ABS INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2192 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-61

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Component Parts LocationINFOID:0000000003533637

Harness LayoutINFOID:0000000003533638

Refer to PG-39, "Harness La INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-61

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Component Parts LocationINFOID:0000000003533637

Harness LayoutINFOID:0000000003533638

Refer to PG-39, "Harness La](/img/42/57029/w960_57029-2191.png)

TROUBLE DIAGNOSIS

LAN-61

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

Component Parts LocationINFOID:0000000003533637

Harness LayoutINFOID:0000000003533638

Refer to PG-39, "Harness Layout".

Malfunction Area ChartINFOID:0000000003533639

MAIN LINE

BRANCH LINE

1. ECM E16 2. IPDM E/R E122 3. ICC sensor E42

4. Display control unit M95 5. Combination meter M24 6. ABS actuator and electric unit (con-

trol unit) E125

7. BCM M18 8. Data link connector M22 9. Steering angle sensor M47

10. Driver seat control unit P2 11. ICC unit B13 12. Air bag diagnosis sensor unit M35

13. A/T assembly F9 14. Front air control M50 15. Transfer control unit E142

BKIA0189E

Malfunction Area Reference

Main line between TCM and driver seat control unitLAN-62, "

Main Line Between TCM and Driver Seat Control Unit"

Main line between TCM and ICC sensorLAN-63, "Main Line Between TCM and ICC Sensor"

Main line between ICC sensor and ICC unitLAN-64, "Main Line Between ICC Sensor and ICC Unit"

Main line between ICC unit and driver seat control unitLAN-65, "Main Line Between ICC Unit and Driver Seat Control

Unit"

Main line between driver seat control unit and data link connectorLAN-65, "Main Line Between Driver Seat Control Unit and Data

Link Connector"

Main line between data link connector and ABS actuator and

electric unit (control unit)LAN-66, "Main Line Between Data Link Connector and ABS Ac-

tuator and Electric Unit (Control Unit)"

Malfunction Area Reference

ECM branch line circuit LAN-67, "

ECM Branch Line Circuit"

TCM branch line circuit LAN-67, "TCM Branch Line Circuit"

ICC sensor branch line circuit LAN-68, "ICC Sensor Branch Line Circuit"

ICC unit branch line circuit LAN-69, "ICC Unit Branch Line Circuit"

Driver seat control unit branch line circuitLAN-69, "Driver Seat Control Unit Branch Line Circuit"

Page 2193 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-62

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

SHORT CIRCUIT

Main Line Between TCM and Driver Seat Control UnitINFOID:0000000003533640

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignitio INFINITI QX56 2007 Factory Service Manual LAN-62

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

SHORT CIRCUIT

Main Line Between TCM and Driver Seat Control UnitINFOID:0000000003533640

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignitio](/img/42/57029/w960_57029-2192.png)

LAN-62

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

SHORT CIRCUIT

Main Line Between TCM and Driver Seat Control UnitINFOID:0000000003533640

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (connector side

and harness side).

- Harness connector F14

- Harness connector E5

- Harness connector E34

- Harness connector B40

OK or NG

OK >> GO TO 2.

NG >> Repair the terminal and connector.

2.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the connector of A/T assembly and the harness connectors F14 and E5.

2. Check the continuity between the A/T assembly harness connector and the harness connector.

OK or NG

OK >> GO TO 3.

NG >> Repair the main line between the A/T assembly and the harness connector F14.

3.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the harness connectors E34 and B40.

2. Check the continuity between harness connectors.

BCM branch line circuit LAN-70, "BCM Branch Line Circuit"

Display control unit branch line circuit LAN-70, "Display Control Unit Branch Line Circuit"

Data link connector branch line circuit LAN-71, "Data Link Connector Branch Line Circuit"

Front air control branch line circuitLAN-71, "Front Air Control Branch Line Circuit"

Combination meter branch line circuit LAN-72, "Combination Meter Branch Line Circuit"

Steering angle sensor branch line circuit LAN-72, "Steering Angle Sensor Branch Line Circuit"

Transfer control unit branch line circuitLAN-73, "Transfer Control Unit Branch Line Circuit"

ABS actuator and electric unit (control unit) branch line circuit LAN-74, "ABS Actuator and Electric Unit (Control Unit) Branch

Line Circuit"

IPDM E/R branch line circuit LAN-74, "IPDM E/R Branch Line Circuit"

Malfunction Area Reference

Malfunction Area Reference

CAN communication circuitLAN-75, "

CAN Communication Circuit"

A/T assembly harness connector Harness connector

Continuity

Connector No. Terminal No. Connector No. Terminal No.

F93

F145Yes

815Yes

Harness connector Harness connector

Continuity

Connector No. Terminal No. Connector No. Terminal No.

Page 2197 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-66

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

OK or NG

OK >> GO TO 3.

NG >> Repair the main line between the harness connectors B37 and B69.

3.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

Check the INFINITI QX56 2007 Factory Service Manual LAN-66

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

OK or NG

OK >> GO TO 3.

NG >> Repair the main line between the harness connectors B37 and B69.

3.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

Check the](/img/42/57029/w960_57029-2196.png)

LAN-66

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

OK or NG

OK >> GO TO 3.

NG >> Repair the main line between the harness connectors B37 and B69.

3.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

Check the continuity between the harness connector and the data link connector.

OK or NG

OK >> • Present error: Check the following items again.

- Decision of CAN system type.

- Not received CONSULT-II data (SELECT SYSTEM, SELF-DIAG RESULTS, CAN DIAG SUP-

PORT MNTR).

- Not copied from on-board diagnosis.

- Procedure for detecting root cause.

• Past error: Error was detected in the main line between the driver seat control unit and the data

link connector.

NG >> Repair the main line between the harness connector M40 and the data link connector.

Main Line Between Data Link Connector and ABS Actuator and Electric Unit (Control

Unit)

INFOID:0000000003533645

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (connector side

and harness side).

- Harness connector M31

- Harness connector E152

OK or NG

OK >> GO TO 2.

NG >> Repair the terminal and connector.

2.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the harness connectors M31 and E152.

2. Check the continuity between the data link connector and the harness connector.

OK or NG

OK >> GO TO 3.

NG >> Repair the main line between the data link connector and the harness connector M31.

3.CHECK HARNESS CONTINUITY (OPEN CIRCUIT)

1. Disconnect the connector of ABS actuator and electric unit (control unit).

B3715

B6951J Yes

14 52J Yes

Harness connector Data link connector

Continuity

Connector No. Terminal No. Connector No. Terminal No.

M4051J

M226Yes

52J 14 Yes

Data link connector Harness connector

Continuity

Connector No. Terminal No. Connector No. Terminal No.

M226

M3131G Yes

14 42G Yes

Page 2198 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-67

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

2. Check the continuity between the harness connector and the ABS actuator and electric unit (control unit)

harne INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-67

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

2. Check the continuity between the harness connector and the ABS actuator and electric unit (control unit)

harne](/img/42/57029/w960_57029-2197.png)

TROUBLE DIAGNOSIS

LAN-67

< SERVICE INFORMATION >[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

2. Check the continuity between the harness connector and the ABS actuator and electric unit (control unit)

harness connector.

OK or NG

OK >> • Present error: Check the following items again.

- Decision of CAN system type.

- Not received CONSULT-II data (SELECT SYSTEM, SELF-DIAG RESULTS, CAN DIAG SUP-

PORT MNTR).

- Not copied from on-board diagnosis.

- Procedure for detecting root cause.

• Past error: Error was detected in the main line between the data link connector and the ABS

actuator and electric unit (control unit).

NG >> Repair the main line between the harness connector E152 and the ABS actuator and electric unit

(control unit).

ECM Branch Line CircuitINFOID:0000000003533646

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the following terminals and connectors for damage, bend and loose connection (unit side and con-

nector side).

- ECM connector

- Harness connector E5

- Harness connector F14

OK or NG

OK >> GO TO 2.

NG >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of ECM.

2. Check the resistance between the ECM harness connector terminals.

OK or NG

OK >> GO TO 3.

NG >> Repair the ECM branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ECM. Refer to EC-101, "

Circuit Diagram".

OK or NG

OK >> • Present error: Replace the ECM. Refer to EC-77, "Procedure After Replacing ECM".

• Past error: Error was detected in the ECM branch line.

NG >> Repair the power supply and the ground circuit.

TCM Branch Line CircuitINFOID:0000000003533647

INSPECTION PROCEDURE

Harness connectorABS actuator and electric unit (control unit)

harness connector

Continuity

Connector No. Terminal No. Connector No. Terminal No.

E15231G

E12511 Ye s

42G 15 Yes

ECM harness connector

Resistance (Ω)

Connector No. Terminal No.

E16 94 86 Approx. 108 – 132

Page 2205 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-74

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

ABS Actuator and Electric Unit (Control Unit) Branch Line Circuit

INFOID:0000000003533658

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignit INFINITI QX56 2007 Factory Service Manual LAN-74

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

ABS Actuator and Electric Unit (Control Unit) Branch Line Circuit

INFOID:0000000003533658

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignit](/img/42/57029/w960_57029-2204.png)

LAN-74

< SERVICE INFORMATION >[CAN]

TROUBLE DIAGNOSIS

ABS Actuator and Electric Unit (Control Unit) Branch Line Circuit

INFOID:0000000003533658

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the ABS actuator and electric unit (control unit) for damage, bend

and loose connection (unit side and connector side).

OK or NG

OK >> GO TO 2.

NG >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of ABS actuator and electric unit (control unit).

2. Check the resistance between the ABS actuator and electric unit (control unit) harness connector termi-

nals.

OK or NG

OK >> GO TO 3.

NG >> Repair the ABS actuator and electric unit (control unit) branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the ABS actuator and electric unit (control unit). Refer to

BRC-15, "

Schematic".

OK or NG

OK >> • Present error: Replace the ABS actuator and electric unit (control unit). Refer to BRC-58,

"Removal and Installation".

• Past error: Error was detected in the ABS actuator and electric unit (control unit) branch line.

NG >> Repair the power supply and the ground circuit.

IPDM E/R Branch Line CircuitINFOID:0000000003533659

INSPECTION PROCEDURE

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the IPDM E/R for damage, bend and loose connection (unit side

and connector side).

OK or NG

OK >> GO TO 2.

NG >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of IPDM E/R.

2. Check the resistance between the IPDM E/R harness connector terminals.

OK or NG

OK >> GO TO 3.

ABS actuator and electric unit (control unit) harness connector

Resistance (Ω)

Connector No. Terminal No.

E125 11 15 Approx. 54 – 66

IPDM E/R harness connector

Resistance (Ω)

Connector No. Terminal No.

E122 39 40 Approx. 108 – 132

Page 2277 of 3061

LT-70

< SERVICE INFORMATION >

LIGHTING AND TURN SIGNAL SWITCH

LIGHTING AND TURN SIGNAL SWITCH

Removal and InstallationINFOID:0000000003533419

Removal

1. Remove steering column cover.

2. While pressing tabs, pull lighting and turn signal switch toward

driver door and disconnect from the base.

Installation

Installation is in the reverse order of removal.

LKIA0013E

Page 2288 of 3061

BACK-UP LAMP

LT-81

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

1. Remove back door lower finisher. Refer to EI-39.

2. Turn bulb socket counterclockwise and remove it from the lamp housing.

3. Pull bulb from socket.

Installation

Installation is in the reverse order of removal.

Removal and InstallationINFOID:0000000003533433

BACK-UP LAMP

Removal

1. Remove license lamp finisher. Refer to EI-23.

2. Carefully release tabs to remove back up lamp housing from

license plate finisher.

Installation

Installation is in the reverse order of removal.

WKIA1898E

Page 2344 of 3061

ILLUMINATION

LT-137

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

2. Carefully pry tabs and remove illumination control switch from

cluster lid A.

Installation

Installation is in the reverse order of removal.

WKIA1403E

Page 2356 of 3061

OIL FILTER

LU-11

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

LU

N

P O

OIL FILTER

Removal and InstallationINFOID:0000000003531557

REMOVAL

1. Remove the engine front undercover using power tool.

2. Remove the oil filter using Tool.

WARNING:

• The oil filter is provided with a relief valve.

Use Genuine NISSAN oil filter or equivalent.

• When removing, prepare a shop cloth to absorb any

engine oil leakage or spillage.

• Do not allow engine oil to adhere to the drive belts.

• Completely wipe off any engine oil that adheres to the

engine and the vehicle.

CAUTION:

• Be careful not to get burned when the engine and engine oil are hot.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply engine oil to the oil seal circumference of the new oil filter.

3. Screw the oil filter manually until it touches the installation sur-

face, then tighten it by 2/3 turn. Or tighten to specification.

4. Inspect the engine for oil leakage. Refer to EM-74, "

Removal

and Installation".

5. Install the engine front undercover using power tool.

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to LU-8, "Inspection".

2. Start the engine and check for engine oil leakage.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level and add engine oil as required.Tool number : KV10115801 (J-38956)

WBIA0388E

SMA010

Oil filter : 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

Page 2379 of 3061

ENGINE MAINTENANCE

MA-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

MA

B

MA

N

O

P

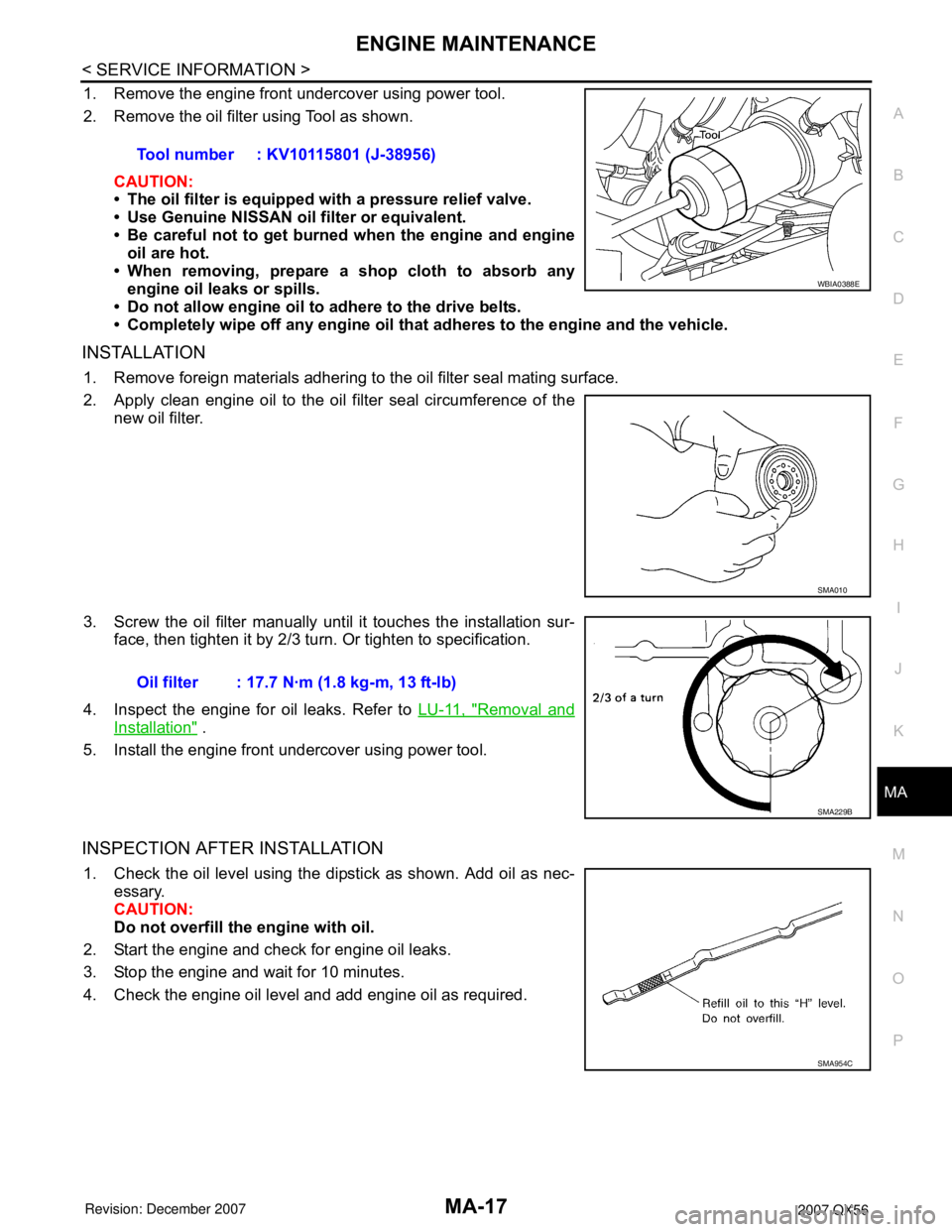

1. Remove the engine front undercover using power tool.

2. Remove the oil filter using Tool as shown.

CAUTION:

• The oil filter is equipped with a pressure relief valve.

• Use Genuine NISSAN oil filter or equivalent.

• Be careful not to get burned when the engine and engine

oil are hot.

• When removing, prepare a shop cloth to absorb any

engine oil leaks or spills.

• Do not allow engine oil to adhere to the drive belts.

• Completely wipe off any engine oil that adheres to the engine and the vehicle.

INSTALLATION

1. Remove foreign materials adhering to the oil filter seal mating surface.

2. Apply clean engine oil to the oil filter seal circumference of the

new oil filter.

3. Screw the oil filter manually until it touches the installation sur-

face, then tighten it by 2/3 turn. Or tighten to specification.

4. Inspect the engine for oil leaks. Refer to LU-11, "

Removal and

Installation" .

5. Install the engine front undercover using power tool.

INSPECTION AFTER INSTALLATION

1. Check the oil level using the dipstick as shown. Add oil as nec-

essary.

CAUTION:

Do not overfill the engine with oil.

2. Start the engine and check for engine oil leaks.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level and add engine oil as required.Tool number : KV10115801 (J-38956)

WBIA0388E

SMA010

Oil filter : 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

SMA954C