ABS INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1744 of 3061

REAR BUMPER

EI-15

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

EI

N

O

P

REMOVAL

1. Disconnect the negative battery cable.

2. Remove quarter panel trim covers LH and RH.

3. Disconnect sonar sensor harness connector under rear fascia assembly.

4. Release retainer clips on both sides of rear fascia assembly with a 1/4 turn and top S clips and remove

fascia assembly.

5. Remove energy absorber.

6. Remove reinforcement assembly.

7. Remove nuts and remove retainer assembly.

• Remove S clips from retainer assembly.

8. Disconnect sonar sensors from sonar sensor retainers.

9. Remove sonar sensors and harness from rear fascia assembly.

• Disconnect sonar sensors from harness.

• Remove sonar sensor retainers from rear fascia assembly.

10. Remove bolts on each side of tow hitch and remove tow hitch.

11. Remove drafter duct from under LH quarter panel.

INSTALLATION

Installation is in the reverse order of removal.

10. Rear fascia assembly 11. Sonar sensor retainer 12. Tow hitch

13. Sonar sensor harness 14. Quarter panel trim cover RH

Page 1838 of 3061

EM-68

< SERVICE INFORMATION >

CYLINDER HEAD

7. Remove the valve oil seal using Tool.

8. Replace the valve seat if necessary. Refer to EM-69, "

Inspection After Disassembly".

9. Replace the valve guide if necessary. Refer to EM-69, "

Inspection After Disassembly".

10. Remove the spark plug tube, as necessary.

• Remove the spark plug tube out of the cylinder head using suitable tool.

CAUTION:

• Do not damage the cylinder head.

• Do not remove the spark plug tube unless absolutely necessary. Once removed, the spark plug

tube will be deformed and cannot be reused.

ASSEMBLY

1. Install the valve guide if necessary. Refer to EM-69, "Inspection After Disassembly".

2. Install the valve seat if necessary. Refer to EM-69, "

Inspection After Disassembly".

3. Install the valve oil seal using Tool.

• Apply new engine oil on the new valve oil seal joint and seal

lip.

• Install the valve oil seal to the specified height "H".

4. Install the valves in their original position.

5. Install the valve spring seats.

6. Install the valve springs.

• Install the narrow pitch end (paint mark side) to the cylinder

head side.

7. Install the valve spring retainers.Tool number : KV10107902 (J-38959)

WBIA0478E

Tool number : KV10115600 (J-38958)

Height "H" (without valve spring installed)

Intake and exhaust : 14.3 - 14.9 mm (0.563 - 0.587 in)

WBIA0490E

SEM085D

Page 1893 of 3061

DRIVE SHAFT

FAX-7

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

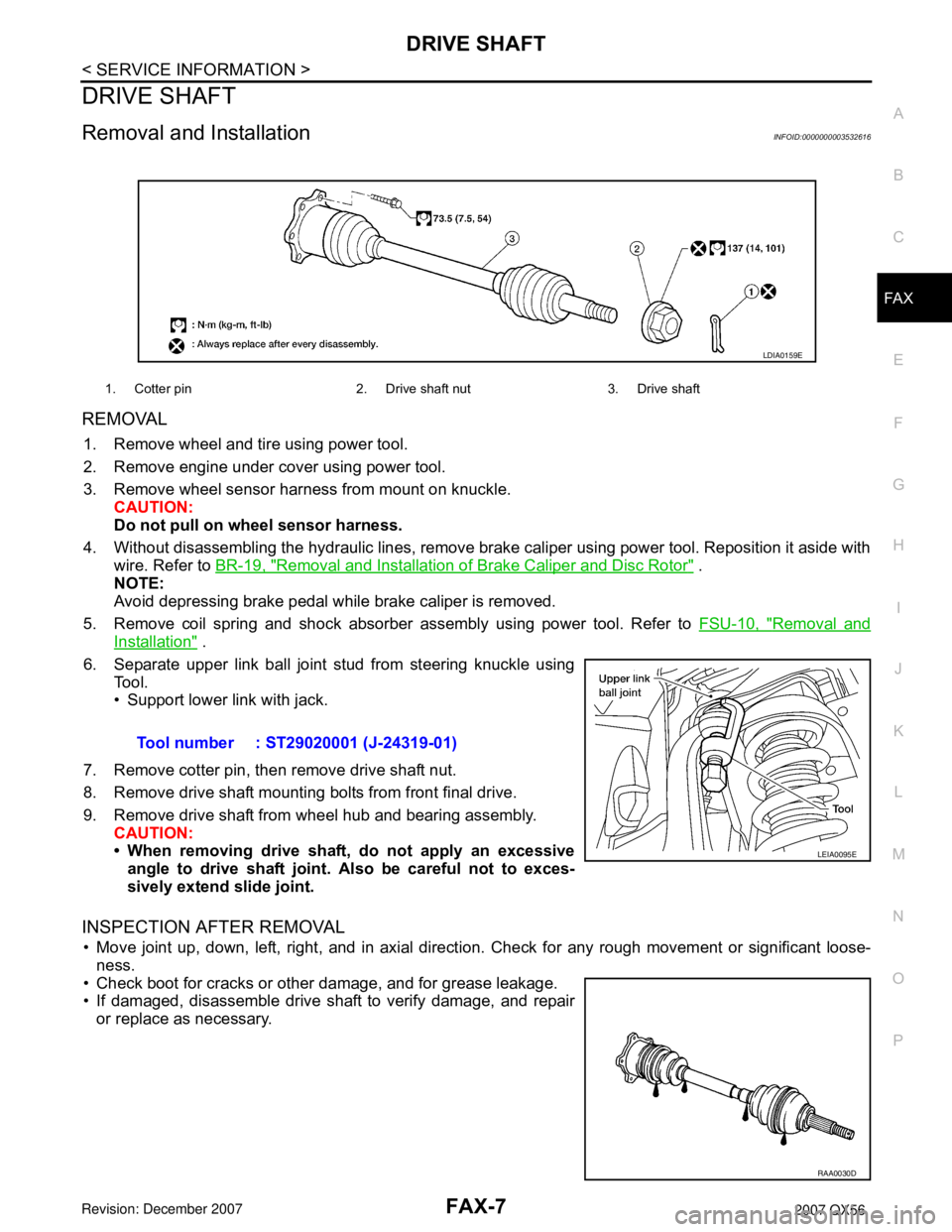

DRIVE SHAFT

Removal and InstallationINFOID:0000000003532616

REMOVAL

1. Remove wheel and tire using power tool.

2. Remove engine under cover using power tool.

3. Remove wheel sensor harness from mount on knuckle.

CAUTION:

Do not pull on wheel sensor harness.

4. Without disassembling the hydraulic lines, remove brake caliper using power tool. Reposition it aside with

wire. Refer to BR-19, "

Removal and Installation of Brake Caliper and Disc Rotor" .

NOTE:

Avoid depressing brake pedal while brake caliper is removed.

5. Remove coil spring and shock absorber assembly using power tool. Refer to FSU-10, "

Removal and

Installation" .

6. Separate upper link ball joint stud from steering knuckle using

Tool.

• Support lower link with jack.

7. Remove cotter pin, then remove drive shaft nut.

8. Remove drive shaft mounting bolts from front final drive.

9. Remove drive shaft from wheel hub and bearing assembly.

CAUTION:

• When removing drive shaft, do not apply an excessive

angle to drive shaft joint. Also be careful not to exces-

sively extend slide joint.

INSPECTION AFTER REMOVAL

• Move joint up, down, left, right, and in axial direction. Check for any rough movement or significant loose-

ness.

• Check boot for cracks or other damage, and for grease leakage.

• If damaged, disassemble drive shaft to verify damage, and repair

or replace as necessary.

1. Cotter pin 2. Drive shaft nut 3. Drive shaft

LDIA0159E

Tool number : ST29020001 (J-24319-01)

LEIA0095E

RAA0030D

Page 1938 of 3061

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-7

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

FL

N

P O

Disconnect the quick connector as follows:

• Hold the sides of the connector, push in tabs and pull out the

tube.

• If the connector and the tube are stuck together, push and pull

several times until they start to move. Then disconnect them

by pulling.

CAUTION:

• The quick connector can be disconnected when the tabs

are completely depressed. Do not twist the quick connec-

tor more than necessary.

• Do not use any tools to disconnect the quick connector.

• Keep the resin tube away from heat. Be especially careful

when welding near the tube.

• Prevent any acid liquids such as battery electrolyte, from

getting on the resin tube.

• Do not bend or twist the resin tube during connection.

• Do not remove the remaining retainer on the hard tube (or

the equivalent) except when the resin tube or the retainer

is replaced.

• When the resin tube or hard tube, or the equivalent, is

replaced, also replace the retainer with a new one (white

colored retainer).

• To keep the quick connector clean and to avoid damage

and contamination from foreign materials, cover the quick

connector with plastic bags or suitable material as shown.

SFE562A

PBIC1268E

PBIC0163E

Page 1939 of 3061

FL-8

< SERVICE INFORMATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

12. Remove the lock ring using Tool.

13. Remove the fuel level sensor, fuel filter, and fuel pump assem-

bly. Remove and discard the fuel level sensor, fuel filter, and fuel

pump assembly O-ring.

CAUTION:

• Do not bend the float arm during removal.

• Avoid impacts such as dropping when handling the com-

ponents.

INSTALLATION

Installation is in the reverse order of removal.

• For installation, use a new fuel level sensor, fuel filter, and fuel pump assembly O-ring.

• Connect the quick connector as follows:

- Check the connection for any damage or foreign materials.

- Align the connector with the pipe, then insert the connector straight into the pipe until a click is heard.

- After connecting the quick connector, make sure that the connec-

tion is secure by checking as follows:

- Pull the tube and the connector to make sure they are securely

connected.

- Visually inspect the connector to make sure the two retainer tabs

are securely connected.

INSPECTION AFTER INSTALLATION

1. Turn the ignition switch ON but do not start engine, then check the fuel pipes and hose connections for

leaks while applying fuel pressure to the system.

2. Start the engine and rev it above idle speed, then check that there are no fuel leaks at any of the fuel pipe

and hose connections.Tool number : — (J-46536)

LBIA0389E

PBIC1653E

Page 1943 of 3061

FL-12

< SERVICE INFORMATION >

FUEL TANK

15. Disconnect the fuel level sensor, fuel filter, and fuel pump

assembly electrical connector, the EVAP hose, and the fuel feed

hose.

Disconnect the quick connector as follows:

• Hold the sides of the connector, push in tabs and pull out the

tube.

• If the connector and the tube are stuck together, push and pull

several times until they start to move. Then disconnect them

by pulling.

CAUTION:

• The quick connector can be disconnected when the tabs

are completely depressed. Do not twist the quick connec-

tor more than necessary.

• Do not use any tools to disconnect the quick connector.

• Keep the resin tube away from heat. Be especially careful

when welding near the tube.

• Prevent any acid liquids such as battery electrolyte, from

getting on the resin tube.

• Do not bend or twist the resin tube during connection.

• Do not remove the remaining retainer on the hard tube (or

the equivalent) except when the resin tube or the retainer

is replaced.

• When the resin tube or hard tube, or the equivalent, is

replaced, also replace the retainer with a new one (white

colored retainer).

LBIA0383E

SFE562A

PBIC1268E

Page 1944 of 3061

FUEL TANK

FL-13

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

FL

N

P O

• To keep the quick connector clean and to avoid damage

and contamination from foreign materials, cover the quick

connector with plastic bags or suitable material as shown.

16. Remove the four bolts and remove the fuel tank shield.

17. Remove the propeller shaft. Refer to PR-8

.

18. Disconnect fuel filler hose, and vent hose at the fuel tank side.

19. Remove the fuel tank strap bolts while supporting the fuel tank

with a suitable lift jack.

20. Disconnect the EVAP hose from the molded clip in the top of the fuel tank while lowering the fuel tank.

21. Lower the fuel tank using a suitable lift jack and remove it.

22. If necessary, remove the lock ring using Tool.

23. If necessary, remove the fuel level sensor, fuel filter, and fuel

pump assembly. Discard the fuel level sensor, fuel filter, and fuel

pump assembly O-ring.

CAUTION:

• Do not bend the float arm during removal.

• Avoid impacts such as dropping when handling the com-

ponents.

INSTALLATION

Installation is in the reverse order of removal.

• For installation, use a new fuel level sensor, fuel filter, and fuel pump assembly O-ring.

• Connect the quick connector as follows:

- Check the connection for any damage or foreign materials.

- Align the connector with the pipe, then insert the connector straight into the pipe until a click is heard.

- After connecting the quick connector, make sure that the connec-

tion is secure by checking as follows:

- Pull the tube and the connector to make sure they are securely

connected.

- Visually inspect the connector to make sure the two retainer tabs

are securely connected.

PBIC0163E

LBIA0387E

Tool number : — (J-46536)

LBIA0389E

PBIC1653E

Page 1947 of 3061

FSU-1

SUSPENSION

C

D

F

G

H

I

J

K

L

M

SECTION FSU

A

B

FSU

N

O

PCONTENTS

FRONT SUSPENSION

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution .................................................................2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................3

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

4

NVH Troubleshooting Chart ......................................4

FRONT SUSPENSION ASSEMBLY ...................5

Component ................................................................5

ON-VEHICLE SERVICE ......................................6

Front Suspension Parts .............................................6

Front Wheel Alignment ..............................................6

COIL SPRING AND SHOCK ABSORBER ........10

Removal and Installation .........................................10

Disassembly and Assembly ....................................10

STABILIZER BAR ..............................................12

Removal and Installation .........................................12

UPPER LINK .....................................................13

Removal and Installation .........................................13

LOWER LINK ....................................................14

Removal and Installation .........................................14

UPPER BALL JOINT AND LOWER BALL

JOINT ................................................................

15

Removal and Installation .........................................15

Inspection ................................................................15

KNUCKLE .........................................................17

On-Vehicle Inspection and Service .........................17

Removal and Installation .........................................17

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

19

General Specification ..............................................19

Spring Free Height ..................................................19

Wheel Alignment (Unladen*1) *6 .............................19

Ball Joint ..................................................................20

Wheelarch Height (Unladen*1) ................................20

Page 1950 of 3061

FSU-4

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000003532634

Use the chart below to help you find the cause of the symptom. Repair or replace parts as necessary.

x: ApplicableReference page

FSU-5FSU-10FSU-5FSU-5FSU-20FSU-6FSU-6FSU-6

PR-3, "

NVH Troubleshooting Chart

"

FFD-6, "

NVH Troubleshooting Chart

"

FAX-4, "

NVH Troubleshooting Chart

"

FAX-4, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

BR-4, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible Cause and

SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation,

damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

Stabilizer bar fatigue

PROPELLER SHAFT

FRONT FINAL DRIVE

DRIVE SHAFT

WHEEL HUB

TIRES

ROAD WHEEL

BRAKES

STEERING

SymptomNoise× × ×××× × × ×× × × ××

Shake× × ×× × × ×× × × ××

Vibration× × ××× × ×× × ×

Shimmy× × ×× × × × × ××

Shudder××× ×××××

Poor quality ride or handling××××× ×× ×××

Page 1951 of 3061

FRONT SUSPENSION ASSEMBLY

FSU-5

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

FSU

N

O

P

FRONT SUSPENSION ASSEMBLY

ComponentINFOID:0000000003532635

1. Dust cover 2. Shock absorber 3. Upper link

4. Steering knuckle 5. Cotter pin 6. Bolt

7. Jounce bumper 8. Washer 9. Lower link

10. Stabilizer bar 11. Stabilizer bar bushing 12. Stabilizer bar mounting bracket

13. Connecting rod 14. Coil spring 15. Upper seat

16. Upper spring seat 17. Shock absorber bushing 18. Shock absorber mounting insulator

19. Spacer 20. Washer⇐Front

WEIA0156E