light INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2281 of 3061

LT-74

< SERVICE INFORMATION >

COMBINATION SWITCH

If CONSULT-II is used with no connection of CONSULT-II CONVERTER, malfunctions might be

detected in self-diagnosis depending on control unit which carries out CAN communication.

1. Connect CONSULT-II, and select "COMB SW" on "SELECT

TEST ITEM" screen.

2. Select "DATA MONITOR".

3. Select "START", and confirm that other switches in malfunction-

ing system operate normally.

Example: When auto light switch is malfunctioning, confirm that

"FRONT WIPER LOW" and "FRONT WIPER INT" in System 3,

to which the auto light switch belongs, turn ON-OFF normally.

Without CONSULT-II

Operate combination switch, and confirm that other switches in malfunctioning system operate normally.

Example: When auto light switch is malfunctioning, confirm that "FRONT WIPER LOW" and "FRONT WIPER

INT" in System 3, to which the auto light switch belongs, operate normally.

Check results

Other switches in malfunctioning system operate normally.>>Replace lighting switch or wiper switch.

Other switches in malfunctioning system do not operate normally.>>GO TO 3.

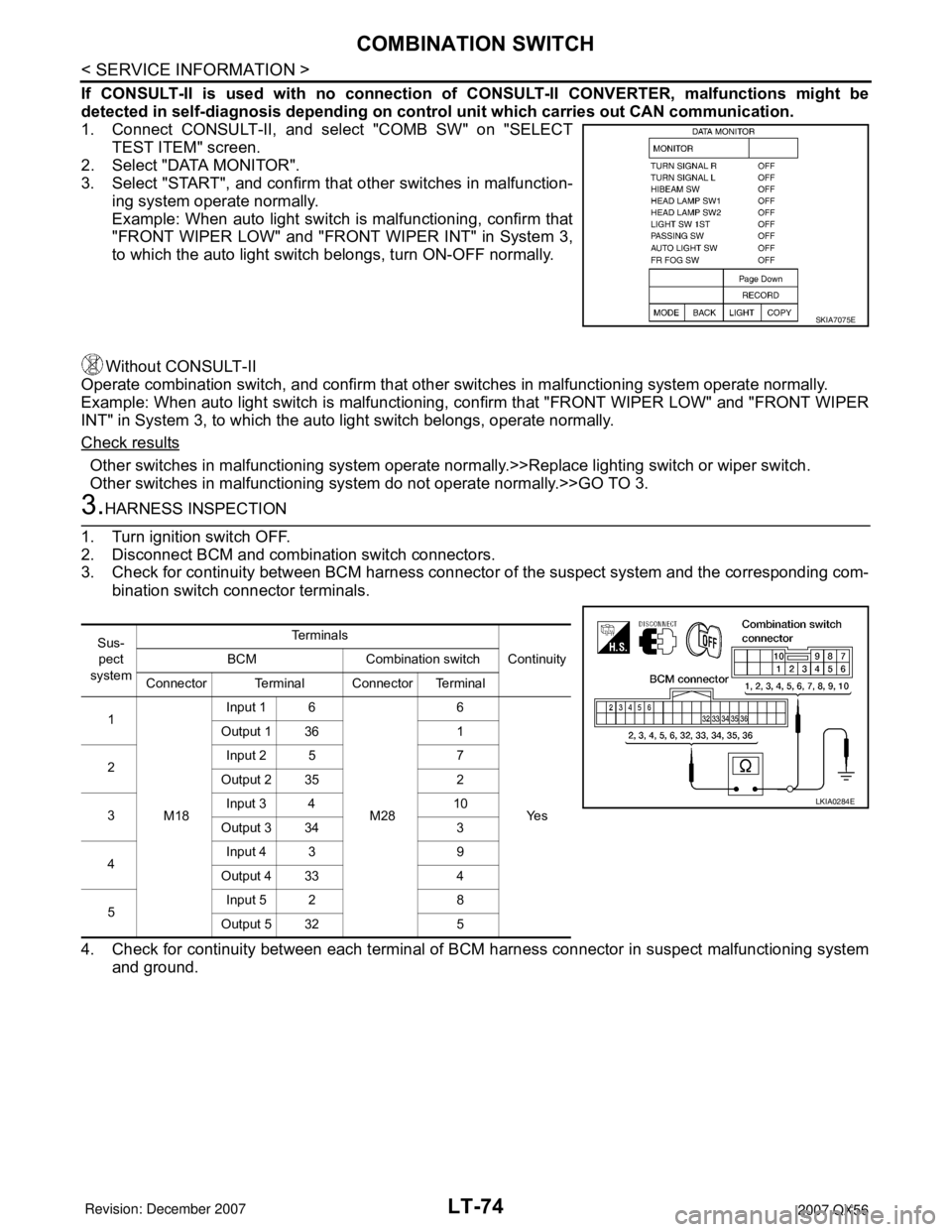

3.HARNESS INSPECTION

1. Turn ignition switch OFF.

2. Disconnect BCM and combination switch connectors.

3. Check for continuity between BCM harness connector of the suspect system and the corresponding com-

bination switch connector terminals.

4. Check for continuity between each terminal of BCM harness connector in suspect malfunctioning system

and ground.

SKIA7075E

Sus-

pect

systemTe r m i n a l s

Continuity BCM Combination switch

Connector Terminal Connector Terminal

1

M18Input 1 6

M286

Ye s Output 1 36 1

2Input 2 5 7

Output 2 35 2

3Input 3 4 10

Output 3 34 3

4Input 4 3 9

Output 4 33 4

5Input 5 2 8

Output 5 32 5

LKIA0284E

Page 2282 of 3061

COMBINATION SWITCH

LT-75

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

OK or NG

OK >> GO TO 4.

NG >> Check harness between BCM and combination switch for open or short circuit.

4.BCM OUTPUT TERMINAL INSPECTION

1. Turn lighting switch and wiper switch to OFF.

2. Set wiper dial to position 4.

3. Connect BCM and combination switch connectors.

4. Turn ignition switch on.

5. Check BCM output terminal voltage waveform of suspect mal-

functioning system.

OK or NG

OK >> Open circuit in combination switch, GO TO 5.

NG >> Replace BCM. Refer to BCS-24, "

BCM" .

5.COMBINATION SWITCH INSPECTION

Referring to table below, perform combination switch inspection.

Suspect

systemTe r m i n a l s

Continuity BCM

Connector Terminal

1

M18Input 1 6

Ground No Output 1 36

2Input 2 5

Output 2 35

3Input 3 4

Output 3 34

4Input 4 3

Output 4 33

5Input 5 2

Output 5 32

Suspect systemTe r m i n a l s

Combination switch (+)

Connector Terminal

1

M28Input 1 1

2 Input 2 2

3 Input 3 3

4 Input 4 4

5 Input 5 5

SKIA4976E

Page 2283 of 3061

LT-76

< SERVICE INFORMATION >

COMBINATION SWITCH

>> Inspection End.

Removal and InstallationINFOID:0000000003533425

Refer to LT-70, "Removal and Installation".

Switch Circuit InspectionINFOID:0000000003533426

Refer to "Switch Circuit Inspection".

Procedure

12 34567

Replace

lighting

switch.Confirm

check re-

sults.OK INSPECTION END

Confirm

check re-

sults.OK INSPECTION END

Confirm

check re-

sults.OK INSPECTION END

NGReplace wiper

switch.NGReplace switch

base.NGConfirm symptom

again.

Page 2289 of 3061

LT-82

< SERVICE INFORMATION >

PARKING, LICENSE PLATE AND TAIL LAMPS

PARKING, LICENSE PLATE AND TAIL LAMPS

Component Parts and Harness Connector LocationINFOID:0000000003533434

System DescriptionINFOID:0000000003533435

Control of the parking, license plate, and tail lamp operation is dependent upon the position of the lighting

switch (combination switch). When the lighting switch is placed in the 1ST position, the BCM (body control

module) receives input signal requesting the parking, license plate, side marker and tail lamps to illuminate.

This input signal is communicated to the IPDM E/R (intelligent power distribution module engine room) across

the CAN communication lines. The CPU (central processing unit) of the IPDM E/R controls the tail lamp relay

coil. This relay, when energized, directs power to the parking, license plate and tail lamps, which then illumi-

nate.

Power is supplied at all times

• to ignition relay, located in the IPDM E/R,

• to tail lamp relay, located in the IPDM E/R,

• through 20A fuse (No. 53, located in the IPDM E/R)

• to CPU of the IPDM E/R, and

• through 50A fusible link (letter f , located in the fuse and fusible link box)

• to BCM terminal 70.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38

• to ignition relay, located in the IPDM E/R, and

Ground is supplied

• to BCM terminal 67

• through grounds M57, M61 and M79, and

• to IPDM E/R terminals 38 and 59

• through grounds E9, E15 and E24.

OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST or 2ND position (or if the auto light system is activated), the BCM receives

input signal requesting the parking, license plate, side marker and tail lamps to illuminate. This input signal is

communicated to the IPDM E/R across the CAN communication lines. The CPU of the IPDM E/R controls the

tail lamp relay coil, which when energized, directs power

WKIA3468E

Page 2290 of 3061

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-83

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

• through 10 A fuse (No. 37, located in the IPDM E/R)

• through IPDM E/R terminal 57

• to front combination lamp LH and RH terminal 3

• to license plate lamps terminal 1 and

• to rear combination lamp LH and RH terminal 3.

Ground is supplied

• to front combination lamp LH and RH terminal 4

• through grounds E9, E15 and E24,

• to rear combination lamp LH terminal 1

• through grounds B7 and B19,

• to rear combination lamp RH terminal 1 and

• to license plate lamps terminal 2

• through grounds B117 and B132.

With power and ground supplied, the parking, license plate and tail lamps illuminate.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-3, "System Description" .

EXTERIOR LAMP BATTERY SAVER CONTROL

When the combination switch (lighting switch) is in the 1ST (or 2ND) position, and the ignition switch is turned

from ON or ACC to OFF, the battery saver control feature is activated.

Under this condition, the parking, license and tail lamps remain illuminated for 5 minutes, then the parking,

license plate and tail lamps are turned off.

Exterior lamp battery saver control mode can be changed by the function setting of CONSULT-II.

CAN Communication System DescriptionINFOID:0000000003533436

Refer to LAN-4, "CAN Communication System".

Page 2295 of 3061

LT-88

< SERVICE INFORMATION >

PARKING, LICENSE PLATE AND TAIL LAMPS

How to Proceed with Trouble Diagnosis

INFOID:0000000003533441

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer to LT-82, "

System Description" .

3. Carry out the Preliminary Check. Refer to LT-88, "

Preliminary Check" .

4. Check symptom and repair or replace the cause of malfunction.

5. Do the parking, license and tail lamps operate normally? If YES: GO TO 6. If NO: GO TO 4.

6. Inspection End.

Preliminary CheckINFOID:0000000003533442

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR BCM

Refer to BCS-15, "BCM Power Supply and Ground Circuit Inspection" .

CHECK POWER SUPPLY AND GROUND CIRCUIT FOR IPDM E/R

Refer to PG-26, "IPDM E/R Power/Ground Circuit Inspection" .

CONSULT-II Function for BCMINFOID:0000000003533443

Refer to BCS-16, "CONSULT-II Function (BCM)" .

CONSULT-II Function for IPDM E/RINFOID:0000000003533444

Refer to PG-18, "CONSULT-II Function (IPDM E/R)" .

Parking, License Plate and/or Tail Lamps Do Not IlluminateINFOID:0000000003533445

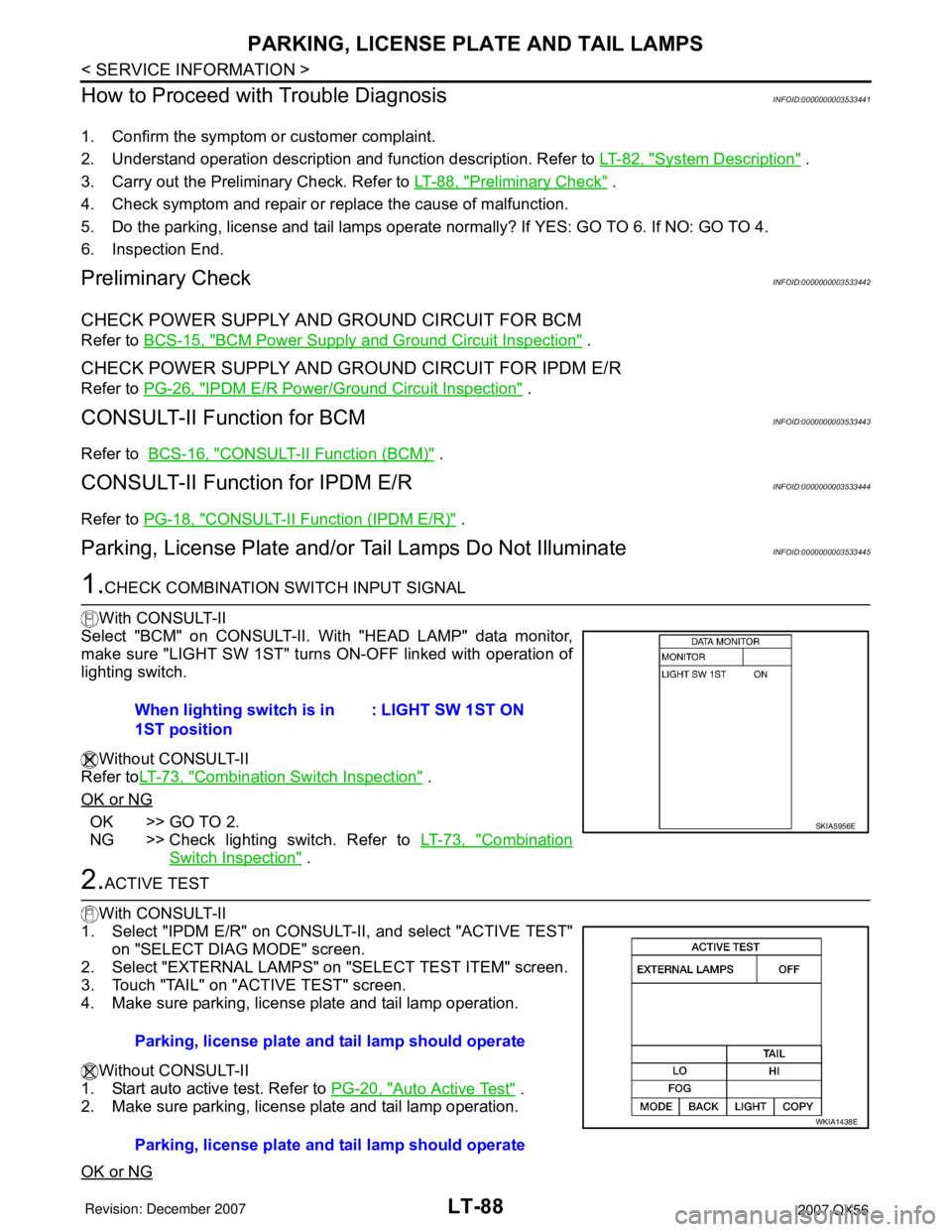

1.CHECK COMBINATION SWITCH INPUT SIGNAL

With CONSULT-II

Select "BCM" on CONSULT-II. With "HEAD LAMP" data monitor,

make sure "LIGHT SW 1ST" turns ON-OFF linked with operation of

lighting switch.

Without CONSULT-II

Refer toLT-73, "

Combination Switch Inspection" .

OK or NG

OK >> GO TO 2.

NG >> Check lighting switch. Refer to LT-73, "

Combination

Switch Inspection" .

2.ACTIVE TEST

With CONSULT-II

1. Select "IPDM E/R" on CONSULT-II, and select "ACTIVE TEST"

on "SELECT DIAG MODE" screen.

2. Select "EXTERNAL LAMPS" on "SELECT TEST ITEM" screen.

3. Touch "TAIL" on "ACTIVE TEST" screen.

4. Make sure parking, license plate and tail lamp operation.

Without CONSULT-II

1. Start auto active test. Refer to PG-20, "

Auto Active Test" .

2. Make sure parking, license plate and tail lamp operation.

OK or NG

When lighting switch is in

1ST position: LIGHT SW 1ST ON

SKIA5956E

Parking, license plate and tail lamp should operate

Parking, license plate and tail lamp should operate

WKIA1438E

Page 2296 of 3061

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-89

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

OK >> GO TO 3.

NG >> GO TO 4.

3.CHECK IPDM E/R

1. Select "IPDM E/R" on CONSULT-II, and select "DATA MONI-

TOR" on "SELECT DIAG MODE" screen.

2. Make sure "TAIL&CLR REQ" turns ON when lighting switch is in

1ST position.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and

Installation of IPDM E/R" .

NG >> Replace BCM. Refer to BCS-24, "

BCM" .

4.CHECK INPUT SIGNAL

With CONSULT-II

1. Turn ignition switch OFF.

2. Disconnect front combination lamp, license plate lamp and rear combination lamp connectors.

3. Turn ignition switch ON.

4. Select "IPDM E/R" on CONSULT-II, and select "ACTIVE TEST" on "SELECT DIAG MODE" screen.

5. Select "TAIL LAMP" on "SELECT TEST ITEM" screen.

6. Touch "ON" on "ACTIVE TEST" screen.

7. When tail lamp is operating, check voltage between front combination lamp, license plate lamp, rear com-

bination lamp harness connector and ground.

Without CONSULT-II

1. Start auto active test. Refer to PG-20, "

Auto Active Test".

2. When tail lamp is operating, check voltage between front combination lamp, license plate lamp, rear com-

bination lamp connector and ground.When lighting switch is in

1ST position: TAIL&CLR REQ ON

SKIA5958E

Front combination lamp (+)

(–) Voltage

Connector Terminal

RH E107

3 Ground Battery voltage

LH E11

WKIA1900E

License plate lamps (+)

(–) Voltage

Connector Terminal

D703 1 Ground Battery voltage

WKIA4613E

Page 2298 of 3061

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-91

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

1. Check continuity between front combination lamp harness con-

nector and ground.

2. Check continuity between license lamps plate connector and

ground.

3. Check continuity between rear combination lamp harness con-

nector and ground.

OK or NG

OK >> Check bulbs.

NG >> Repair harness or connector.

Parking, License Plate and Tail Lamps Do Not Turn OFF (After Approx. 10 Minutes)

INFOID:0000000003533446

1.CHECK IPDM E/R

1. Turn ignition switch ON. Turn the combination switch (lighting switch) to the OFF position. Turn ignition

switch OFF.

2. Verify that the parking, license plate, and tail lamps turn on and off after approximately 10 minutes.

OK or NG

OK >> Ignition relay malfunction. Refer to PG-18, "Function of Detecting Ignition Relay Malfunction" .

NG >> Inspection End.

Bulb ReplacementINFOID:0000000003533447

FRONT PARKING LAMP

Refer to LT-21, "Bulb Replacement".

LICENSE PLATE LAMP

Removal

1. Remove back door lower finisher. Refer to EI-23, "Removal and Installation".

2. Turn bulb socket counterclockwise to remove it.

3. Pull bulb from socket.

Front combination lamp

Continuity

Connector Terminal

RH E107

4GroundYes

LH E11

WKIA1904E

License plate lamps

Continuity

Connector Terminal

D703 2 Ground Yes

WKIA4615E

Rear combination lamp

Continuity

Connector Terminal

RH B130

1 Ground Yes

LH B70

WKIA1905E

Page 2301 of 3061

LT-94

< SERVICE INFORMATION >

TRAILER TOW

TRAILER TOW

Component Parts and Harness Connector LocationINFOID:0000000003533451

System DescriptionINFOID:0000000003533452

Power is supplied at all times

• to ignition relay, located in the IPDM E/R (intelligent power distribution module engine room),

• through 50A fusible link (letter f , located in the fuse and fusible link box)

• to BCM (body control module) terminal 70,

• through 10A fuse (No. 32, located in the IPDM E/R)

• through IPDM E/R terminal 61

1. Fuse and fusible link box 2. IPDM E/R fuse layout 3. Fuse and relay box

4. IPDM E/R E118, E119, E120, E121,

E122, E123, E1245. A. Steering column

B. Data link connector M22

C. BCM M18, M19, M20

(view with instrument lower panel LH

removed)6. A. Trailer turn relay LH E156

B. Battery

C. Trailer tow relay 2 E140

D. Trailer turn relay RH E157

7. A. Trailer tow relay 1 M51

B. Electric brake (pre-wiring) M76

(view with instrument lower panel LH

removed)8. Trailer connector C2 9. Combination switch (lighting switch)

M28

WKIA4616E

Page 2302 of 3061

TRAILER TOW

LT-95

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

• to trailer tow relay 1 terminal 3,

• through 20A fuse (No. 53, located in the IPDM E/R)

• to CPU (central processing unit) of the IPDM E/R,

• through 30A fusible link (letter j , located in the fuse and fusible link box)

• to trailer tow relay 2 terminals 3 and 6, and

• through 40A fusible link (letter k , located in the fuse and fusible link box)

• to electric brake (pre-wiring) terminal 5.

With the ignition switch in the ON or START position, power is supplied

• to ignition relay, located in the IPDM E/R,

• through 10A fuse (No. 59, located in the fuse and relay box)

• to BCM terminal 38, and

• through 10A fuse (No. 51, located in the IPDM E/R)

• to trailer tow relay 2 terminal 1.

Ground is supplied

• to BCM terminal 67

• to electric brake (pre-wiring) terminal 1,

• through grounds M57, M61 and M79,

• to IPDM E/R terminals 38 and 59

• to trailer tow relay 1 terminal 2

• to trailer tow relay 2 terminal 2, and

• to trailer connector terminal 2

• to trailer turn relay LH and RH terminal 2

• through grounds E9, E15 and E24.

TRAILER TAIL LAMP OPERATION

The trailer tail lamps are controlled by the trailer tow relay 1.

With the lighting switch in the parking and tail lamp ON (1ST) position, AUTO position (and the auto light sys-

tem is activated) or headlamp ON (2ND) position, power is supplied

• through the tail lamp relay, located in the IPDM E/R

• through 10A fuse (No. 36, located in the IPDM E/R)

• through IPDM E/R terminal 49

• to trailer tow relay 1 terminal 1.

When energized, trailer tow relay 1 supplies tail lamp power to trailer connector terminal 6.

TRAILER TURN SIGNAL AND HAZARD LAMP OPERATION

The trailer turn signal and hazard lamps are controlled by the BCM through trailer turn relays (LH and RH). If

either turn signal or the hazard lamps are turned on, the BCM supplies voltage to the trailer turn relays (LH

and RH) to make them cycle on and off.

Trailer turn relay LH output is supplied

• through BCM terminal 52

• to trailer turn relay LH terminal 1.

Trailer turn relay RH output is supplied

• through BCM terminal 51

• to trailer turn relay RH terminal 1.

Left turn signal and hazard lamp output is supplied

• through trailer turn relay LH terminal 3

• to trailer connector terminal 1.

Right turn signal and hazard lamp output is supplied

• through trailer turn relay RH terminal 3

• to trailer connector terminal 4.

TRAILER STOP LAMP OPERATION

The trailer stop lamps are controlled by the electric brake. The electric brake receives stop lamp switch signal

when the brake pedal is pressed.

When the brake pedal is pressed, power is supplied

• through electric brake (pre-wiring) terminal 3

• to trailer connector terminal 3.

TRAILER POWER SUPPLY OPERATION

The trailer power supply is controlled by the trailer tow relay 2.

When the ignition switch is in the ON or START position, power is supplied

• through 10A fuse (No. 51, located in the IPDM E/R)