wheel INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2524 of 3061

RAX-6

< SERVICE INFORMATION >

WHEEL HUB

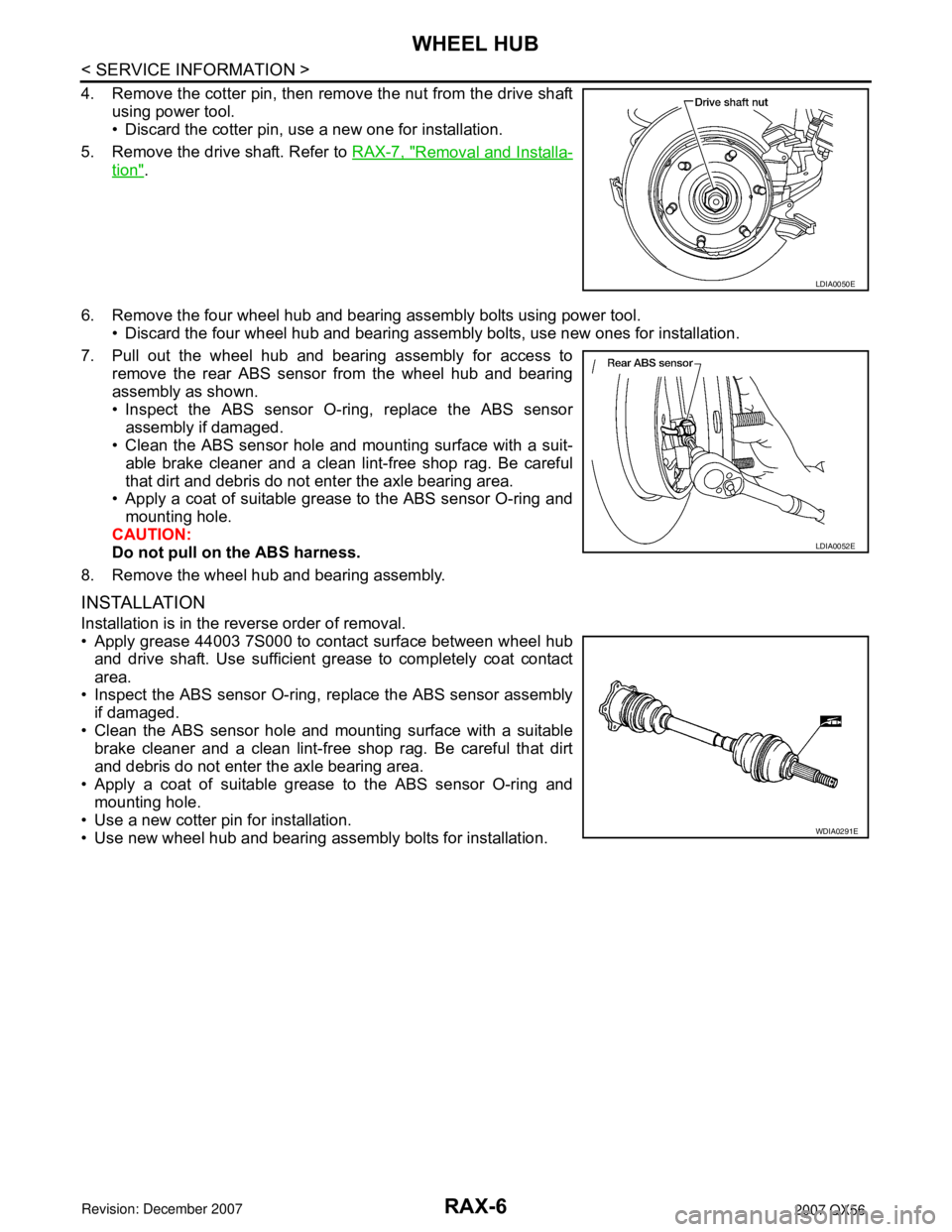

4. Remove the cotter pin, then remove the nut from the drive shaft

using power tool.

• Discard the cotter pin, use a new one for installation.

5. Remove the drive shaft. Refer to RAX-7, "

Removal and Installa-

tion".

6. Remove the four wheel hub and bearing assembly bolts using power tool.

• Discard the four wheel hub and bearing assembly bolts, use new ones for installation.

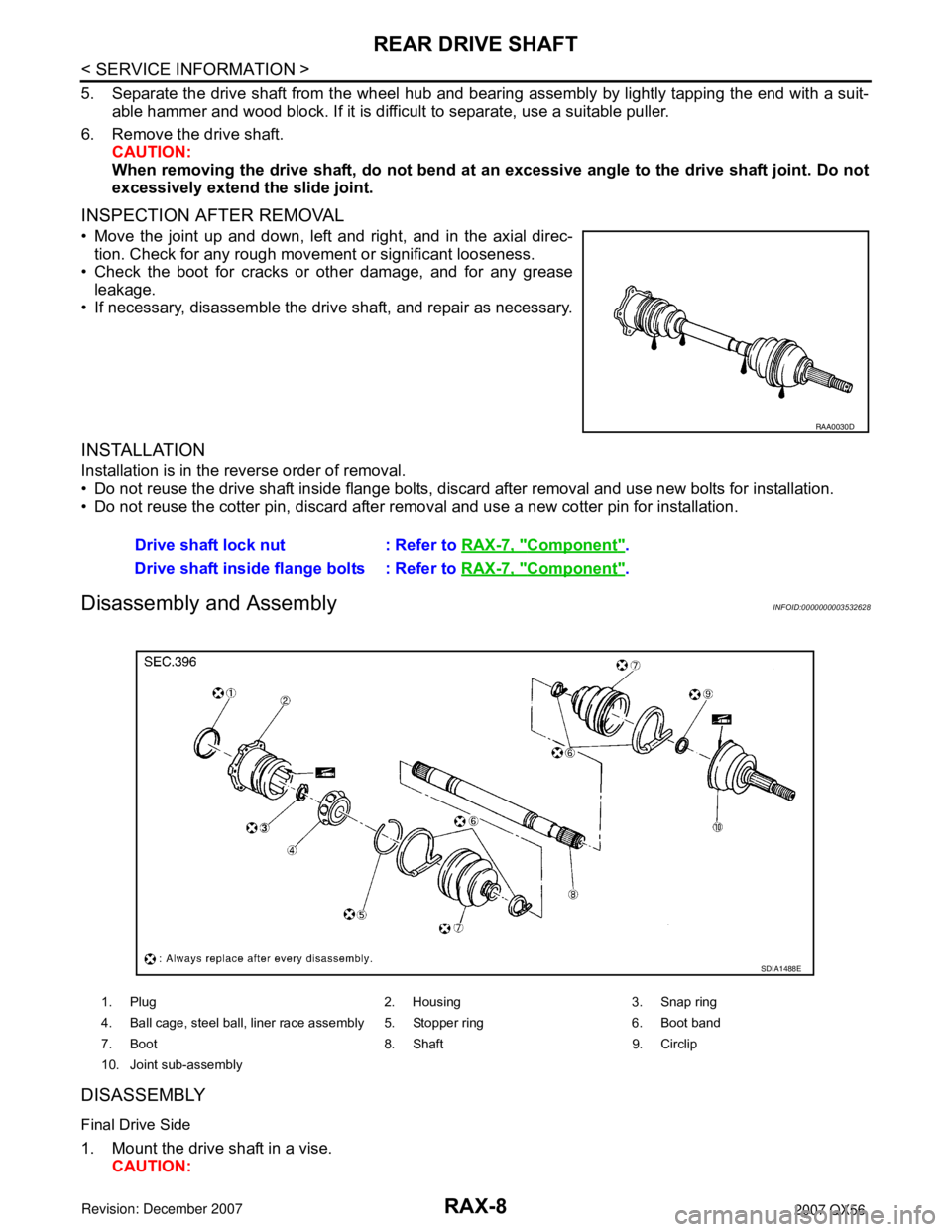

7. Pull out the wheel hub and bearing assembly for access to

remove the rear ABS sensor from the wheel hub and bearing

assembly as shown.

• Inspect the ABS sensor O-ring, replace the ABS sensor

assembly if damaged.

• Clean the ABS sensor hole and mounting surface with a suit-

able brake cleaner and a clean lint-free shop rag. Be careful

that dirt and debris do not enter the axle bearing area.

• Apply a coat of suitable grease to the ABS sensor O-ring and

mounting hole.

CAUTION:

Do not pull on the ABS harness.

8. Remove the wheel hub and bearing assembly.

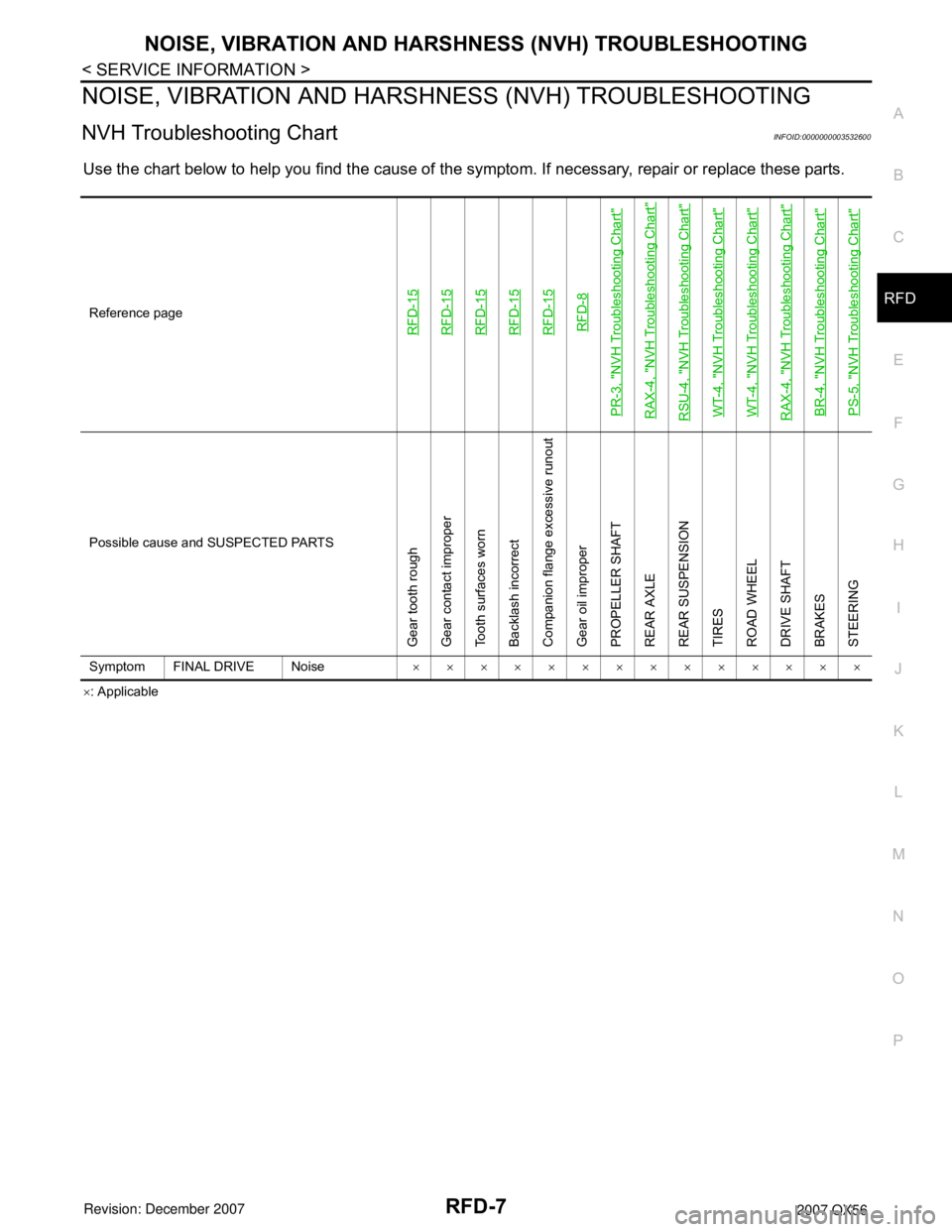

INSTALLATION

Installation is in the reverse order of removal.

• Apply grease 44003 7S000 to contact surface between wheel hub

and drive shaft. Use sufficient grease to completely coat contact

area.

• Inspect the ABS sensor O-ring, replace the ABS sensor assembly

if damaged.

• Clean the ABS sensor hole and mounting surface with a suitable

brake cleaner and a clean lint-free shop rag. Be careful that dirt

and debris do not enter the axle bearing area.

• Apply a coat of suitable grease to the ABS sensor O-ring and

mounting hole.

• Use a new cotter pin for installation.

• Use new wheel hub and bearing assembly bolts for installation.

LDIA0050E

LDIA0052E

WDIA0291E

Page 2525 of 3061

REAR DRIVE SHAFT

RAX-7

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

RAX

N

O

P

REAR DRIVE SHAFT

ComponentINFOID:0000000003532626

Rear Drive Shaft

Removal and InstallationINFOID:0000000003532627

REMOVAL

1. Remove the wheel and tire using power tool.

2. Remove the stabilizer bar clamp. Refer to RSU-21, "

Component".

3. Remove the cotter pin and discard, then remove the drive shaft

nut from the drive shaft.

• Do not reuse the cotter pin, discard after removal and use a

new cotter pin for installation.

4. Remove the six bolts from the inside flange of the drive shaft using power tool.

• Do not reuse the drive shaft inside flange bolts, discard after removal and use new bolts for installation.

WDIA0263E

1. Rear final drive assembly 2. Rear drive shaft 3. Rear brake and hub assembly

4. Cotter pin

LDIA0050E

Page 2526 of 3061

RAX-8

< SERVICE INFORMATION >

REAR DRIVE SHAFT

5. Separate the drive shaft from the wheel hub and bearing assembly by lightly tapping the end with a suit-

able hammer and wood block. If it is difficult to separate, use a suitable puller.

6. Remove the drive shaft.

CAUTION:

When removing the drive shaft, do not bend at an excessive angle to the drive shaft joint. Do not

excessively extend the slide joint.

INSPECTION AFTER REMOVAL

• Move the joint up and down, left and right, and in the axial direc-

tion. Check for any rough movement or significant looseness.

• Check the boot for cracks or other damage, and for any grease

leakage.

• If necessary, disassemble the drive shaft, and repair as necessary.

INSTALLATION

Installation is in the reverse order of removal.

• Do not reuse the drive shaft inside flange bolts, discard after removal and use new bolts for installation.

• Do not reuse the cotter pin, discard after removal and use a new cotter pin for installation.

Disassembly and AssemblyINFOID:0000000003532628

DISASSEMBLY

Final Drive Side

1. Mount the drive shaft in a vise.

CAUTION:

RAA0030D

Drive shaft lock nut : Refer to RAX-7, "Component".

Drive shaft inside flange bolts : Refer to RAX-7, "

Component".

1. Plug 2. Housing 3. Snap ring

4. Ball cage, steel ball, liner race assembly 5. Stopper ring 6. Boot band

7. Boot 8. Shaft 9. Circlip

10. Joint sub-assembly

SDIA1488E

Page 2527 of 3061

REAR DRIVE SHAFT

RAX-9

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

RAX

N

O

P

When mounting the drive shaft in a vise, use copper or aluminum plates between the vise and the

drive shaft.

2. Remove the boot bands.

3. If the plug needs to be removed, move the boot to the wheel side, then drive the plug out using a suitable

plastic hammer.

4. Remove the stopper ring with a flat-bladed screwdriver as

shown, and pull the housing out.

5. Remove the snap ring, then remove the ball cage, steel ball,

inner race assembly from the drive shaft.

6. Remove the boot from the drive shaft.

7. Remove any old grease on the housing using paper towels.

Wheel Side

1. Mount the drive shaft in a vise.

CAUTION:

When mounting the drive shaft in a vise, use copper or aluminum plates between the vise and the

drive shaft.

2. Remove the boot bands, then remove the boot from the joint sub-assembly.

3. Screw a suitable drive shaft puller 30 mm (1.18 in) or more into

the threaded part of the joint sub-assembly. Pull the joint sub-

assembly out of the drive shaft as shown.

CAUTION:

• If the joint sub-assembly cannot be removed after five or

more attempts, replace the drive shaft and joint sub-

assembly as a set.

• Align the sliding hammer and drive shaft and remove the

joint sub-assembly by pulling directly.

4. Remove the boot from the drive shaft.

5. Remove the circlip from the drive shaft.

6. While rotating the ball cage, remove any old grease on the joint sub-assembly using paper towels.

INSPECTION AFTER DISASSEMBLY

Drive Shaft

• Replace the drive shaft if there is any runout, cracking, or other damage.

SRA249A

SFA514A

SDIA0606E

Page 2529 of 3061

REAR DRIVE SHAFT

RAX-11

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

RAX

N

O

P

4. Install the ball cage, steel ball, and inner race assembly on the

shaft, and secure them tightly using the snap ring.

NOTE:

Discard the old snap ring and use a new one for assembly.

5. Insert the specified quantity of Genuine NISSAN Grease or

equivalent, onto the housing (indicated by * marks), and install it

onto shaft. Refer to MA-10

.

6. Install the stopper ring onto the housing.

7. After installation, pull on the shaft to check engagement between the joint sub-assembly and the stopper

ring.

8. Install the boot securely into the grooves (indicated by * marks)

as shown.

CAUTION:

If there is grease on boot mounting surfaces (indicated by*

marks) of shaft and housing, boot may come off. Remove

all grease from surfaces.

9. Check that the boot installation length “L” is the length indicated

below. Insert a flat-bladed screwdriver or similar tool into smaller

side of boot. Bleed the air from the boot to prevent any boot

deformation.

CAUTION:

• The boot may break if the boot installation length is less than the specified value.

• Do not to touch the tip of the screwdriver to the inside of the boot.

10. Secure the big and small ends of the boot with the new boot

bands as shown.

NOTE:

Discard the old boot bands and use new ones for assembly.

11. After installing the housing and shaft, rotate the boot to check that the boot is positioned correctly. If the

boot is not positioned correctly, reposition the boot and secure the boot using a new boot band.

Wheel Side

SDIA1125E

Grease capacity : 175 − 195 g (6.17 − 6.88 oz)

RAC0678D

Boot installation length “L ” : 147.9 mm (5.82 in)

WDIA0045E

SFA395

Page 2532 of 3061

RAX-14

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Wheel BearingINFOID:0000000003532629

Drive ShaftINFOID:0000000003532630

Measurement of spring scale Less than 26.6 N (2.7 kg, 5.95 lb)

Axial end play0 mm (0 in)

Joint Wheel side Final drive side

Grease capacity140 − 160 g

(4.93 − 5.64 oz)175 − 195 g

(6.17 − 6.88 oz)

Boot installed length 134.5 mm (5.30 in) 147.9 mm (5.82 in)

Page 2564 of 3061

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

RFD-7

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

RFD

N

O

P

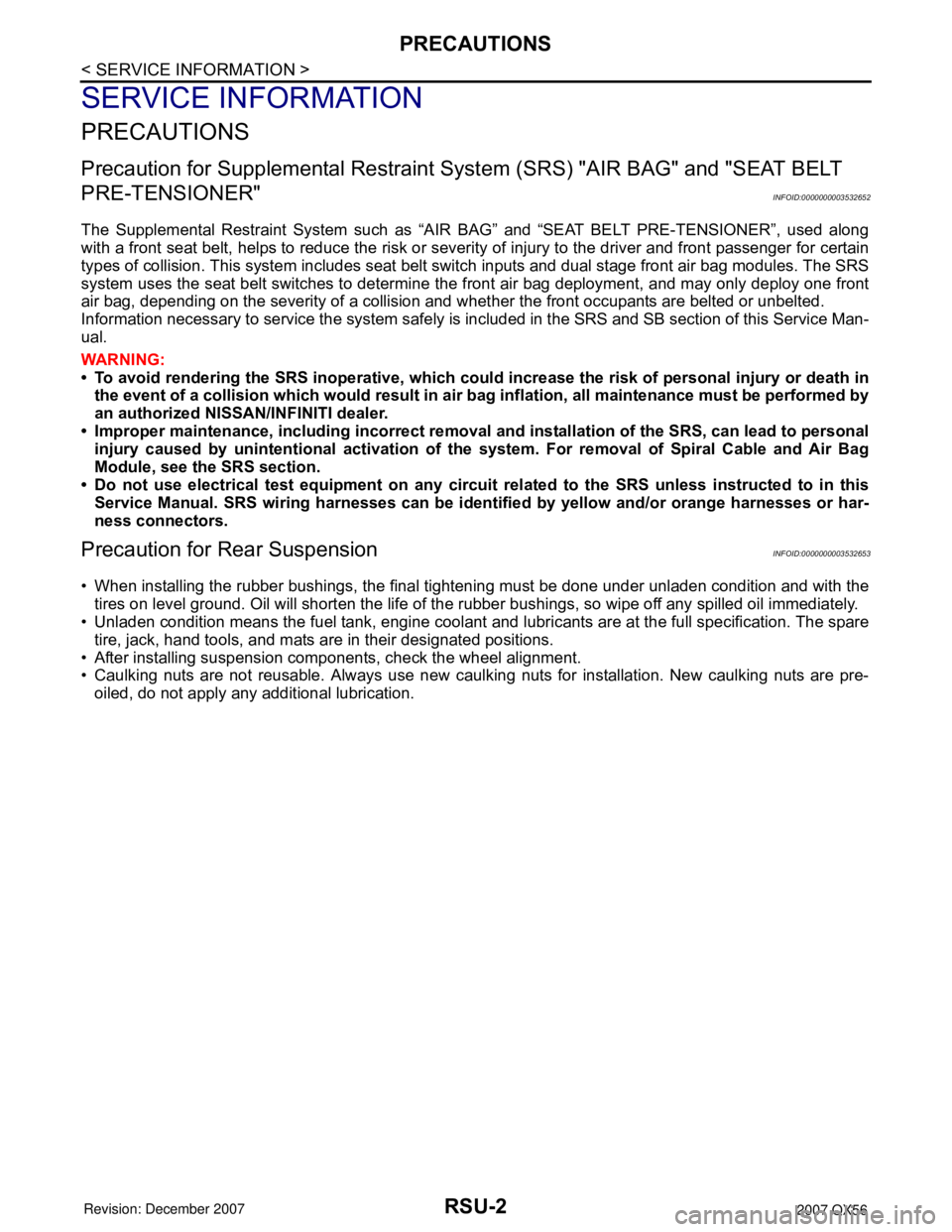

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000003532600

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: Applicable Reference page

RFD-15RFD-15RFD-15RFD-15RFD-15RFD-8

PR-3, "

NVH Troubleshooting Chart

"

RAX-4, "

NVH Troubleshooting Chart

"

RSU-4, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

RAX-4, "

NVH Troubleshooting Chart

"

BR-4, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Gear tooth rough

Gear contact improper

Tooth surfaces worn

Backlash incorrect

Companion flange excessive runout

Gear oil improper

PROPELLER SHAFT

REAR AXLE

REAR SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

Symptom FINAL DRIVE Noise××××××××××××××

Page 2591 of 3061

RSU-1

SUSPENSION

C

D

F

G

H

I

J

K

L

M

SECTION RSU

A

B

RSU

N

O

PCONTENTS

REAR SUSPENSION

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

Precaution for Rear Suspension ...............................2

PREPARATION ...................................................3

Commercial Service Tool ..........................................3

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

4

NVH Troubleshooting Chart ......................................4

CAN COMMUNICATION .....................................5

System Description ...................................................5

TROUBLE DIAGNOSIS ......................................6

How to Perform Trouble Diagnosis for Quick and

Accurate Repair ........................................................

6

Component Parts and Harness Connector Loca-

tion ............................................................................

8

Wiring Diagram - A/SUSP - .......................................9

Basic Inspection ......................................................10

Chek Suspension Indicator Lamp Timing ...............11

Control Unit Input/Output Signal Standard ..............11

CONSULT-II Function (AIR LEVELIZER) ...............11

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS ..................................................

14

Height Sensor System Inspection ...........................14

Exhaust Valve Solenoid System Inspection ............15

Compressor Motor, Compressor Motor Relay and

Circuit Inspection .....................................................

17

TROUBLE DIAGNOSES FOR SYMPTOMS ......19

Load Leveling Rear Air Suspension System Does

Not Operate .............................................................

19

Chek Suspension Indicator Lamp Stays On When

Ignition Switch Is Turned On ...................................

20

REAR SUSPENSION ASSEMBLY ...................21

Component ..............................................................21

On-Vehicle Inspection and Service .........................22

Wheel AlignmentInspection .....................................23

REAR SUSPENSION MEMBER .......................26

Removal and Installation .........................................26

SHOCK ABSORBER ........................................30

Removal and Installation .........................................30

SUSPENSION ARM ..........................................31

Removal and Installation .........................................31

FRONT LOWER LINK .......................................33

Removal and Installation .........................................33

REAR LOWER LINK & COIL SPRING .............35

Removal and Installation .........................................35

STABILIZER BAR .............................................37

Removal and Installation .........................................37

REAR LOAD LEVELING AIR SUSPENSION

COMPRESSOR ASSEMBLY ............................

38

Removal and Installation .........................................38

HEIGHT SENSOR .............................................40

Removal and Installation .........................................40

CONTROL UNIT ................................................42

Removal and Installation .........................................42

Initialization Procedure ............................................42

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

43

Wheel Alignment .....................................................43

Ball Joint ..................................................................43

Wheelarch Height (Unladen*1) ................................44

Page 2592 of 3061

RSU-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003532652

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and whether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Rear SuspensionINFOID:0000000003532653

• When installing the rubber bushings, the final tightening must be done under unladen condition and with the

tires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immediately.

• Unladen condition means the fuel tank, engine coolant and lubricants are at the full specification. The spare

tire, jack, hand tools, and mats are in their designated positions.

• After installing suspension components, check the wheel alignment.

• Caulking nuts are not reusable. Always use new caulking nuts for installation. New caulking nuts are pre-

oiled, do not apply any additional lubrication.

Page 2593 of 3061

PREPARATION

RSU-3

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

PREPARATION

Commercial Service ToolINFOID:0000000003532654

Tool nameDescription

Power tool• Removing wheel nuts

• Removing brake caliper assembly

• Removing rear suspension component

parts

PBIC0190E