light INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2327 of 3061

LT-120

< SERVICE INFORMATION >

ILLUMINATION

ILLUMINATION

Component Parts and Harness Connector LocationINFOID:0000000003533468

System DescriptionINFOID:0000000003533469

Control of the illumination lamps operation is dependent upon the position of the lighting switch (combination

switch). When the lighting switch is placed in the 1ST or 2ND position (or if the auto light system is activated)

the BCM (body control module) receives input signal requesting the illumination lamps to illuminate. This input

signal is communicated to the IPDM E/R (intelligent power distribution module engine room) across the CAN

communication lines. The CPU (central processing unit) of the IPDM E/R controls the tail lamp relay coil. This

relay, when energized, directs power to the illumination lamps, which then illuminate.

Power is supplied at all times

• to ignition relay, located in the IPDM E/R,

• to tail lamp relay, located in the IPDM E/R,

• through 50A fusible link (letter f , located in the fuse and fusible link box)

• to BCM terminal 70,

• through 20A fuse (No. 53, located in the IPDM E/R)

• to CPU of the IPDM E/R, and

• through 10A fuse [No.19, located in fuse block (J/B)]

• to combination meter terminal 8

With the ignition switch in the ON or START position, power is supplied

• to ignition relay, located in the IPDM E/R,

• through 10A fuse (No. 59, located in the fuse and relay box)

WKIA3471E

Page 2328 of 3061

![INFINITI QX56 2007 Factory Service Manual ILLUMINATION

LT-121

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

• to BCM terminal 38, and

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal INFINITI QX56 2007 Factory Service Manual ILLUMINATION

LT-121

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

• to BCM terminal 38, and

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal](/img/42/57029/w960_57029-2327.png)

ILLUMINATION

LT-121

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

LT

N

O

P

• to BCM terminal 38, and

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal 24.

Ground is supplied

• to BCM terminal 67

• to combination meter terminal 17

• through grounds M57, M61 and M79, and

• to IPDM E/R terminals 38 and 59

• through grounds E9, E15 and E24.

ILLUMINATION OPERATION BY LIGHTING SWITCH

With the lighting switch in the 1ST or 2ND position (or if the auto light system is activated), the BCM receives

input signal requesting the illumination lamps to illuminate. This input signal is communicated to the IPDM E/R

across the CAN communication lines. The CPU of the IPDM E/R controls the tail lamp relay coil, which, when

energized, directs power

• through 10A fuse (No. 36, located in the IPDM E/R)

• through IPDM E/R terminal 49

• to illumination control switch terminal 1

• to power liftgate switch terminal 3

• to front room/map lamp assembly (console box illumination) terminal 7

• to hazard switch terminal 3

• to rear sonar system OFF switch terminal 3

• to glove box lamp terminal 1

• to door mirror remote control switch terminal 16

• to display control unit terminal 14

• to power window and door lock/unlock switch RH terminal 5 (early production)

• to main power window and door lock/unlock switch LH terminal 16 (early production)

• to 4WD shift switch terminal 7 (with 4-wheel drive)

• to front air control terminal 23

• to rear power vent window switch terminal 5

• to DVD player terminal 12 (with DVD entertainment system)

• to NAVI control unit terminal 61

• to pedal adjusting switch terminal 5

• to electric brake (pre-wiring) terminal 4 (with trailer tow)

• to front and rear heated seat switch LH and RH terminal 5

• to A/T device terminal 11

• to VDC OFF switch terminal 3

• to tow mode switch terminal 3

• to headlamp aiming switch terminal 3

• to clock terminal 3, and

• through 10A fuse (No. 37, located in the IPDM E/R)

• through IPDM E/R terminal 57

• to AV switch terminal 3

• to audio unit terminal 8

• to rear air control terminal 1 and

• to rear audio remote control unit terminal 6.

The illumination control switch controls illumination intensity by varying the ground to the following

• through illumination control switch terminal 2

• to power liftgate switch terminal 4

• to front room/map lamp assembly (console box illumination) terminal 8

• to AV switch terminal 4

• to hazard switch terminal 4

• to audio unit terminal 7

• to rear sonar system OFF switch terminal 4

• to power window and door lock/unlock switch RH terminal 1 (early production)

• to main power window and door lock/unlock switch LH terminal 12 (early production)

• to 4WD switch terminal 8 (with 4-wheel drive)

• to front air control terminal 24

• to rear power vent window switch terminal 6

• to DVD player terminal 10 (with DVD entertainment system)

• to pedal adjusting switch terminal 6

• to A/T device terminal 12

Page 2329 of 3061

LT-122

< SERVICE INFORMATION >

ILLUMINATION

• to front heated seat switch LH and RH terminal 6

• to VDC OFF switch terminal 4

• to tow mode switch terminal 4

• to headlamp aiming switch terminal 4

• to clock terminal 4 and

• to combination meter terminal 18.

Ground is supplied

• to illumination control switch terminal 3

• to glove box lamp terminal 2

• to door mirror remote control switch terminal 15

• to display control unit terminal 3

• to rear heated seat switches terminal 6

• to electric brake (pre-wiring) terminal 1 (with trailer tow)

• to combination meter terminal 17

• through grounds M57, M61 and M79, and

• to NAVI control unit terminal 1

• to rear air control terminal 3

• to rear audio remote control unit terminal 15

• through grounds B117 and B132.

With power and ground supplied, illumination lamps illuminate.

EXTERIOR LAMP BATTERY SAVER CONTROL

When the combination switch (lighting switch) is in the 1ST or 2ND position (or if auto light system is acti-

vated), and the ignition switch is turned from ON or ACC to OFF, the battery saver control function is activated.

Under this condition, the illumination lamps remain illuminated for 5 minutes, then the illumination lamps are

turned off.

When the lighting switch is turned from OFF to 1ST or 2ND position (or if auto light system is activated) after

illumination lamps are turned off by the battery saver control, the illumination lamps illuminate again.

Exterior lamp battery saver control mode can be changed by the function setting of CONSULT-II.

CAN Communication System DescriptionINFOID:0000000003533470

Refer to LAN-4, "CAN Communication System" .

Page 2347 of 3061

LU-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003531549

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Precaution for Liquid GasketINFOID:0000000003531550

REMOVAL OF LIQUID GASKET SEALING

• After removing the bolts and nuts, separate the mating surface and

remove the old liquid gasket sealing using Tool.

CAUTION:

Do not damage the mating surfaces.

• Tap the seal cutter to insert it.

• In areas where the Tool is difficult to use, lightly tap to slide it.

LIQUID GASKET APPLICATION PROCEDURE

1. Remove the old liquid gasket adhering to the gasket application

surface and the mating surface using suitable tool.

• Remove the liquid gasket completely from the groove of the

liquid gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering

moisture, grease and foreign material.Tool number : KV10111100 (J-37228)

WBIA0566E

PBIC0003E

Page 2359 of 3061

LU-14

< SERVICE INFORMATION >

OIL PUMP

OIL PUMP

Removal and InstallationINFOID:0000000003531559

REMOVAL

1. Remove front cover. Refer to EM-38, "Removal and Installation".

2. Remove the oil pump drive spacer.

3. Remove the oil pump.

INSTALLATION

Installation is in the reverse order of removal, paying attention of the following:

• When inserting the oil pump drive spacer, align the crankshaft key

and the flat face of the inner rotor.

• If they are not aligned, rotate the oil pump inner rotor by hand.

• Make sure that the each part is aligned and tap lightly until it

reaches the end.

INSPECTION AFTER INSTALLATION

• Start the engine, and check for leaks of engine oil.

• Stop engine and wait 10 minutes.

• Check level and add engine oil as required. Refer to LU-8, "

Inspection".

WBIA0415E

1. Oil pump body 2. Outer rotor 3. Inner rotor

4. Oil pump cover 5. Oil pump drive spacer 6. Regulator valve

7. Regulator spring 8. Regulator plug

KBIA2512E

KBIA2490E

Page 2376 of 3061

MA-14

< SERVICE INFORMATION >

ENGINE MAINTENANCE

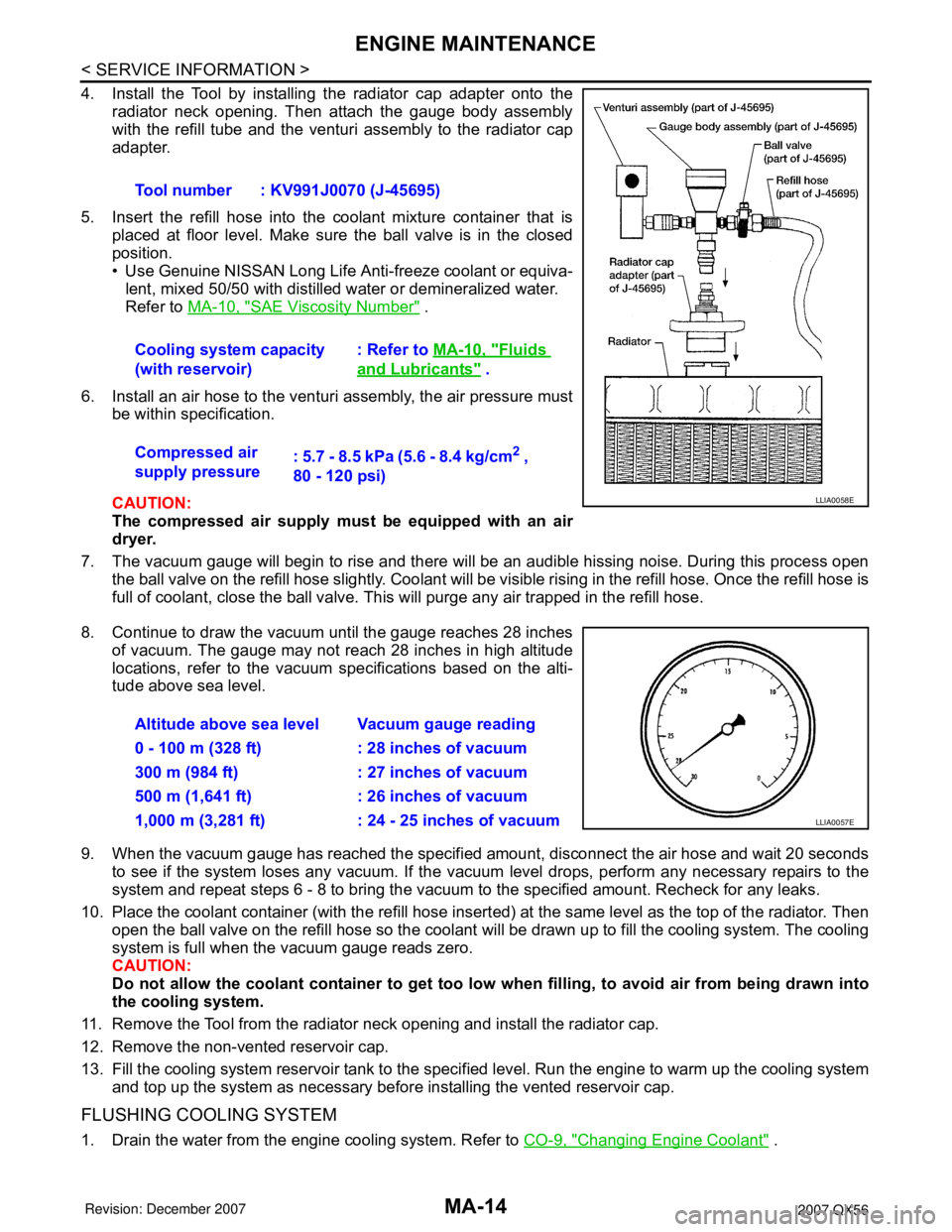

4. Install the Tool by installing the radiator cap adapter onto the

radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the coolant mixture container that is

placed at floor level. Make sure the ball valve is in the closed

position.

• Use Genuine NISSAN Long Life Anti-freeze coolant or equiva-

lent, mixed 50/50 with distilled water or demineralized water.

Refer to MA-10, "

SAE Viscosity Number" .

6. Install an air hose to the venturi assembly, the air pressure must

be within specification.

CAUTION:

The compressed air supply must be equipped with an air

dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open

the ball valve on the refill hose slightly. Coolant will be visible rising in the refill hose. Once the refill hose is

full of coolant, close the ball valve. This will purge any air trapped in the refill hose.

8. Continue to draw the vacuum until the gauge reaches 28 inches

of vacuum. The gauge may not reach 28 inches in high altitude

locations, refer to the vacuum specifications based on the alti-

tude above sea level.

9. When the vacuum gauge has reached the specified amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to bring the vacuum to the specified amount. Recheck for any leaks.

10. Place the coolant container (with the refill hose inserted) at the same level as the top of the radiator. Then

open the ball valve on the refill hose so the coolant will be drawn up to fill the cooling system. The cooling

system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the coolant container to get too low when filling, to avoid air from being drawn into

the cooling system.

11. Remove the Tool from the radiator neck opening and install the radiator cap.

12. Remove the non-vented reservoir cap.

13. Fill the cooling system reservoir tank to the specified level. Run the engine to warm up the cooling system

and top up the system as necessary before installing the vented reservoir cap.

FLUSHING COOLING SYSTEM

1. Drain the water from the engine cooling system. Refer to CO-9, "Changing Engine Coolant" . Tool number : KV991J0070 (J-45695)

Cooling system capacity

(with reservoir): Refer to MA-10, "

Fluids

and Lubricants" .

Compressed air

supply pressure: 5.7 - 8.5 kPa (5.6 - 8.4 kg/cm

2 ,

80 - 120 psi)

LLIA0058E

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

LLIA0057E

Page 2424 of 3061

PG-22

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

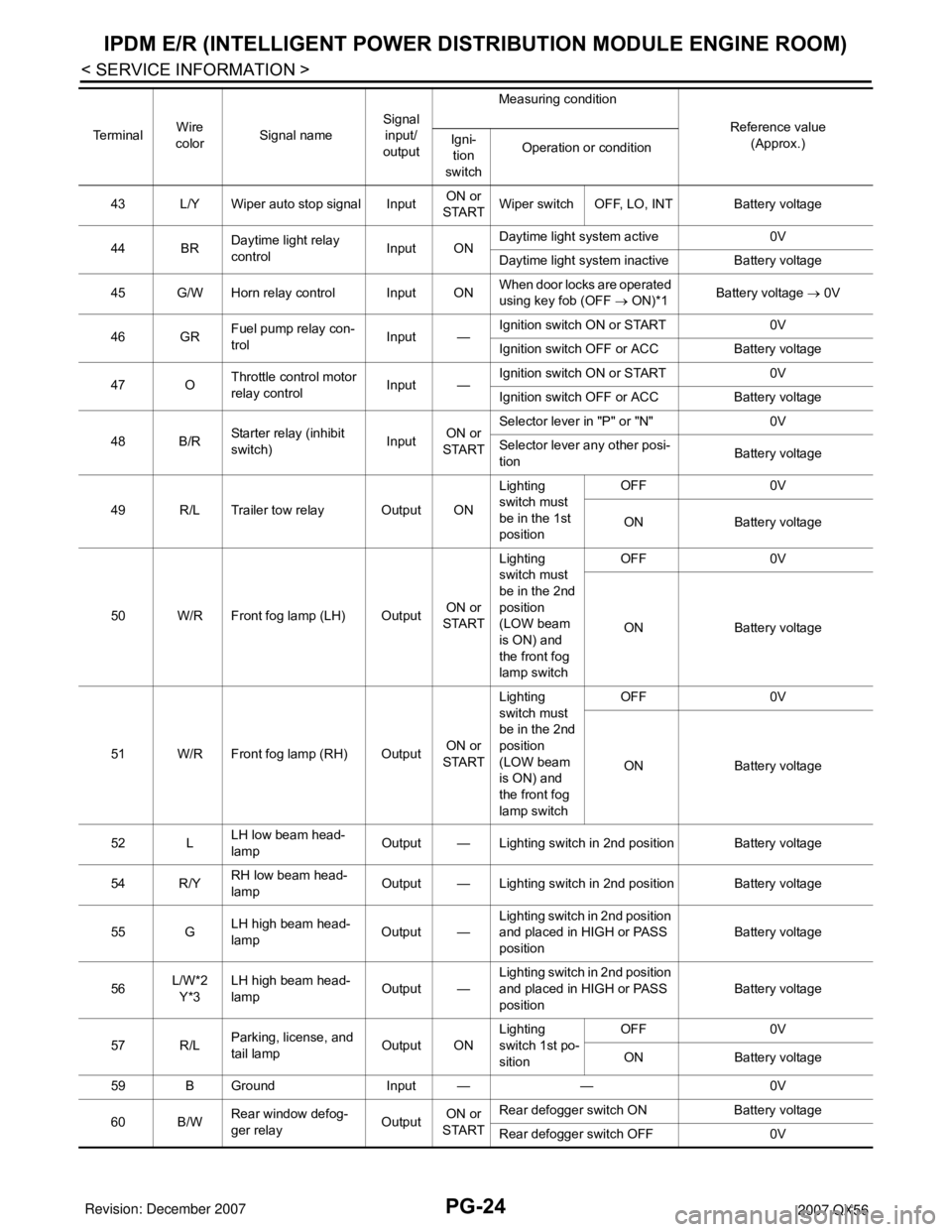

Terminal and Reference Value for IPDM E/R

INFOID:0000000003533840

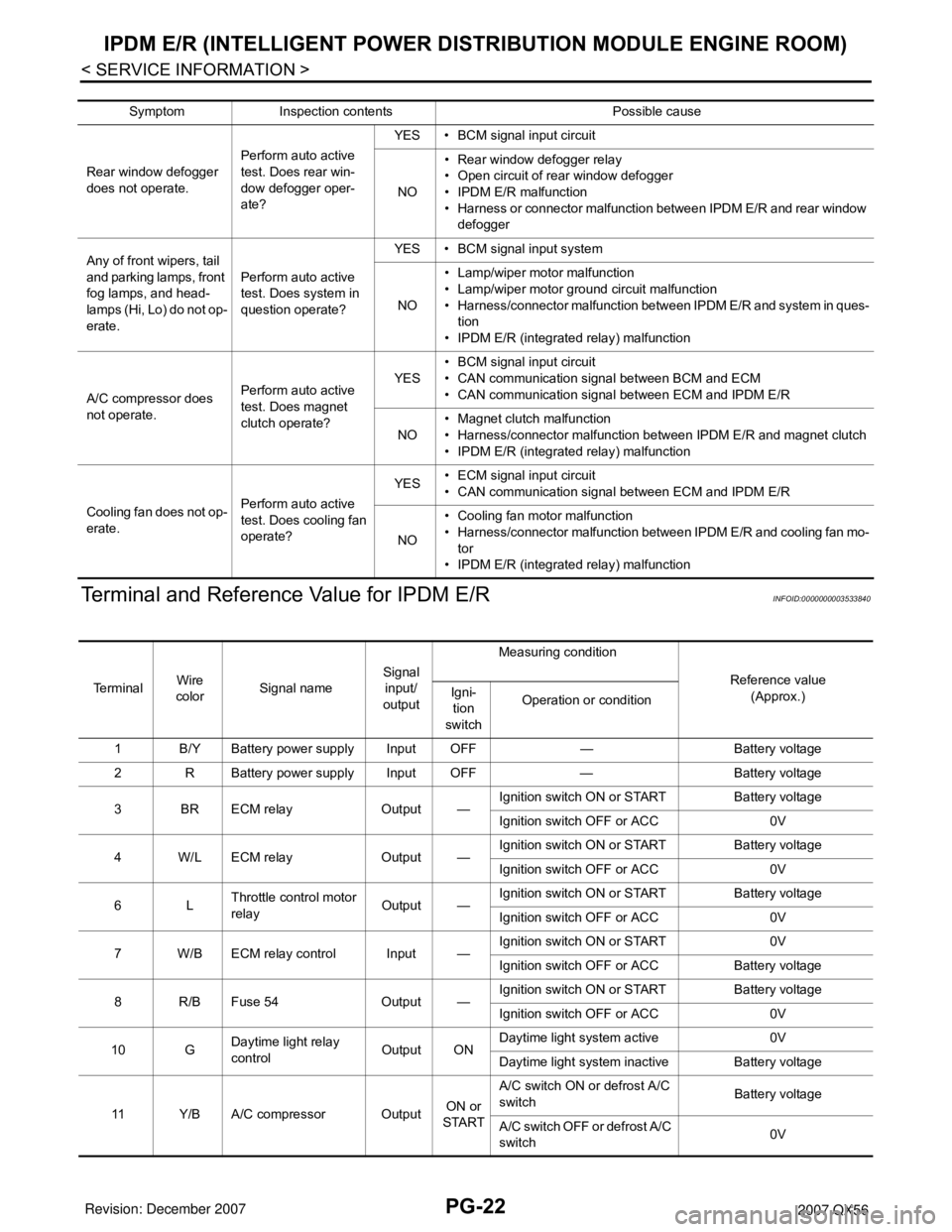

Symptom Inspection contents Possible cause

Rear window defogger

does not operate.Perform auto active

test. Does rear win-

dow defogger oper-

ate?YES • BCM signal input circuit

NO• Rear window defogger relay

• Open circuit of rear window defogger

•IPDM E/R malfunction

• Harness or connector malfunction between IPDM E/R and rear window

defogger

Any of front wipers, tail

and parking lamps, front

fog lamps, and head-

lamps (Hi, Lo) do not op-

erate.Perform auto active

test. Does system in

question operate?YES • BCM signal input system

NO• Lamp/wiper motor malfunction

• Lamp/wiper motor ground circuit malfunction

• Harness/connector malfunction between IPDM E/R and system in ques-

tion

• IPDM E/R (integrated relay) malfunction

A/C compressor does

not operate.Perform auto active

test. Does magnet

clutch operate?YES• BCM signal input circuit

• CAN communication signal between BCM and ECM

• CAN communication signal between ECM and IPDM E/R

NO• Magnet clutch malfunction

• Harness/connector malfunction between IPDM E/R and magnet clutch

• IPDM E/R (integrated relay) malfunction

Cooling fan does not op-

erate.Perform auto active

test. Does cooling fan

operate?YES• ECM signal input circuit

• CAN communication signal between ECM and IPDM E/R

NO• Cooling fan motor malfunction

• Harness/connector malfunction between IPDM E/R and cooling fan mo-

tor

• IPDM E/R (integrated relay) malfunction

Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value

(Approx.) Igni-

tion

switchOperation or condition

1 B/Y Battery power supply Input OFF — Battery voltage

2 R Battery power supply Input OFF — Battery voltage

3 BR ECM relay Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

4 W/L ECM relay Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

6LThrottle control motor

relayOutput —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

7 W/B ECM relay control Input —Ignition switch ON or START 0V

Ignition switch OFF or ACC Battery voltage

8 R/B Fuse 54 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

10 GDaytime light relay

controlOutput ONDaytime light system active 0V

Daytime light system inactive Battery voltage

11 Y/B A/C compressor OutputON or

STARTA/C switch ON or defrost A/C

switchBattery voltage

A/C switch OFF or defrost A/C

switch0V

Page 2425 of 3061

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PG-23

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

PG

N

O

P

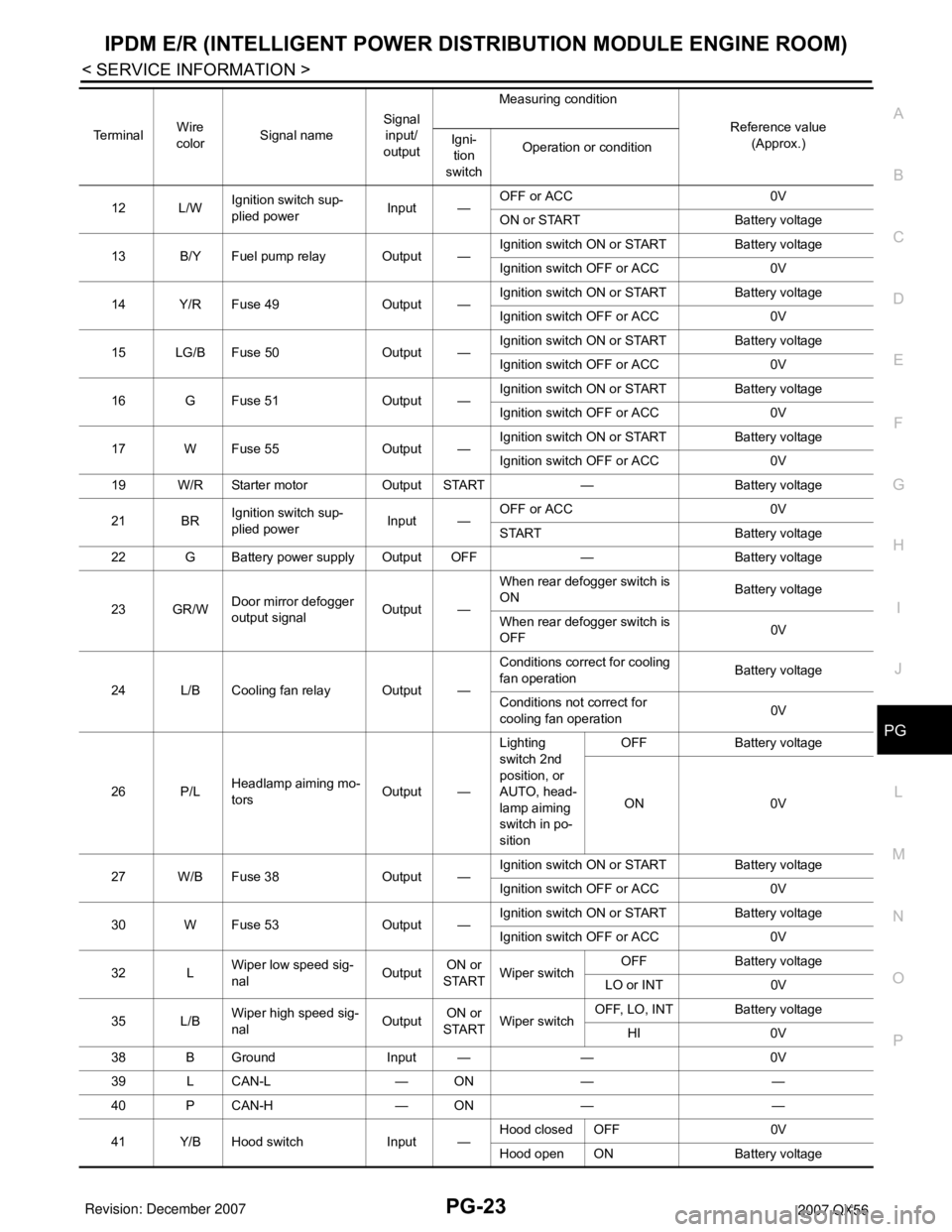

12 L/WIgnition switch sup-

plied powerInput —OFF or ACC 0V

ON or START Battery voltage

13 B/Y Fuel pump relay Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

14 Y/R Fuse 49 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

15 LG/B Fuse 50 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

16 G Fuse 51 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

17 W Fuse 55 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

19 W/R Starter motor Output START — Battery voltage

21 BRIgnition switch sup-

plied powerInput —OFF or ACC 0V

START Battery voltage

22 G Battery power supply Output OFF — Battery voltage

23 GR/WDoor mirror defogger

output signalOutput —When rear defogger switch is

ONBattery voltage

When rear defogger switch is

OFF0V

24 L/B Cooling fan relay Output —Conditions correct for cooling

fan operationBattery voltage

Conditions not correct for

cooling fan operation0V

26 P/LHeadlamp aiming mo-

torsOutput —Lighting

switch 2nd

position, or

AUTO, head-

lamp aiming

switch in po-

sitionOFF Battery voltage

ON 0V

27 W/B Fuse 38 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

30 W Fuse 53 Output —Ignition switch ON or START Battery voltage

Ignition switch OFF or ACC 0V

32 LWiper low speed sig-

nalOutputON or

STARTWiper switchOFF Battery voltage

LO or INT 0V

35 L/BWiper high speed sig-

nalOutputON or

STARTWiper switchOFF, LO, INT Battery voltage

HI 0V

38 B Ground Input — — 0V

39 L CAN-L — ON — —

40 P CAN-H — ON — —

41 Y/B Hood switch Input —Hood closed OFF 0V

Hood open ON Battery voltage Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value

(Approx.) Igni-

tion

switchOperation or condition

Page 2426 of 3061

PG-24

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

43 L/Y Wiper auto stop signal InputON or

STARTWiper switch OFF, LO, INT Battery voltage

44 BRDaytime light relay

controlInput ONDaytime light system active 0V

Daytime light system inactive Battery voltage

45 G/W Horn relay control Input ONWhen door locks are operated

using key fob (OFF → ON)*1Battery voltage → 0V

46 GRFuel pump relay con-

trolInput —Ignition switch ON or START 0V

Ignition switch OFF or ACC Battery voltage

47 OThrottle control motor

relay controlInput —Ignition switch ON or START 0V

Ignition switch OFF or ACC Battery voltage

48 B/RStarter relay (inhibit

switch)InputON or

STARTSelector lever in "P" or "N" 0V

Selector lever any other posi-

tionBattery voltage

49 R/L Trailer tow relay Output ONLighting

switch must

be in the 1st

positionOFF 0V

ON Battery voltage

50 W/R Front fog lamp (LH) OutputON or

STARTLighting

switch must

be in the 2nd

position

(LOW beam

is ON) and

the front fog

lamp switchOFF 0V

ON Battery voltage

51 W/R Front fog lamp (RH) OutputON or

STARTLighting

switch must

be in the 2nd

position

(LOW beam

is ON) and

the front fog

lamp switchOFF 0V

ON Battery voltage

52 LLH low beam head-

lampOutput — Lighting switch in 2nd position Battery voltage

54 R/YRH low beam head-

lampOutput — Lighting switch in 2nd position Battery voltage

55 GLH high beam head-

lampOutput —Lighting switch in 2nd position

and placed in HIGH or PASS

positionBattery voltage

56L/W*2

Y*3LH high beam head-

lampOutput —Lighting switch in 2nd position

and placed in HIGH or PASS

positionBattery voltage

57 R/LParking, license, and

tail lampOutput ONLighting

switch 1st po-

sitionOFF 0V

ON Battery voltage

59 B Ground Input — — 0V

60 B/WRear window defog-

ger relayOutputON or

STARTRear defogger switch ON Battery voltage

Rear defogger switch OFF 0V Te r m i n a lWire

colorSignal nameSignal

input/

outputMeasuring condition

Reference value

(Approx.) Igni-

tion

switchOperation or condition

Page 2462 of 3061

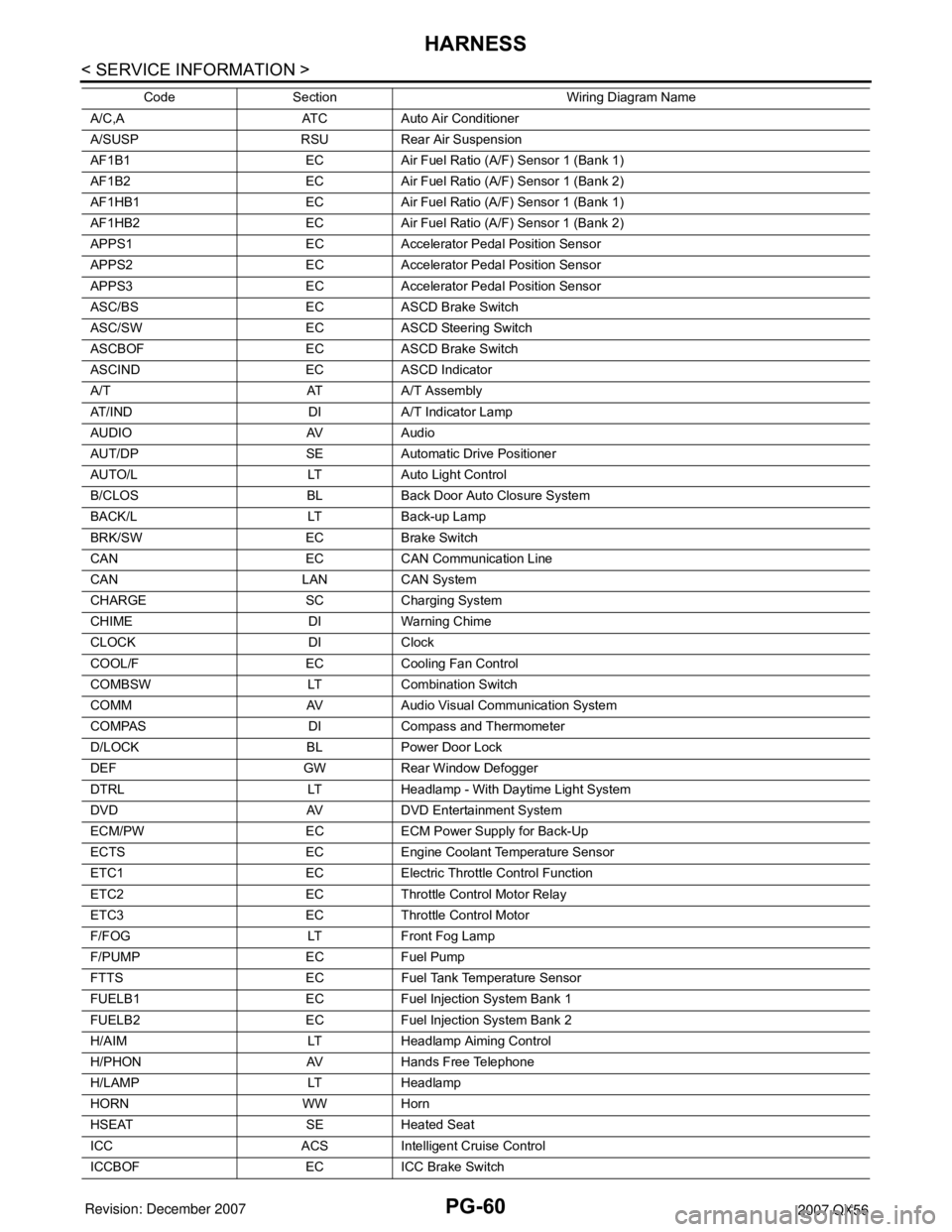

PG-60

< SERVICE INFORMATION >

HARNESS

Code Section Wiring Diagram Name

A/C,A ATC Auto Air Conditioner

A/SUSP RSU Rear Air Suspension

AF1B1 EC Air Fuel Ratio (A/F) Sensor 1 (Bank 1)

AF1B2 EC Air Fuel Ratio (A/F) Sensor 1 (Bank 2)

AF1HB1 EC Air Fuel Ratio (A/F) Sensor 1 (Bank 1)

AF1HB2 EC Air Fuel Ratio (A/F) Sensor 1 (Bank 2)

APPS1 EC Accelerator Pedal Position Sensor

APPS2 EC Accelerator Pedal Position Sensor

APPS3 EC Accelerator Pedal Position Sensor

ASC/BS EC ASCD Brake Switch

ASC/SW EC ASCD Steering Switch

ASCBOF EC ASCD Brake Switch

ASCIND EC ASCD Indicator

A/T AT A/T Assembly

AT/IND DI A/T Indicator Lamp

AUDIO AV Audio

AUT/DP SE Automatic Drive Positioner

AUTO/L LT Auto Light Control

B/CLOS BL Back Door Auto Closure System

BACK/L LT Back-up Lamp

BRK/SW EC Brake Switch

CAN EC CAN Communication Line

CAN LAN CAN System

CHARGE SC Charging System

CHIME DI Warning Chime

CLOCK DI Clock

COOL/F EC Cooling Fan Control

COMBSW LT Combination Switch

COMM AV Audio Visual Communication System

COMPAS DI Compass and Thermometer

D/LOCK BL Power Door Lock

DEF GW Rear Window Defogger

DTRL LT Headlamp - With Daytime Light System

DVD AV DVD Entertainment System

ECM/PW EC ECM Power Supply for Back-Up

ECTS EC Engine Coolant Temperature Sensor

ETC1 EC Electric Throttle Control Function

ETC2 EC Throttle Control Motor Relay

ETC3 EC Throttle Control Motor

F/FOG LT Front Fog Lamp

F/PUMP EC Fuel Pump

FTTS EC Fuel Tank Temperature Sensor

FUELB1 EC Fuel Injection System Bank 1

FUELB2 EC Fuel Injection System Bank 2

H/AIM LT Headlamp Aiming Control

H/PHON AV Hands Free Telephone

H/LAMP LT Headlamp

HORN WW Horn

HSEAT SE Heated Seat

ICC ACS Intelligent Cruise Control

ICCBOF EC ICC Brake Switch