wheel bolts INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 524 of 3061

ATC-154

< SERVICE INFORMATION >

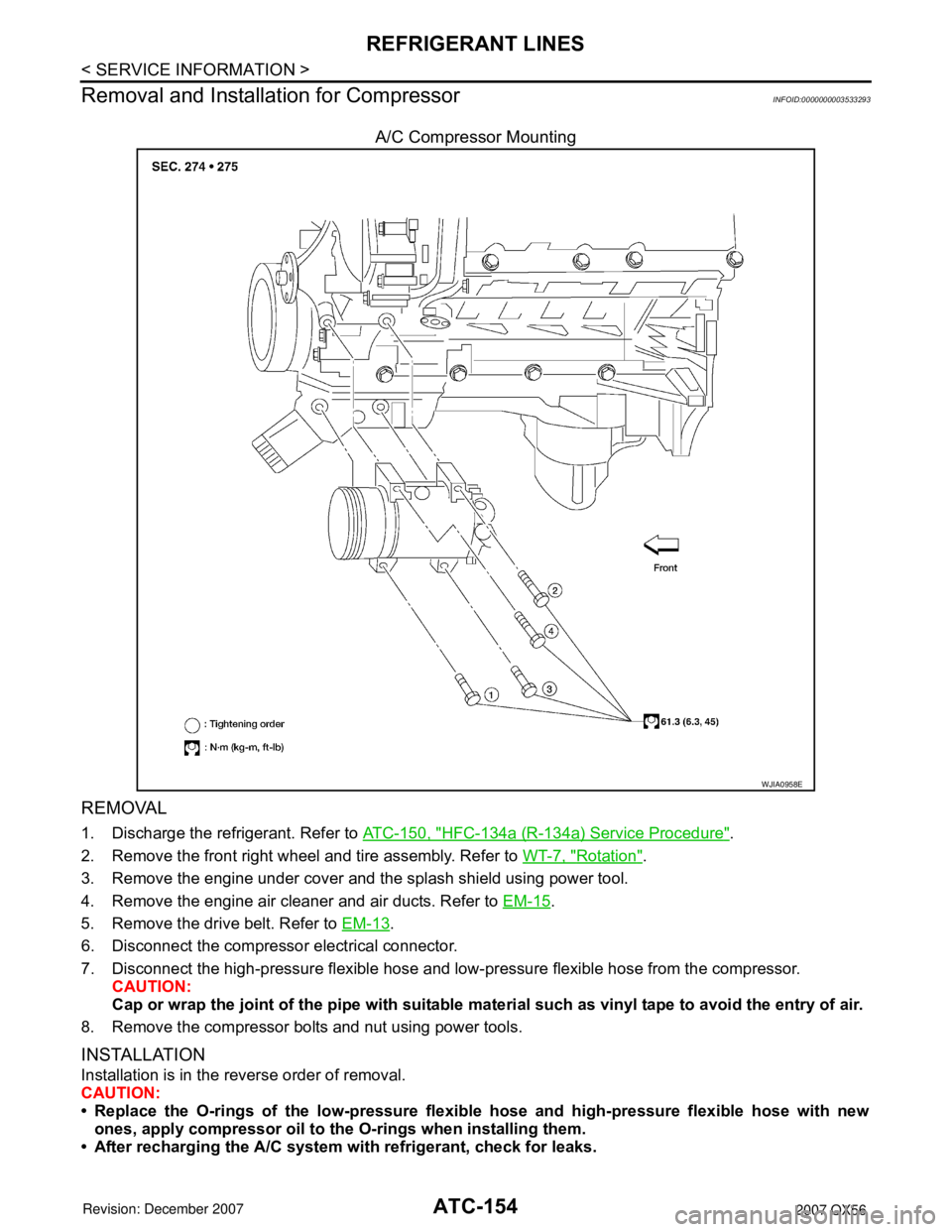

REFRIGERANT LINES

Removal and Installation for Compressor

INFOID:0000000003533293

A/C Compressor Mounting

REMOVAL

1. Discharge the refrigerant. Refer to ATC-150, "HFC-134a (R-134a) Service Procedure".

2. Remove the front right wheel and tire assembly. Refer to WT-7, "

Rotation".

3. Remove the engine under cover and the splash shield using power tool.

4. Remove the engine air cleaner and air ducts. Refer to EM-15

.

5. Remove the drive belt. Refer to EM-13

.

6. Disconnect the compressor electrical connector.

7. Disconnect the high-pressure flexible hose and low- pressure flexible hose from the compressor.

CAUTION:

Cap or wrap the joint of the pipe with suitable mate rial such as vinyl tape to avoid the entry of air.

8. Remove the compressor bolts and nut using power tools.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace the O-rings of the low-pressure flexibl e hose and high-pressure flexible hose with new

ones, apply compressor oil to the O-rings when installing them.

• After recharging the A/C system with refrigerant, check for leaks.

WJIA0958E

Page 531 of 3061

REFRIGERANT LINESATC-161

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

5. Remove the front and rear bumper fascia. Refer to EI-12 (front), EI-14 (rear).

6. Reposition the front fender protector out of the way. Refer to EI-22

.

7. Disconnect the chassis harness connector.

8. Remove the spare wheel and tire.

9. Remove the tailpipe and tailpipe hanger bracket. Refer to EX-3, "

Removal and Installation".

10. Remove the seatbelt latch anchor. Refer to RSU-21, "

Component".

11. Remove the front floor heat shield.

12. Disconnect each end of the underfloor rear high- and low-pressure A/C and heater core pipes. Refer to

ATC-152, "

Component".

CAUTION:

Cap or wrap the joint of the pipes with suitable material such as viny l tape to avoid the entry of air.

13. Set two suitable jacks at the RH body mount points to support the vehicle body when it is separated from the RH side of the frame.

14. Remove the RH body mount bolts. Refer to BL-135, "

Body Mounting".

15. Use the vehicle hoist to lower the RH side of the frame from the RH side of the body [approximately 305

mm (12 in)] until there is sufficient clearance to remove the underfloor rear high- and low-pressure A/C

and heater core pipes from between the body and the frame.

16. Remove the underfloor rear high- and low-pressure A/ C and heater core pipes from the back of the vehi-

cle.

INSTALLATION

Installation is in the reverse order of removal.

Refer to ATC-152, "

Component".

CAUTION:

• Replace the O-ring of the high/low-pressure pipe with a new one, then apply compressor oil to it

when installing it.

• After charging refrigerant, check for leaks.

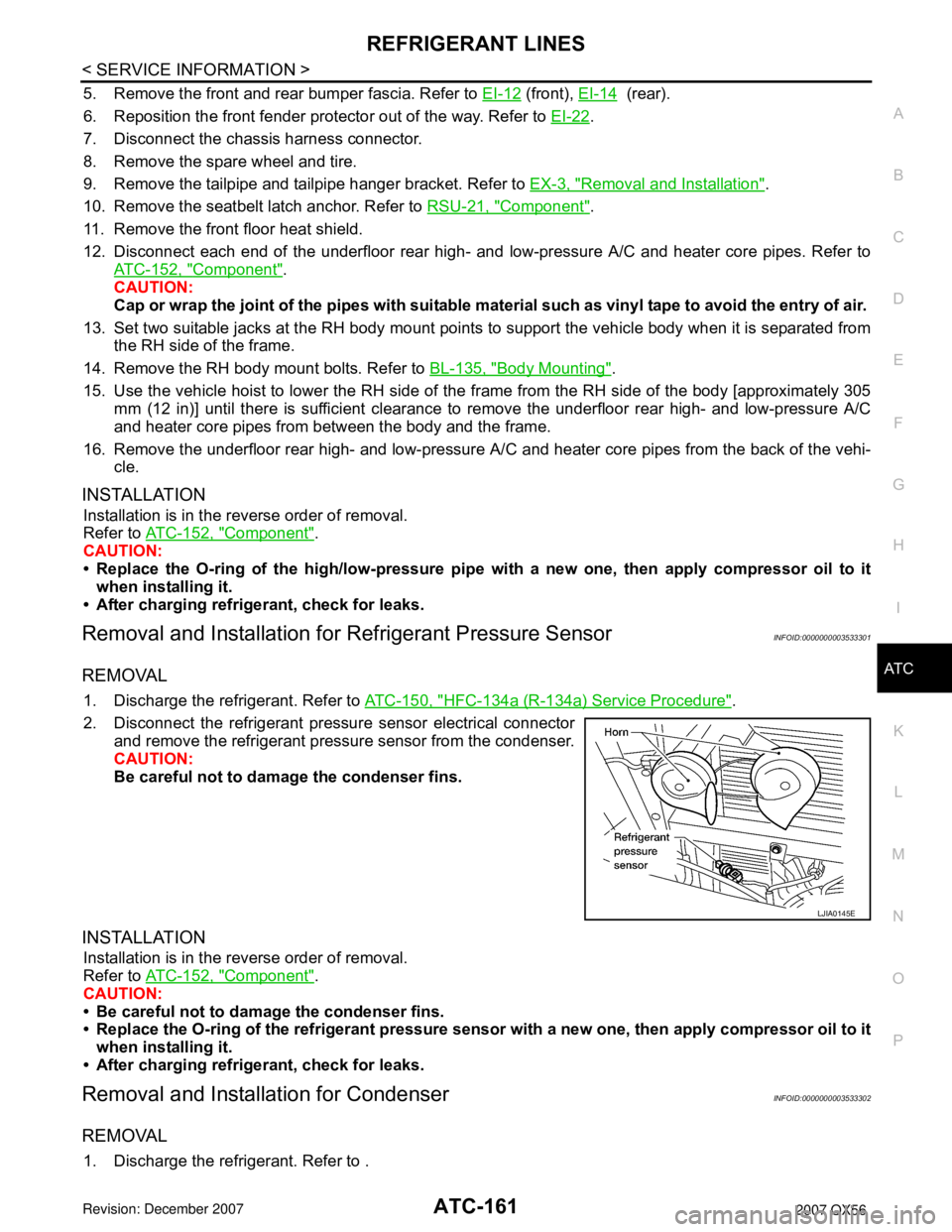

Removal and Installation for Refrigerant Pressure SensorINFOID:0000000003533301

REMOVAL

1. Discharge the refrigerant. Refer to ATC-150, "HFC-134a (R-134a) Service Procedure".

2. Disconnect the refrigerant pressu re sensor electrical connector

and remove the refrigerant pressure sensor from the condenser.

CAUTION:

Be careful not to damage the condenser fins.

INSTALLATION

Installation is in the reverse order of removal.

Refer to ATC-152, "

Component".

CAUTION:

• Be careful not to damage the condenser fins.

• Replace the O-ring of the refrig erant pressure sensor with a new one, then apply compressor oil to it

when installing it.

• After charging refrigerant, check for leaks.

Removal and Installation for CondenserINFOID:0000000003533302

REMOVAL

1. Discharge the refrigerant. Refer to .

LJIA0145E

Page 591 of 3061

AUDIO

AV-51

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

AV

N

O

P

5. Remove satellite radio tuner screws (A) and remove satellite

radio tuner from Bose speaker amp./satellite radio tuner bracket

(1).

Installation

Installation is in the reverse order of removal.

STEERING WHEEL AUDIO CONTROL SWITCHES

Removal

1. Remove steering wheel. Refer to PS-7.

2. Remove steering wheel rear cover screws and remove steering wheel rear cover.

3. Remove steering wheel switch assembly screws and steering

wheel switches.

Installation

Installation is in the reverse order of removal.

SUBWOOFER

Removal

1. Remove front driver seat. Refer to SE-83.

2. Remove the subwoofer bolts.

3. Disconnect subwoofer connector and remove the subwoofer.

Installation

Installation is in the reverse order of removal.

LKIA0677E

WKIA1226E

WKIA1496E

Page 1844 of 3061

EM-74

< SERVICE INFORMATION >

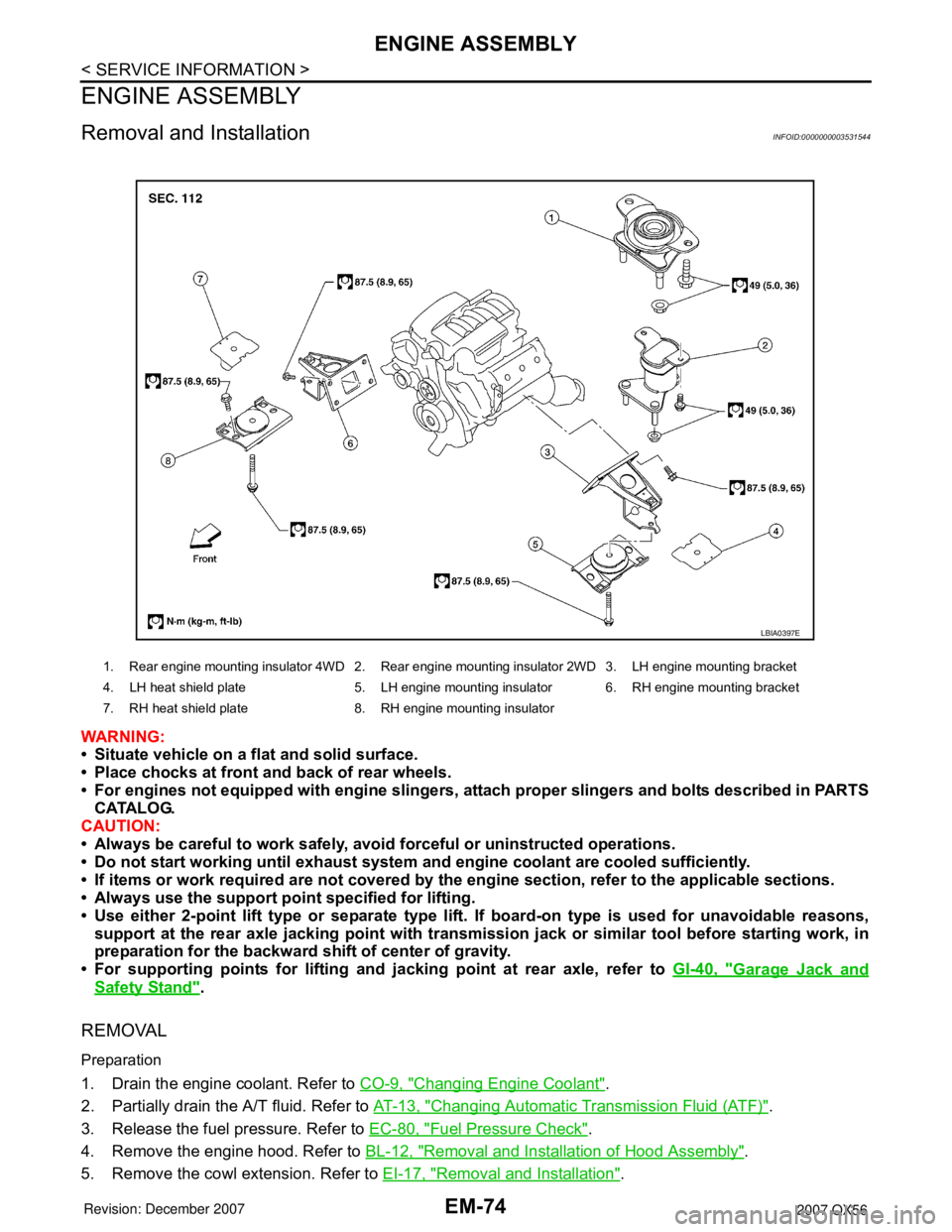

ENGINE ASSEMBLY

ENGINE ASSEMBLY

Removal and InstallationINFOID:0000000003531544

WARNING:

• Situate vehicle on a flat and solid surface.

• Place chocks at front and back of rear wheels.

• For engines not equipped with engine slingers, attach proper slingers and bolts described in PARTS

CATALOG.

CAUTION:

• Always be careful to work safely, avoid forceful or uninstructed operations.

• Do not start working until exhaust system and engine coolant are cooled sufficiently.

• If items or work required are not covered by the engine section, refer to the applicable sections.

• Always use the support point specified for lifting.

• Use either 2-point lift type or separate type lift. If board-on type is used for unavoidable reasons,

support at the rear axle jacking point with transmission jack or similar tool before starting work, in

preparation for the backward shift of center of gravity.

• For supporting points for lifting and jacking point at rear axle, refer to GI-40, "

Garage Jack and

Safety Stand".

REMOVAL

Preparation

1. Drain the engine coolant. Refer to CO-9, "Changing Engine Coolant".

2. Partially drain the A/T fluid. Refer to AT-13, "

Changing Automatic Transmission Fluid (ATF)".

3. Release the fuel pressure. Refer to EC-80, "

Fuel Pressure Check".

4. Remove the engine hood. Refer to BL-12, "

Removal and Installation of Hood Assembly".

5. Remove the cowl extension. Refer to EI-17, "

Removal and Installation".

1. Rear engine mounting insulator 4WD 2. Rear engine mounting insulator 2WD 3. LH engine mounting bracket

4. LH heat shield plate 5. LH engine mounting insulator 6. RH engine mounting bracket

7. RH heat shield plate 8. RH engine mounting insulator

LBIA0397E

Page 1891 of 3061

WHEEL HUB

FAX-5

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

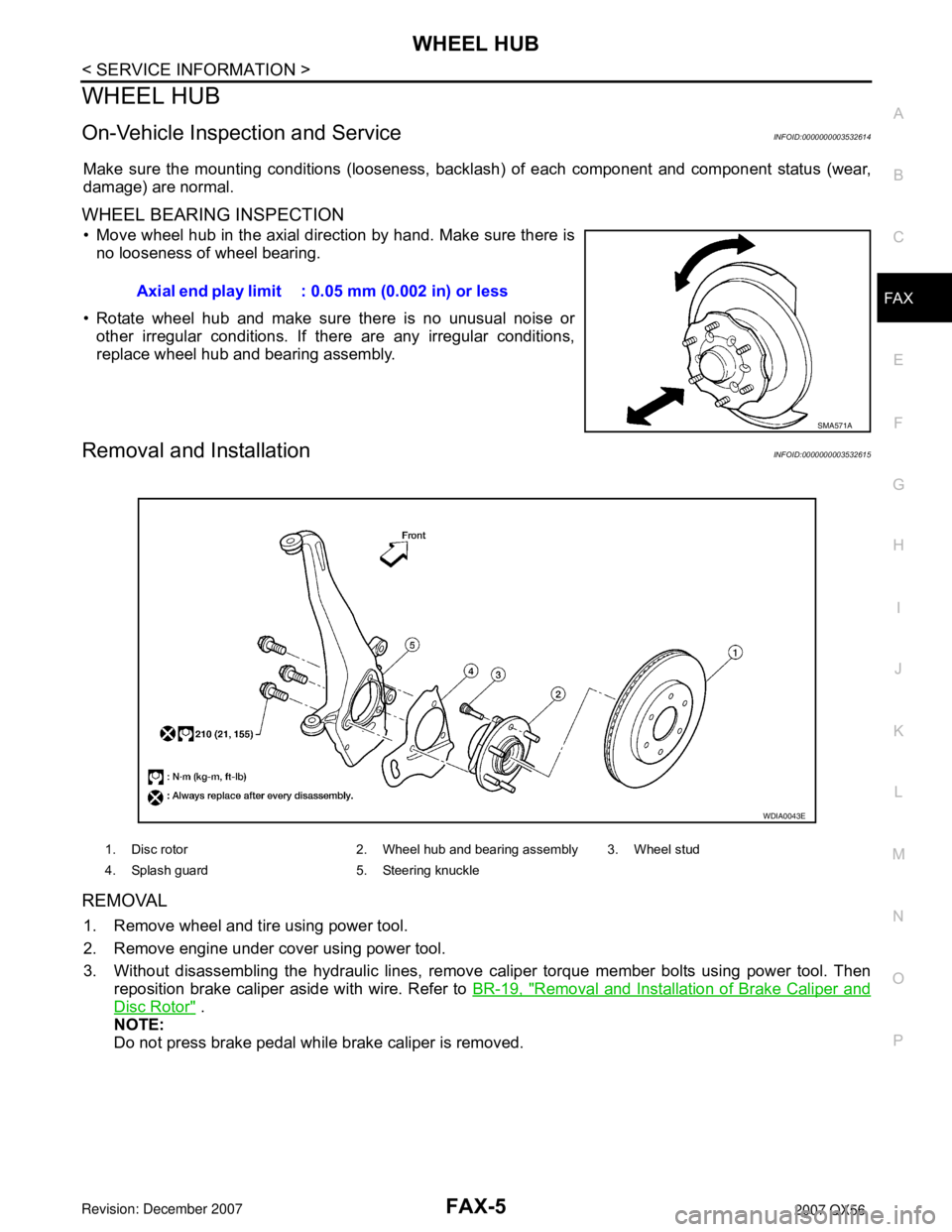

WHEEL HUB

On-Vehicle Inspection and ServiceINFOID:0000000003532614

Make sure the mounting conditions (looseness, backlash) of each component and component status (wear,

damage) are normal.

WHEEL BEARING INSPECTION

• Move wheel hub in the axial direction by hand. Make sure there is

no looseness of wheel bearing.

• Rotate wheel hub and make sure there is no unusual noise or

other irregular conditions. If there are any irregular conditions,

replace wheel hub and bearing assembly.

Removal and InstallationINFOID:0000000003532615

REMOVAL

1. Remove wheel and tire using power tool.

2. Remove engine under cover using power tool.

3. Without disassembling the hydraulic lines, remove caliper torque member bolts using power tool. Then

reposition brake caliper aside with wire. Refer to BR-19, "

Removal and Installation of Brake Caliper and

Disc Rotor" .

NOTE:

Do not press brake pedal while brake caliper is removed.Axial end play limit : 0.05 mm (0.002 in) or less

SMA571A

1. Disc rotor 2. Wheel hub and bearing assembly 3. Wheel stud

4. Splash guard 5. Steering knuckle

WDIA0043E

Page 1892 of 3061

FAX-6

< SERVICE INFORMATION >

WHEEL HUB

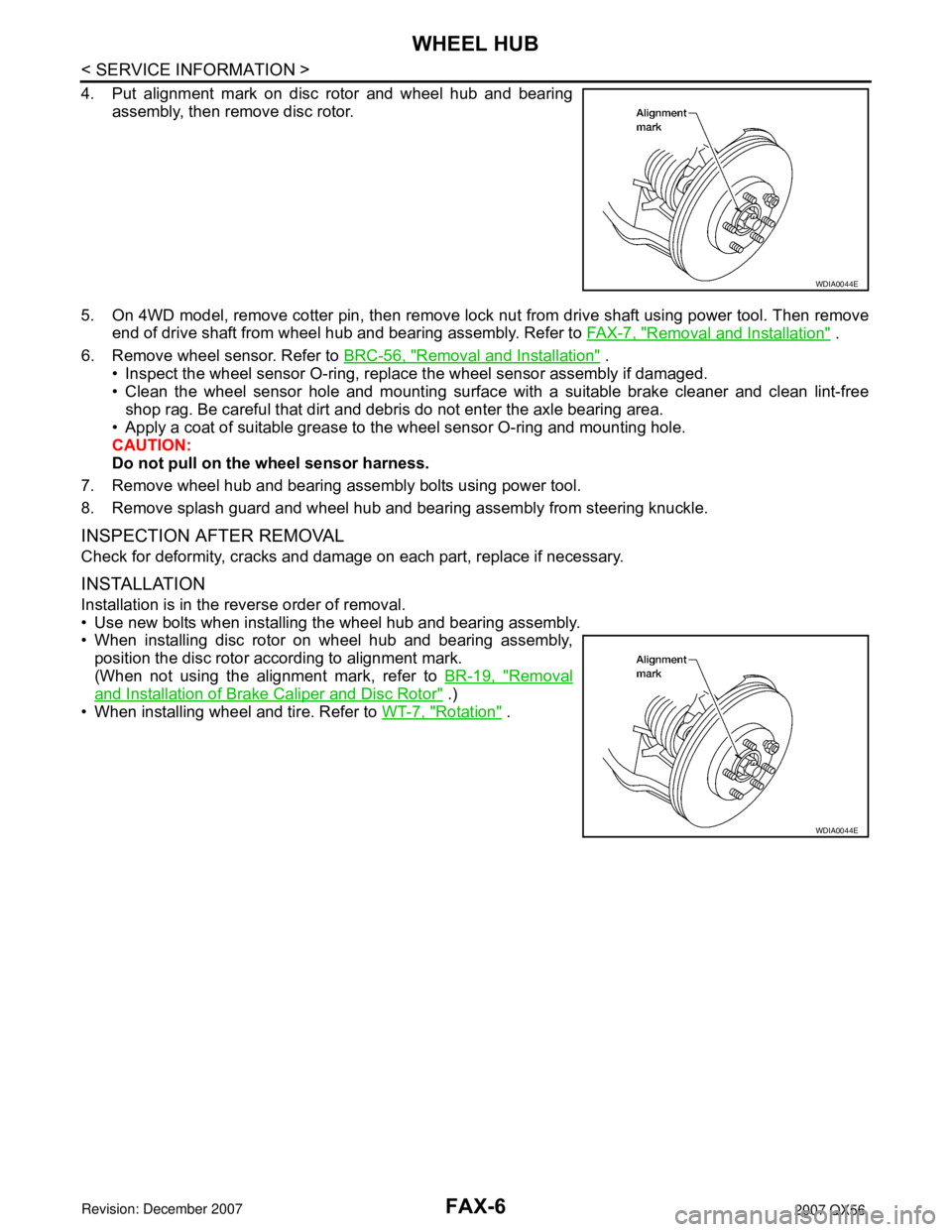

4. Put alignment mark on disc rotor and wheel hub and bearing

assembly, then remove disc rotor.

5. On 4WD model, remove cotter pin, then remove lock nut from drive shaft using power tool. Then remove

end of drive shaft from wheel hub and bearing assembly. Refer to FA X - 7 , "

Removal and Installation" .

6. Remove wheel sensor. Refer to BRC-56, "

Removal and Installation" .

• Inspect the wheel sensor O-ring, replace the wheel sensor assembly if damaged.

• Clean the wheel sensor hole and mounting surface with a suitable brake cleaner and clean lint-free

shop rag. Be careful that dirt and debris do not enter the axle bearing area.

• Apply a coat of suitable grease to the wheel sensor O-ring and mounting hole.

CAUTION:

Do not pull on the wheel sensor harness.

7. Remove wheel hub and bearing assembly bolts using power tool.

8. Remove splash guard and wheel hub and bearing assembly from steering knuckle.

INSPECTION AFTER REMOVAL

Check for deformity, cracks and damage on each part, replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• Use new bolts when installing the wheel hub and bearing assembly.

• When installing disc rotor on wheel hub and bearing assembly,

position the disc rotor according to alignment mark.

(When not using the alignment mark, refer to BR-19, "

Removal

and Installation of Brake Caliper and Disc Rotor" .)

• When installing wheel and tire. Refer to WT-7, "

Rotation" .

WDIA0044E

WDIA0044E

Page 1893 of 3061

DRIVE SHAFT

FAX-7

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

DRIVE SHAFT

Removal and InstallationINFOID:0000000003532616

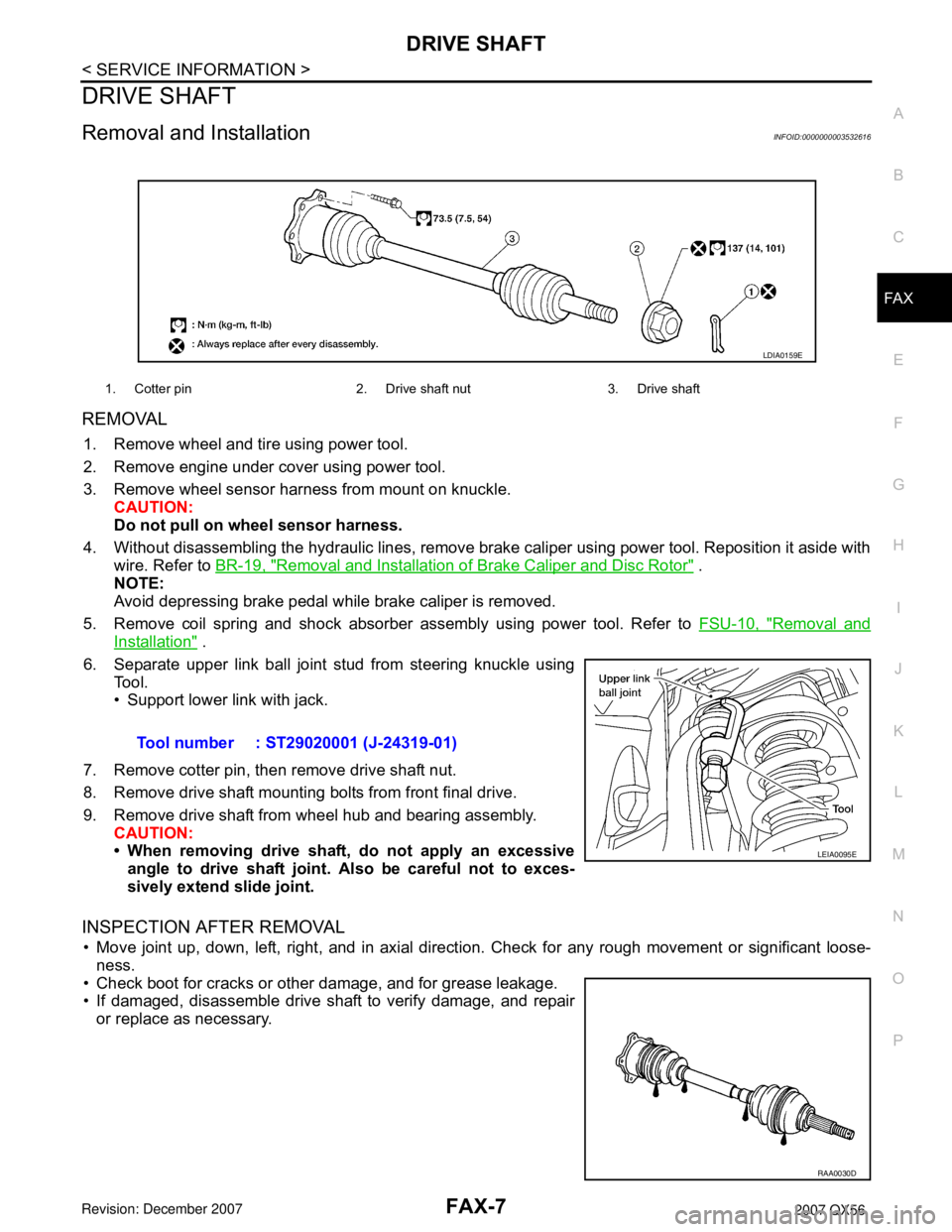

REMOVAL

1. Remove wheel and tire using power tool.

2. Remove engine under cover using power tool.

3. Remove wheel sensor harness from mount on knuckle.

CAUTION:

Do not pull on wheel sensor harness.

4. Without disassembling the hydraulic lines, remove brake caliper using power tool. Reposition it aside with

wire. Refer to BR-19, "

Removal and Installation of Brake Caliper and Disc Rotor" .

NOTE:

Avoid depressing brake pedal while brake caliper is removed.

5. Remove coil spring and shock absorber assembly using power tool. Refer to FSU-10, "

Removal and

Installation" .

6. Separate upper link ball joint stud from steering knuckle using

Tool.

• Support lower link with jack.

7. Remove cotter pin, then remove drive shaft nut.

8. Remove drive shaft mounting bolts from front final drive.

9. Remove drive shaft from wheel hub and bearing assembly.

CAUTION:

• When removing drive shaft, do not apply an excessive

angle to drive shaft joint. Also be careful not to exces-

sively extend slide joint.

INSPECTION AFTER REMOVAL

• Move joint up, down, left, right, and in axial direction. Check for any rough movement or significant loose-

ness.

• Check boot for cracks or other damage, and for grease leakage.

• If damaged, disassemble drive shaft to verify damage, and repair

or replace as necessary.

1. Cotter pin 2. Drive shaft nut 3. Drive shaft

LDIA0159E

Tool number : ST29020001 (J-24319-01)

LEIA0095E

RAA0030D

Page 1949 of 3061

PREPARATION

FSU-3

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

FSU

N

O

P

PREPARATION

Special Service ToolINFOID:0000000003532632

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000003532633

Tool number

(Kent-Moore No.)

Tool nameDescription

ST29020001

(J-24319-01)

Pitman arm pullerRemoving upper link ball joint from knuckle

spindle

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

HT72520000

(J-25730-A)

Ball joint removerRemoving tie-rod outer end

NT694

NT146

Tool nameDescription

Attachment wheel alignment Measure wheel alignment

a: Screw M24 x 1.5 pitch

b: 35 mm (1.38 in) dia.

c: 65 mm (2.56 in) dia.

d: 56 mm (2.20 in)

e: 12 mm (0.47 in)

Spring compressor Removing and installing coil spring

Power toolLoosening bolts and nuts

NT148

NT717

PBIC0190E

Page 1952 of 3061

FSU-6

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

ON-VEHICLE SERVICE

Front Suspension PartsINFOID:0000000003532636

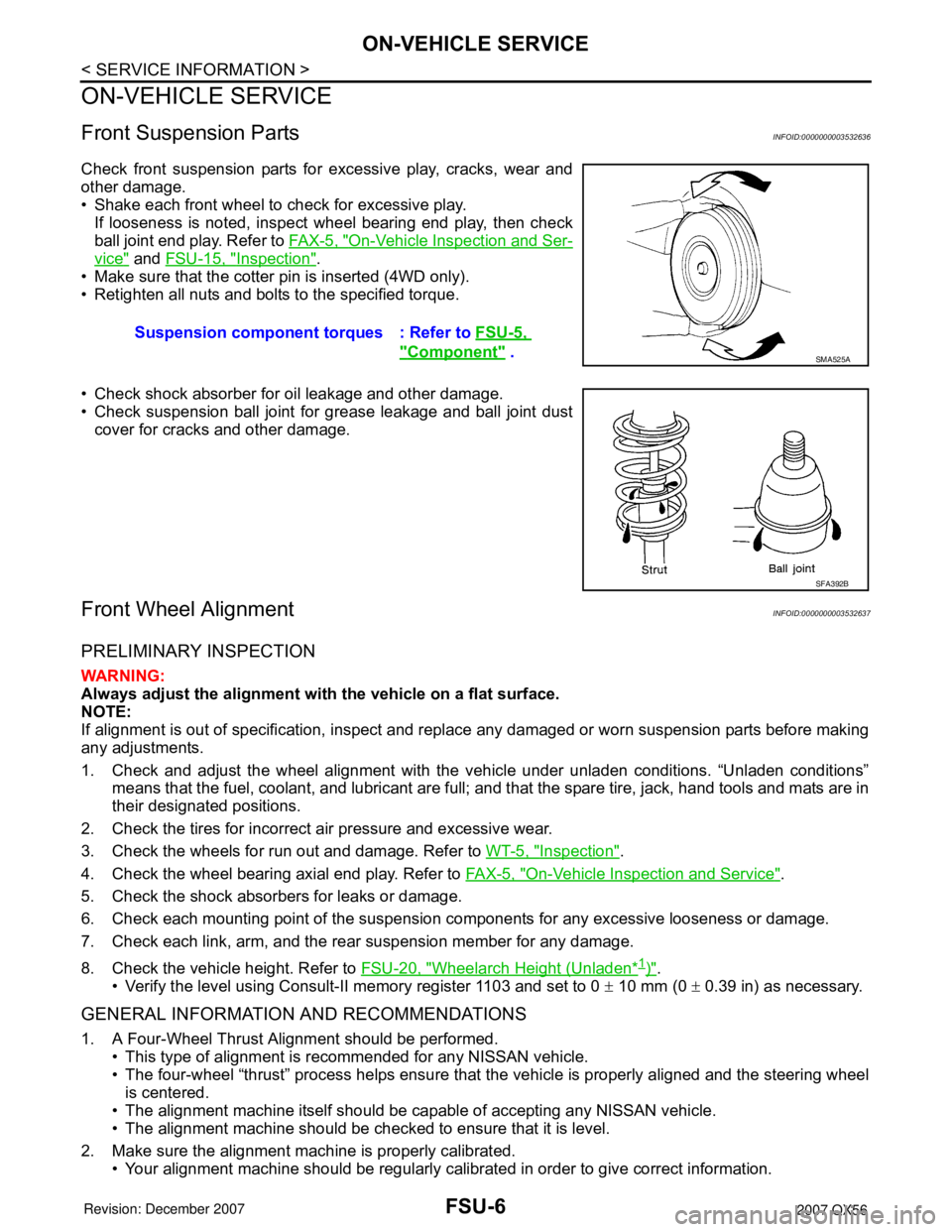

Check front suspension parts for excessive play, cracks, wear and

other damage.

• Shake each front wheel to check for excessive play.

If looseness is noted, inspect wheel bearing end play, then check

ball joint end play. Refer to FA X - 5 , "

On-Vehicle Inspection and Ser-

vice" and FSU-15, "Inspection".

• Make sure that the cotter pin is inserted (4WD only).

• Retighten all nuts and bolts to the specified torque.

• Check shock absorber for oil leakage and other damage.

• Check suspension ball joint for grease leakage and ball joint dust

cover for cracks and other damage.

Front Wheel AlignmentINFOID:0000000003532637

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface.

NOTE:

If alignment is out of specification, inspect and replace any damaged or worn suspension parts before making

any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for run out and damage. Refer to WT-5, "

Inspection".

4. Check the wheel bearing axial end play. Refer to FA X - 5 , "

On-Vehicle Inspection and Service".

5. Check the shock absorbers for leaks or damage.

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the rear suspension member for any damage.

8. Check the vehicle height. Refer to FSU-20, "

Wheelarch Height (Unladen*1)".

• Verify the level using Consult-II memory register 1103 and set to 0 ± 10 mm (0 ± 0.39 in) as necessary.

GENERAL INFORMATION AND RECOMMENDATIONS

1. A Four-Wheel Thrust Alignment should be performed.

• This type of alignment is recommended for any NISSAN vehicle.

• The four-wheel “thrust” process helps ensure that the vehicle is properly aligned and the steering wheel

is centered.

• The alignment machine itself should be capable of accepting any NISSAN vehicle.

• The alignment machine should be checked to ensure that it is level.

2. Make sure the alignment machine is properly calibrated.

• Your alignment machine should be regularly calibrated in order to give correct information.Suspension component torques : Refer to FSU-5,

"Component" . SMA525A

SFA392B

Page 1953 of 3061

ON-VEHICLE SERVICE

FSU-7

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

FSU

N

O

P

• Check with the manufacturer of your specific alignment machine for their recommended Service/Cali-

bration Schedule.

THE ALIGNMENT PROCESS

IMPORTANT: Use only the alignment specifications listed in this Service Manual. Refer to FSU-19, "Wheel

Alignment (Unladen*1) *6".

1. When displaying the alignment settings, many alignment machines use “indicators”: (Green/red, plus or

minus, Go/No Go). Do NOT use these indicators.

• The alignment specifications programmed into your alignment machine that operate these indicators

may not be correct.

• This may result in an ERROR.

2. Some newer alignment machines are equipped with an optional “Rolling Compensation” method to “com-

pensate” the sensors (alignment targets or head units). Do NOT use this “Rolling Compensation”

method.

• Use the “Jacking Compensation” method. After installing the alignment targets or head units, raise the

vehicle and rotate the wheels 1/2 turn both ways.

• See Instructions in the alignment machine you are using for more information.

CAMBER AND CASTER

1. Measure camber and caster of both the right and left wheels

with a suitable alignment gauge and adjust as necessary to

specification.

NOTE:

Some vehicles may be equipped with straight (non-adjustable)

lower link bolts and washers. In order to adjust camber and

caster on these vehicles, first replace the lower link bolts and

washers with adjustable (cam) bolts and washers.

2. If outside of the specified value, adjust camber and caster using

the cam bolts (1) in the front lower link (2).

CAUTION:

After adjusting the camber then check the toe-in.

NOTE:

Camber changes about 3' (0.05°) minutes with each graduation

of one cam bolt. Refer to table below for examples of lower link

cam bolt effect on camber and caster.

3. Tighten the adjusting bolt nuts to specification. Refer to FSU-5, "

Component".

TOE-IN

WARNING:

• Always perform the following procedure on a flat surface.

• Make sure that no person is in front of the vehicle before pushing it.Camber and

Caster: Refer to FSU-19, "

Wheel Alignment

(Unladen*1) *6" .

SRA096A

WEIA0153E

Rear cam bolt 1 In 1 Out 1 In 1 Out 0 0 1 In 1 Out

Front cam bolt 1 Out 1 In 1 In 1 Out 1 In 1 Out 0 0

Camber

Degree minute

(Decimal degree)0 (0) 0 (0) 7' (0.12°) - 7' (-0.12°)3' (0.05°) - 3' (-0.05°)3' (0.05°) - 3' (-0.05°)

Caster

Degree minute

(Decimal degree)- 14' (-0.23°)14' (0.23°) 0 (0) 0 (0) 7' (0.12°) - 7' (-0.12°) - 7' (-0.12°)7' (0.12°)