door lock INFINITI QX56 2007 Factory Owner's Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 717 of 3061

BL-6

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

If the noise can be duplicated easily during the test drive, to help identify the source of the noise, try to dupli-

cate the noise with the vehicle stopped by doing one or all of the following:

1) Close a door.

2) Tap or push/pull around the area where the noise appears to be coming from.

3) Rev the engine.

4) Use a floor jack to recreate vehicle “twist”.

5) At idle, apply engine load (electrical load, half-clutch on M/T model, drive position on A/T model).

6) Raise the vehicle on a hoist and hit a tire with a rubber hammer.

• Drive the vehicle and attempt to duplicate the conditions the customer states exist when the noise occurs.

• If it is difficult to duplicate the noise, drive the vehicle slowly on an undulating or rough road to stress the

vehicle body.

CHECK RELATED SERVICE BULLETINS

After verifying the customer concern or symptom, check ASIST for Technical Service Bulletins (TSBs) related

to that concern or symptom.

If a TSB relates to the symptom, follow the procedure to repair the noise.

LOCATE THE NOISE AND IDENTIFY THE ROOT CAUSE

1. Narrow down the noise to a general area.To help pinpoint the source of the noise, use a listening tool

(Chassis Ear: J-39570, Engine Ear: J-39565 and mechanic's stethoscope).

2. Narrow down the noise to a more specific area and identify the cause of the noise by:

• removing the components in the area that you suspect the noise is coming from.

Do not use too much force when removing clips and fasteners, otherwise clips and fasteners can be broken

or lost during the repair, resulting in the creation of new noise.

• tapping or pushing/pulling the component that you suspect is causing the noise.

Do not tap or push/pull the component with excessive force, otherwise the noise will be eliminated only tem-

porarily.

• feeling for a vibration with your hand by touching the component(s) that you suspect is (are) causing the

noise.

• placing a piece of paper between components that you suspect are causing the noise.

• looking for loose components and contact marks.

Refer to BL-7, "

Generic Squeak and Rattle Troubleshooting".

REPAIR THE CAUSE

• If the cause is a loose component, tighten the component securely.

• If the cause is insufficient clearance between components:

- separate components by repositioning or loosening and retightening the component, if possible.

- insulate components with a suitable insulator such as urethane pads, foam blocks, felt cloth tape or urethane

tape. A NISSAN Squeak and Rattle Kit (J-43980) is available through your authorized NISSAN Parts Depart-

ment.

CAUTION:

Do not use excessive force as many components are constructed of plastic and may be damaged.

Always check with the Parts Department for the latest parts information.

The following materials are contained in the NISSAN Squeak and Rattle Kit (J-43980). Each item can be

ordered separately as needed.

URETHANE PADS [1.5 mm (0.059 in) thick]

Insulates connectors, harness, etc.

76268-9E005: 100×135 mm (3.94×5.31 in)/76884-71L01: 60×85 mm (2.36×3.35 in)/76884-71L02: 15×25

mm (0.59×0.98 in)

INSULATOR (Foam blocks)

Insulates components from contact. Can be used to fill space behind a panel.

73982-9E000: 45 mm (1.77 in) thick, 50×50 mm (1.97×1.97 in)/73982-50Y00: 10 mm (0.39 in) thick,

50×50 mm (1.97×1.97 in)

INSULATOR (Light foam block)

80845-71L00: 30 mm (1.18 in) thick, 30×50 mm (1.18×1.97 in)

FELT CLOTH TAPE

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15×25 mm (0.59×0.98 in) pad/68239-13E00: 5 mm (0.20 in) wide tape roll. The following

materials not found in the kit can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

Page 718 of 3061

SQUEAK AND RATTLE TROUBLE DIAGNOSIS

BL-7

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

SILICONE GREASE

Used instead of UHMW tape that will be visible or not fit.

Note: Will only last a few months.

SILICONE SPRAY

Use when grease cannot be applied.

DUCT TAPE

Use to eliminate movement.

CONFIRM THE REPAIR

Confirm that the cause of a noise is repaired by test driving the vehicle. Operate the vehicle under the same

conditions as when the noise originally occurred. Refer to the notes on the Diagnostic Worksheet.

Generic Squeak and Rattle TroubleshootingINFOID:0000000003532889

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by apply-

ing felt cloth tape or silicone spray (in hard to reach areas). Urethane pads can be used to insulate wiring har-

ness.

CAUTION:

Do not use silicone spray to isolate a squeak or rattle. If you saturate the area with silicone, you will

not be able to recheck the repair.

CENTER CONSOLE

Components to pay attention to include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation procedures also apply to the center console.

DOORS

Pay attention to the:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping or moving the components or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. You can usually insulate the areas with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the owner.

In addition look for:

1. Trunk lid bumpers out of adjustment

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Page 726 of 3061

POWER DOOR LOCK SYSTEM

BL-15

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

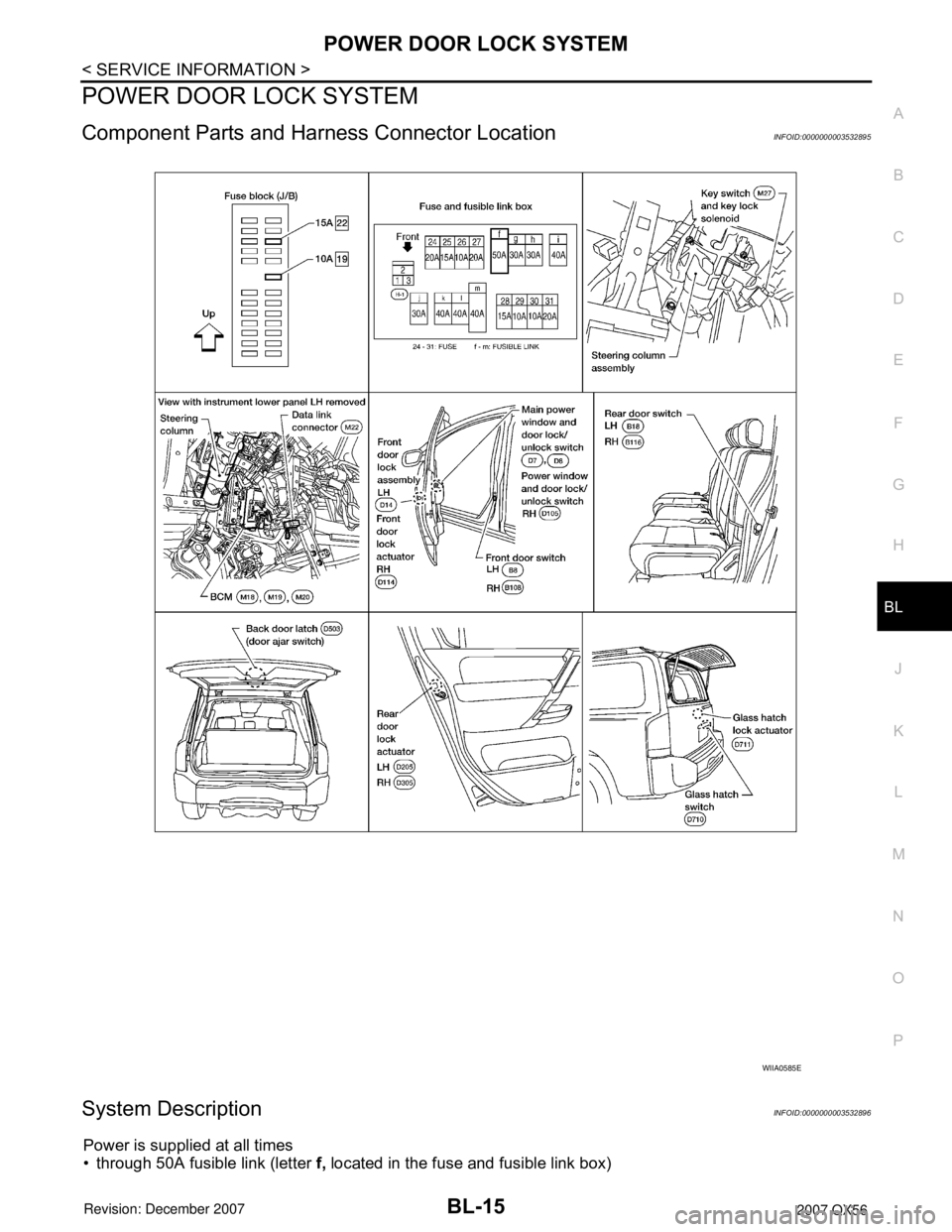

POWER DOOR LOCK SYSTEM

Component Parts and Harness Connector LocationINFOID:0000000003532895

System DescriptionINFOID:0000000003532896

Power is supplied at all times

• through 50A fusible link (letter f, located in the fuse and fusible link box)

WIIA0585E

Page 727 of 3061

![INFINITI QX56 2007 Factory Owners Manual BL-16

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

• to BCM terminal 70

• through 15A fuse [No. 22, located in the fuse block (J/B)]

• to BCM terminal 57

• through 10A fuse [No. 19, located INFINITI QX56 2007 Factory Owners Manual BL-16

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

• to BCM terminal 70

• through 15A fuse [No. 22, located in the fuse block (J/B)]

• to BCM terminal 57

• through 10A fuse [No. 19, located](/img/42/57029/w960_57029-726.png)

BL-16

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

• to BCM terminal 70

• through 15A fuse [No. 22, located in the fuse block (J/B)]

• to BCM terminal 57

• through 10A fuse [No. 19, located in the fuse block (J/B)]

• to key switch and key lock solenoid terminal 3.

With ignition key inserted, power is supplied

• through key switch and key lock solenoid terminal 4

• to BCM terminal 37.

Ground is supplied to terminal 67 of BCM through body grounds M57, M61 and M79.

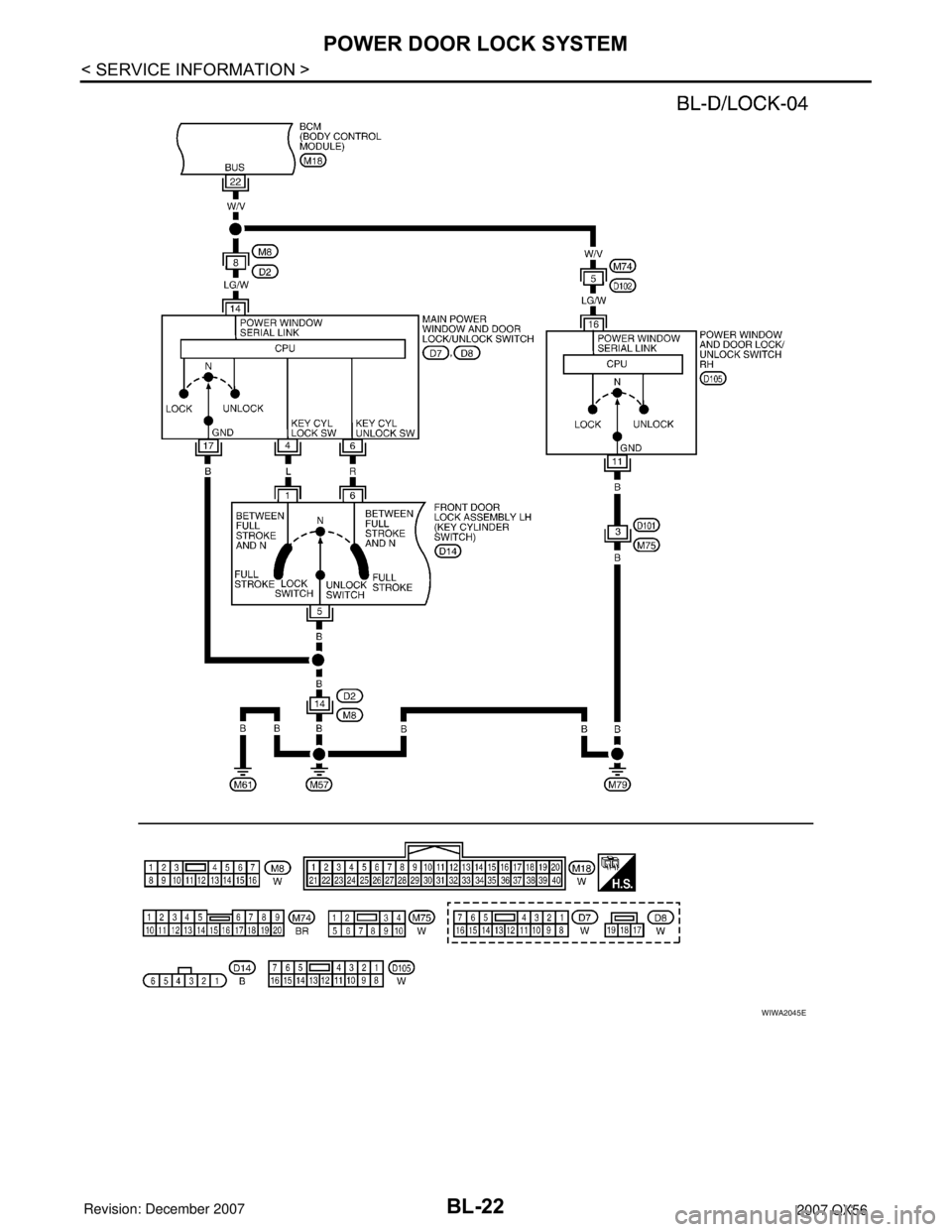

When the door is locked or unlocked with main power window and door lock/unlock switch, ground is supplied

• to CPU of main power window and door lock/unlock switch

• through main power window and door lock/unlock switch terminal 17

• through grounds M57, M61 and M79.

Then main power window and door lock/unlock switch operation signal is supplied

• to BCM terminal 22

• through main power window and door lock/unlock switch terminal 14.

When the door is locked or unlocked with power window and door lock/unlock switch RH, ground is supplied

• to CPU of power window and door lock/unlock switch RH

• through power window and door lock/unlock switch RH terminal 11

• through grounds M57, M61 and M79.

Then power window and door lock/unlock switch RH operation signal is supplied

• to BCM terminal 22

• through power window and door lock/unlock switch RH terminal 16.

When the door is locked with front door lock assembly LH (key cylinder switch), ground is supplied

• to main power window and door lock/unlock switch terminal 4

• through front door lock assembly LH (key cylinder switch) terminals 1 and 5

• through grounds M57, M61 and M79.

Then front door lock assembly LH (key cylinder switch) operation signal is supplied

• to BCM terminal 22

• through main power window and door lock/unlock switch terminal 14.

When the door is unlocked with front door lock assembly LH (key cylinder switch), ground is supplied

• to main power window and door lock/unlock switch terminal 6

• through front door lock assembly LH (key cylinder switch) terminals 6 and 5

• through grounds M57, M61 and M79.

Then front door lock assembly LH (key cylinder switch) operation signal is supplied

• to BCM terminal 22

• through main power window and door lock/unlock switch terminal 14.

BCM is connected to main power window and door lock/unlock switch and power window and door lock/unlock

switch RH through a bus.

When the front door switch LH is ON (door is open), ground is supplied

• to BCM terminal 47

• through front door switch LH terminal 2

• through front door switch LH case ground.

When the front door switch RH is ON (door is open), ground is supplied

• to BCM terminal 12

• through front door switch RH terminal 2

• through front door switch RH case ground.

When the rear door switch LH is ON (door is open), ground is supplied

• to BCM terminal 48

• through rear door switch LH terminal 2

• through rear door switch LH case ground.

When the rear door switch RH is ON (door is open), ground is supplied

• to BCM terminal 13

• through rear door switch RH terminal 2

• through rear door switch RH case ground.

When the back door latch (door ajar switch) is ON (door is open), ground is supplied

• to BCM terminal 43

• through back door latch (door ajar switch) terminal 7

• through back door latch (door ajar switch) terminal 8

• through grounds B7 and B19.

OUTLINE

Page 728 of 3061

POWER DOOR LOCK SYSTEM

BL-17

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

NOTE:

The glass hatch switch will be operational only when the front door lock actuator RH is in the unlock position.

Functions available by operating the door lock and unlock switches on driver door and passenger door

• Interlocked with the locking operation of door lock and unlock switch, door lock actuators of all doors and

glass hatch actuator are locked.

• Interlocked with the unlocking operation of door lock and unlock switch, door lock actuators of all doors and

glass hatch actuator are unlocked.

Functions available by operating the front door lock assembly LH (key cylinder switch)

• Interlocked with the locking operation of door key cylinder, door lock actuators of all doors are locked.

• When door key cylinder is unlocked, front door lock assembly LH (actuator) is unlocked.

• When door key cylinder is unlocked for the second time within 5 seconds after the first operation, door lock

actuators on all doors are unlocked.

Key reminder door system

When door lock and unlock switch is operated to lock doors with ignition key in key cylinder and any door

open, all door lock actuators are locked and then unlocked.

Page 729 of 3061

BL-18

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

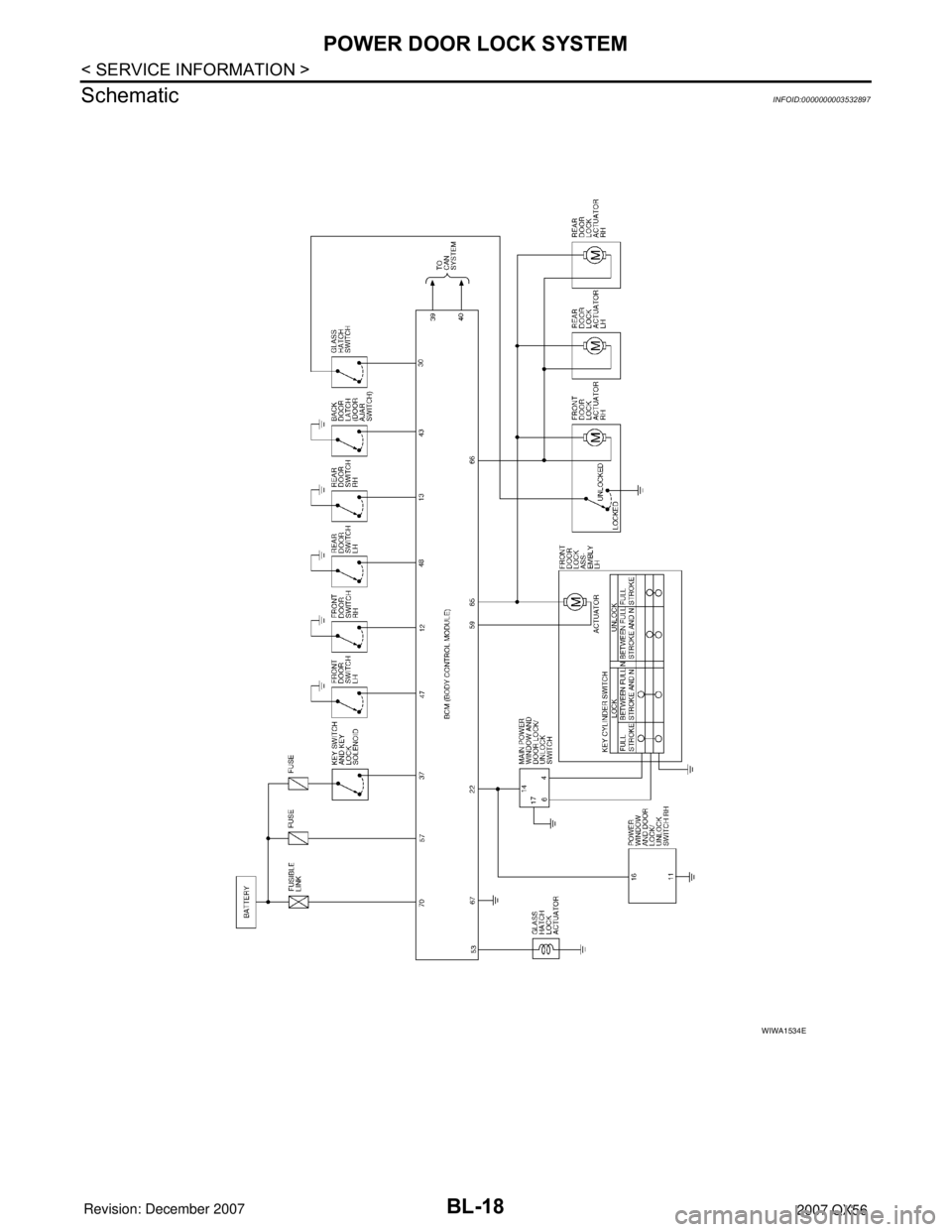

Schematic

INFOID:0000000003532897

WIWA1534E

Page 730 of 3061

POWER DOOR LOCK SYSTEM

BL-19

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

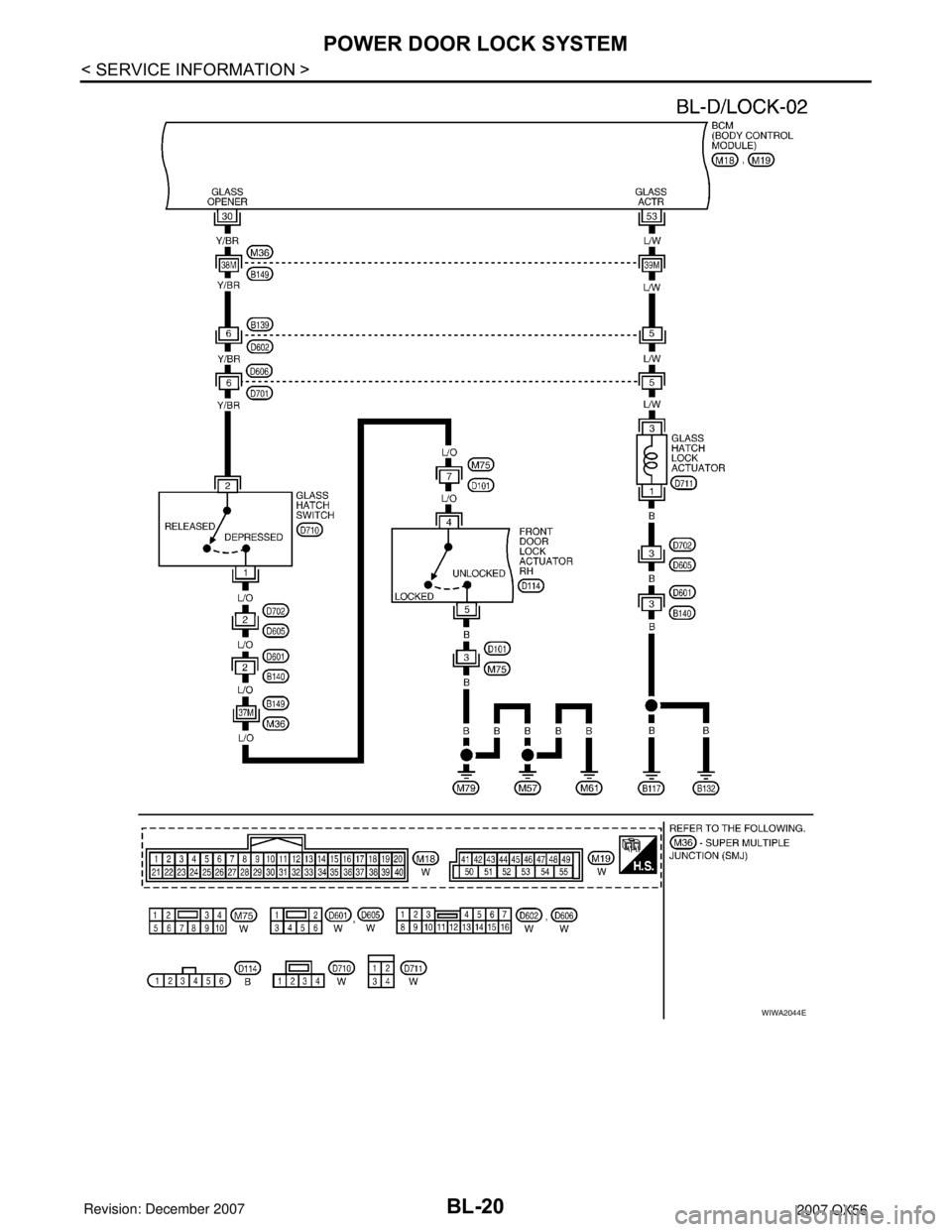

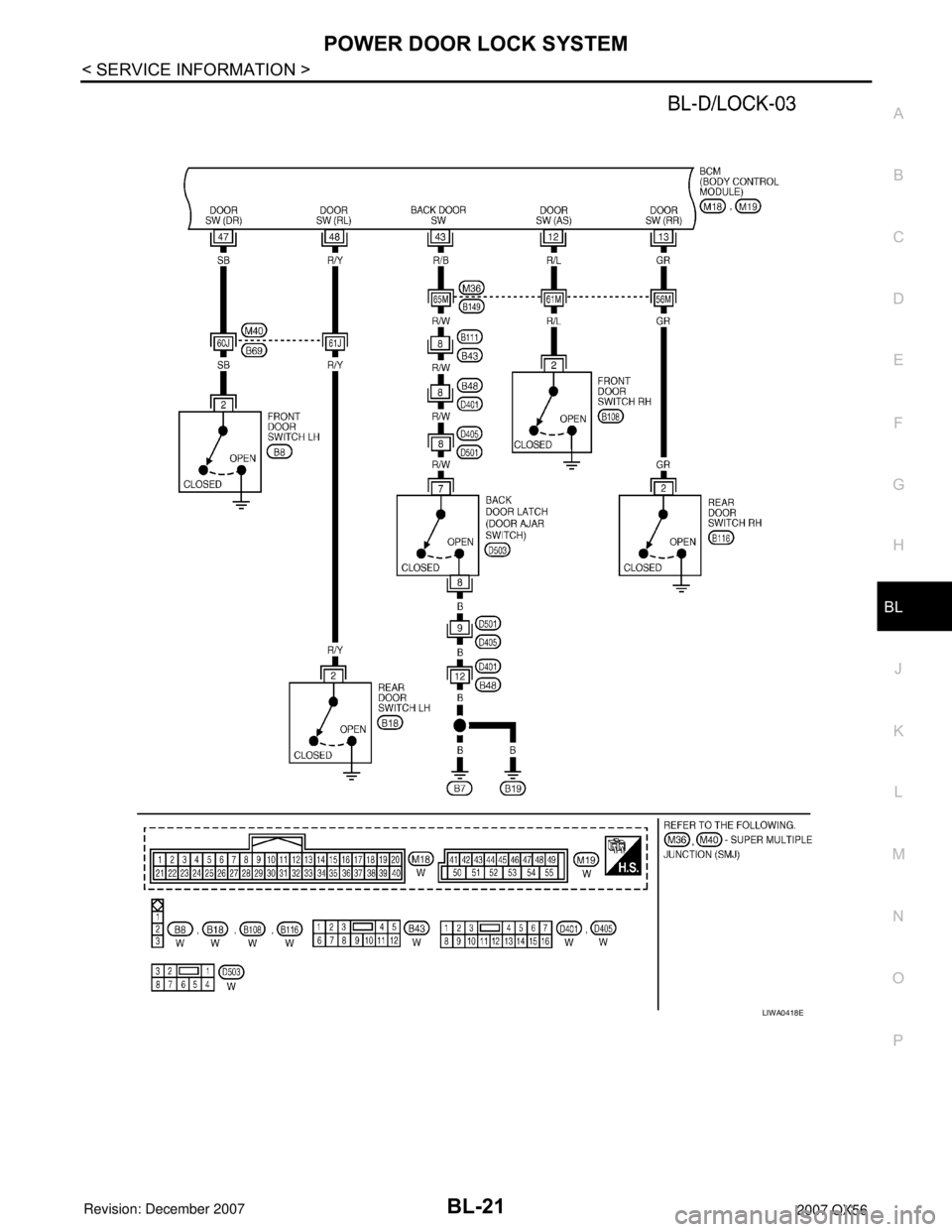

Wiring Diagram - D/LOCK -INFOID:0000000003532898

WIWA0742E

Page 731 of 3061

BL-20

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

WIWA2044E

Page 732 of 3061

POWER DOOR LOCK SYSTEM

BL-21

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

LIWA0418E

Page 733 of 3061

BL-22

< SERVICE INFORMATION >

POWER DOOR LOCK SYSTEM

WIWA2045E