ABS INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 14 of 3061

ACS-1

ELECTRICAL

C

D

E

F

G

H

I

J

L

M

SECTION ACS

A

B

ACS

N

O

P

CONTENTS

AUTO CRUISE CONTROL SYSTEM

ASCD

SERVICE INFORMATION ............................

3

AUTOMATIC SPEED CONTROL DEVICE

(ASCD) ................................................................

3

Description ................................................................3

ICC

SERVICE INFORMATION ............................

4

PRECAUTIONS ...................................................4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

4

Precaution for ICC System Service ...........................4

PREPARATION ...................................................5

Special Service Tool .................................................5

DESCRIPTION ....................................................6

Outline .......................................................................6

Schematic .................................................................6

Component Description .............................................7

CAN Communication .................................................7

Switch Operation .......................................................7

ICC System Display ..................................................8

ACTION TEST .....................................................9

ICC System Running Test .........................................9

LASER BEAM AIMING ADJUSTMENT .............12

Outline of Laser Beam Aiming Adjustment Proce-

dure .........................................................................

12

Preparation ..............................................................12

Setting up the ICC Target Board .............................12

Sensor Adjustment ..................................................14

ELECTRICAL UNITS LOCATION ......................18

Component Parts and Harness Connector Loca-

tion ..........................................................................

18

WIRING DIAGRAM ...........................................19

Schematic ................................................................19

Wiring Diagram - ICC - ............................................20

TERMINALS AND REFERENCE VALUE .........24

Terminal and Reference Value for ICC Unit ............24

Terminal and Reference Value for ICC Sensor .......24

TROUBLE DIAGNOSIS — GENERAL DE-

SCRIPTION .......................................................

25

Work Flow ................................................................25

CONSULT-II Function (ICC) ....................................25

Self-Diagnostic Function ..........................................30

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS .................................................

34

Diagnostic Trouble Code (DTC) Chart ....................34

DTC 11 CONTROL UNIT ........................................36

DTC 12 VDC CONTROL UNIT ................................36

DTC 20 CAN COMM CIRCUIT ................................37

DTC 31 POWER SUPPLY CIR1, DTC 34 POWER

SUPPLY CIR2 .........................................................

37

DTC 41 VHCL SPEED SE CIRC .............................38

DTC 43 VDC/TCS/ABS CIRC .................................38

DTC 45 BRAKE SW/STOP L SW ............................38

DTC 46 OPERATION SW CIRC .............................40

DTC 74 LASER BEAM OFF CNTR .........................41

DTC 90 STOP LAMP RLY FIX ................................41

DTC 92 ECM CIRCUIT ............................................45

DTC 96 NP RANGE ................................................45

DTC 97 AT CIRCUIT ...............................................46

DTC 98 GEAR POSITION .......................................46

DTC 102 LASER STAIN ..........................................47

DTC 103 LASER SENSOR FAIL .............................47

DTC 104 LASER AIMING INCMP ...........................48

DTC 107 LASER COMM FAIL ................................48

DTC 109 LASER HIGH TEMP ................................48

TROUBLE DIAGNOSIS FOR SYMPTOMS ......49

Symptom Chart ........................................................49

Page 20 of 3061

![INFINITI QX56 2007 Factory Service Manual DESCRIPTION

ACS-7

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

Component DescriptionINFOID:0000000003533777

CAN CommunicationINFOID:0000000003533778

SYSTEM DESCRIPTION

Refer to LAN-4 INFINITI QX56 2007 Factory Service Manual DESCRIPTION

ACS-7

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

Component DescriptionINFOID:0000000003533777

CAN CommunicationINFOID:0000000003533778

SYSTEM DESCRIPTION

Refer to LAN-4](/img/42/57029/w960_57029-19.png)

DESCRIPTION

ACS-7

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

Component DescriptionINFOID:0000000003533777

CAN CommunicationINFOID:0000000003533778

SYSTEM DESCRIPTION

Refer to LAN-4 .

Switch OperationINFOID:0000000003533779

The system is operated by a master ON/OFF switch and four control switches, all mounted on the steering

wheel.

ComponentVehicle-to-vehicle

distance control

modeConventional

(fixed speed)

cruise control

modeBrake assist

(with preview

brake)Description

ICC unit×××Controls vehicle speed through ECM via CAN

communication.

ICC sensor××Irradiate laser beam, and receives reflected la-

ser beam to measure distance from preceding

vehicle.

ECM×××Transmits throttle position signal and ICC steer-

ing switch signal to ICC unit.

ABS actuator and electric

unit (control unit)×××Transmits wheel speed signal to ICC unit. Oper-

ates brake booster based on CAN communica-

tion.

Brake pressure sensor××Detects fluid pressure in master cylinder.

Brake booster××Adjusts brake fluid pressure based on command

from ABS actuator and electric unit (control unit).

BCM×Transmit front wiper request signal to ICC unit.

TCM××Transmits gear position signal and output shaft

revolution signal to ICC unit.

No. Switch nameDescription

1 ACCEL/RES switch Resumes set speed or increases speed incrementally.

2 COAST/SET switch Sets desired cruise speed, reduces speed incrementally.

3 ON/OFF switch Master switch to activate the system.

SKIA5973E

Page 39 of 3061

![INFINITI QX56 2007 Factory Service Manual ACS-26

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

WORK SUPPORT

Work Item

Cause of Auto-Cancel

1. To INFINITI QX56 2007 Factory Service Manual ACS-26

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

WORK SUPPORT

Work Item

Cause of Auto-Cancel

1. To](/img/42/57029/w960_57029-38.png)

ACS-26

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS — GENERAL DESCRIPTION

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

WORK SUPPORT

Work Item

Cause of Auto-Cancel

1. Touch “WORK SUPPORT” on "SELECT DIAG MODE" screen.

2. Touch “CAUSE OF AUTO-CANCEL” on "SELECT WORK ITEM"

screen.

3. Cause of automatic cancellation screen will be shown.

4. The last five causes of automatic cancellation of ICC system will

be displayed.

Possible Causes of "Auto-Cancel"

Laser Beam Adjust

For details, refer to ACS-12 .

SELF-DIAGNOSTIC RESULTS

For details, refer to ACS-34, "Diagnostic Trouble Code (DTC) Chart" .

DATA MONITOR

CAN DIAG SUPPORT MNTR The results of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST Operation of electrical loads can be checked by sending driving signal to them.

ECU PART NUMBER ICC unit part number can be read.ICC diagnostic mode Description

Operation Function

CAUSE OF AUTO-CANCEL Indicates causes of automatic cancellation of the ICC system.

LASER BEAM ADJUST Outputs laser beam, calculates dislocation of the beam, and indicates adjustment direction.

SKIA6191E

Cause of cancellation Description

OPERATING WIPER Windshield wipers were operated at HI or LO speed operation.

OPERATING ABS ABS function was operated.

OPERATING TCS TCS function was operated.

OPERATING VDC VDC function was operated.

ECM CIRCUIT ECM did not permit ICC operation.

OPE SW VOLT CIRC Voltage outside the standard was detected.

LASER SUN BEAM Intense light such as sunlight entered ICC sensor light sensing part.

LASER TEMP Temperature around ICC sensor became low.

WHL SPD ELEC NOISE Wheel speed sensor signal caught electromagnetic noise.

OP SW DOUBLE TOUCH ICC steering switches were pressed at the same time.

VDC/TCS OFF SW VDC OFF switch was pressed.

WHEEL SPD UNMATCH Wheel speed became different from AT vehicle speed.

TIRE SLIP Wheel slipped.

PKB SW ON Parking brake is applied.

IGN LOW VOLT Power supply voltage became low.

NO RECORD—

Page 47 of 3061

![INFINITI QX56 2007 Factory Service Manual ACS-34

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Diagnostic Trouble Code (DTC) ChartINFOID:0000000003533794

×:Applicable

DTC INFINITI QX56 2007 Factory Service Manual ACS-34

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Diagnostic Trouble Code (DTC) ChartINFOID:0000000003533794

×:Applicable

DTC](/img/42/57029/w960_57029-46.png)

ACS-34

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Diagnostic Trouble Code (DTC) ChartINFOID:0000000003533794

×:Applicable

DTC

No.CONSULT-II screen termsICC sys-

tem

warning

lampFail-safe

Malfunctions detected where...Refer-

ence

page Vehicle-

to-vehi-

cle dis-

tance

control

modeConven-

tional

(fixed

speed)

cruise

control

modeBrake as-

sist (with

preview

function)

11 CONTROL UNIT×××ו ICC unit internal malfunctionACS-36,

"DTC 11

CON-

TROL

UNIT"

12 VDC CONTROL UNIT×××ו VDC malfunction

• Brake booster signal harness is

open or shortedACS-36,

"DTC 12

VDC

CON-

TROL

UNIT"

20 CAN COMM CIRCUIT×××ו ICC unit detected CAN communi-

cation malfunctionACS-37,

"DTC 20

CAN

COMM

CIR-

CUIT"

31 POWER SUPPLY CIR1×××ו ICC unit power supply voltage is

excessively low (less than 8V)ACS-37,

"DTC 31

POWER

SUPPLY

CIR1,

DTC 34

POWER

SUPPLY

CIR2"

34 POWER SUPPLY CIR2×××ו ICC unit power supply voltage is

excessively high.ACS-37,

"DTC 31

POWER

SUPPLY

CIR1,

DTC 34

POWER

SUPPLY

CIR2"

41 VHCL SPEED SE CIRC×××ו Wheel sensor malfunction

• ABS actuator and electric unit

(control unit) malfunction

• A/T vehicle speed sensor mal-

function

•TCM malfunctionACS-38,

"DTC 41

VHCL

SPEED

SE CIRC"

43 VDC/TCS/ABS CIRC×××ו VDC/TCS/ABS system malfunc-

tionACS-38,

"DTC 43

VDC/

TCS/ABS

CIRC"

Page 49 of 3061

![INFINITI QX56 2007 Factory Service Manual ACS-36

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

NOTE: DTC 55 will display when no malfunction is detected.

DTC 11 CONTROL UNITINFOID:0000000003533795

1.DIAGNOSTIC CHECK INFINITI QX56 2007 Factory Service Manual ACS-36

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

NOTE: DTC 55 will display when no malfunction is detected.

DTC 11 CONTROL UNITINFOID:0000000003533795

1.DIAGNOSTIC CHECK](/img/42/57029/w960_57029-48.png)

ACS-36

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

NOTE: DTC 55 will display when no malfunction is detected.

DTC 11 CONTROL UNITINFOID:0000000003533795

1.DIAGNOSTIC CHECK

Are any items other than “DTC 11 CONTROL UNIT” indicated on self-diagnosis display?

YES or NO

YES >> Repair or replace as necessary. Erase DTC and perform ICC system running test. Refer to ACS-

9, "ICC System Running Test" . Then perform self-diagnosis of ICC system again.

NO >> Replace ICC unit. Refer to ACS-55

. Erase DTC and perform ICC system running test. Refer to

ACS-9, "

ICC System Running Test". Then perform self-diagnosis of ICC system again.

DTC 12 VDC CONTROL UNITINFOID:0000000003533796

1.DIAGNOSIS CHECK

With CONSULT-II

Perform self-diagnosis of ABS actuator and electric unit (control unit). Is malfunction indicated?

YES or NO

YES >> Repair or replace as necessary. Erase DTC and perform ICC system running test. Refer to ACS-

9, "ICC System Running Test". Then perform self-diagnosis of ICC system again.

NO >> GO TO 2.

2.CHECK CONNECTOR ICC UNIT AND ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

1. Turn ignition switch OFF.

2. Disconnect ICC unit, and ABS actuator and electric unit (control unit) connectors, and connect them

securely again. Erase DTC, then perform self-diagnosis of ICC system again.

OK or NG

OK >> Poor connector connection. Check connector housing for disconnected, loose, bent and collapsed

terminals. If any malfunction is detected, repair as necessary. Erase DTC and perform ICC sys-

tem running test. Refer to ACS-9, "

ICC System Running Test". Then perform self-diagnosis of ICC

system again.

NG >> GO TO 3.

3.CHECK HARNESS BETWEEN ICC UNIT AND ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

104 LASER AIMING INCMP×× ×• Laser beam aiming of ICC sensor

is not adjustedACS-48,

"DTC 104

LASER

AIMING

INCMP"

107 LASER COMM FAIL×× ×• CAN data received by ICC sensor

is strange (from ICC unit, combi-

nation meter or ECM)ACS-48,

"DTC 107

LASER

COMM

FA IL"

109 LASER HIGH TEMP×× ×• Temperature around ICC sensor

is excessively highACS-48,

"DTC 109

LASER

HIGH

TEMP"

DTC

No.CONSULT-II screen termsICC sys-

tem

warning

lampFail-safe

Malfunctions detected where...Refer-

ence

page Vehicle-

to-vehi-

cle dis-

tance

control

modeConven-

tional

(fixed

speed)

cruise

control

modeBrake as-

sist (with

preview

function)

Page 50 of 3061

![INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-37

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

1. Turn ignition switch OFF.

2. Disconnect ICC unit and ABS actuator and electric unit INFINITI QX56 2007 Factory Service Manual TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-37

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

1. Turn ignition switch OFF.

2. Disconnect ICC unit and ABS actuator and electric unit](/img/42/57029/w960_57029-49.png)

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

ACS-37

< SERVICE INFORMATION >[ICC]

C

D

E

F

G

H

I

J

L

MA

B

ACS

N

O

P

1. Turn ignition switch OFF.

2. Disconnect ICC unit and ABS actuator and electric unit (control

unit) connectors.

3. Check continuity between ICC unit harness connector B13 ter-

minal 10, and ABS actuator and electric unit (control unit) con-

nector E125 terminal 7.

OK or NG

OK >> Replace ICC unit. Refer to ACS-55. Erase DTC and per-

form ICC system running test. Refer to ACS-9, "

ICC

System Running Test". Then perform self-diagnosis of ICC system again.

NG >> • Repair harness between ICC unit, and ABS actuator and electric unit (control unit).

• Erase DTC and perform ICC system running test. Refer to ACS-9, "

ICC System Running Test".

Then perform self-diagnosis of ICC system again.

DTC 20 CAN COMM CIRCUITINFOID:0000000003533797

1.CHECK CAN COMMUNICATION

With CONSULT-II

1. Perform self-diagnosis.

2. Print self-diagnostic result.

>> After printing self-diagnostic result, GO TO “CAN system”. Refer to LAN-4, "

CAN Communication

System" .

DTC 31 POWER SUPPLY CIR1, DTC 34 POWER SUPPLY CIR2INFOID:0000000003533798

1.CHECK ICC UNIT CONNECTOR

1. Turn ignition switch OFF.

2. Disconnect ICC unit connectors and connect them securely again. Erase DTC, then perform self-diagno-

sis of ICC system again.

OK or NG

OK >> GO TO 2.

NG >> • Poor connector connection.

• Check connector. Check connector housing for disconnected, loose, bent, and collapsed termi-

nals. If any malfunction is detected, repair as as necessary. Erase DTC and perform ICC system

running test. Refer to ACS-9, "

ICC System Running Test". Then perform self-diagnosis of ICC

system again.

2.CHECK POWER SUPPLY CIRCUIT FOR ICC UNIT

1. Turn ignition switch ON.

2. Check voltage between ICC unit harness connector B17 termi-

nal 33, 42 and ground.

OK or NG

OK >> GO TO 3.

NG >> • Repair ICC unit power supply harness.

• Erase DTC and perform ICC system running test.

Refer to ACS-9, "

ICC System Running Test". Then

perform self-diagnosis of ICC system again.

3.CHECK GROUND CIRCUIT FOR ICC UNITContinuity should exist.

WKIA3616E

Battery voltage should exist.

SKIA1173E

Page 51 of 3061

![INFINITI QX56 2007 Factory Service Manual ACS-38

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

1. Turn ignition switch OFF.

2. Disconnect ICC unit connectors.

3. Check continuity between ICC unit harness connector B INFINITI QX56 2007 Factory Service Manual ACS-38

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

1. Turn ignition switch OFF.

2. Disconnect ICC unit connectors.

3. Check continuity between ICC unit harness connector B](/img/42/57029/w960_57029-50.png)

ACS-38

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

1. Turn ignition switch OFF.

2. Disconnect ICC unit connectors.

3. Check continuity between ICC unit harness connector B13 ter-

minals 19, 20, and connector B17 terminal 46 and ground.

OK or NG

OK >> Replace ICC unit. Refer to ACS-55 . Erase DTC and

perform ICC system running test. Refer to ACS-9, "

ICC

System Running Test" . Then perform self-diagnosis of

ICC system again.

NG >> • Repair ICC unit ground harness.

• Erase DTC and perform ICC system running test. Refer to ACS-9, "

ICC System Running Test" .

Then perform self-diagnosis of ICC system again.

DTC 41 VHCL SPEED SE CIRCINFOID:0000000003533799

1.PERFORM ICC UNIT SELF-DIAGNOSIS

Perform self-diagnosis. Is “DTC 43 VDC/TCS/ABS CIRC” or “DTC 20 CAN COMM CIRCUIT” indicated in self-

diagnosis item display?

YES or NO

YES >> Repair or replace as necessary. Erase DTC and perform ICC system running test. Refer to ACS-

9, "ICC System Running Test". Then perform self-diagnosis of ICC system again.

NO >> GO TO 2.

2.CHECK A/T VEHICLE SPEED SENSOR

With CONSULT-II

With data monitor, check “VHCL SPD AT”.

OK or NG

OK >> Replace ICC unit. Refer to ACS-55. Erase DTC and perform ICC system running test. Refer to

ACS-9, "

ICC System Running Test". Then perform self-diagnosis of ICC system again.

NG >> • Check TCM.

• Erase DTC and perform ICC system running test. Refer to ACS-9, "

ICC System Running Test" .

Then perform self-diagnosis of ICC system again.

DTC 43 VDC/TCS/ABS CIRCINFOID:0000000003533800

1.DIAGNOSIS CHECK 1

With CONSULT-II

Perform self-diagnosis. Is “CAN COMM CIRCUIT” indicated?

YES or NO

YES >> Repair or replace as necessary. Erase DTC and perform ICC system running test. Refer to ACS-

9, "ICC System Running Test". Then perform self-diagnosis of ICC system again.

NO >> GO TO 2.

2.DIAGNOSIS CHECK 2

With CONSULT-II

Perform self-diagnosis of ABS actuator and electric unit (control unit). Is malfunction indicated?

YES or NO

YES >> Repair or replace as necessary. Erase DTC and perform ICC system running test. Refer to ACS-

9, "ICC System Running Test" . Then perform self-diagnosis of ICC system again.

NO >> Replace ICC unit. Refer to ACS-55

. Erase DTC and perform ICC system running test. Refer to

ACS-9, "

ICC System Running Test". Then perform self-diagnosis of ICC system again.

DTC 45 BRAKE SW/STOP L SWINFOID:0000000003533801

1.CHECK CONNECTORS FOR ICC UNITContinuity should exist.

SKIA6650E

Page 59 of 3061

![INFINITI QX56 2007 Factory Service Manual ACS-46

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

• Check connector. Check connector housing for disconnected, loose, bent, and collapsed termi-

nals. If any malfunctio INFINITI QX56 2007 Factory Service Manual ACS-46

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

• Check connector. Check connector housing for disconnected, loose, bent, and collapsed termi-

nals. If any malfunctio](/img/42/57029/w960_57029-58.png)

ACS-46

< SERVICE INFORMATION >[ICC]

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

• Check connector. Check connector housing for disconnected, loose, bent, and collapsed termi-

nals. If any malfunction is detected, repair as necessary. Erase DTC and perform ICC system

running test. Refer to ACS-9, "

ICC System Running Test". Then perform self-diagnosis of ICC

system again.

2.CHECK NP RANGE SWITCH SIGNAL

With CONSULT-II

With data monitor, check that “NP RANGE SW” operates normally.

OK or NG

OK >> Perform TCM diagnosis. Refer to AT-83, "CONSULT-II Function (A/T)".

NG >> GO TO 3.

3.CHECK HARNESS BETWEEN ICC UNIT AND TCM

1. Turn ignition switch OFF.

2. Disconnect ICC unit harness connectors and A/T assembly har-

ness connector.

3. Check continuity between ICC unit harness connector B13 ter-

minal 7 and A/T assembly harness connector F9 terminal 9.

OK or NG

OK >> Replace ICC unit. Refer to ACS-55, "ICC Unit". Erase

DTC and perform ICC system running test. Refer to

ACS-9, "

ICC System Running Test". Then perform self-

diagnosis of ICC system again.

NG >> • Repair harness between ICC unit and TCM.

• Erase DTC and perform ICC system running test. Refer to ACS-9, "

ICC System Running Test".

Then perform self-diagnosis of ICC system again.

DTC 97 AT CIRCUITINFOID:0000000003533807

1.CHECK A/T CIRCUIT

With CONSULT-II

With TCM diagnosis, check that shift operates normally. Refer to AT- 9 9

.

OK or NG

OK >> Replace ICC unit. Refer to ACS-55, "ICC Unit". Erase DTC and perform self-diagnosis of ICC sys-

tem again.

NG >> • Perform TCM diagnosis.

• Erase DTC and perform self-diagnosis of ICC system again.

DTC 98 GEAR POSITIONINFOID:0000000003533808

1.DIAGNOSTIC CHECK

With CONSULT-II

Is “DTC 43 VDC/TCS/ABS CIRC” or “DTC 41 VHCL SPEED SE CIRC” indicated in self-diagnosis display

item?

YES or NO

YES >> Repair or replace as necessary. Erase DTC and perform self-diagnosis of ICC system again.

NO >> GO TO 2.

2.CHECK VEHICLE SPEED SIGNAL

With CONSULT-II

With data monitor, check that “VHCL SPEED SE” is normal.

OK or NG

OK >> GO TO 3.

NG >> Replace ICC unit. Refer to ACS-55, "

ICC Unit". Erase DTC and perform self-diagnosis of ICC sys-

tem again.

7 - 9 Continuity should exist.

SKIA5982E

Page 107 of 3061

A/T CONTROL SYSTEM

AT-37

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

When shifting from the lock-up released state to the lock-up applied state, the current output to the torque con-

verter clutch solenoid is controlled with the TCM. In this way, when shifting to the lock-up applied state, the

torque converter clutch is temporarily set to the half-clutched state to reduce the shock.

Half-clutched State

• The current output from the TCM to the torque converter clutch solenoid is varied to gradually increase the

torque converter clutch solenoid pressure.

In this way, the lock-up apply pressure gradually rises and while the torque converter clutch piston is put into

half-clutched status, the torque converter clutch piston operating pressure is increased and the coupling is

completed smoothly.

Slip Lock-up Control

• In the slip region, the torque converter clutch solenoid current is controlled with the TCM to put it into the

half-clutched state. This absorbs the engine torque fluctuation and lock-up operates from low speed.

This raises the fuel efficiency for 4th and 5th gears at both low speed and when the accelerator has a low

degree of opening.

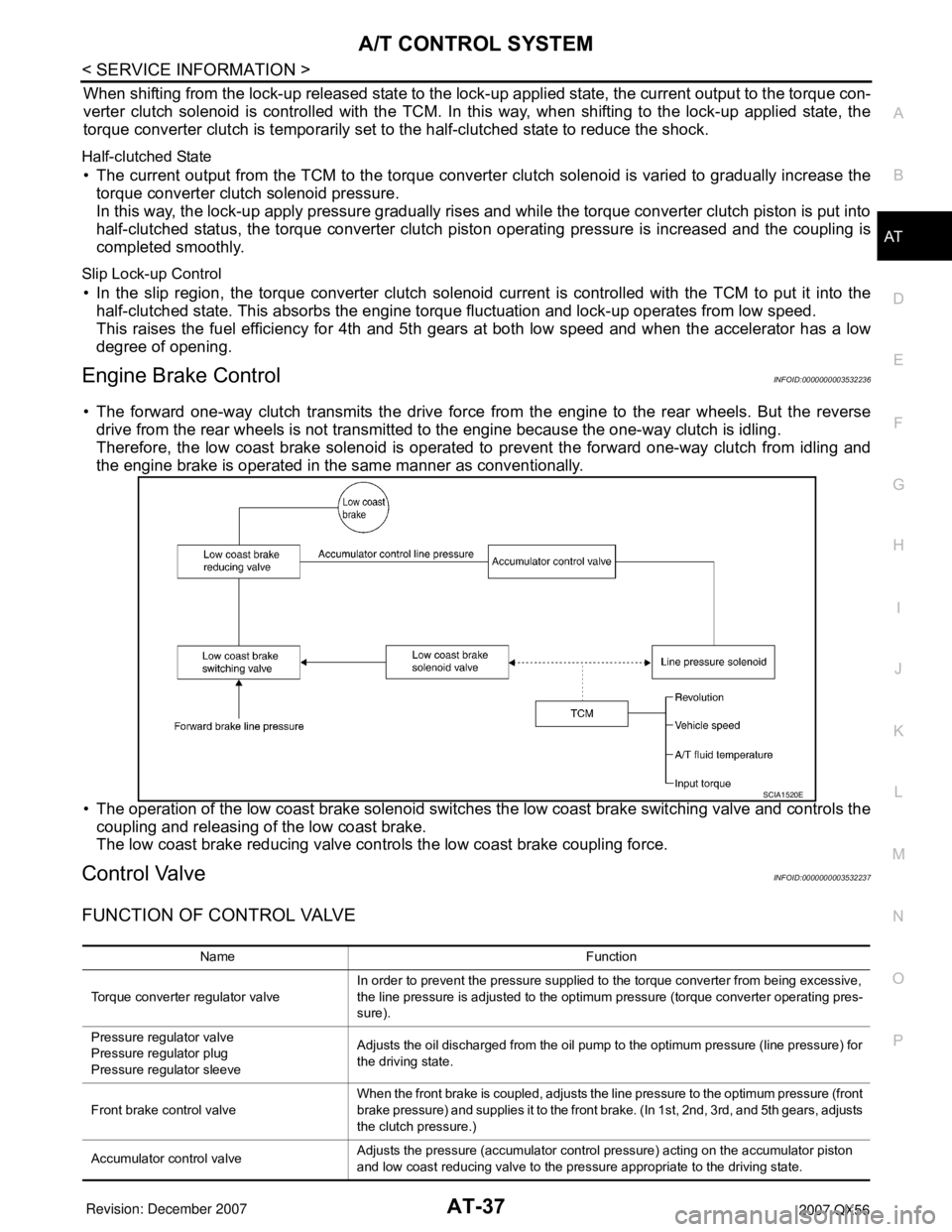

Engine Brake ControlINFOID:0000000003532236

• The forward one-way clutch transmits the drive force from the engine to the rear wheels. But the reverse

drive from the rear wheels is not transmitted to the engine because the one-way clutch is idling.

Therefore, the low coast brake solenoid is operated to prevent the forward one-way clutch from idling and

the engine brake is operated in the same manner as conventionally.

• The operation of the low coast brake solenoid switches the low coast brake switching valve and controls the

coupling and releasing of the low coast brake.

The low coast brake reducing valve controls the low coast brake coupling force.

Control ValveINFOID:0000000003532237

FUNCTION OF CONTROL VALVE

SCIA1520E

Name Function

Torque converter regulator valveIn order to prevent the pressure supplied to the torque converter from being excessive,

the line pressure is adjusted to the optimum pressure (torque converter operating pres-

sure).

Pressure regulator valve

Pressure regulator plug

Pressure regulator sleeveAdjusts the oil discharged from the oil pump to the optimum pressure (line pressure) for

the driving state.

Front brake control valveWhen the front brake is coupled, adjusts the line pressure to the optimum pressure (front

brake pressure) and supplies it to the front brake. (In 1st, 2nd, 3rd, and 5th gears, adjusts

the clutch pressure.)

Accumulator control valveAdjusts the pressure (accumulator control pressure) acting on the accumulator piston

and low coast reducing valve to the pressure appropriate to the driving state.

Page 158 of 3061

AT-88

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

POWERSHIFT SW (ON-OFF display) X — X

Not mounted but displayed. HOLD SW (ON-OFF display) X — X

MANU MODE SW (ON-OFF display) X — X

NON M-MODE SW (ON-OFF display) X — X

UP SW LEVER (ON-OFF display) X — X

DOWN SW LEVER (ON-OFF display) X — X

SFT UP ST SW (ON-OFF display) — — X

SFT DWN ST SW (ON-OFF display) — — X

ASCD-OD CUT (ON-OFF display) — — X

ASCD-CRUISE (ON-OFF display) — — X

ABS SIGNAL (ON-OFF display) — — X

ACC OD CUT (ON-OFF display) — — X

ICC (Intelligent cruise control)

ACC SIGNAL (ON-OFF display) — — X

TCS GR/P KEEP (ON-OFF display) — — X

TCS SIGNAL 2 (ON-OFF display) — — X

TCS SIGNAL 1 (ON-OFF display) — — X

TCC SOLENOID (A) — X X

LINE PRES SOL (A) — X X

I/C SOLENOID (A) — X X

FR/B SOLENOID (A) — X X

D/C SOLENOID (A) — X X

HLR/C SOL (A) — X X

ON OFF SOL (ON-OFF display) — — X LC/B solenoid

TCC SOL MON (A) — — X

L/P SOL MON (A) — — X

I/C SOL MON (A) — — X

FR/B SOL MON (A) — — X

D/C SOL MON (A) — — X

HLR/C SOL MON (A) — — X

ONOFF SOL MON (ON-OFF display) — — X LC/B solenoid

P POSI IND (ON-OFF display) — — X

R POSI IND (ON-OFF display) — — X

N POSI IND (ON-OFF display) — — X

D POSI IND (ON-OFF display) — — X

4TH POSI IND (ON-OFF display) — — X

3RD POSI IND (ON-OFF display) — — X

2ND POSI IND (ON-OFF display) — — X

1ST POSI IND (ON-OFF display) — — X

MANU MODE IND (ON-OFF display) — — X

Not mounted but displayed.

POWER M LAMP (ON-OFF display) — — X

F-SAFE IND/L (ON-OFF display) — — XMonitored item (Unit)Monitor Item Selection

Remarks ECU IN-

PUT SIG-

NALSMAIN SIG-

NALSSELEC-

TION

FROM

MENU