cooling INFINITI QX56 2007 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 388 of 3061

ATC-18

< SERVICE INFORMATION >

REFRIGERATION SYSTEM

REAR REFRIGERATION SYSTEM

1. Defroster nozzle 2. LH side demister duct 3. LH ventilator duct

4. RH side demister duct 5. RH ventilator duct 6. Center ventilator duct

7. Front heater and cooling unit assembly 8. Floor duct 9. Clips

10. Heat duct

WJIA0956E

Page 389 of 3061

REFRIGERATION SYSTEMATC-19

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P1. Rear floor duct 2. Rear heater and cooling unit assembly 3. Rear lower overhead duct

4. Rear upper overhead duct

LJIA0142E

Page 390 of 3061

ATC-20

< SERVICE INFORMATION >

OIL

OIL

Maintenance of Oil Quantity in CompressorINFOID:0000000003533232

The oil in the compressor circulates through the system with the refrigerant. Add oil to compressor when

replacing any component or after a large refrigerant leakage has occurred. It is important to maintain the spec-

ified amount.

If oil quantity is not maintained properly, the following malfunctions may result:

• Lack of oil: May lead to a seized compressor

• Excessive oil: Inadequate cooling (thermal exchange interference)

OIL

Name: NISSAN A/C System Oil Type S or equivalent

CHECKING AND ADJUSTING

CAUTION:

If excessive oil leakage is noted, do no t perform the oil return operation.

Start the engine and set the following conditions:

Test Condition

• Engine speed: Idling to 1,200 rpm

• A/C switch: On

• Blower fan speed: MAX position

• Temp. control: Optional [Set so that intake air temperature is 25 ° to 30 ° C (77 ° to 86 °F)]

• Intake position: Recirculation ( )

• Perform oil return operation for about ten minutes

Adjust the oil quantity according to the following table.

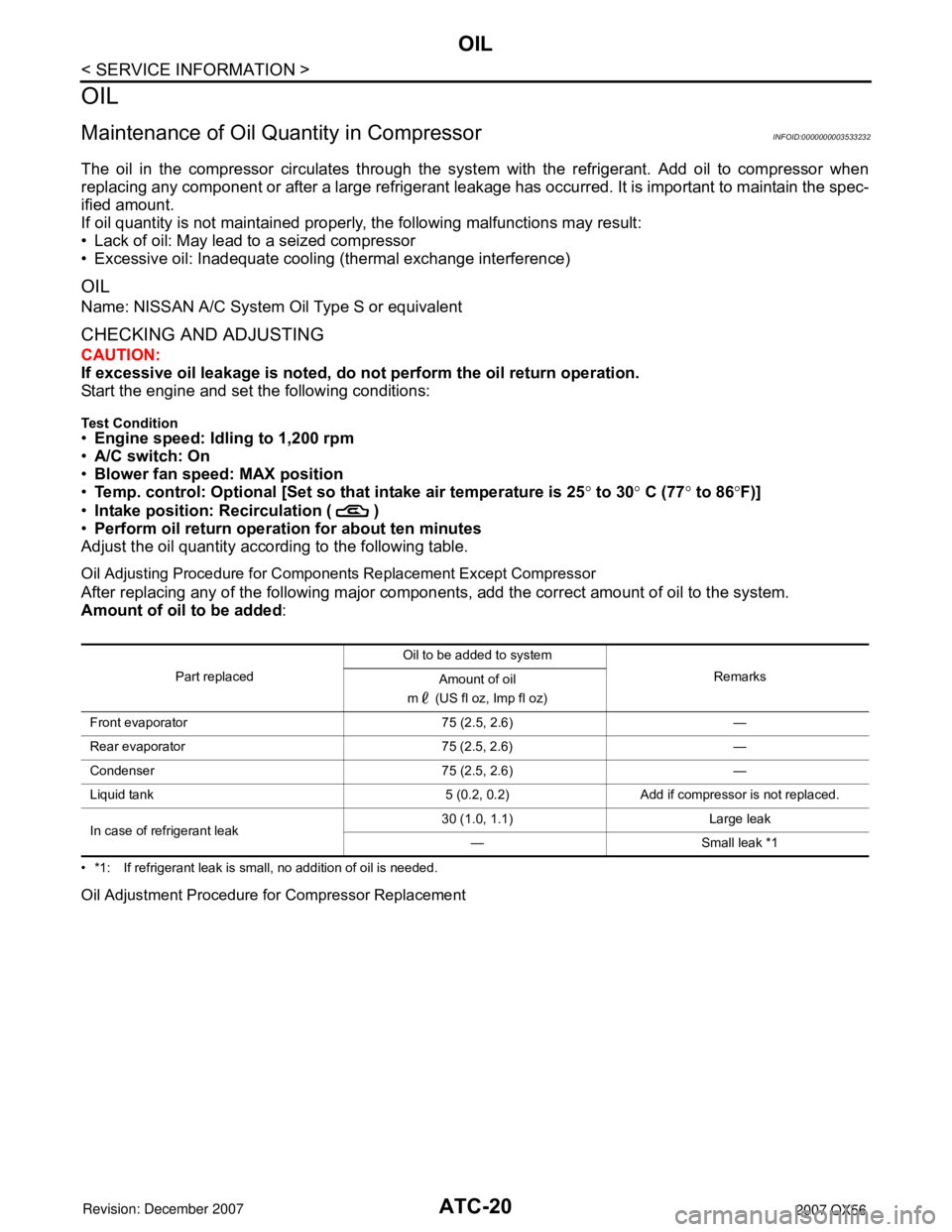

Oil Adjusting Procedure for Components Replacement Except Compressor

After replacing any of the following major component s, add the correct amount of oil to the system.

Amount of oil to be added :

• *1: If refrigerant leak is small, no addition of oil is needed.

Oil Adjustment Procedure for Compressor Replacement

Part replaced Oil to be added to system

Remarks

Amount of oil

m (US fl oz, Imp fl oz)

Front evaporator 75 (2.5, 2.6) —

Rear evaporator 75 (2.5, 2.6) —

Condenser 75 (2.5, 2.6) —

Liquid tank 5 (0.2, 0.2) Add if compressor is not replaced.

In case of refrigerant leak 30 (1.0, 1.1) Large leak

— Small leak *1

Page 402 of 3061

ATC-32

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

How to Perform Trouble Diagnosis for Quick and Accurate Repair

INFOID:0000000003533243

WORK FLOW

SYMPTOM TABLE

Component Parts and Harness Connector LocationINFOID:0000000003533244

ENGINE COMPARTMENT

*1AT C - 5 0 , "Operational Check (Front)"

or AT C - 5 1 , "

Operational Check

(Rear)" .

SHA900E

Symptom Reference Page

A/C system does not come on. Go to Trouble Diagnosis Procedure for A/C System. AT C - 5 2

A/C system display is malfunctioning. Go to Navigation System. AV- 7 3

A/C system cannot be controlled. Go to Self-diagnosis Function.AT C - 4 8 , "

A/C Sys-

tem Self-Diagno-

sis Function"

Air outlet does not change.

Go to Trouble Diagnosis Procedure for Mode Door Motor. AT C - 5 4

Mode door motor is malfunctioning.

Discharge air temperature does not change.

Go to Trouble Diagnosis Procedure for Air Mix Door Motor. AT C - 5 9

Air mix door motor is malfunctioning.

Intake door does not change.

Go to Trouble Diagnosis Procedure for Intake Door Motor. AT C - 7 0

Intake door motor is malfunctioning.

Defroster door motor is malfunctioning. Go to Trouble Diagnosis Procedure for Defroster Door Motor. AT C - 7 4

Front blower motor operation is malfunction-

ing.Go to Trouble Diagnosis Procedure for Front Blower Motor.

AT C - 7 8

Rear blower motor operation is malfunction-

ing.Go to Trouble Diagnosis Procedure for Rear Blower Motor.

AT C - 8 5

Rear discharge air temperature and/or air

outlet does not change.Go to Trouble Diagnosis Procedure for Rear Air Control circuit.

AT C - 9 3

Magnet clutch does not engage. Go to Trouble Diagnosis Procedure for Magnet Clutch. AT C - 9 6

Insufficient cooling Go to Trouble Diagnosis Procedure for Insufficient Cooling.AT C - 1 0 0

Insufficient heating Go to Trouble Diagnosis Procedure for Insufficient Heating.AT C - 1 0 8

Noise Go to Trouble Diagnosis Procedure for Noise.AT C - 1 0 9

Self-diagnosis cannot be performed. Go to Trouble Diagnosis Procedure for Self-diagnosis. AT C - 111

Memory function does not operate. Go to Trouble Diagnosis Procedure for Memory Function.AT C - 11 2

Page 421 of 3061

TROUBLE DIAGNOSISATC-51

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

1. Rotate temperature control dial (driver si de or passenger side) counterclockwise until 16 °C (60 °F) is dis-

played.

2. Check for cold air at appropriate discharge air outlets.

If NG, listen for sound of air mix door motor operat ion. If OK, go to trouble diagnosis procedure for ATC-100,

"Insufficient Cooling" . If air mix door motor appears to be malfunctioning, go to ATC-59, "Air Mix Door Motor

Circuit" or ATC-59, "Air Mix Door Motor Circuit".

If OK, continue the check.

CHECKING TEMPERATURE INCREASE

1. Rotate temperature control dial clockw ise (driver side or passenger side) until 32°C (90 °F) is displayed.

2. Check for hot air at appropriate discharge air outlets.

If NG, listen for sound of air mix door motor operat ion. If OK, go to trouble diagnosis procedure for ATC-108,

"Insufficient Heating" . If air mix door motor appears to be malfunctioning, go to ATC-59, "Air Mix Door Motor

Circuit" or ATC-59, "Air Mix Door Motor Circuit".

If OK, continue with next check.

CHECK A/C SWITCH

1. Press A/C switch when AUTO switch is ON, or in manual mode.

2. A/C switch indicator will turn ON.

• Confirm that the compressor clutch engages (sound or visual inspection).

NOTE:

If current mode setting is DEF or D/F, compressor clutch may already be engaged.

If NG, go to trouble diagnosis procedure for ATC-96, "

Magnet Clutch Circuit" .

If OK, continue with next check.

CHECKING AUTO MODE

1. Press AUTO switch.

2. Display should indicate AUTO.

• If ambient temperature is warm, and selected temperat ure is cool, confirm that the compressor clutch

engages (sound or visual inspection). (Discharge air and blower speed will depend on ambient, in-vehi-

cle, and set temperatures.)

If NG, go to trouble diagnosis procedure for ATC-52, "

Power Supply and Ground Circuit for Front Air Control" ,

then if necessary, trouble diagnosis procedure for ATC-96, "

Magnet Clutch Circuit" .

If all operational checks are OK (symptom cannot be duplicated), go to malfunction Simulation Tests in AT C -

32, "How to Perform Trouble Diagnosis for Quick and Accurate Repair" and perform tests as outlined to simu-

late driving conditions environment . If symptom appears. Refer to ATC-32, "

How to Perform Trouble Diagnosis

for Quick and Accurate Repair", ATC-32, "How to Perform Trouble Diagnosis for Quick and Accurate Repair"

and perform applicable trouble diagnosis procedures.

Operational Check (Rear)INFOID:0000000003533250

The purpose of the operational check is to confirm that the system operates properly.

CHECKING BLOWER

1. Turn the rear blower control dial to swit ch position "1". Blower should operate on low speed.

2. Turn the rear blower control dial counterclockwis e to switch position "2", "3", and "4" until all speeds are

checked.

3. Leave blower on MAX speed.

If NG, go to trouble diagnosis procedure for ATC-85, "

Rear Blower Motor Circuit" .

If OK, continue the check.

CHECKING TEMPERATURE DECREASE

1. Rotate temperature and mode dial fully counterclockwise.

2. Check for cold air at appropriate discharge air outlets. Conditions : Engine running and at normal operating temperature

Page 422 of 3061

ATC-52

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

If NG, listen for sound of air mix door motor operation if OK, go to trouble diagnosis procedure for ATC-100,

"Insufficient Cooling" . If air mix door motor appears to be malfunctioning, go to ATC-59, "Air Mix Door Motor

Circuit".

If OK, continue the check.

CHECKING TEMPERATURE INCREASE

1. Rotate temperature and mode dial clockwise.

2. Check for hot air at appropriate discharge air outlets.

If NG, listen for sound of air mix door motor operat ion. If OK, go to trouble diagnosis procedure for ATC-108,

"Insufficient Heating". If air mix door motor appears to be malfunctioning, go to ATC-59, "Air Mix Door Motor

Circuit" .

If OK, continue the check.

Power Supply and Ground Circu it for Front Air ControlINFOID:0000000003533251

SYMPTOM: A/C system does not come on.

INSPECTION FLOW

1.CONFIRM SYMPTOM BY PERFORMING OPERATIONAL CHECK - AUTO MODE

1. Press AUTO switch.

2. Display should indicate AUTO. Confirm that the compressor clutch engages (sound or visual inspection).

(Discharge air and blower speed will depend on am bient, in-vehicle and set temperatures.)

Can a symptom be duplicated?

YES >> GO TO 3.

NO >> GO TO 2.

2.PERFORM COMPLETE OPERATIONAL CHECK

Perform a complete operational check and check for any symptoms. Refer to ATC-50, "

Operational Check

(Front)".

Can a symptom be duplicated

YES >> Refer to ATC-32, "How to Perform Trouble Diagnosis for Quick and Accurate Repair".

NO >> System OK.

3.CHECK FOR SERVICE BULLETINS

Check for any service bulletins.

>> GO TO 4.

4.CHECK POWER AND GROUND CIRCUIT

Check main power supply and ground circuit. Refe r to "DIAGNOSTIC PROCEDURE FOR A/C SYSTEM".

OK or NG

OK >> System OK.

NO >> Replace front air control. Refer to ATC-123, "

Removal and Installation".

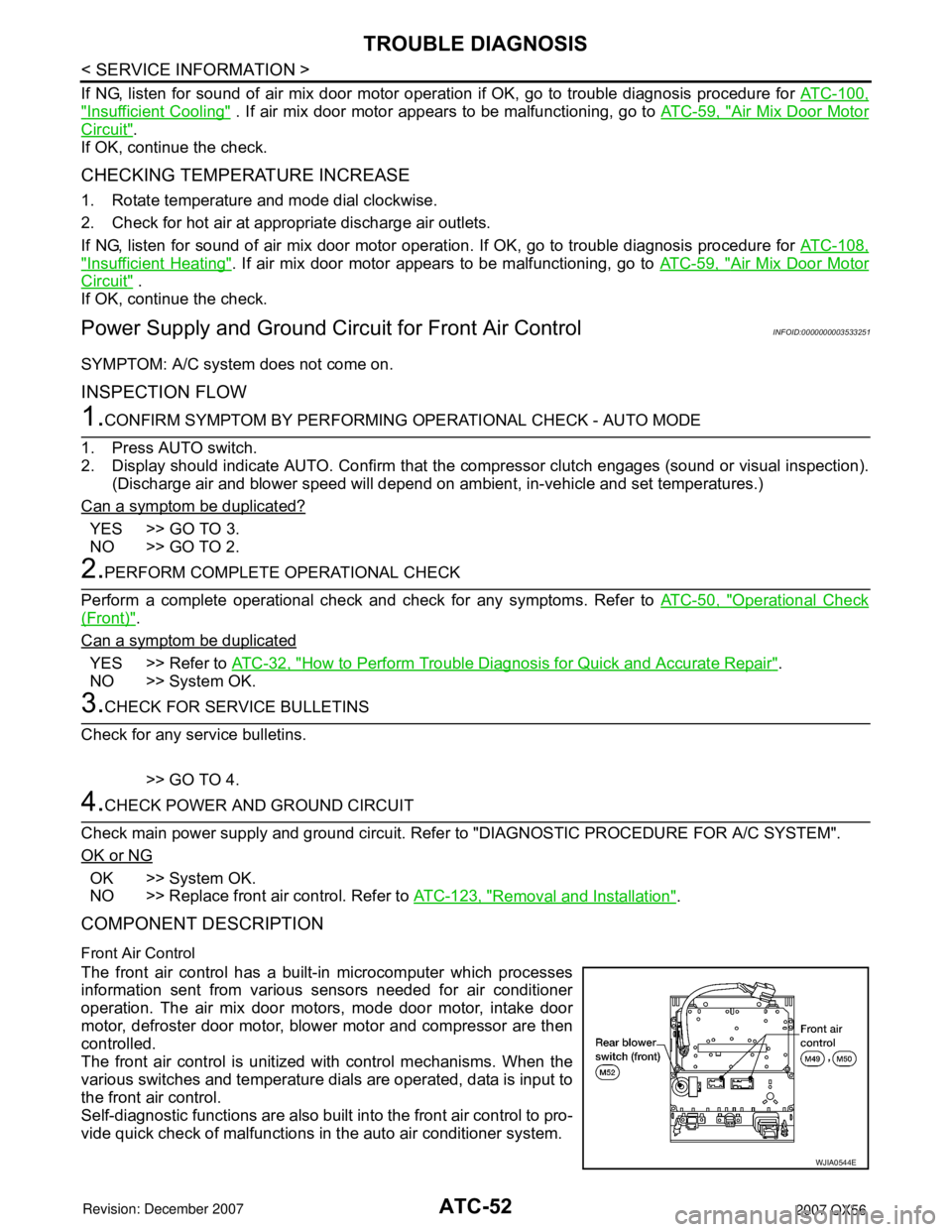

COMPONENT DESCRIPTION

Front Air Control

The front air control has a built-in microcomputer which processes

information sent from various sensors needed for air conditioner

operation. The air mix door motors, mode door motor, intake door

motor, defroster door motor, blower motor and compressor are then

controlled.

The front air control is unitized with control mechanisms. When the

various switches and temperature dials are operated, data is input to

the front air control.

Self-diagnostic functions are also built into the front air control to pro-

vide quick check of malfunctions in the auto air conditioner system.

WJIA0544E

Page 426 of 3061

ATC-56

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Mode Door Control Specification

COMPONENT DESCRIPTION

Mode Door Motor

The mode door motor is attached to the heater & cooling unit. It

rotates so that air is discharged from the outlet as indicated by the

front air control. Motor rotation is conveyed to a link which activates

the mode door.

DIAGNOSTIC PROCEDURE FOR MODE DOOR MOTOR

1.CHECK FRONT AIR CONTROL FOR POWER AND GROUND

1. Turn ignition switch ON.

2. Press the mode switch to the B/L ( ) mode.

3. Check voltage between front air control harness connector M49 terminal 5 and terminal 6 while pressing the mode switch to the

floor ( ) mode.

OK or NG

OK >> GO TO 3.

NG >> GO TO 2.

2.CHECK MODE DOOR MOTOR CIRCUITS FOR SHORT TO GROUND

1. Turn ignition switch OFF.

2. Disconnect the front air control harness connector.

3. Check continuity between front air control harness connector M49 terminal 5, 6 and ground.

OK or NG

OK >> Replace front air control. Refer to ATC-123, "Removal

and Installation" .

NG >> Repair or replace harness as necessary.

3.CHECK FRONT AIR CONTROL FOR GROUND AND POWER

WJIA0434E

WJIA0587E

Connector Te r m i n a l s

Condition Voltage

(Approx.)

(+) (-)

Front air control: M49 6 5 Press

mode

switch Battery

voltage

WJIA1727E

5 - Ground : Continuity should not exist.

6 - Ground : Continuity should not exist.

WJIA1734E

Page 431 of 3061

TROUBLE DIAGNOSISATC-61

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

Subsequently, HOT/COLD or DEFROST/VENT or FR ESH/RECIRCULATION operation is selected. The new

door position data is returned to the front air control.

Air Mix Door Control Specification

COMPONENT DESCRIPTION

Air Mix Door Motors

The driver (1) and front passenger (2) air mix door motors are

attached to the front heater & cooling unit assembly. The rear air mix

door motor is attached to the rear heater & cooling unit. These

motors rotate so that the air mix door is opened or closed to a posi-

tion set by the front (or rear) air control. Motor rotation is then con-

veyed through a shaft and the air mix door position is then fed back

to the front air control by the PBR built into the air mix door motors.

DIAGNOSTIC PROCEDURE FOR AIR MIX DOOR MOTOR (DRIVER)

1.CHECK FRONT AIR CONTROL FOR POWER AND GROUND

WJIA1244E

WJIA0435E

WJIA2309E

WJIA1245E

Page 445 of 3061

TROUBLE DIAGNOSISATC-75

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

• PBR (Built into defroster door motor)

• In-vehicle sensor

• Ambient sensor

• Optical sensor

• Intake sensor

System Operation

The front air control determines defroster door position based on the position of the defroster switch. When the

defroster switch is depressed, the defroster door moto r rotates directing air to the defroster ducts. When any

mode other than defroster is selected, the defroster moto r rotates in the opposite direction closing off air flow

to the defroster ducts.

In the AUTO mode, the front air control determines defroster door position based on the ambient temperature,

the intake air temperature and the in-vehicle temperature.

COMPONENT DESCRIPTION

Defroster door motor

The defroster door motor is attached to the front heater & cooling

unit assembly. The front air control sends a voltage to rotate to the

defroster door directing the air flow either to the defroster ducts, or to

the floor ducts, depending on which way the voltage and ground are

applied to the motor leads. Motor rotation is conveyed to a lever

which activates the defroster door.

DIAGNOSTIC PROCEDURE FOR DEFROSTER DOOR MOTOR

1.CHECK FRONT AIR CONTROL FOR POWER AND GROUND

1. Turn ignition switch ON.

2. Press the defroster switch ( ).

3. Check voltage between front air control harness connector M49 terminal 20 and terminal 19 and press the defroster switch ( )

again.

WJIA1354E

WJIA0592E

WJIA2277E

Page 451 of 3061

TROUBLE DIAGNOSISATC-81

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

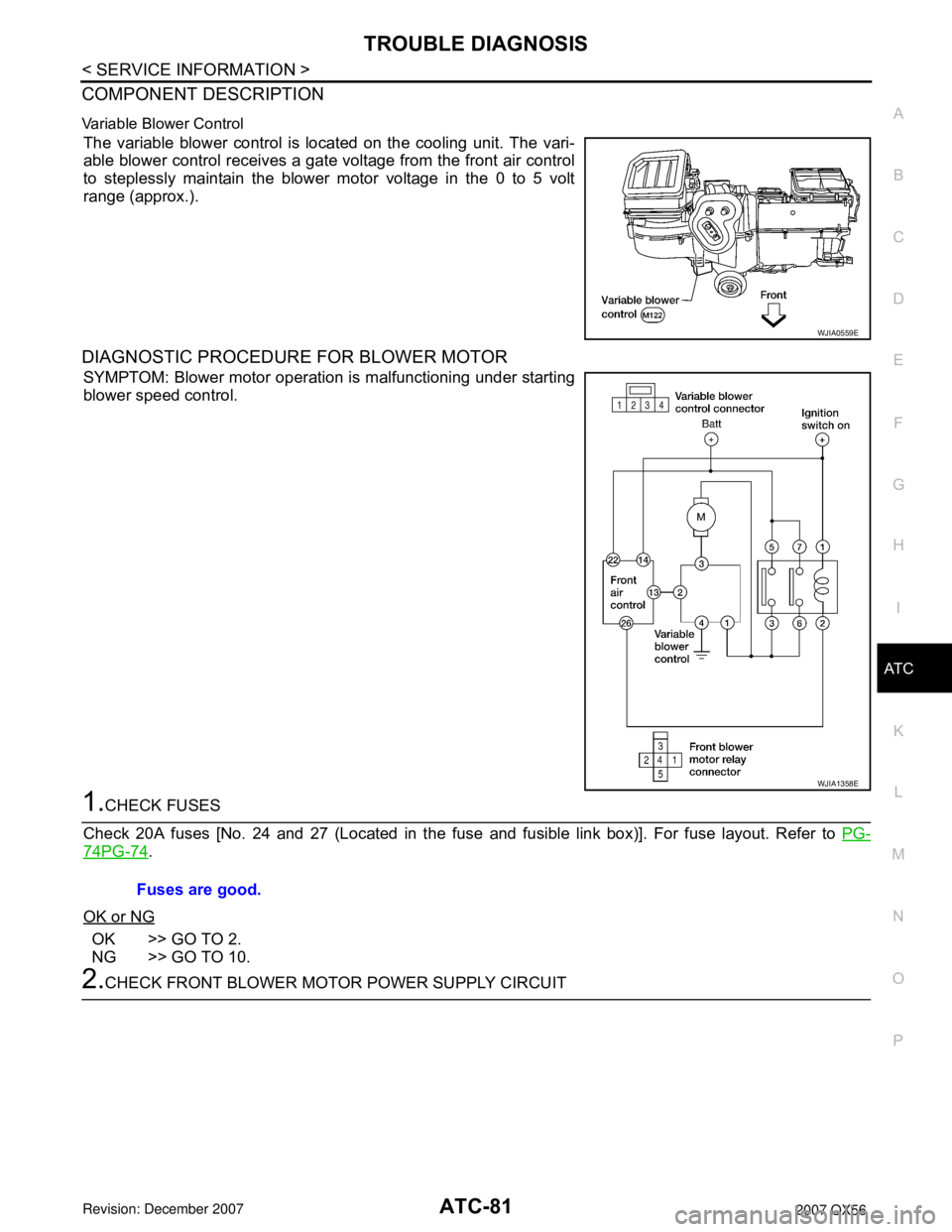

COMPONENT DESCRIPTION

Variable Blower Control

The variable blower control is located on the cooling unit. The vari-

able blower control receives a gate voltage from the front air control

to steplessly maintain the blower motor voltage in the 0 to 5 volt

range (approx.).

DIAGNOSTIC PROCEDURE FOR BLOWER MOTOR

SYMPTOM: Blower motor operation is malfunctioning under starting

blower speed control.

1.CHECK FUSES

Check 20A fuses [No. 24 and 27 (Located in the fuse and fusible link box)]. For fuse layout. Refer to PG-

74PG-74.

OK or NG

OK >> GO TO 2.

NG >> GO TO 10.

2.CHECK FRONT BLOWER MOTOR POWER SUPPLY CIRCUIT

WJIA0559E

WJIA1358E

Fuses are good.