INFINITI QX56 2007 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 281 of 3061

ON-VEHICLE SERVICE

AT-211

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

CONTROL VALVE WITH TCM REMOVAL AND INSTALLATION

Removal

1. Disconnect negative battery terminal

2. Drain ATF through drain plug.

3. Disconnect A/T assembly harness connector.

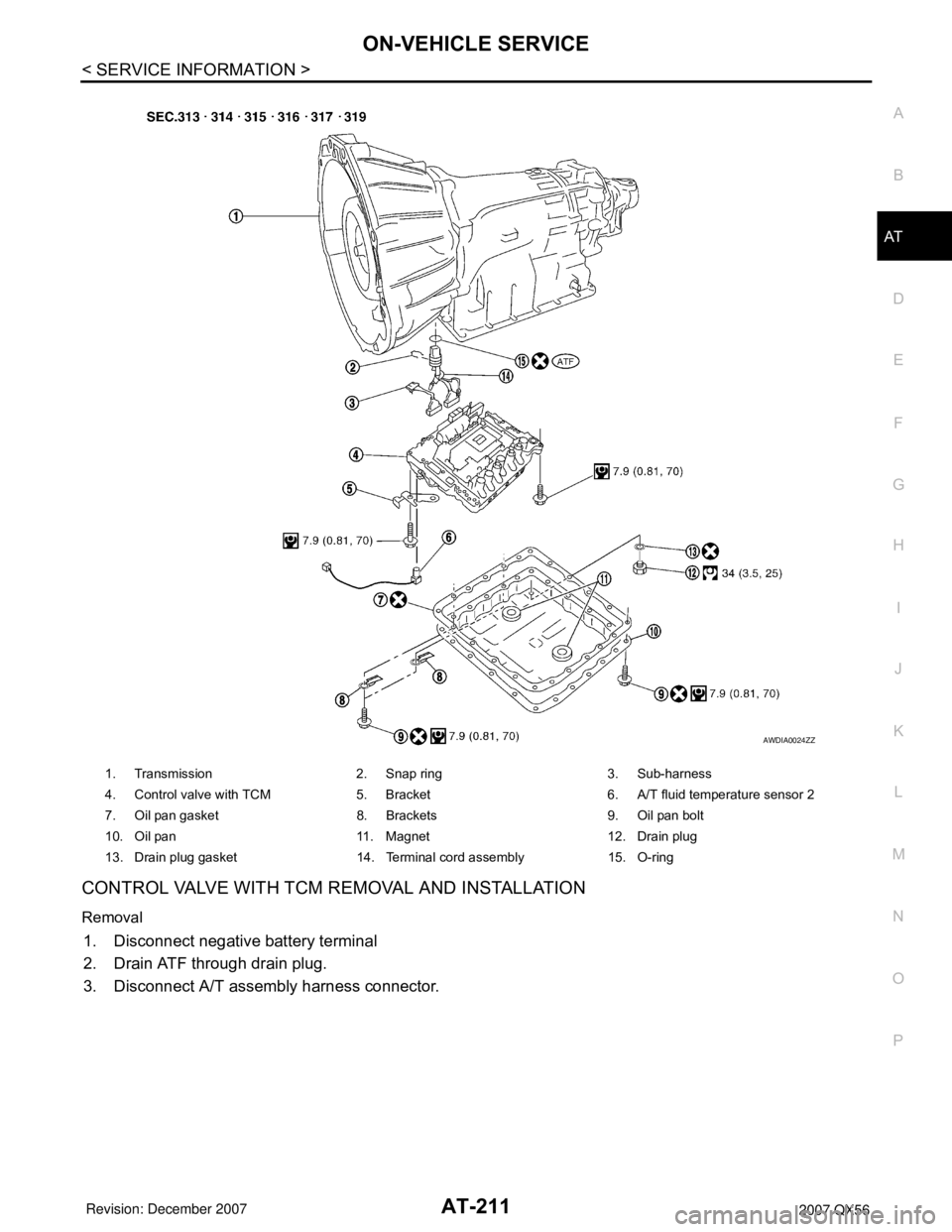

1. Transmission 2. Snap ring 3. Sub-harness

4. Control valve with TCM 5. Bracket 6. A/T fluid temperature sensor 2

7. Oil pan gasket 8. Brackets 9. Oil pan bolt

10. Oil pan 11. Magnet 12. Drain plug

13. Drain plug gasket 14. Terminal cord assembly 15. O-ring

AWDIA0024ZZ

Page 282 of 3061

AT-212

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

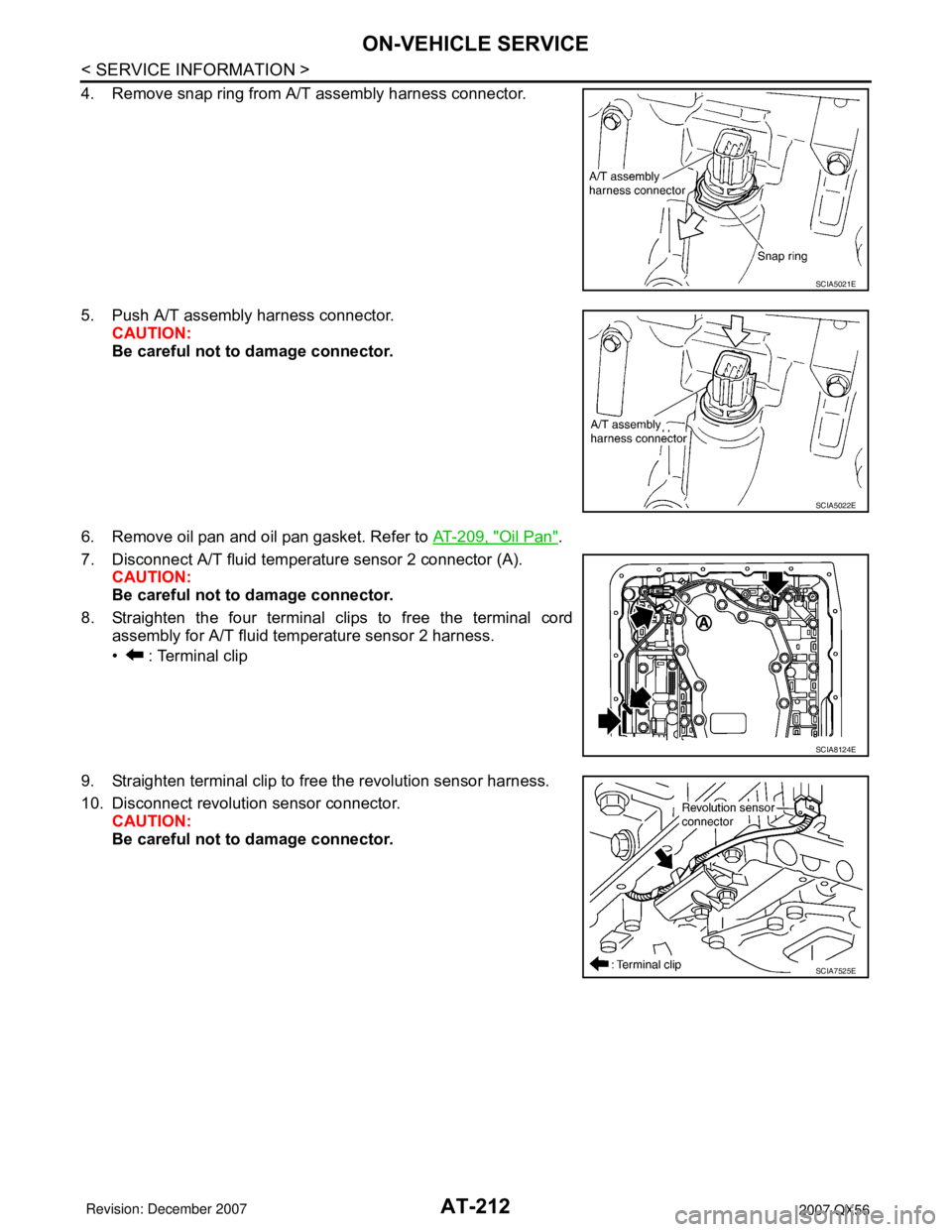

4. Remove snap ring from A/T assembly harness connector.

5. Push A/T assembly harness connector.

CAUTION:

Be careful not to damage connector.

6. Remove oil pan and oil pan gasket. Refer to AT-209, "

Oil Pan".

7. Disconnect A/T fluid temperature sensor 2 connector (A).

CAUTION:

Be careful not to damage connector.

8. Straighten the four terminal clips to free the terminal cord

assembly for A/T fluid temperature sensor 2 harness.

• : Terminal clip

9. Straighten terminal clip to free the revolution sensor harness.

10. Disconnect revolution sensor connector.

CAUTION:

Be careful not to damage connector.

SCIA5021E

SCIA5022E

SCIA8124E

SCIA7525E

Page 283 of 3061

ON-VEHICLE SERVICE

AT-213

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

11. Remove bolts (A), (B) and (C) from control valve with TCM.

• : Front

12. Remove control valve with TCM from transmission case.

CAUTION:

Be careful with the manual valve notch and manual plate

height. Remove it vertically.

13. Remove A/T fluid temperature sensor 2 with bracket from con-

trol valve with TCM.

14. Remove bracket from A/T fluid temperature sensor 2.

15. Remove O-ring from A/T assembly harness connector.

Bolt symbol Length mm (in) Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA8074E

SCIA5142E

SCIA5253E

SCIA5264E

SCIA5155E

Page 284 of 3061

AT-214

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

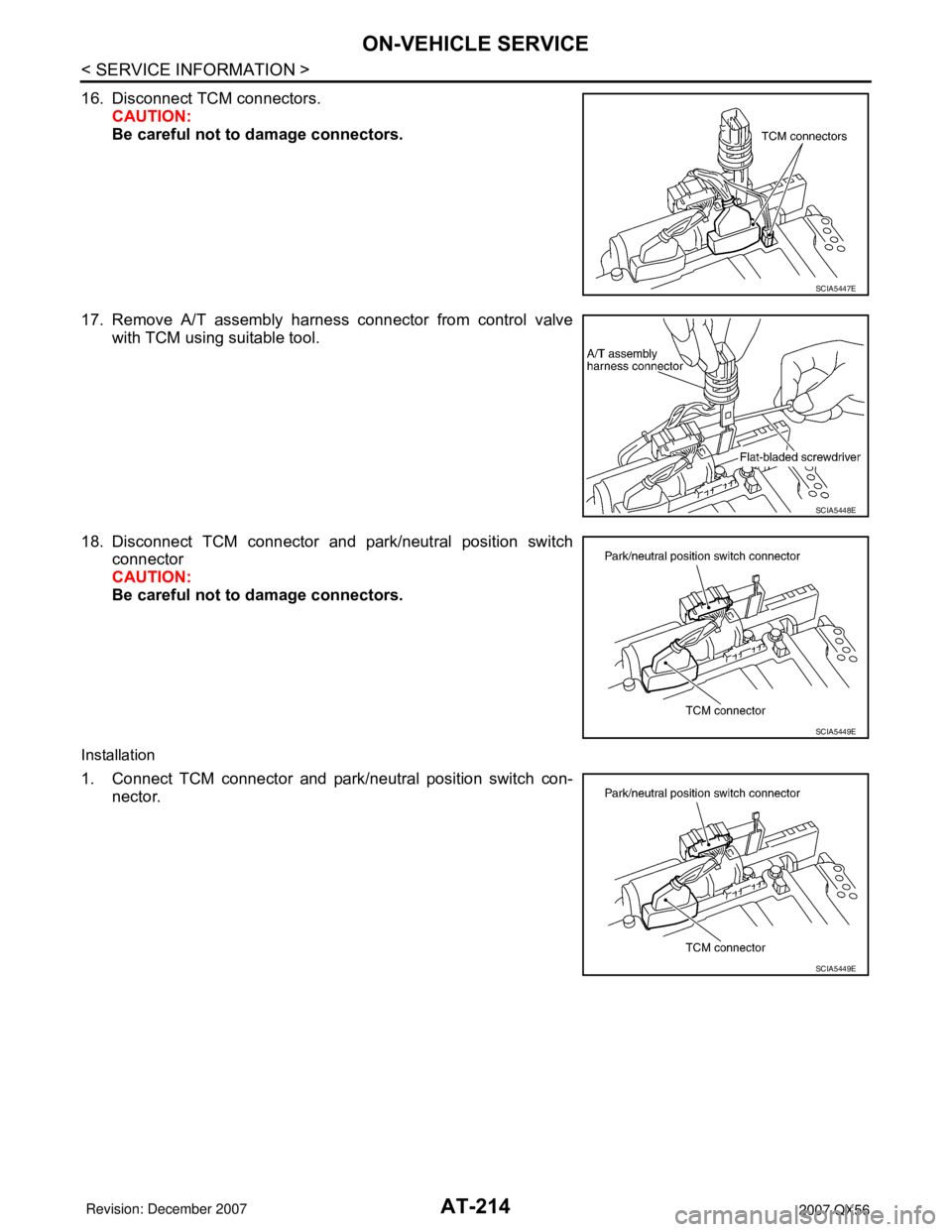

16. Disconnect TCM connectors.

CAUTION:

Be careful not to damage connectors.

17. Remove A/T assembly harness connector from control valve

with TCM using suitable tool.

18. Disconnect TCM connector and park/neutral position switch

connector

CAUTION:

Be careful not to damage connectors.

Installation

1. Connect TCM connector and park/neutral position switch con-

nector.

SCIA5447E

SCIA5448E

SCIA5449E

SCIA5449E

Page 285 of 3061

ON-VEHICLE SERVICE

AT-215

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

2. Install A/T assembly harness connector to control valve with

TCM.

3. Connect TCM connector.

4. Install new O-ring in A/T assembly harness connector.

NOTE:

• Do not reuse O-ring.

• Apply ATF to O-ring.

5. Install A/T fluid temperature sensor 2 to bracket.

6. Install A/T fluid temperature sensor 2 (with bracket) in control

valve with TCM. Tighten A/T fluid temperature sensor 2 bolts to

the specified torque. Refer to AT-228, "

Component".

CAUTION:

Adjust bolt hole of bracket to bolt hole of control valve with

TCM.

SCIA5450E

SCIA5447E

SCIA5155E

SCIA5264E

SCIA5253E

Page 286 of 3061

AT-216

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

7. Install control valve with TCM in transmission case.

CAUTION:

• Make sure that turbine revolution sensor securely installs

turbine revolution sensor hole.

• Hang down revolution sensor harness toward outside so

as not to disturb installation of control valve with TCM.

• Adjust A/T assembly harness connector of control valve

with TCM to terminal hole of transmission case.

• Assemble it so that manual valve cutout is engaged with

manual plate projection.

8. Install bolts (A), (B) and (C) in control valve with TCM.

• : Front

9. Tighten bolt (1), (2) and (3) temporarily to prevent dislocation. Then tighten them in order (1 → 2 → 3),

and then tighten other bolts.

• : Front

10. Tighten control valve with TCM bolts to the specified torque.

Refer to AT-228, "

Component".

SCIA5034E

SCIA5142E

Bolt symbol Length mm (in) Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA8074E

SCIA8075E

Page 287 of 3061

ON-VEHICLE SERVICE

AT-217

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

11. Connect A/T fluid temperature sensor 2 connector (A).

12. Securely fasten terminal cord assembly and A/T fluid tempera-

ture sensor 2 harness with terminal clips.

• : Terminal clip

13. Connect revolution sensor connector.

14. Securely fasten revolution sensor harness with terminal clip.

15. Install oil pan to transmission case. Refer to AT-209, "

Oil Pan".

16. Pull up A/T assembly harness connector.

CAUTION:

Be careful not to damage connector.

SCIA8124E

SCIA7524E

SCIA7525E

SCIA5038E

Page 288 of 3061

AT-218

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

17. Install snap ring to A/T assembly harness connector.

18. Connect A/T assembly harness connector.

19. Connect the negative battery terminal

20. Refill the A/T with fluid and check fluid level and for fluid leak-

age. Refer to AT-13, "

Changing Automatic Transmission Fluid

(ATF)".

CAUTION:

After completing installation, check A/T fluid leakage and fluid

level. Refer to AT-13, "

Changing Automatic Transmission Fluid

(ATF)", AT-13, "Checking Automatic Transmission Fluid (ATF)".

A/T FLUID TEMPERATURE SENSOR 2 REMOVAL AND INSTALLATION

Removal

1. Disconnect negative battery terminal

2. Remove oil pan and oil pan gasket. Refer to AT-209, "

Oil Pan".

3. Disconnect A/T fluid temperature sensor 2 connector (A).

CAUTION:

Be careful not to damage connector.

4. Straighten terminal clip to free A/T fluid temperature sensor 2

harness.

• : Terminal clip

5. Remove A/T fluid temperature sensor 2 with bracket from con-

trol valve with TCM.

6. Remove bracket from A/T fluid temperature sensor 2.

Installation

SCIA5039E

SCIA8125E

SCIA5253E

SCIA5264E

Page 289 of 3061

ON-VEHICLE SERVICE

AT-219

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

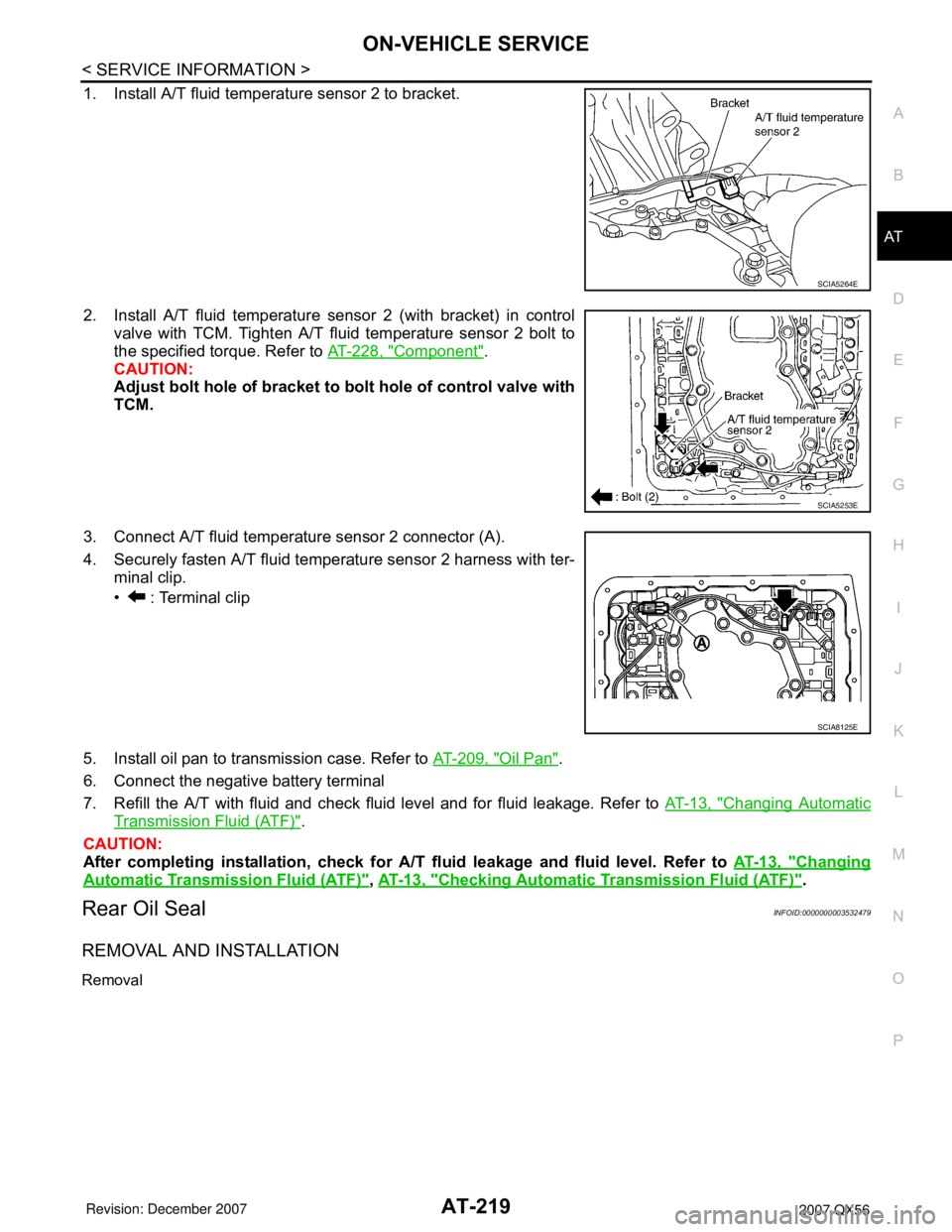

1. Install A/T fluid temperature sensor 2 to bracket.

2. Install A/T fluid temperature sensor 2 (with bracket) in control

valve with TCM. Tighten A/T fluid temperature sensor 2 bolt to

the specified torque. Refer to AT-228, "

Component".

CAUTION:

Adjust bolt hole of bracket to bolt hole of control valve with

TCM.

3. Connect A/T fluid temperature sensor 2 connector (A).

4. Securely fasten A/T fluid temperature sensor 2 harness with ter-

minal clip.

• : Terminal clip

5. Install oil pan to transmission case. Refer to AT-209, "

Oil Pan".

6. Connect the negative battery terminal

7. Refill the A/T with fluid and check fluid level and for fluid leakage. Refer to AT-13, "

Changing Automatic

Transmission Fluid (ATF)".

CAUTION:

After completing installation, check for A/T fluid leakage and fluid level. Refer to AT-13, "

Changing

Automatic Transmission Fluid (ATF)", AT-13, "Checking Automatic Transmission Fluid (ATF)".

Rear Oil SealINFOID:0000000003532479

REMOVAL AND INSTALLATION

Removal

SCIA5264E

SCIA5253E

SCIA8125E

Page 290 of 3061

AT-220

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

1. Remove rear propeller shaft. Refer to PR-8, "Removal and

Installation".

2. Remove transfer from transmission (4WD models). Refer to TF-

128, "Removal and Installation".

3. Remove rear oil seal using suitable tool.

CAUTION:

Be careful not to scratch rear extension assembly (2WD

models) or adapter case assembly (4WD models).

Installation

1. Install new rear oil seal until it is flush with component face into

the extension case (2WD models) using Tool, or adapter case

(4WD models) using suitable tool.

CAUTION:

• Apply ATF to rear oil seal.

• Do not reuse rear oil seal.

2. Install transfer to transmission (4WD models). Refer to TF-128,

"Removal and Installation".

3. Install rear propeller shaft. Refer to PR-8, "

Removal and Installa-

tion".

CAUTION:

After completing installation, check for A/T fluid leakage and

fluid level. Refer to AT-13, "

Changing Automatic Transmission

Fluid (ATF)" and AT-13, "Checking Automatic Transmission

Fluid (ATF)".

SCIA5254E

Tool number : ST33400001 (J-26082)

SCIA5583E