relay INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2303 of 3061

LT-96

< SERVICE INFORMATION >

TRAILER TOW

• through IPDM E/R terminal 16

• to trailer tow relay 2 terminal 1.

When energized, the trailer tow relay 2 supplies power

• through trailer tow relay 2 terminals 5 and 7

• to trailer connector terminal 5.

SchematicINFOID:0000000003533453

WKWA3664E

Page 2309 of 3061

LT-102

< SERVICE INFORMATION >

INTERIOR ROOM LAMP

switch LH, unlock signal from keyfob, door lock and unlock switch, front door lock assembly LH (key cylinder

switch), ignition switch, and glass hatch ajar switch.

When room lamp and personal lamp turns ON, there is a gradual brightening over 1 second. When room lamp

and personal lamp turns OFF, there is a gradual dimming over 1 second.

The room lamp and personal lamp timer is controlled by the BCM (body control module).

Room lamp and personal lamp timer control settings can be changed with CONSULT-II.

Ignition keyhole illumination turns ON when front door LH is opened (door switch ON) or key is removed from

key cylinder. Illumination turns OFF when front door LH is closed (door switch OFF).

Step and foot lamps turn ON when front or rear doors are opened (door switch ON). Lamps turn OFF when

front and rear doors are closed (all door switches OFF).

POWER SUPPLY AND GROUND

Power is supplied at all times

• through 10A fuse [No. 19, located in the fuse block (J/B)]

• to key switch and key lock solenoid terminal 3,

• through 15A fuse [No. 22, located in the fuse block (J/B)]

• to BCM terminal 57, and

• through 50A fusible link (letter f , located in the fuse and fusible link box)

• to BCM terminal 70.

When the key is inserted in key switch and key lock solenoid, power is supplied

• through the key switch and key lock solenoid terminal 4

• to BCM terminal 37.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67

• through grounds M57, M61 and M79.

When the front door LH is opened, ground is supplied

• to BCM terminal 47

• through case ground of front door switch LH.

When the front door RH is opened, ground is supplied

• to BCM terminal 12

• through case ground of front door switch RH.

When the rear door LH is opened, ground is supplied

• to BCM terminal 48

• through case ground of rear door switch LH.

When the rear door RH is opened, ground is supplied

• to BCM terminal 13

• through case ground of rear door switch RH.

When the liftgate is opened, ground is supplied

• to BCM terminal 43

• through back door latch (door ajar switch) terminal 7

• through back door latch (door ajar switch) terminal 8

• through grounds B7 and B19.

When the glass hatch is opened, ground is supplied

• to BCM terminal 42

• through case ground of glass hatch ajar switch.

When the front door LH or front door RH door is unlocked by the door lock and unlock switch, BCM receives

serial data

• to BCM terminal 22

• through main power window and door lock/unlock switch terminal 14 or power window and door lock/unlock

switch RH terminal 16

• through main power window and door lock/unlock switch terminal 17 or power window and door lock/unlock

switch RH terminal 11

• through grounds M57, M61 and M79.

When the front door LH is unlocked by the key, the BCM receives serial data

• to BCM terminal 22

• through main power window and door lock/unlock switch terminal 14

• through main power window and door lock/unlock switch terminal 6

• through front door lock assembly LH (key cylinder switch) terminal 6

• through front door lock assembly LH (key cylinder switch) terminal 5

Page 2327 of 3061

LT-120

< SERVICE INFORMATION >

ILLUMINATION

ILLUMINATION

Component Parts and Harness Connector LocationINFOID:0000000003533468

System DescriptionINFOID:0000000003533469

Control of the illumination lamps operation is dependent upon the position of the lighting switch (combination

switch). When the lighting switch is placed in the 1ST or 2ND position (or if the auto light system is activated)

the BCM (body control module) receives input signal requesting the illumination lamps to illuminate. This input

signal is communicated to the IPDM E/R (intelligent power distribution module engine room) across the CAN

communication lines. The CPU (central processing unit) of the IPDM E/R controls the tail lamp relay coil. This

relay, when energized, directs power to the illumination lamps, which then illuminate.

Power is supplied at all times

• to ignition relay, located in the IPDM E/R,

• to tail lamp relay, located in the IPDM E/R,

• through 50A fusible link (letter f , located in the fuse and fusible link box)

• to BCM terminal 70,

• through 20A fuse (No. 53, located in the IPDM E/R)

• to CPU of the IPDM E/R, and

• through 10A fuse [No.19, located in fuse block (J/B)]

• to combination meter terminal 8

With the ignition switch in the ON or START position, power is supplied

• to ignition relay, located in the IPDM E/R,

• through 10A fuse (No. 59, located in the fuse and relay box)

WKIA3471E

Page 2328 of 3061

![INFINITI QX56 2007 Factory Service Manual ILLUMINATION

LT-121

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

• to BCM terminal 38, and

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal INFINITI QX56 2007 Factory Service Manual ILLUMINATION

LT-121

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

• to BCM terminal 38, and

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal](/img/42/57029/w960_57029-2327.png)

ILLUMINATION

LT-121

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

• to BCM terminal 38, and

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal 24.

Ground is supplied

• to BCM terminal 67

• to combination meter terminal 17

• through grounds M57, M61 and M79, and

• to IPDM E/R terminals 38 and 59

• through grounds E9, E15 and E24.

ILLUMINATION OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST or 2ND position (or if the auto light system is activated), the BCM receives

input signal requesting the illumination lamps to illuminate. This input signal is communicated to the IPDM E/R

across the CAN communication lines. The CPU of the IPDM E/R controls the tail lamp relay coil, which, when

energized, directs power

• through 10A fuse (No. 36, located in the IPDM E/R)

• through IPDM E/R terminal 49

• to illumination control switch terminal 1

• to power liftgate switch terminal 3

• to front room/map lamp assembly (console box illumination) terminal 7

• to hazard switch terminal 3

• to rear sonar system OFF switch terminal 3

• to glove box lamp terminal 1

• to door mirror remote control switch terminal 16

• to display control unit terminal 14

• to power window and door lock/unlock switch RH terminal 5 (early production)

• to main power window and door lock/unlock switch LH terminal 16 (early production)

• to 4WD shift switch terminal 7 (with 4-wheel drive)

• to front air control terminal 23

• to rear power vent window switch terminal 5

• to DVD player terminal 12 (with DVD entertainment system)

• to NAVI control unit terminal 61

• to pedal adjusting switch terminal 5

• to electric brake (pre-wiring) terminal 4 (with trailer tow)

• to front and rear heated seat switch LH and RH terminal 5

• to A/T device terminal 11

• to VDC OFF switch terminal 3

• to tow mode switch terminal 3

• to headlamp aiming switch terminal 3

• to clock terminal 3, and

• through 10A fuse (No. 37, located in the IPDM E/R)

• through IPDM E/R terminal 57

• to AV switch terminal 3

• to audio unit terminal 8

• to rear air control terminal 1 and

• to rear audio remote control unit terminal 6.

The illumination control switch controls illumination intensity by varying the ground to the following

• through illumination control switch terminal 2

• to power liftgate switch terminal 4

• to front room/map lamp assembly (console box illumination) terminal 8

• to AV switch terminal 4

• to hazard switch terminal 4

• to audio unit terminal 7

• to rear sonar system OFF switch terminal 4

• to power window and door lock/unlock switch RH terminal 1 (early production)

• to main power window and door lock/unlock switch LH terminal 12 (early production)

• to 4WD switch terminal 8 (with 4-wheel drive)

• to front air control terminal 24

• to rear power vent window switch terminal 6

• to DVD player terminal 10 (with DVD entertainment system)

• to pedal adjusting switch terminal 6

• to A/T device terminal 12

Page 2403 of 3061

PG-1

ELECTRICAL

C

D

E

F

G

H

I

J

L

M

SECTION PG

A

B

PG

N

O

P

CONTENTS

POWER SUPPLY, GROUND & CIRCUIT ELEMENTS

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

POWER SUPPLY ROUTING CIRCUIT ...............3

Schematic .................................................................3

Wiring Diagram - POWER - ......................................5

Fuse ........................................................................16

Fusible Link .............................................................16

Circuit Breaker (Built Into BCM) ..............................16

IPDM E/R (INTELLIGENT POWER DISTRI-

BUTION MODULE ENGINE ROOM) .................

17

System Description .................................................17

CAN Communication System Description ...............18

Function of Detecting Ignition Relay Malfunction ....18

CONSULT-II Function (IPDM E/R) ..........................18

Auto Active Test ......................................................20

Terminal and Reference Value for IPDM E/R .........22

IPDM E/R Terminal Arrangement ...........................26

IPDM E/R Power/Ground Circuit Inspection ...........26

Inspection with CONSULT-II (Self-Diagnosis) ........27

Removal and Installation of IPDM E/R ....................28

GROUND CIRCUIT ............................................29

Ground Distribution ..................................................29

HARNESS .........................................................39

Harness Layout .......................................................39

Wiring Diagram Codes (Cell Codes) .......................59

ELECTRICAL UNITS LOCATION ....................63

Electrical Units Location ..........................................63

HARNESS CONNECTOR .................................66

Description ...............................................................66

ELECTRICAL UNITS ........................................68

Terminal Arrangement .............................................68

STANDARDIZED RELAY .................................69

Description ...............................................................69

SUPER MULTIPLE JUNCTION (SMJ) .............71

Terminal Arrangement .............................................71

FUSE BLOCK - JUNCTION BOX (J/B) ............73

Terminal Arrangement .............................................73

FUSE AND FUSIBLE LINK BOX ......................74

Terminal Arrangement .............................................74

FUSE AND RELAY BOX ..................................75

Terminal Arrangement .............................................75

Page 2419 of 3061

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

System DescriptionINFOID:0000000003533835

• IPDM E/R (Intelligent Power Distribution Module Engine Room) integrates the relay box and fuse block

which were originally placed in engine compartment. It controls integrated relays via IPDM E/R control cir-

cuits.

• IPDM E/R-integrated control circuits perform ON-OFF operation of relays, CAN communication control, etc.

• It controls operation of each electrical component via ECM, BCM and CAN communication lines.

CAUTION:

None of the IPDM E/R integrated relays can be removed.

SYSTEMS CONTROLLED BY IPDM E/R

1. Lamp control

Using CAN communication lines, it receives signals from the BCM and controls the following lamps:

• Headlamps (Hi, Lo)

• Parking lamps

• Tail and license lamps

• Front fog lamps

2. Wiper control

Using CAN communication lines, it receives signals from the BCM and controls the front wipers.

3. Rear window defogger relay control

Using CAN communication lines, it receives signals from the BCM and controls the rear window defogger

relay.

4. A/C compressor control

Using CAN communication lines, it receives signals from the ECM and controls the A/C compressor

(magnetic clutch).

5. Starter control

Using CAN communication lines, it receives signals from the BCM and controls the starter relay.

6. Cooling fan control

Using CAN communication lines, it receives signals from the ECM and controls the cooling fan relays.

7. Horn control

Using CAN communication lines, it receives signals from the BCM and controls the horn relay.

CAN COMMUNICATION LINE CONTROL

With CAN communication, by connecting each control unit using two communication lines (CAN L-line, CAN

H-line), it is possible to transmit a maximum amount of information with minimum wiring. Each control unit can

transmit and receive data, and reads necessary information only.

1. Fail-safe control

• When CAN communication with other control units is impossible, IPDM E/R performs fail-safe control.

After CAN communication returns to normal operation, it also returns to normal control.

• Operation of control parts by IPDM E/R during fail-safe mode is as follows:

Controlled system Fail-safe mode

Headlamp• With the ignition switch ON, the headlamp (low) is ON.

• With the ignition switch OFF, the headlamp (low) is OFF.

Tail and parking lamps• With the ignition switch ON, the tail and parking lamps are ON.

• With the ignition switch OFF, the tail and parking lamps are OFF.

Cooling fan• With the ignition switch ON, the cooling fan HI operates.

• With the ignition switch OFF, the cooling fan stops.

Front wiperUntil the ignition switch is turned off, the front wiper LO and HI remains in the same status it

was in just before fail−safe control was initiated.

Rear window defogger Rear window defogger relay OFF

A/C compressor A/C compressor OFF

Front fog lamps Front fog lamp relay OFF

Page 2420 of 3061

PG-18

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R STATUS CONTROL

In order to save power, IPDM E/R switches status automatically based on each operating condition.

1. CAN communication status

• CAN communication is normally performed with other control units.

• Individual unit control by IPDM E/R is normally performed.

• When sleep request signal is received from BCM, mode is switched to sleep waiting status.

2. Sleep waiting status

• Process to stop CAN communication is activated.

• All systems controlled by IPDM E/R are stopped. When 1 second has elapsed after CAN communica-

tion with other control units is stopped, mode switches to sleep status.

3. Sleep status

• IPDM E/R operates in low current-consumption mode.

• CAN communication is stopped.

• When a change in CAN communication signal is detected, mode switches to CAN communication sta-

tus.

• When a change in ignition switch signal is detected, mode switches to CAN communication status.

CAN Communication System DescriptionINFOID:0000000003533836

Refer to LAN-4.

Function of Detecting Ignition Relay MalfunctionINFOID:0000000003533837

• When the integrated ignition relay is stuck in a "closed contact" position and cannot be turned OFF, IPDM E/

R turns ON tail and parking lamps for 10 minutes to indicate IPDM E/R malfunction.

• When the state of the integrated ignition relay does not agree with the state of the ignition switch signal

received via CAN communication, the IPDM E/R activates the tail lamp relay.

NOTE:

When the ignition switch is turned ON, the tail lamps are OFF.

CONSULT-II Function (IPDM E/R)INFOID:0000000003533838

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II Start Procedure

Refer to GI-36, "CONSULT-II Start Procedure".

SELF-DIAGNOSTIC RESULTS

Display Item List

Ignition switch signal Ignition relay status Tail lamp relay

ON ON —

OFF OFF —

ON OFF —

OFF ON ON (10 minutes)

IPDM E/R diagnostic Mode Description

SELF-DIAG RESULTS Displays IPDM E/R self-diagnosis results.

DATA MONITOR Displays IPDM E/R input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

Page 2421 of 3061

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-19

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

NOTE:

The details for display of the period are as follows:

• CRNT: Error currently detected with IPDM E/R.

• PAST: Error detected in the past and placed in IPDM E/R memory.

DATA MONITOR

All Signals, Main Signals, Selection From Menu

Display itemsCONSULT-II

display codeMalfunction detectionTIME

Possible causes

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.—————

CAN COMM CIRC U1000• If CAN communication reception/transmission

data has a malfunction, or if any of the control

units fail, data reception/transmission cannot

be confirmed.

• When the data in CAN communication is not

received before the specified time.XXAny of items listed be-

low have errors:

• TRANSMIT DIAG

•ECM

•BCM/SEC

ALL SIGNALS All signals will be monitored.

MAIN SIGNALS Monitors the predetermined item(s).

SELECTION FROM MENU Selects and monitors individual signal(s).

Item nameCONSULT-II

screen displayDisplay or unitMonitor item selection

Description

ALL

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Motor fan requestMOTOR FAN

REQ1/2/3/4 X X X Signal status input from ECM

Compressor re-

questAC COMP REQ ON/OFF X X X Signal status input from ECM

Parking, license,

and tail lamp re-

questTAIL & CLR REQ ON/OFF X X X Signal status input from BCM

Headlamp low

beam requestHL LO REQ ON/OFF X X X Signal status input from BCM

Headlamp high

beam requestHL HI REQ ON/OFF X X X Signal status input from BCM

Front fog request FR FOG REQ ON/OFF X X X Signal status input from BCM

Front wiper re-

questFR WIP REQSTOP/1LOW/

LOW/HIX X X Signal status input from BCM

Wiper auto stopWIP AUTO

STOPACT P/STOP P X X X Output status of IPDM E/R

Wiper protection WIP PROT OFF/Block X X X Control status of IPDM E/R

Starter request ST RLY REQ ON/OFF X X

Status of input signal

NOTE

Ignition relay

statusIGN RLY ON/OFF X X XIgnition relay status monitored

with IPDM E/R

Rear defogger re-

questRR DEF REQ ON/OFF X X X Signal status input from BCM

Oil pressure

switchOIL P SW (*1) OPEN/CLOSE X XSignal status input from IPDM

E/R

Hood switch HOOD SW OFF XSignal status input from IPDM

E/R

Page 2422 of 3061

PG-20

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

NOTE:

• Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is in ACC posi-

tion, display may not be correct.

• (*1) This item is displayed, but does not function.

CAN DIAG SUPPORT MNTR

Refer to LAN-4.

ACTIVE TEST

Auto Active TestINFOID:0000000003533839

DESCRIPTION

• In auto active test mode, operation inspection can be performed when IPDM E/R sends a drive signal to the

following systems:

- Rear window defogger

- Front wipers

- Tail and parking lamps

- Front fog lamps

- Headlamps (Hi, Lo)

- A/C compressor (magnet clutch)

- Cooling fan

OPERATION PROCEDURE

1. Close hood and front door RH, and lift wiper arms away from windshield (to prevent glass damage by

wiper operation).

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield beforehand.

2. Turn ignition switch OFF.

3. Turn ignition switch ON and, within 20 seconds, press front door switch LH 10 times. Then turn ignition

switch OFF.

4. Turn ignition switch ON within 10 seconds after ignition switch OFF.

5. When auto active test mode is actuated, horn chirps once.

6. After a series of operations is repeated three times, auto active test is completed.

NOTE:

When auto active test mode has to be cancelled halfway, turn ignition switch OFF.

Theft warning

horn requestTHFT HRN REQ ON/OFF X X Signal status input from BCM

Horn chirp HORN CHIRP ON/OFF X X Output status of IPDM E/R

Daytime running

lamp requestDTRL REQ ON/OFF X X Signal status input from BCM Item nameCONSULT-II

screen displayDisplay or unitMonitor item selection

Description

ALL

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

Test name CONSULT-II screen display Description

Rear defogger output REAR DEFOGGERWith a certain ON-OFF operation, the rear defogger relay can be oper-

ated.

Front wiper (HI, LO) output FRONT WIPERWith a certain operation (OFF, HI ON, LO ON), the front wiper relay (Lo,

Hi) can be operated.

Cooling fan output MOTOR FAN With a certain operation (1, 2, 3, 4), the cooling fan can be operated.

Lamp (HI, LO, TAIL, FOG)

outputEXTERNAL LAMPSWith a certain operation (OFF, HI ON, LO ON, TAIL ON, FOG ON), the

lamp relay (Low, High, Tail, Fog) can be operated.

Cornering lamp output CORNERING LAMP —

Horn output HORN With a certain ON-OFF operation, the horn relay can be operated.

Page 2424 of 3061

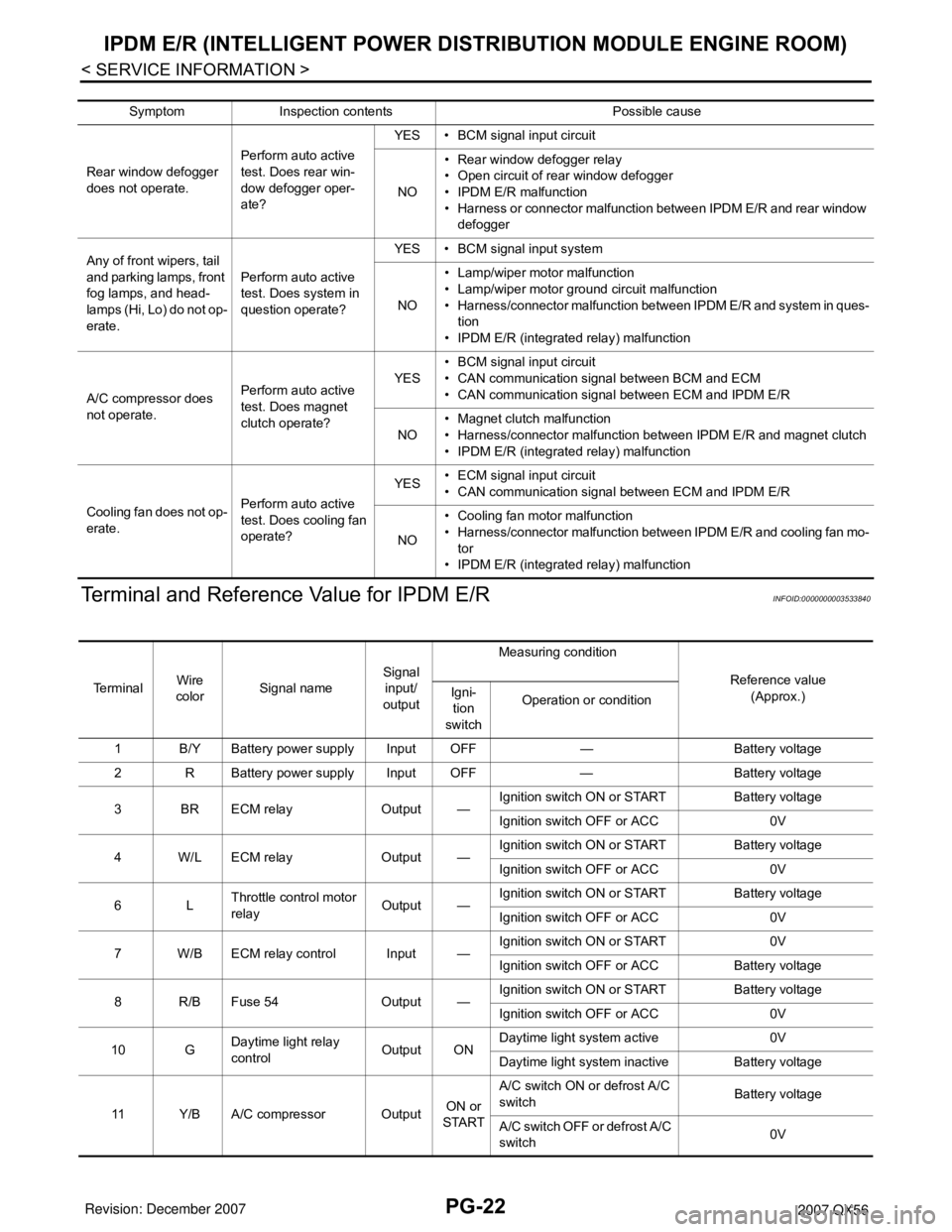

PG-22

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

Terminal and Reference Value for IPDM E/R

INFOID:0000000003533840

Symptom Inspection contents Possible cause

Rear window defogger

does not operate.Perform auto active

test. Does rear win-

dow defogger oper-

ate?YES • BCM signal input circuit

NO• Rear window defogger relay

• Open circuit of rear window defogger

•IPDM E/R malfunction

• Harness or connector malfunction between IPDM E/R and rear window

defogger

Any of front wipers, tail

and parking lamps, front

fog lamps, and head-

lamps (Hi, Lo) do not op-

erate.Perform auto active

test. Does system in

question operate?YES • BCM signal input system

NO• Lamp/wiper motor malfunction

• Lamp/wiper motor ground circuit malfunction

• Harness/connector malfunction between IPDM E/R and system in ques-

tion

• IPDM E/R (integrated relay) malfunction

A/C compressor does

not operate.Perform auto active

test. Does magnet

clutch operate?YES• BCM signal input circuit

• CAN communication signal between BCM and ECM

• CAN communication signal between ECM and IPDM E/R

NO• Magnet clutch malfunction

• Harness/connector malfunction between IPDM E/R and magnet clutch

• IPDM E/R (integrated relay) malfunction

Cooling fan does not op-

erate.Perform auto active

test. Does cooling fan

operate?YES• ECM signal input circuit

• CAN communication signal between ECM and IPDM E/R

NO• Cooling fan motor malfunction

• Harness/connector malfunction between IPDM E/R and cooling fan mo-

tor

• IPDM E/R (integrated relay) malfunction

Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value

(Approx.) Igni-

tion

switchOperation or condition

1 B/Y Battery power supply Input OFF — Battery voltage

2 R Battery power supply Input OFF — Battery voltage

3 BR ECM relay Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

4 W/L ECM relay Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

6LThrottle control motor

relayOutput —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

7 W/B ECM relay control Input —Ignition switch ON or START 0V

Ignition switch OFF or ACC Battery voltage

8 R/B Fuse 54 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

10 GDaytime light relay

controlOutput ONDaytime light system active 0V

Daytime light system inactive Battery voltage

11 Y/B A/C compressor OutputON or

STARTA/C switch ON or defrost A/C

switchBattery voltage

A/C switch OFF or defrost A/C

switch0V