check engine INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1084 of 3061

EC-1

ENGINE

C

D

E

F

G

H

I

J

K

L

M

SECTION EC

A

EC

N

O

P

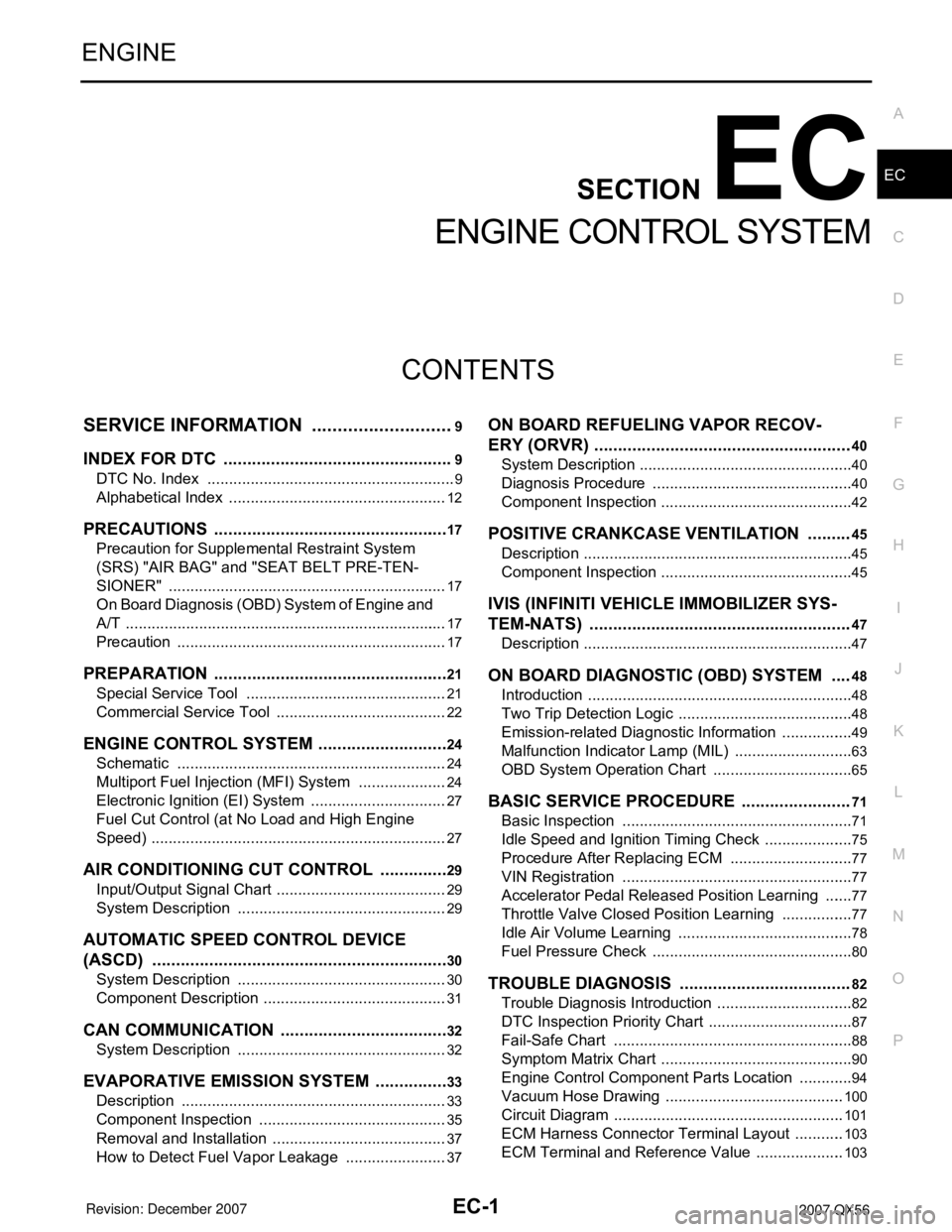

CONTENTS

ENGINE CONTROL SYSTEM

SERVICE INFORMATION ............................9

INDEX FOR DTC .................................................9

DTC No. Index ..........................................................9

Alphabetical Index ...................................................12

PRECAUTIONS ..................................................17

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................

17

On Board Diagnosis (OBD) System of Engine and

A/T ...........................................................................

17

Precaution ...............................................................17

PREPARATION ..................................................21

Special Service Tool ...............................................21

Commercial Service Tool ........................................22

ENGINE CONTROL SYSTEM ............................24

Schematic ...............................................................24

Multiport Fuel Injection (MFI) System .....................24

Electronic Ignition (EI) System ................................27

Fuel Cut Control (at No Load and High Engine

Speed) .....................................................................

27

AIR CONDITIONING CUT CONTROL ...............29

Input/Output Signal Chart ........................................29

System Description .................................................29

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ...............................................................

30

System Description .................................................30

Component Description ...........................................31

CAN COMMUNICATION ....................................32

System Description .................................................32

EVAPORATIVE EMISSION SYSTEM ................33

Description ..............................................................33

Component Inspection ............................................35

Removal and Installation .........................................37

How to Detect Fuel Vapor Leakage ........................37

ON BOARD REFUELING VAPOR RECOV-

ERY (ORVR) ......................................................

40

System Description ..................................................40

Diagnosis Procedure ...............................................40

Component Inspection .............................................42

POSITIVE CRANKCASE VENTILATION .........45

Description ...............................................................45

Component Inspection .............................................45

IVIS (INFINITI VEHICLE IMMOBILIZER SYS-

TEM-NATS) .......................................................

47

Description ...............................................................47

ON BOARD DIAGNOSTIC (OBD) SYSTEM ....48

Introduction ..............................................................48

Two Trip Detection Logic .........................................48

Emission-related Diagnostic Information .................49

Malfunction Indicator Lamp (MIL) ............................63

OBD System Operation Chart .................................65

BASIC SERVICE PROCEDURE .......................71

Basic Inspection ......................................................71

Idle Speed and Ignition Timing Check .....................75

Procedure After Replacing ECM .............................77

VIN Registration ......................................................77

Accelerator Pedal Released Position Learning .......77

Throttle Valve Closed Position Learning .................77

Idle Air Volume Learning .........................................78

Fuel Pressure Check ...............................................80

TROUBLE DIAGNOSIS ....................................82

Trouble Diagnosis Introduction ................................82

DTC Inspection Priority Chart ..................................87

Fail-Safe Chart ........................................................88

Symptom Matrix Chart .............................................90

Engine Control Component Parts Location .............94

Vacuum Hose Drawing ..........................................100

Circuit Diagram ......................................................101

ECM Harness Connector Terminal Layout ............103

ECM Terminal and Reference Value .....................103

Page 1085 of 3061

EC-2

CONSULT-II Function (ENGINE) ..........................111

Generic Scan Tool (GST) Function .......................122

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

124

Major Sensor Reference Graph in Data Monitor

Mode ......................................................................

127

TROUBLE DIAGNOSIS - SPECIFICATION

VALUE .............................................................

129

Description .............................................................129

Testing Condition ...................................................129

Inspection Procedure .............................................129

Diagnosis Procedure .............................................130

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT ........................................................

138

Description .............................................................138

Diagnosis Procedure .............................................138

POWER SUPPLY AND GROUND CIRCUIT ...139

Wiring Diagram ......................................................139

Diagnosis Procedure .............................................140

Ground Inspection .................................................143

DTC U1000, U1001 CAN COMMUNICATION

LINE .................................................................

145

Description .............................................................145

On Board Diagnosis Logic .....................................145

DTC Confirmation Procedure ................................145

Wiring Diagram ......................................................146

Diagnosis Procedure .............................................146

DTC U1010 CAN COMMUNICATION .............147

Description .............................................................147

On Board Diagnosis Logic .....................................147

DTC Confirmation Procedure ................................147

Diagnosis Procedure .............................................147

DTC P0011, P0021 IVT CONTROL .................149

Description .............................................................149

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

150

On Board Diagnosis Logic .....................................150

DTC Confirmation Procedure ................................150

Wiring Diagram ......................................................152

Diagnosis Procedure .............................................155

Component Inspection ...........................................159

Removal and Installation .......................................160

DTC P0031, P0032, P0051, P0052 A/F SEN-

SOR 1 HEATER ...............................................

163

Description .............................................................163

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

163

On Board Diagnosis Logic .....................................163

DTC Confirmation Procedure ................................163

Wiring Diagram ......................................................164

Diagnosis Procedure .............................................167

Component Inspection ...........................................168

Removal and Installation .......................................169

DTC P0037, P0038, P0057, P0058 HO2S2

HEATER ...........................................................

170

Description ............................................................170

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

170

On Board Diagnosis Logic ....................................170

DTC Confirmation Procedure ................................170

Wiring Diagram .....................................................172

Diagnosis Procedure .............................................175

Component Inspection ..........................................176

Removal and Installation .......................................177

DTC P0075, P0081 IVT CONTROL SOLE-

NOID VALVE ....................................................

178

Component Description ........................................178

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

178

On Board Diagnosis Logic ....................................178

DTC Confirmation Procedure ................................178

Wiring Diagram .....................................................179

Diagnosis Procedure .............................................182

Component Inspection ..........................................183

Removal and Installation .......................................184

DTC P0101 MAF SENSOR ..............................186

Component Description ........................................186

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

186

On Board Diagnosis Logic ....................................186

DTC Confirmation Procedure ................................186

Overall Function Check .........................................188

Wiring Diagram .....................................................189

Diagnosis Procedure .............................................190

Component Inspection ..........................................192

Removal and Installation .......................................193

DTC P0102, P0103 MAF SENSOR ..................194

Component Description ........................................194

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

194

On Board Diagnosis Logic ....................................194

DTC Confirmation Procedure ................................194

Wiring Diagram .....................................................196

Diagnosis Procedure .............................................197

Component Inspection ..........................................199

Removal and Installation .......................................200

DTC P0112, P0113 IAT SENSOR ....................201

Component Description ........................................201

On Board Diagnosis Logic ....................................201

DTC Confirmation Procedure ................................201

Wiring Diagram .....................................................202

Diagnosis Procedure .............................................202

Component Inspection ..........................................204

Removal and Installation .......................................204

DTC P0117, P0118 ECT SENSOR ...................205

Component Description ........................................205

On Board Diagnosis Logic ....................................205

DTC Confirmation Procedure ................................206

Page 1089 of 3061

EC-6

DTC P0605 ECM ..............................................444

Component Description .........................................444

On Board Diagnosis Logic .....................................444

DTC Confirmation Procedure ................................444

Diagnosis Procedure .............................................445

DTC P0643 SENSOR POWER SUPPLY ........447

On Board Diagnosis Logic .....................................447

DTC Confirmation Procedure ................................447

Wiring Diagram ......................................................448

Diagnosis Procedure .............................................449

DTC P0850 PNP SWITCH ...............................452

Component Description .........................................452

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

452

On Board Diagnosis Logic .....................................452

DTC Confirmation Procedure ................................452

Overall Function Check .........................................453

Wiring Diagram ......................................................454

Diagnosis Procedure .............................................455

DTC P1140, P1145 IVT CONTROL POSITION

SENSOR ..........................................................

457

Component Description .........................................457

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

457

On Board Diagnosis Logic .....................................457

DTC Confirmation Procedure ................................457

Wiring Diagram ......................................................458

Diagnosis Procedure .............................................461

Component Inspection ...........................................463

Removal and Installation .......................................464

DTC P1148, P1168 CLOSED LOOP CON-

TROL ................................................................

466

On Board Diagnosis Logic .....................................466

DTC P1211 TCS CONTROL UNIT ..................467

Description .............................................................467

On Board Diagnosis Logic .....................................467

DTC Confirmation Procedure ................................467

Diagnosis Procedure .............................................467

DTC P1212 TCS COMMUNICATION LINE .....468

Description .............................................................468

On Board Diagnosis Logic .....................................468

DTC Confirmation Procedure ................................468

Diagnosis Procedure .............................................468

DTC P1217 ENGINE OVER TEMPERATURE .469

Description .............................................................469

CONSULT-II Reference Value in Data Monitor

Mode ......................................................................

469

On Board Diagnosis Logic .....................................470

Overall Function Check .........................................470

Wiring Diagram ......................................................472

Diagnosis Procedure .............................................473

Main 13 Causes of Overheating ............................476

Component Inspection ...........................................476

DTC P1225 TP SENSOR ..................................477

Component Description ........................................477

On Board Diagnosis Logic ....................................477

DTC Confirmation Procedure ................................477

Diagnosis Procedure .............................................477

Removal and Installation .......................................478

DTC P1226 TP SENSOR ..................................479

Component Description ........................................479

On Board Diagnosis Logic ....................................479

DTC Confirmation Procedure ................................479

Diagnosis Procedure .............................................479

Removal and Installation .......................................480

DTC P1421 COLD START CONTROL ............481

Description ............................................................481

On Board Diagnosis Logic ....................................481

DTC Confirmation Procedure ................................481

Diagnosis Procedure .............................................481

DTC P1550 BATTERY CURRENT SENSOR ...483

Component Description ........................................483

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

483

On Board Diagnosis Logic ....................................483

DTC Confirmation Procedure ................................483

Wiring Diagram .....................................................485

Diagnosis Procedure .............................................486

Component Inspection ..........................................488

DTC P1551, P1552 BATTERY CURRENT

SENSOR ...........................................................

489

Component Description ........................................489

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

489

On Board Diagnosis Logic ....................................489

DTC Confirmation Procedure ................................489

Wiring Diagram .....................................................491

Diagnosis Procedure .............................................492

Component Inspection ..........................................494

DTC P1553 BATTERY CURRENT SENSOR ...495

Component Description ........................................495

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

495

On Board Diagnosis Logic ....................................495

DTC Confirmation Procedure ................................495

Wiring Diagram .....................................................497

Diagnosis Procedure .............................................498

Component Inspection ..........................................500

DTC P1554 BATTERY CURRENT SENSOR ...501

Component Description ........................................501

CONSULT-II Reference Value in Data Monitor

Mode .....................................................................

501

On Board Diagnosis Logic ....................................501

Overall Function Check .........................................501

Wiring Diagram .....................................................503

Diagnosis Procedure .............................................504

Component Inspection ..........................................506

Page 1105 of 3061

EC-22

< SERVICE INFORMATION >

PREPARATION

Commercial Service Tool

INFOID:0000000003531584

(J-45488)

Quick connector re-

leaseRemove fuel tube quick connectors in engine

room.

(J-23688)

Engine coolant refrac-

tometerChecking concentration of ethylene glycol in en-

gine coolant Tool number

(Kent-Moore No.)

Tool nameDescription

PBIC0198E

WBIA0539E

Tool name

(Kent-Moore No.)Description

Leak detector

i.e.: (J-41416)Locating the EVAP leak

EVAP service port

adapter

i.e.: (J-41413-OBD)Applying positive pressure through EVAP service

port

Fuel filler cap adapter

i.e.: (MLR-8382)Checking fuel tank vacuum relief valve opening

pressure

Socket wrench Removing and installing engine coolant tempera-

ture sensor

S-NT703

S-NT704

S-NT815

S-NT705

Page 1123 of 3061

EC-40

< SERVICE INFORMATION >

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

System DescriptionINFOID:0000000003531598

From the beginning of refueling, the air and vapor inside the fuel tank go through refueling EVAP vapor cut

valve and EVAP/ORVR line to the EVAP canister. The vapor is absorbed by the EVAP canister and the air is

released to the atmosphere.

When the refueling has reached the full level of the fuel tank, the refueling EVAP vapor cut valve is closed and

refueling is stopped because of auto shut-off. The vapor which was absorbed by the EVAP canister is purged

during driving.

WARNING:

When conducting inspections below, be sure to observe the following:

• Put a “CAUTION: FLAMMABLE” sign in workshop.

• Do not smoke while servicing fuel system. Keep open flames and sparks away from work area.

• Be sure to furnish the workshop with a CO

2 fire extinguisher.

CAUTION:

• Before removing fuel line parts, carry out the following procedures:

- Put drained fuel in an explosion-proof container and put lid on securely.

- Release fuel pressure from fuel line. Refer to EC-80, "

Fuel Pressure Check" .

- Disconnect battery ground cable.

• Always replace O-ring when the fuel gauge retainer is removed.

• Do not kink or twist hose and tube when they are installed.

• Do not tighten hose and clamps excessively to avoid damaging hoses.

• After installation, run engine and check for fuel leaks at connection.

• Do not attempt to top off the fuel tank after the fuel pump nozzle shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray and possibly a fire.

Diagnosis ProcedureINFOID:0000000003531599

SYMPTOM: FUEL ODOR FROM EVAP CANISTER IS STRONG.

1.CHECK EVAP CANISTER

1. Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

2. Weigh the EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 2.5 kg (5.5 lb).

OK or NG

OK >> GO TO 2.

NG >> GO TO 3.

2.CHECK IF EVAP CANISTER SATURATED WITH WATER

PBIB1068E

Page 1131 of 3061

EC-48

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000003531604

The ECM has an on board diagnostic system, which detects malfunctions related to engine sensors or actua-

tors. The ECM also records various emission-related diagnostic information including:

The above information can be checked using procedures listed in the table below.

×: Applicable —: Not applicable

*: When DTC and 1st trip DTC simultaneously appear on the display, they cannot be clearly distinguished from each other.

The malfunction indicator lamp (MIL) on the instrument panel lights up when the same malfunction is detected

in two consecutive trips (Two trip detection logic), or when the ECM enters fail-safe mode. (Refer to EC-88,

"Fail-Safe Chart".)

Two Trip Detection LogicINFOID:0000000003531605

When a malfunction is detected for the first time, 1st trip DTC and 1st trip Freeze Frame data are stored in the

ECM memory. The MIL will not light up at this stage. <1st trip>

If the same malfunction is detected again during the next drive, the DTC and Freeze Frame data are stored in

the ECM memory, and the MIL lights up. The MIL lights up at the same time when the DTC is stored. <2nd

trip> The “trip” in the “Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed

during vehicle operation. Specific on board diagnostic items will cause the ECM to light up or blink the MIL,

and store DTC and Freeze Frame data, even in the 1st trip, as shown below.

×: Applicable —: Not applicable

When there is an open circuit on MIL circuit, the ECM cannot warn the driver by lighting up MIL when there is

malfunction on engine control system.

Emission-related diagnostic information Diagnostic service

Diagnostic Trouble Code (DTC) Service $03 of SAE J1979

Freeze Frame data Service $02 of SAE J1979

System Readiness Test (SRT) code Service $01 of SAE J1979

1st Trip Diagnostic Trouble Code (1st Trip DTC) Service $07 of SAE J1979

1st Trip Freeze Frame data

Test values and Test limits Service $06 of SAE J1979

Calibration ID Service $09 of SAE J1979

DTC 1st trip DTCFreeze

Frame data1st trip Freeze

Frame dataSRT code SRT status Test value

CONSULT-II×× × × × ×—

GST×× ×—×××

ECM××*— — —×—

ItemsMIL DTC 1st trip DTC

1st trip 2nd trip

1st trip

displaying2nd trip

displaying1st trip

displaying2nd trip

display-

ing BlinkingLighting

upBlinkingLighting

up

Misfire (Possible three way catalyst

damage) — DTC: P0300 - P0308 is

being detected×———— —×—

Misfire (Possible three way catalyst

damage) — DTC: P0300 - P0308 is

being detected——×——×——

One trip detection diagnoses (Re-

fer to EC-49, "

Emission-related Di-

agnostic Information".)—×——×———

Except above — — —×—××—

Page 1143 of 3061

EC-60

< SERVICE INFORMATION >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

• Sea level

• Flat road

• Ambient air temperature: 20 - 30°C (68 - 86°F)

• Diagnosis is performed as quickly as possible under normal conditions.

Under different conditions [For example: ambient air temperature other than 20 - 30°C (68 - 86°F)], diagno-

sis may also be performed.

Pattern 1:

•The engine is started at the engine coolant temperature of −10 to 35°C (14 to 95°F)

(where the voltage between the ECM terminal 73 and ground is 3.0 - 4.3V).

•The engine must be operated at idle speed until the engine coolant temperature is greater than 70°C

(158°F) (where the voltage between the ECM terminal 73 and ground is lower than 1.4V).

•The engine is started at the fuel tank temperature of warmer than 0°C (32°F) (where the voltage

between the ECM terminal 107 and ground is less than 4.1V).

Pattern 2:

• When steady-state driving is performed again even after it is interrupted, each diagnosis can be conducted.

In this case, the time required for diagnosis may be extended.

Pattern 3:

• Operate vehicle following the driving pattern shown in the figure.

• Release the accelerator pedal during decelerating vehicle speed

from 90 km/h (56 MPH) to 0 km/h (0 MPH).

Pattern 4:

• The accelerator pedal must be held very steady during steady-

state driving.

• If the accelerator pedal is moved, the test must be conducted all

over again.

*1: Depress the accelerator pedal until vehicle speed is 90 km/h (56

MPH), then release the accelerator pedal and keep it released for

more than 10 seconds. Depress the accelerator pedal until vehicle

speed is 90 km/h (56 MPH) again.

*2: Checking the vehicle speed with GST is advised.

Suggested Transmission Gear Position

Set the selector lever in the D position with the overdrive switch turned ON.

TEST VALUE AND TEST LIMIT (GST ONLY — NOT APPLICABLE TO CONSULT-II)

The following is the information specified in Service $06 of SAE J1979.

The test value is a parameter used to determine whether a system/circuit diagnostic test is OK or NG while

being monitored by the ECM during self-diagnosis. The test limit is a reference value which is specified as the

maximum or minimum value and is compared with the test value being monitored.

These data (test value and test limit) are specified by Test ID (TID) and Component ID (CID) and can be dis-

played on the GST screen.

PBIB2244E

Item Self-diagnostic test item DTCTest value (GST display)

Test limit Conversion

TID CID

CATALYSTThree way catalyst function (Bank 1)P0420 01H 01H Max. 1/128

P0420 02H 81H Min. 1

Three way catalyst function (Bank 2)P0430 03H 02H Max. 1/128

P0430 04H 82H Min. 1

EVAP

SYSTEMEVAP control system (Small leak) P0442 05H 03H Max.

1/128 mm

2

EVAP control system purge flow monitoring P0441 06H 83H Min. 20 mV

EVAP control system (Very small leak) P0456 07H 03H Max.

1/128 mm

2

Page 1146 of 3061

ON BOARD DIAGNOSTIC (OBD) SYSTEM

EC-63

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

Actual work procedures are explained using a DTC as an example. Be careful so that not only the DTC, but all

of the data listed above, are cleared from the ECM memory during work procedures.

Malfunction Indicator Lamp (MIL)INFOID:0000000003531607

DESCRIPTION

The MIL is located on the instrument panel.

1. The MIL will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

If the MIL does not light up, refer to DI-26

or see EC-643.

2. When the engine is started, the MIL should go off.

If the MIL remains on, the on board diagnostic system has

detected an engine system malfunction.

ON BOARD DIAGNOSTIC SYSTEM FUNCTION

The on board diagnostic system has the following three functions.

When there is an open circuit on MIL circuit, the ECM cannot warn the driver by lighting up MIL when there is

malfunction on engine control system.

Therefore, when electrical controlled throttle and part of ECM related diagnoses are continuously detected as

NG for 5 trips, ECM warns the driver that engine control system malfunctions and MIL circuit is open by means

of operating fail-safe function.

The fail-safe function also operates when above diagnoses except MIL circuit are detected and demands the

driver to repair the malfunction.

MIL Flashing Without DTC

SEF217U

Diagnostic Test

ModeKEY and ENG.

Sta tusFunction Explanation of Function

Mode I Ignition switch in

ON position

Engine stoppedBULB CHECK This function checks the MIL bulb for damage (blown, open

circuit, etc.).

If the MIL does not come on, check MIL circuit.

Engine running MALFUNCTION

WARNINGThis is a usual driving condition. When a malfunction is de-

tected twice in two consecutive driving cycles (two trip de-

tection logic), the MIL will light up to inform the driver that a

malfunction has been detected.

The following malfunctions will light up or blink the MIL in

the 1st trip.

• Misfire (Possible three way catalyst damage)

• One trip detection diagnoses

Mode II Ignition switch in

ON position

Engine stoppedSELF-DIAGNOSTIC

RESULTSThis function allows DTCs and 1st trip DTCs to be read.

Engine operating condition in fail-safe mode Engine speed will not rise more than 2,500 rpm due to the fuel cut

Page 1154 of 3061

BASIC SERVICE PROCEDURE

EC-71

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

BASIC SERVICE PROCEDURE

Basic InspectionINFOID:0000000003531609

1.INSPECTION START

1. Check service records for any recent repairs that may indicate a related malfunction, or a current need for

scheduled maintenance.

2. Open engine hood and check the following:

- Harness connectors for improper connections

- Wiring harness for improper connections, pinches and cut

- Vacuum hoses for splits, kinks and improper connections

- Hoses and ducts for leaks

- Air cleaner clogging

- Gasket

3. Confirm that electrical or mechanical loads are not applied.

- Headlamp switch is OFF.

- Air conditioner switch is OFF.

- Rear window defogger switch is OFF.

- Steering wheel is in the straight-ahead position, etc.

4. Start engine and warm it up until engine coolant temperature

indicator points the middle of gauge.

Ensure engine stays below 1,000 rpm.

5. Run engine at about 2,000 rpm for about 2 minutes under no

load.

6. Make sure that no DTC is displayed with CONSULT-II or GST.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.REPAIR OR REPLACE

Repair or replace components as necessary according to corresponding Diagnostic Procedure.

>> GO TO 3.

3.CHECK TARGET IDLE SPEED

With CONSULT-II

1. Run engine at about 2,000 rpm for about 2 minutes under no load.

SEF983U

SEF976U

SEF977U

Page 1155 of 3061

EC-72

< SERVICE INFORMATION >

BASIC SERVICE PROCEDURE

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for about 1 minute.

3. Read idle speed in “DATA MONITOR” mode with CONSULT-II.

Refer to EC-75, "

Idle Speed and Ignition Timing Check" .

Without CONSULT-II

1. Run engine at about 2,000 rpm for about 2 minutes under no load.

2. Rev engine (2,000 to 3,000 rpm) two or three times under no load, then run engine at idle speed for about

1 minute.

3. Check idle speed.

Refer to EC-75, "

Idle Speed and Ignition Timing Check" .

OK or NG

OK >> GO TO 10.

NG >> GO TO 4.

4.PERFORM ACCELERATOR PEDAL RELEASED POSITION LEARNING

1. Stop engine.

2. Perform EC-77, "

Accelerator Pedal Released Position Learning" .

>> GO TO 5.

5.PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Perform EC-77, "

Throttle Valve Closed Position Learning" .

>> GO TO 6.

6.PERFORM IDLE AIR VOLUME LEARNING

Refer to EC-78, "

Idle Air Volume Learning" .

Is Idle Air Volume Learning carried out successfully?

Ye s o r N o

Ye s > > G O T O 7 .

No >> 1. Follow the instruction of Idle Air Volume Learning.

2. GO TO 4.

7.CHECK TARGET IDLE SPEED AGAIN

With CONSULT-II

PBIA8513J

650 ± 50 rpm (in P or N position)

SEF058Y

650 ± 50 rpm (in P or N position)