cooling INFINITI QX56 2007 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 470 of 3061

ATC-100

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

1. Turn ignition switch OFF.

2. Disconnect BCM connector and front air control connector.

3. Check continuity between BCM harness connector M18 terminal28 and front air control harness connector M49 terminal 10.

OK or NG

OK >> GO TO 11.

NG >> Repair harness or connector.

11 .CHECK VOLTAGE FOR FRONT AIR CONTROL (FAN ON SIGNAL)

1. Reconnect BCM connector and front air control connector.

2. Turn ignition switch ON.

3. Check voltage between front air control harness connector M49 terminal 10 and ground.

OK or NG

OK >> GO TO 12.

NG-1 >> If the voltage is approx. 5V when blower moto r is ON, replace front air control. Refer to ATC-123,

"Removal and Installation" .

NG-2 >> If the voltage is approx. 0V when blower motor is OFF, replace BCM. Refer to BCS-24, "

BCM".

12.CHECK CAN COMMUNICATION

Check CAN communication. Refer to LAN-4

.

•BCM – ECM

• ECM – IPDM E/R

• ECM – Front air control

OK or NG

OK >> Inspection End.

NG >> Repair or replace malfunctioning part(s).

Insufficient CoolingINFOID:0000000003533260

SYMPTOM: Insufficient cooling

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPER ATIONAL CHECK - TEMPERATURE DECREASE

1. Press the AUTO switch.

2. Turn temperature control dial (driver) counterclockwise until 16 ° C (60 ° F) is displayed.

3. Check for cold air at discharge air outlets.

Can the symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.CHECK FOR ANY SYMPTOMS

Perform a complete operational check for any symptoms. Refer to ATC-50, "

Operational Check (Front)" .

Does another symptom exist?

28 - 10 Continuity should exist.

WJIA0450E

Te r m i n a l s

Condition Voltage

(+)

(-)

Front air con-

trol connector Te r m i n a l N o .

M49 10 Ground A/C switch: ON

Blower motor

operates

Approx. 0V

A/C switch: OFF Approx. 5V

WJIA0451E

Page 471 of 3061

TROUBLE DIAGNOSISATC-101

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

YES >> Refer to ATC-32, "How to Perform Trouble Diagnosis for Quick and Accurate Repair" .

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 3.

4.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis Refer to ATC-48, "

A/C System Self-Diagnosis Function" .

OK or NG

OK >> GO TO 5.

NG >> Refer to ATC-48, "

A/C System Self-Diagnosis Function" .

5.CHECK DRIVE BELTS

Check compressor belt tension. Refer to EM-13, "

Checking Drive Belts" .

OK or NG

OK >> GO TO 6.

NG >> Adjust or replace compressor belt. Refer to EM-13, "

Removal and Installation" .

6.CHECK AIR MIX DOOR OPERATION

Check and verify air mix door me chanism for smooth operation.

Does air mix door operate correctly?

YES >> GO TO 7.

NO >> Repair or replace air mix door control linkage.

7.CHECK COOLING FAN MOTOR OPERATION

Check and verify cooling fan moto r for smooth operation. Refer to EC-469, "

Description" .

Does cooling fan motor operate correctly?

YES >> GO TO 8.

NO >> Check cooling fan motor. Refer to EC-469

.

8.CHECK WATER VALVE OPERATION

Check and verify water valve for smooth operation. Refer to ATC-113, "

Water Valve Circuit".

Does water valve operate correctly?

YES >> GO TO 8.

NO >> Check water valve circuit. Refer to ATC-113, "

Water Valve Circuit" .

9.CHECK RECOVERY/RECYCLING EQUIPMENT BEFORE USAGE

Check recovery/recycling equipment befor e connecting to vehicle. Verify there is no pressure in the recovery/

recycling equipment by checking the gauges. If pressure exists, recover refrigerant from equipment lines.

>> GO TO 9.

10.CHECK REFRIGERANT PURITY

1. Connect recovery/recycling equipment to vehicle.

2. Confirm refrigerant purity in supply tank us ing recovery/recycling and refrigerant identifier.

OK or NG

OK >> GO TO 10.

NG >> Check contaminated refrigerant. Refer to AT C - 3 , "

Contaminated Refrigerant" .

11 .CHECK FOR EVAPORATOR FREEZE UP

Start engine and run A/C. Check for evaporator freeze up.

Does evaporator freeze up?

YES >> Perform performance test diagnoses. Refer to "PERFORMANCE TEST DIAGNOSES" .

NO >> GO TO 11.

Page 476 of 3061

ATC-106

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too High

Both High- and Low-pressure Sides are Too Low

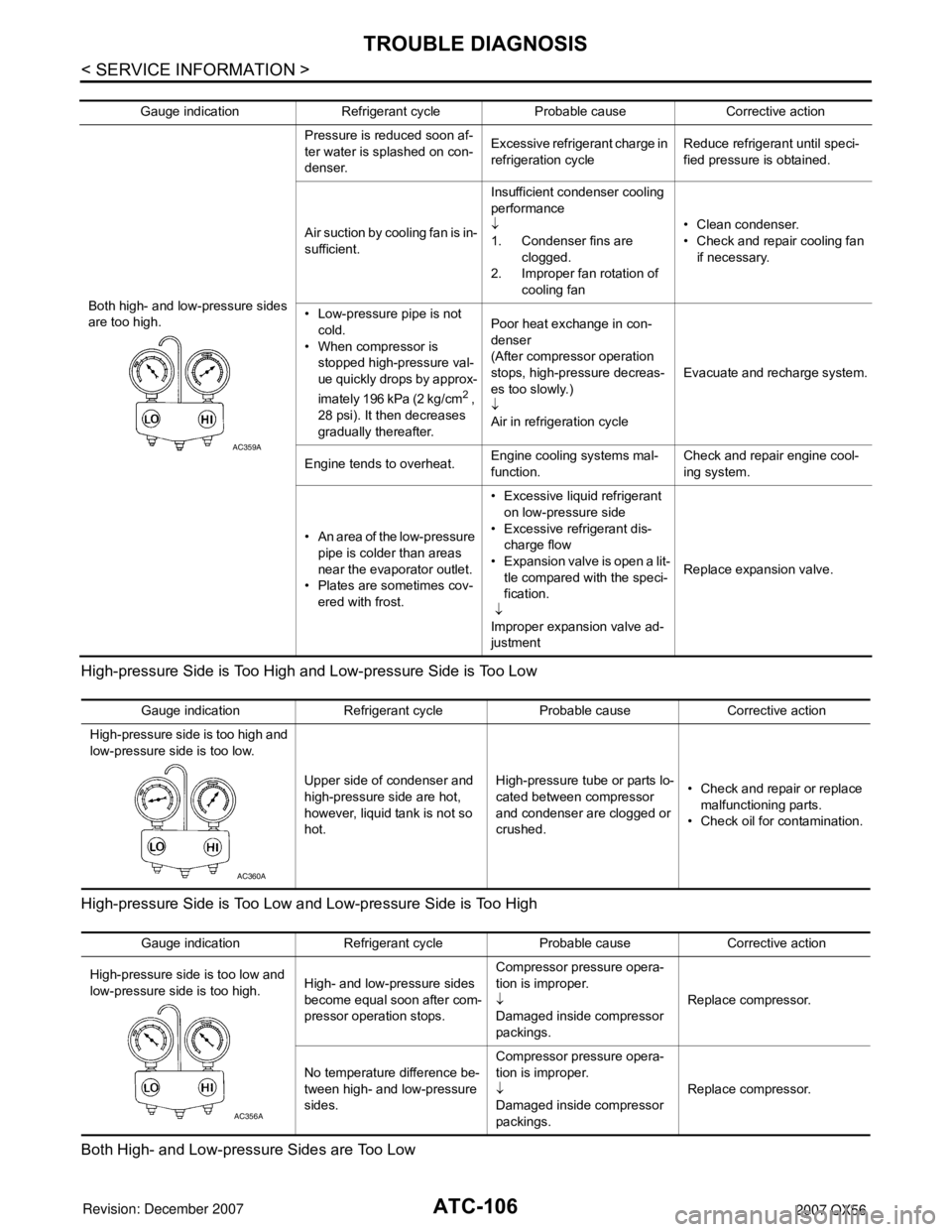

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure sides

are too high. Pressure is reduced soon af-

ter water is splashed on con-

denser.

Excessive refrigerant charge in

refrigeration cycle

Reduce refrigerant until speci-

fied pressure is obtained.

Air suction by cooling fan is in-

sufficient. Insufficient condenser cooling

performance

↓

1. Condenser fins are

clogged.

2. Improper fan rotation of cooling fan • Clean condenser.

• Check and repair cooling fan

if necessary.

• Low-pressure pipe is not cold.

• When compressor is stopped high-pressure val-

ue quickly drops by approx-

imately 196 kPa (2 kg/cm

2 ,

28 psi). It then decreases

gradually thereafter. Poor heat exchange in con-

denser

(After compressor operation

stops, high-pressure decreas-

es too slowly.)

↓

Air in refrigeration cycle

Evacuate and recharge system.

Engine tends to overheat. Engine cooling systems mal-

function. Check and repair engine cool-

ing system.

• An area of the low-pressure pipe is colder than areas

near the evaporator outlet.

• Plates are sometimes cov- ered with frost. • Excessive liquid refrigerant

on low-pressure side

• Excessive refrigerant dis- charge flow

• Expansion valve is open a lit- tle compared with the speci-

fication.

↓

Improper expansion valve ad-

justment Replace expansion valve.

AC359A

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too high and

low-pressure side is too low.

Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tu

be or parts lo-

cated between compressor

and condenser are clogged or

crushed. • Check and repair or replace

malfunctioning parts.

• Check oil for contamination.

AC360A

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too low and

low-pressure side is too high. High- and low-pressure sides

become equal soon after com-

pressor operation stops.Compressor pressure opera-

tion is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides. Compressor pressure opera-

tion is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

AC356A

Page 478 of 3061

ATC-108

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

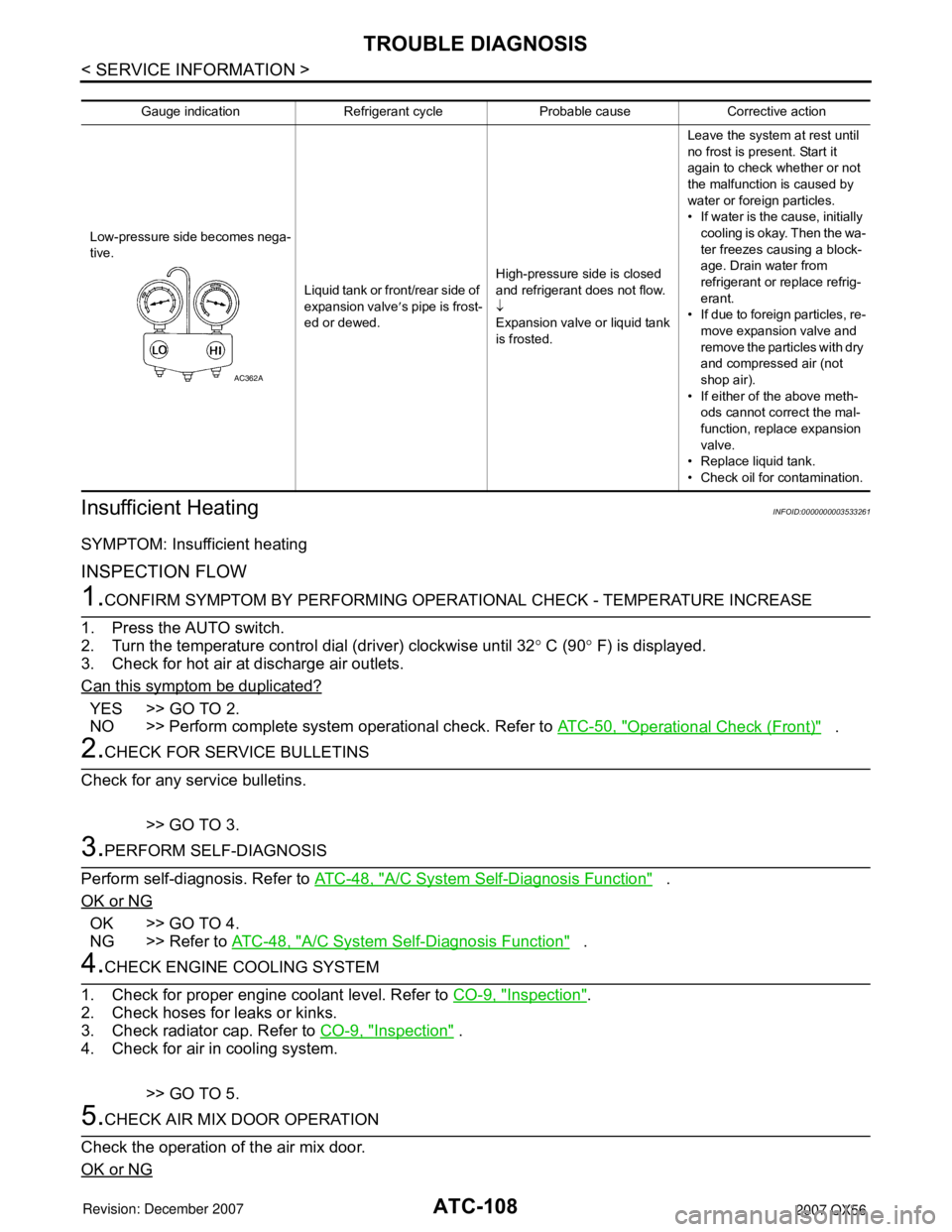

Insufficient Heating

INFOID:0000000003533261

SYMPTOM: Insufficient heating

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPER ATIONAL CHECK - TEMPERATURE INCREASE

1. Press the AUTO switch.

2. Turn the temperature control dial (driver) clockwise until 32 ° C (90 ° F) is displayed.

3. Check for hot air at discharge air outlets.

Can this symptom be duplicated?

YES >> GO TO 2.

NO >> Perform complete system operational check. Refer to ATC-50, "

Operational Check (Front)" .

2.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 3.

3.PERFORM SELF-DIAGNOSIS

Perform self-diagnosis. Refer to ATC-48, "

A/C System Self-Diagnosis Function" .

OK or NG

OK >> GO TO 4.

NG >> Refer to ATC-48, "

A/C System Self-Diagnosis Function" .

4.CHECK ENGINE COOLING SYSTEM

1. Check for proper engine coolant level. Refer to CO-9, "

Inspection".

2. Check hoses for leaks or kinks.

3. Check radiator cap. Refer to CO-9, "

Inspection" .

4. Check for air in cooling system.

>> GO TO 5.

5.CHECK AIR MIX DOOR OPERATION

Check the operation of the air mix door.

OK or NG

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side becomes nega-

tive. Liquid tank or front/rear side of

expansion valve′s pipe is frost-

ed or dewed. High-pressure side is closed

and refrigerant does not flow.

↓

Expansion valve or liquid tank

is frosted. Leave the system at rest until

no frost is present. Start it

again to check whether or not

the malfunction is caused by

water or foreign particles.

• If water is the cause, initially

cooling is okay. Then the wa-

ter freezes causing a block-

age. Drain water from

refrigerant or replace refrig-

erant.

• If due to foreign particles, re-

move expansion valve and

remove the particles with dry

and compressed air (not

shop air).

• If either of the above meth- ods cannot correct the mal-

function, replace expansion

valve.

• Replace liquid tank.

• Check oil for contamination.

AC362A

Page 483 of 3061

TROUBLE DIAGNOSISATC-113

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

Does another symptom exist?

YES >> Refer to ATC-32, "How to Perform Trouble Diagnosis for Quick and Accurate Repair".

NO >> Replace front air control. Refer to ATC-123, "

Removal and Installation".

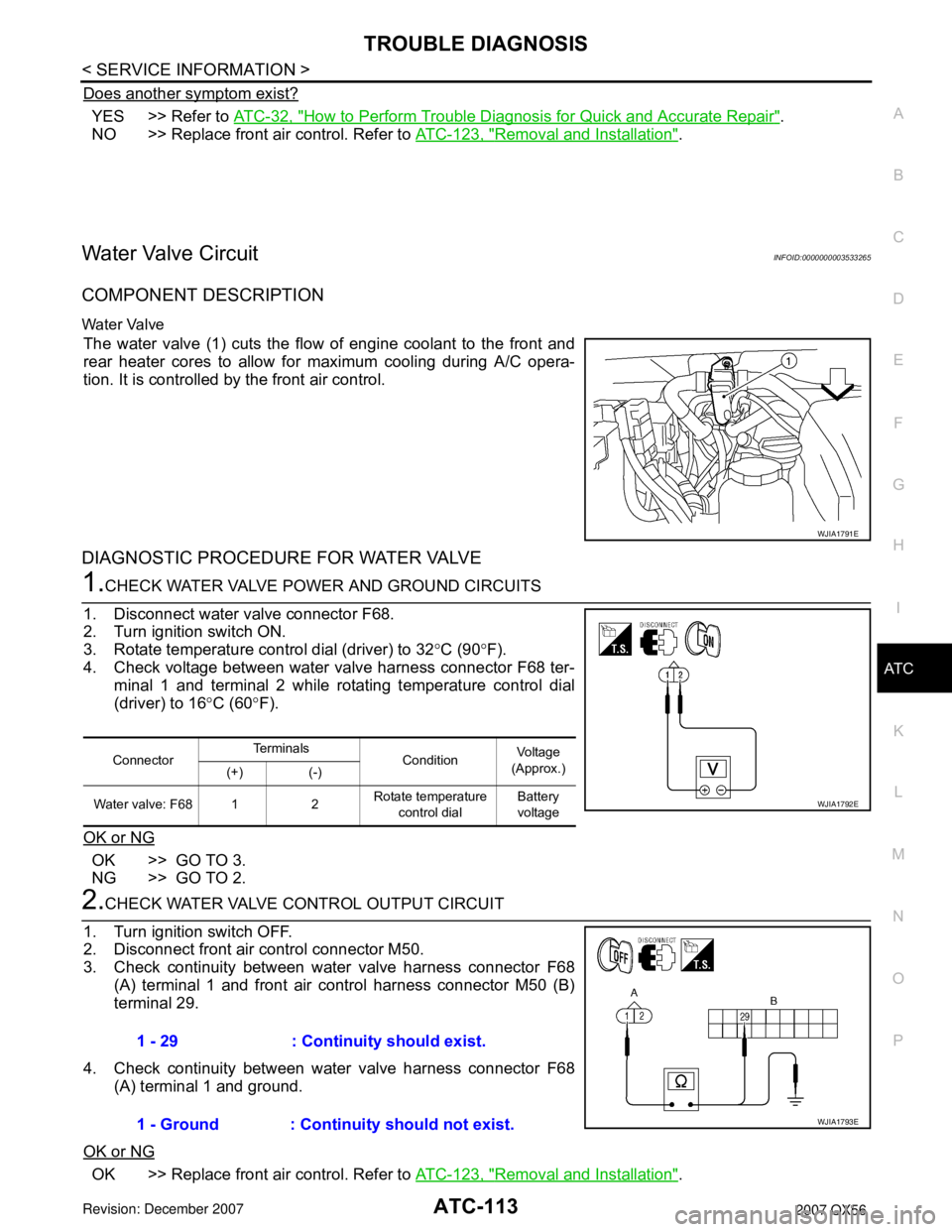

Water Valve CircuitINFOID:0000000003533265

COMPONENT DESCRIPTION

Water Valve

The water valve (1) cuts the flow of engine coolant to the front and

rear heater cores to allow for maximum cooling during A/C opera-

tion. It is controlled by the front air control.

DIAGNOSTIC PROCEDURE FOR WATER VALVE

1.CHECK WATER VALVE POWER AND GROUND CIRCUITS

1. Disconnect water valve connector F68.

2. Turn ignition switch ON.

3. Rotate temperature control dial (driver) to 32 °C (90 °F).

4. Check voltage between water valve harness connector F68 ter- minal 1 and terminal 2 while rotating temperature control dial

(driver) to 16 °C (60 °F).

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.CHECK WATER VALVE CONTROL OUTPUT CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect front air control connector M50.

3. Check continuity between water valve harness connector F68 (A) terminal 1 and front air control harness connector M50 (B)

terminal 29.

4. Check continuity between water valve harness connector F68 (A) terminal 1 and ground.

OK or NG

OK >> Replace front air control. Refer to ATC-123, "Removal and Installation".

WJIA1791E

ConnectorTe r m i n a l s

Condition Voltage

(Approx.)

(+) (-)

Water valve: F68 1 2 Rotate temperature

control dial Battery

voltage

WJIA1792E

1 - 29 : Continuity should exist.

1 - Ground : Continuity should not exist.

WJIA1793E

Page 491 of 3061

TROUBLE DIAGNOSISATC-121

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

The intake sensor is located on the heater & cooling unit. It converts

temperature of air after it passes through the evaporator into a resis-

tance value which is then input to the front air control.

DIAGNOSTIC PROCEDURE FOR INTAKE SENSOR

SYMPTOM: Intake sensor circuit is open or shorted. Using the CON-

SULT-II, DTC B2581 or B2582 is di splayed. Without a CONSULT-II,

code 56 or 57 is indicated on front air control as a result of conduct-

ing the front air control self-diagnosis.

1.CHECK VOLTAGE BETWEEN INTAKE SENSOR AND GROUND

1. Disconnect intake sensor connector.

2. Turn ignition switch ON.

3. Check voltage between intake sensor harness connector M146 terminal 2 and ground.

OK or NG

OK >> GO TO 2.

NG >> GO TO 4.

2.CHECK CIRCUIT CONTINUITY BETWEEN IN TAKE SENSOR AND FRONT AIR CONTROL

1. Turn ignition switch OFF.

2. Disconnect front air control connector.

3. Check continuity between intake sensor harness connector M146 terminal 1 and front air control harness connector M49 ter-

minal 21.

OK or NG

OK >> GO TO 3.

NG >> Repair harness or connector.

3.CHECK INTAKE SENSOR

Refer to "Intake Sensor Circuit".

OK or NG

OK >> 1. Replace front air control. Refer to ATC-123, "Removal and Installation"

2. Go to ATC-48, "A/C System Self-Diagnosis Function" and perform self-diagnosis.

NG >> 1. Replace intake sensor. Refer to ATC-127

.

2. Go to ATC-48, "

A/C System Self-Diagnosis Function" and perform self-diagnosis.

WJIA0571E

WJIA0464E

2 - Ground : Approx. 5V

WJIA1375E

1 - 21 : Continuity should exist.

WJIA1376E

Page 497 of 3061

INTAKE SENSORATC-127

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

INTAKE SENSOR

Removal and InstallationINFOID:0000000003533274

REMOVAL

1. Remove the glove box . Refer to IP-10, "Removal and Installation".

2. Disconnect the intake sensor electrical connector. NOTE:

The intake sensor is located on the top of the front heater and

cooling unit assembly next to the A/C evaporator cover.

3. Twist the intake sensor to remove the intake sensor from the front heater and cooling unit assembly.

INSTALLATION

Installation is in the reverse order of removal.

LJIA0133E

Page 498 of 3061

ATC-128

< SERVICE INFORMATION >

BLOWER MOTOR

BLOWER MOTOR

ComponentINFOID:0000000003533275

Front Blower MotorRear Blower Motor

Removal and InstallationINFOID:0000000003533276

FRONT BLOWER MOTOR

Removal

1. Remove the glove box assembly. Refer to IP-10, "Removal and Installation".

2. Disconnect the front blower motor electrical connector.

3. Remove the three screws and remove the front blower motor.

Installation

Installation is in the reverse order of removal.

LJIA0136E

1. Front heater and cooling unit assembly 2. Front blower motor 3. Variable blower control

LJIA0055E

1. Rear blower motor 2. Rear blower motor case 3. Rear blower motor resistor

Page 500 of 3061

ATC-130

< SERVICE INFORMATION >

IN-CABIN MICROFILTER

IN-CABIN MICROFILTER

Removal and InstallationINFOID:0000000003533277

FUNCTION

The air inside the passenger compartment is filtered by the in-cabin

microfilters when the heater or A/C controls are set on either the

recirculation or fresh mode. The two in-cabin microfilters are located

in the front heater and cooling unit assembly. The rear heater and

cooling unit assembly only draws in air from the passenger compart-

ment to recirculate into the passenger compartment, so the rear

heater and cooling unit assembly is not equipped with in-cabin

microfilters.

REPLACEMENT TIMING

Replacement of the two in-cabin microfilters is recommended on a regular interval depending on the driving

conditions. Refer to MA-6

. It may also be necessary to replace the tw o in-cabin microfilters as part of a compo-

nent replacement if the in-cabin microfilters are damaged.

REPLACEMENT PROCEDURE

1. Remove the two lower glove box hinge pins to remove the glove box from the instrument panel and let it hang from the cord.

2. Remove the screw and remove the in-cabin microfilter cover.

3. Remove the in-cabin microfilters from the front heater and cool- ing unit assembly housing.

4. Insert the first new in-cabin micr ofilter into the front heater and

cooling unit assembly housing and slide it over to the right.

Insert the second new in-cabin mi crofilter into the front heater

and cooling unit assembly housing.

NOTE:

The in-cabin microfilters are marked with air flow arrows. The

end of the microfilter with the arro w should face the rear of the

vehicle. The arrows should point downward.

LJIA0012E

WLIA0027E

LJIA0134E

LJIA0148E

Page 502 of 3061

ATC-132

< SERVICE INFORMATION >

HEATER & COOLING UNIT ASSEMBLY

HEATER & COOLING UNIT ASSEMBLY

ComponentINFOID:0000000003533278

Front Heater and Cooling Unit Assembly

AWJIA0319ZZ

1. High-pressure A/C pipe 2. Front expansion valve 3. Low-pressure A/C pipe

4. Front heater core pipe 5. Front heater core hose 6. A/C drain hose

7. Front heater and cooling unit assembly