ABS INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2111 of 3061

IDX-7

A

C

D

E

F

G

H

I

J

K

L B

IDX

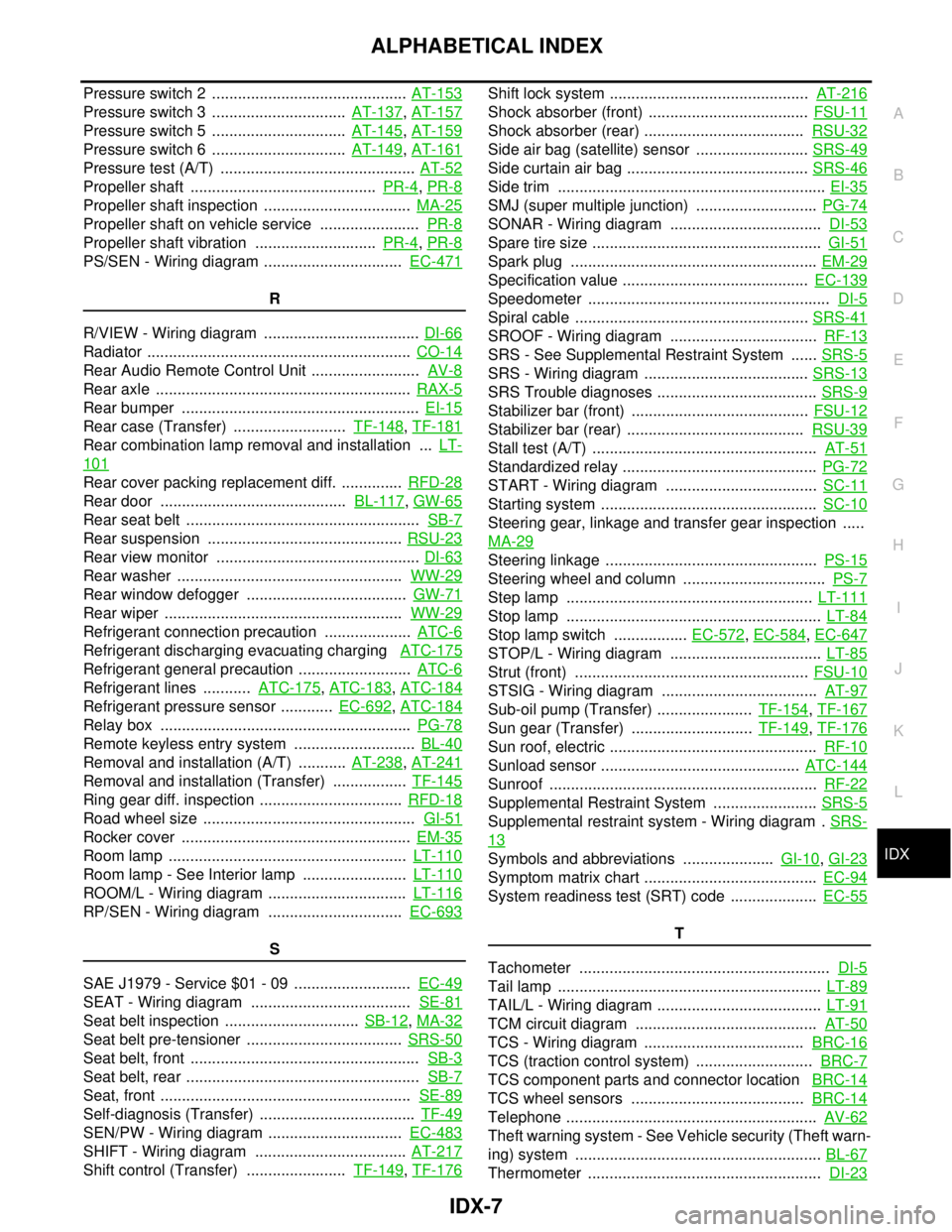

ALPHABETICAL INDEX

Pressure switch 2 ............................................. AT-153

Pressure switch 3 ............................... AT-137, AT-157

Pressure switch 5 ............................... AT-145, AT-159

Pressure switch 6 ............................... AT-149, AT-161

Pressure test (A/T) ............................................. AT-52

Propeller shaft ........................................... PR-4, PR-8

Propeller shaft inspection .................................. MA-25

Propeller shaft on vehicle service ....................... PR-8

Propeller shaft vibration ............................ PR-4, PR-8

PS/SEN - Wiring diagram ................................ EC-471

R

R/VIEW - Wiring diagram .................................... DI-66

Radiator ............................................................. CO-14

Rear Audio Remote Control Unit ......................... AV-8

Rear axle ........................................................... RAX-5

Rear bumper ....................................................... EI-15

Rear case (Transfer) .......................... TF-148, TF-181

Rear combination lamp removal and installation ... LT-

101

Rear cover packing replacement diff. .............. RFD-28

Rear door ........................................... BL-117, GW-65

Rear seat belt ...................................................... SB-7

Rear suspension ............................................. RSU-23

Rear view monitor ............................................... DI-63

Rear washer .................................................... WW-29

Rear window defogger ..................................... GW-71

Rear wiper ....................................................... WW-29

Refrigerant connection precaution .................... ATC-6

Refrigerant discharging evacuating charging ATC-175

Refrigerant general precaution .......................... ATC-6

Refrigerant lines ........... ATC-175, ATC-183, ATC-184

Refrigerant pressure sensor ............ EC-692, ATC-184

Relay box .......................................................... PG-78

Remote keyless entry system ............................ BL-40

Removal and installation (A/T) ........... AT-238, AT-241

Removal and installation (Transfer) ................. TF-145

Ring gear diff. inspection ................................. RFD-18

Road wheel size ................................................. GI-51

Rocker cover ..................................................... EM-35

Room lamp ....................................................... LT-110

Room lamp - See Interior lamp ........................ LT-110

ROOM/L - Wiring diagram ................................ LT-116

RP/SEN - Wiring diagram ............................... EC-693

S

SAE J1979 - Service $01 - 09 ........................... EC-49

SEAT - Wiring diagram ..................................... SE-81

Seat belt inspection ............................... SB-12, MA-32

Seat belt pre-tensioner .................................... SRS-50

Seat belt, front ..................................................... SB-3

Seat belt, rear ...................................................... SB-7

Seat, front .......................................................... SE-89

Self-diagnosis (Transfer) .................................... TF-49

SEN/PW - Wiring diagram ............................... EC-483

SHIFT - Wiring diagram ................................... AT-217

Shift control (Transfer) ....................... TF-149, TF-176

Shift lock system .............................................. AT-216

Shock absorber (front) ..................................... FSU-11

Shock absorber (rear) ..................................... RSU-32

Side air bag (satellite) sensor .......................... SRS-49

Side curtain air bag .......................................... SRS-46

Side trim .............................................................. EI-35

SMJ (super multiple junction) ............................ PG-74

SONAR - Wiring diagram ................................... DI-53

Spare tire size ..................................................... GI-51

Spark plug ......................................................... EM-29

Specification value ........................................... EC-139

Speedometer ........................................................ DI-5

Spiral cable ...................................................... SRS-41

SROOF - Wiring diagram .................................. RF-13

SRS - See Supplemental Restraint System ...... SRS-5

SRS - Wiring diagram ...................................... SRS-13

SRS Trouble diagnoses ..................................... SRS-9

Stabilizer bar (front) ......................................... FSU-12

Stabilizer bar (rear) ......................................... RSU-39

Stall test (A/T) .................................................... AT-51

Standardized relay ............................................. PG-72

START - Wiring diagram ................................... SC-11

Starting system .................................................. SC-10

Steering gear, linkage and transfer gear inspection .....

MA-29

Steering linkage ................................................. PS-15

Steering wheel and column ................................. PS-7

Step lamp ......................................................... LT-111

Stop lamp ........................................................... LT-84

Stop lamp switch ................. EC-572, EC-584, EC-647

STOP/L - Wiring diagram ................................... LT-85

Strut (front) ...................................................... FSU-10

STSIG - Wiring diagram .................................... AT-97

Sub-oil pump (Transfer) ...................... TF-154, TF-167

Sun gear (Transfer) ............................ TF-149, TF-176

Sun roof, electric ................................................ RF-10

Sunload sensor .............................................. ATC-144

Sunroof .............................................................. RF-22

Supplemental Restraint System ........................ SRS-5

Supplemental restraint system - Wiring diagram . SRS-

13

Symbols and abbreviations ..................... GI-10, GI-23

Symptom matrix chart ........................................ EC-94

System readiness test (SRT) code .................... EC-55

T

Tachometer .......................................................... DI-5

Tail lamp ............................................................. LT-89

TAIL/L - Wiring diagram ...................................... LT-91

TCM circuit diagram .......................................... AT-50

TCS - Wiring diagram ..................................... BRC-16

TCS (traction control system) ........................... BRC-7

TCS component parts and connector location BRC-14

TCS wheel sensors ........................................ BRC-14

Telephone .......................................................... AV-62

Theft warning system - See Vehicle security (Theft warn-

ing) system ......................................................... BL-67

Thermometer ...................................................... DI-23

Page 2132 of 3061

LAN-1

ELECTRICAL

C

D

E

F

G

H

I

J

L

M

SECTION LAN

A

B

LAN

N

O

P

CONTENTS

LAN SYSTEM

CAN FUNDAMENTAL

SERVICE INFORMATION ............................

3

PRECAUTIONS ...................................................3

Precaution When Using CONSULT-II .......................3

Precaution for Trouble Diagnosis ..............................3

Precaution for Harness Repair ..................................3

SYSTEM DESCRIPTION .....................................4

CAN Communication System ....................................4

Diag on CAN .............................................................5

TROUBLE DIAGNOSIS ......................................7

Condition of Error Detection ......................................7

Symptom When Error Occurs in CAN Communi-

cation System ............................................................

7

Self-Diagnosis .........................................................10

CAN Diagnostic Support Monitor ............................10

TROUBLE DIAGNOSES WORK FLOW ............13

Information Needed for Trouble Diagnosis .............13

How to Use CAN Communication Signal Chart ......13

Trouble Diagnosis Flow Chart .................................14

Trouble Diagnosis Procedure ..................................14

CAN

SERVICE INFORMATION ...........................

36

INDEX FOR DTC ................................................36

DTC No. Index ........................................................36

HOW TO USE THIS SECTION ...........................37

Caution ....................................................................37

Abbreviation List ......................................................37

PRECAUTIONS ..................................................38

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

38

Precaution When Using CONSULT-II .....................38

Precaution for Trouble Diagnosis ............................38

Precaution for Harness Repair ................................38

TROUBLE DIAGNOSIS ....................................40

CAN Diagnostic Support Monitor .............................40

CAN System Specification Chart .............................44

CAN Communication Signal Chart ..........................44

Schematic ................................................................49

Wiring Diagram - CAN - ...........................................50

Interview Sheet ........................................................53

Data Sheet ...............................................................54

CAN System (Type 1) ..............................................57

CAN System (Type 2) ..............................................58

CAN System (Type 3) ..............................................59

CAN System (Type 4) ..............................................60

Component Parts Location ......................................61

Harness Layout .......................................................61

Malfunction Area Chart ............................................61

Main Line Between TCM and Driver Seat Control

Unit ..........................................................................

62

Main Line Between TCM and ICC Sensor ...............63

Main Line Between ICC Sensor and ICC Unit .........64

Main Line Between ICC Unit and Driver Seat Con-

trol Unit ....................................................................

65

Main Line Between Driver Seat Control Unit and

Data Link Connector ................................................

65

Main Line Between Data Link Connector and ABS

Actuator and Electric Unit (Control Unit) ..................

66

ECM Branch Line Circuit .........................................67

TCM Branch Line Circuit .........................................67

ICC Sensor Branch Line Circuit ...............................68

ICC Unit Branch Line Circuit ....................................69

Driver Seat Control Unit Branch Line Circuit ...........69

BCM Branch Line Circuit .........................................70

Display Control Unit Branch Line Circuit .................70

Data Link Connector Branch Line Circuit ................71

Front Air Control Branch Line Circuit .......................71

Combination Meter Branch Line Circuit ...................72

Steering Angle Sensor Branch Line Circuit .............72

Transfer Control Unit Branch Line Circuit ................73

ABS Actuator and Electric Unit (Control Unit)

Branch Line Circuit ..................................................

74

Page 2139 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-8

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Data link connector branch line open circuit

NOTE:

• When data link connector branch line is open, transmission and receptio INFINITI QX56 2007 Factory Service Manual LAN-8

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Data link connector branch line open circuit

NOTE:

• When data link connector branch line is open, transmission and receptio](/img/42/57029/w960_57029-2138.png)

LAN-8

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Example: Data link connector branch line open circuit

NOTE:

• When data link connector branch line is open, transmission and reception of CAN communication signals is

not affected. Therefore, no symptoms occur. However, be sure to repair malfunctioning circuit.

• When data link connector branch line is open, the screen-display of the CONSULT-II “SELECT SYSTEM”

screen may be the same as when the CAN communication line has short-circuit. However, symptoms differ

depending on the case. See below chart for the differences.

Unit name Symptom

ECM Engine torque limiting is affected, and shift harshness increases.

BCM Reverse warning chime does not sound.

EPS control unit Normal operation.

Combination meter• Shift position indicator and OD OFF indicator turn OFF.

• Warning lamps turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/R Normal operation.

SKIB8739E

Unit name Symptom

ECM

Normal operation. BCM

EPS control unit

Combination meter

ABS actuator and electric unit (control unit)

TCM

IPDM E/R

SELECT SYSTEM

(CONSULT-II)Difference of symptom

Data link connector branch line open circuit

All Diag on CAN units are not

indicated.Normal operation.

CAN-H, CAN-L harness short-circuitMost the units which are connected to the CAN com-

munication system enter fail-safe mode or are deac-

tivated.

Page 2140 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-9

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P Example: Main Line Between Data Link Connector and ABS Actuator and Electric Unit (Control Unit) Open INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS

LAN-9

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P Example: Main Line Between Data Link Connector and ABS Actuator and Electric Unit (Control Unit) Open](/img/42/57029/w960_57029-2139.png)

TROUBLE DIAGNOSIS

LAN-9

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P Example: Main Line Between Data Link Connector and ABS Actuator and Electric Unit (Control Unit) Open Circuit

Example: CAN-H, CAN-L Harness Short Circuit

SKIB8740E

Unit name Symptom

ECM Engine torque limiting is affected, and shift harshness increases.

BCM• Reverse warning chime does not sound.

• The front wiper moves under continuous operation mode even though the front wip-

er switch being in the intermittent position.

EPS control unit The steering effort increases.

Combination meter• The shift position indicator and OD OFF indicator turn OFF.

• The speedometer is inoperative.

• The odo/trip meter stops.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/RWhen the ignition switch is ON,

• The headlamps (Lo) turn ON.

• The cooling fan continues to rotate.

SKIB8741E

Page 2141 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-10

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Self-Diagnosis

INFOID:0000000003533613

CAN Diagnostic Support MonitorINFOID:0000000003533614

CONSULT-II and CAN diagnostic support mon INFINITI QX56 2007 Factory Service Manual LAN-10

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Self-Diagnosis

INFOID:0000000003533613

CAN Diagnostic Support MonitorINFOID:0000000003533614

CONSULT-II and CAN diagnostic support mon](/img/42/57029/w960_57029-2140.png)

LAN-10

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSIS

Self-Diagnosis

INFOID:0000000003533613

CAN Diagnostic Support MonitorINFOID:0000000003533614

CONSULT-II and CAN diagnostic support monitor (on-board diagnosis function) are used for detecting root

cause.

MONITOR ITEM (CONSULT-II)

Unit name Symptom

ECM• Engine torque limiting is affected, and shift harshness increases.

• Engine speed drops.

BCM• Reverse warning chime does not sound.

• The front wiper moves under continuous operation mode even though the front

wiper switch being in the intermittent position.

• The room lamp does not turn ON.

• The engine does not start (if an error or malfunction occurs while turning the igni-

tion switch is OFF.)

• The steering lock does not release (if an error or malfunction occurs while turning

the ignition switch is OFF.)

EPS control unit The steering effort increases.

Combination meter• The tachometer and the speedometer do not move.

• Warning lamps turn ON.

• Indicator lamps do not turn ON.

ABS actuator and electric unit (control unit) Normal operation.

TCM No impact on operation.

IPDM E/RWhen the ignition switch is ON,

• The headlamps (Lo) turn ON.

• The cooling fan continues to rotate.

DTCSelf-diagnosis item

(CONSULT-II indication)DTC detection condition Inspection/Action

U1000 CAN COMM CIRCUITWhen ECM is not transmitting or receiving CAN

communication signal of OBD (emission-related

diagnosis) for 2 seconds or more.

Refer to LAN-13

. When a control unit (except for ECM) is not

transmitting or receiving CAN communication

signal for 2 seconds or more.

U1001 CAN COMM CIRCUITWhen ECM is not transmitting or receiving CAN

communication signal other than OBD (emis-

sion-related diagnosis) for 2 seconds or more.

U1002 SYSTEM COMMWhen a control unit is not transmitting or receiv-

ing CAN communication signal for 2 seconds or

less.Start the inspection. Re-

fer to the applicable sec-

tion of the indicated

control unit.

U1010 CONTROL UNIT [CAN]When an error is detected during the initial diag-

nosis for CAN controller of each control unit.Replace the control unit

indicating “U1010”.

Page 2156 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-25

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

h. Reception item of “ABS”: “UNKWN” is not indicated. This indicates normal communi INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-25

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

h. Reception item of “ABS”: “UNKWN” is not indicated. This indicates normal communi](/img/42/57029/w960_57029-2155.png)

TROUBLE DIAGNOSES WORK FLOW

LAN-25

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

h. Reception item of “ABS”: “UNKWN” is not indicated. This indicates normal communication between ABS

and its receiving units. Do not draw any line.

i. Reception item of “IPDM E/R”: “UNKWN” is not indicated. This indicates normal communication between

IPDM-E and its receiving units. Do not draw any line.

3. Based on information received from “CAN DIAG SUPPORT MNTR”, place a check mark on the known

good CAN communication line between ECM and IPDM-E.

a. Through the previous procedure, the circuit between ADP splice and TCM has the most amount of lines

(shade 3-a in the figure).

b. Place a check mark on the known good lines to establish the error circuit.

SKIB8727E

Page 2160 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-29

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

1. SELF-DIAG RESULTS: Inspect the control units indicating “U1000” or “U1001” on SE INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-29

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

1. SELF-DIAG RESULTS: Inspect the control units indicating “U1000” or “U1001” on SE](/img/42/57029/w960_57029-2159.png)

TROUBLE DIAGNOSES WORK FLOW

LAN-29

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

1. SELF-DIAG RESULTS: Inspect the control units indicating “U1000” or “U1001” on SELF-DIAG RESULTS.

2. CAN DIAG SUPPORT MNTR (with PAST): Check the CAN DIAG SUPPORT MNTR (with PAST) of units

indicating “U1000” or “U1001” on SELF-DIAG RESULTS. Draw a line on the diagnosis sheet to indicate

the possible error circuit.

NOTE:

For the details of each indication on CAN DIAG SUPPORT MNTR, refer to LAN-40, "

CAN Diagnostic Sup-

port Monitor".

a. Reception item of “ENGINE”: “VDC/TCS/ABS”, “3” is indicated in the “PAST”. This means ECM could not

receive the signal from ABS in the past. Draw a line between ECM and ABS (line 2-a in the figure).

SKIB8731E

Page 2161 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-30

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSES WORK FLOW

b. Reception item of “METER”: “VDC/TCS/ABS”, “3” is indicated in the “PAST”. This means M&A could not

receiv INFINITI QX56 2007 Factory Service Manual LAN-30

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSES WORK FLOW

b. Reception item of “METER”: “VDC/TCS/ABS”, “3” is indicated in the “PAST”. This means M&A could not

receiv](/img/42/57029/w960_57029-2160.png)

LAN-30

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSES WORK FLOW

b. Reception item of “METER”: “VDC/TCS/ABS”, “3” is indicated in the “PAST”. This means M&A could not

receive the signal from ABS in the past. Draw a line between M&A and ABS (line 2-b in the figure).

c. Reception item of “TRANSMISSION”: “VDC/TCS/ABS”, “3” is indicated in the “PAST”. This means TCM

could not receive the signal from ABS in the past. Draw a line between TCM and ABS (line 2-c in the fig-

ure).

3. CAN DIAG SUPPORT MNTR (without PAST): Check the CAN DIAG SUPPORT MNTR (without PAST) of

units indicating “U1000” or “U1001” on SELF-DIAG RESULTS. Draw a line on the diagnosis sheet to indi-

cate the possible error circuit.

NOTE:

• While an error occurred in the past according to SELF-DIAG RESULTS, it is unclear which signal is not

received. Assume that errors were detected from all reception items.

• Draw a single line among the unit and all reception items. (Work flow differs from CAN DIAG SUPPORT

MNTR (with PAST).)

a. Reception item of “EPS”: Assume that the unit could not receive the signals from ECM, ABS, and M&A.

Draw a line among EPS, ECM, ABS, and M&A (line 3-a in the figure).

SKIB8732E

Page 2162 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-31

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

b. Reception item of “ABS”: Assume that the unit could not receive the signal from ECM. INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSES WORK FLOW

LAN-31

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

b. Reception item of “ABS”: Assume that the unit could not receive the signal from ECM.](/img/42/57029/w960_57029-2161.png)

TROUBLE DIAGNOSES WORK FLOW

LAN-31

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

C

D

E

F

G

H

I

J

L

MA

B

LAN

N

O

P

b. Reception item of “ABS”: Assume that the unit could not receive the signal from ECM. Draw a line

between ABS and ECM (line 3-b in the figure).

4. Search for the possible cause using CAN communication signal chart using information from the interview

with the customer.

NOTE:

For the details of CAN communication signal, refer to LAN-44, "

CAN Communication Signal Chart".

a. ABS warning lamp turned ON and speedometer did not move: This means that “ABS warning lamp signal”

and “Vehicle speed signal” could not communicate between M&A and ABS (4-a in the figure).

SKIB8733E

Page 2163 of 3061

![INFINITI QX56 2007 Factory Service Manual LAN-32

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSES WORK FLOW

b. The tachometer moved normally: This means that “Engine speed signal” could communicate normally

between ECM and M&A ( INFINITI QX56 2007 Factory Service Manual LAN-32

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSES WORK FLOW

b. The tachometer moved normally: This means that “Engine speed signal” could communicate normally

between ECM and M&A (](/img/42/57029/w960_57029-2162.png)

LAN-32

< SERVICE INFORMATION >[CAN FUNDAMENTAL]

TROUBLE DIAGNOSES WORK FLOW

b. The tachometer moved normally: This means that “Engine speed signal” could communicate normally

between ECM and M&A (4-b in the figure).

5. Fill out the diagnosis sheet based on information from step 4.

a. The ABS warning lamp turned ON and speedometer did not move: Assume that a possible cause is no

communication between M&A and ABS. Draw a line between M&A and ABS. (Line 5-a in the figure).

SKIB8895E