12

Changing Engine Coolant .......................................12

Checking Fuel Line .................................................15

Changing Fuel Filter ................................................15

Changing Engine Air Cleaner Filter .........................15

Changing Engine Oil ................................................16

Changing Oil Filter ...................................................16

Changing Spark Plugs .............................................18

Checking EVAP Vapor Line .....................................19

CHASSIS AND BODY MAINTENANCE ...........20

Changing In-cabin Microfilter ...................................20

Checking Exhaust System .......................................21

Checking Automatic Transmission Fluid (ATF) .......21

Changing Automatic Transmission Fluid (ATF) .......23

Changing Transfer Fluid ..........................................23

Checking Transfer Fluid ..........................................24

Checking Propeller Shaft .........................................24

Checking Final Drive Oil ..........................................24

Changing Final Drive Oil ..........................................25

Balancing Wheels ....................................................25

Tire Rotation ............................................................27

Checking Brake Fluid Level and Leaks ...................27

CheckingBrake Line and Cables .............................27

Checking Disc Brake ...............................................27

Checking Steering Gear and Linkage ......................28

Checking Power Steering Fluid and Line ................28

Checking Axle and Suspension Parts .....................29

Lubricating Locks, Hinges and Hood Latches .........30

Checking Seat Belts, Buckles, Retractors, An-

chors and Adjusters .................................................

30

Page 2366 of 3061

MA-4

< SERVICE INFORMATION >

GENERAL MAINTENANCE

GENERAL MAINTENANCE

General MaintenanceINFOID:0000000003533859

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owner can perform these

checks and inspections or have their INFINITI dealers perform them.

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

ItemReference page

TiresCheck the pressure with a gauge at least once a month and always prior to a

long distance trip. Adjust to the specified pressure if necessary. Check carefully

for damage, cuts or excessive wear.—

Wheel lug nutsWhen checking the tires, make sure no nuts are missing, and check for any loose

nuts. Tighten if necessary.WT-7, "

Rotation"

WindshieldClean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary.—

Tire rotationTires should be rotated every 12,000 km (7,500 miles).WT-7, "

Rotation"

Wheel alignment and

balanceIf the vehicle pulls to either side while driving on a straight and level road, or if

you detect uneven or abnormal tire wear, there may be a need for wheel align-

ment. If the steering wheel or seat vibrates at normal highway speeds, wheel bal-

ancing may be needed.WT-6, "Balancing

Wheels", FSU-6, "Front

Wheel Alignment"

Windshield wiper

bladesCheck for cracks or wear if they do not wipe properly.

—

Doors and engine

hoodCheck that all doors and the engine hood operate smoothly as well as the back

hatch. Also make sure that all latches lock securely. Lubricate if necessary. Make

sure that the secondary latch keeps the hood from opening when the primary

latch is released.

When driving in areas using road salt or other corrosive materials, check lubri-

cation frequently.MA-30, "

Lubricating

Locks, Hinges and Hood

Latches"

Lamps

Make sure that the head lamps, stop lamps, tail lamps, turn signal lamps, and

other lamps are all operating properly and installed securely. Also check head

lamp aim. Clean the head lamps on a regular basis.LT- 2 0 , "Aiming Adjust-

ment" for US, LT- 3 3 ,

"Aiming Adjustment" for

Canada

ItemReference page

Warning lamps and

buzzers/chimesMake sure that all warning lamps and buzzers/chimes are operating properly.DI-21, "

Electrical Com-

ponent Inspection"

Windshield wiper and

washerCheck that the wipers and washer operate properly and that the wipers do not

streak.—

Windshield defrosterCheck that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioner.—

Steering wheelCheck that it has the specified play. Be sure to check for changes in the steering

condition, such as excessive play, hard steering or strange noises.PS-7, "

On-Vehicle In-

spection and Service"

SeatsCheck seat position controls such as seat adjusters, seat back recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restraints move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seat backs.—

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly and are installed securely. Check the

belt webbing for cuts, fraying, wear or damage.SB-10, "

Seat Belt Inspec-

tion", MA-30, "Checking

Seat Belts, Buckles, Re-

tractors, Anchors and

Adjusters"

Accelerator pedalCheck the pedal for smooth operation. Keep the floor mats away from the pedal. —

Page 2367 of 3061

GENERAL MAINTENANCE

MA-5

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically (e.g. each time you check the engine oil or refuel).

BrakesCheck that the brake does not pull the vehicle to one side when applied. —

Brake pedal and

boosterCheck the pedal for smooth operation and make sure it has the proper distance

under it when depressed fully. Check the brake booster function. Keep the floor

mats away from the pedal.BR-5, "

Inspection and

Adjustment", BR-15,

"On-Vehicle Service"

Parking brakeCheck that the parking brake control has the proper travel and make sure that

the vehicle is held securely on a fairly steep hill when only the parking brake is

applied.PB-4

Automatic transmis-

sion “Park” mecha-

nismOn a fairly steep hill check that the vehicle is held securely with the selector lever

in the P position without applying the brakes. — ItemReference page

ItemReference page

Windshield washer

fluidCheck that there is adequate fluid in the tank.

—

Engine coolant levelCheck the coolant level when the engine is cold. —

Radiator and hosesCheck the front of the radiator and clean off any dirt, insects, leaves, etc., that

may have accumulated. Make sure the hoses have no cracks, deformation, de-

terioration or loose connections.—

Brake fluid levelMake sure that the brake fluid level is between the “MAX” and “MIN” lines on the

reservoirsMA-27

BatteryCheck the fluid level in each cell. It should be between the “MAX” and “MIN” lines.

Vehicles operated in high temperatures or under severe conditions require fre-

quent checks of the battery fluid level.—

Engine drive beltMake sure that no belt is frayed, worn, cracked or oily.MA-12

Engine oil levelCheck the level on the dipstick after parking the vehicle on a level spot and turn-

ing off the engine.—

Power steering fluid

level and linesCheck the level on the reservoir with the engine off. Check the lines for improper

attachment, leaks, cracks, etc.MA-28

Automatic transmis-

sion fluid levelCheck the level on the dipstick after putting the selector lever in “P” with the en-

gine idling.MA-21

Exhaust systemMake sure there are no loose supports, cracks or holes. If the sound of the ex-

haust seems unusual or there is a smell of exhaust fumes, immediately locate

the trouble and correct it.MA-21

UnderbodyThe underbody is frequently exposed to corrosive substances such as those

used on icy roads or to control dust. It is very important to remove these sub-

stances, otherwise rust will form on the floor pan, frame, fuel lines and around the

exhaust system. At the end of winter, the underbody should be thoroughly

flushed with plain water, being careful to clean those areas where mud and dirt

can easily accumulate.—

Fluid leaksCheck under the vehicle for fuel, oil, water or other fluid leaks after the vehicle

has been parked for a while. Water dripping from the air conditioner after use is

normal. If you should notice any leaks or gasoline fumes are evident, check for

the cause and correct it immediately.—