lock INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 1914 of 3061

FRONT FINAL DRIVE ASSEMBLY

FFD-15

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FFD

N

O

P Total Preload Torque

1. Install the differential side shaft and differential side flange if necessary.

CAUTION:

The differential side shaft and differential side flange must be installed in order to measure total

preload torque.

2. Rotate the drive pinion back and forth 2 to 3 times to check for unusual noise and rotation malfunction.

3. Rotate the drive pinion at least 20 times to check for smooth operation of the bearings.

4. Measure total preload torque using Tool.

NOTE:

Total preload torque = Drive pinion bearing preload torque +

Side bearing preload torque

• If the measured value is out of the specification, check and adjust each part. Adjust the drive pinion

bearing preload torque first, then adjust the side bearing preload torque.

Drive Gear Runout

1. Fit a dial indicator to the drive gear back face.

2. Rotate the drive gear to measure runout.

• If the runout is outside of the limit, check the condition of the drive

gear assembly. Foreign material may be caught between the drive

gear and differential case, or the differential case or drive gear may

be deformed.

CAUTION:

Replace drive gear and drive pinion as a set.

Tooth Contact

Tool number : ST3127S000 (J-25765-A)

Total preload torque:

2.98 - 4.76 N·m (0.31 - 0.48 kg-m, 27 - 42 in-lb)

PDIA0697E

If the total preload torque is greater than specification

On drive pinion bearings: Replace the collapsible spacer.

On side bearings: Loosen the side bearing adjuster by the same amount on each

side.

If the total preload torque is less than specification

On drive pinion bearings: Tighten the drive pinion lock nut.

On side bearings: Tighten the side bearing adjuster by the same amount on each

side.

Runout limit: 0.08 mm (0.0031 in) or less

SPD886

Page 1919 of 3061

FFD-20

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

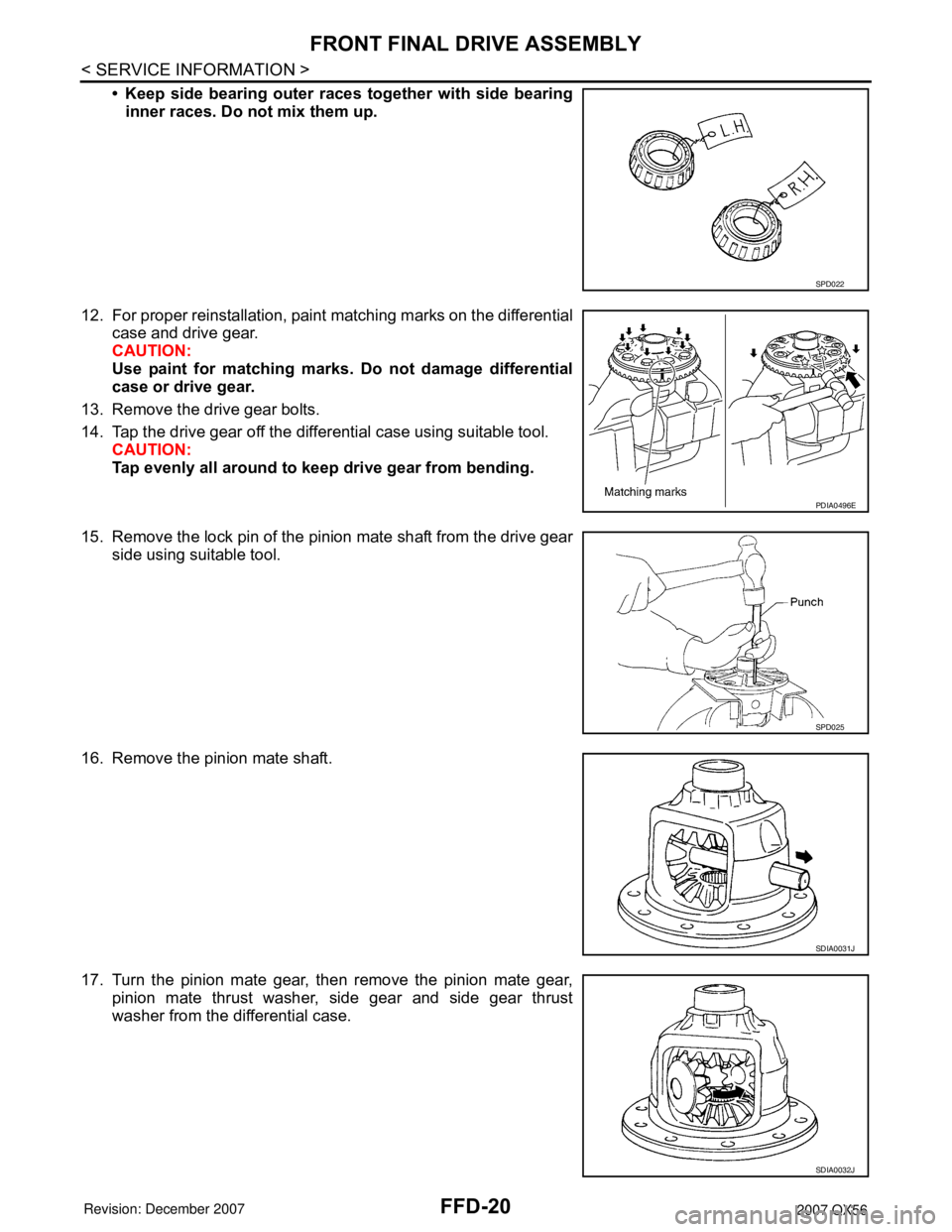

• Keep side bearing outer races together with side bearing

inner races. Do not mix them up.

12. For proper reinstallation, paint matching marks on the differential

case and drive gear.

CAUTION:

Use paint for matching marks. Do not damage differential

case or drive gear.

13. Remove the drive gear bolts.

14. Tap the drive gear off the differential case using suitable tool.

CAUTION:

Tap evenly all around to keep drive gear from bending.

15. Remove the lock pin of the pinion mate shaft from the drive gear

side using suitable tool.

16. Remove the pinion mate shaft.

17. Turn the pinion mate gear, then remove the pinion mate gear,

pinion mate thrust washer, side gear and side gear thrust

washer from the differential case.

SPD022

PDIA0496E

SPD025

SDIA0031J

SDIA0032J

Page 1920 of 3061

FRONT FINAL DRIVE ASSEMBLY

FFD-21

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FFD

N

O

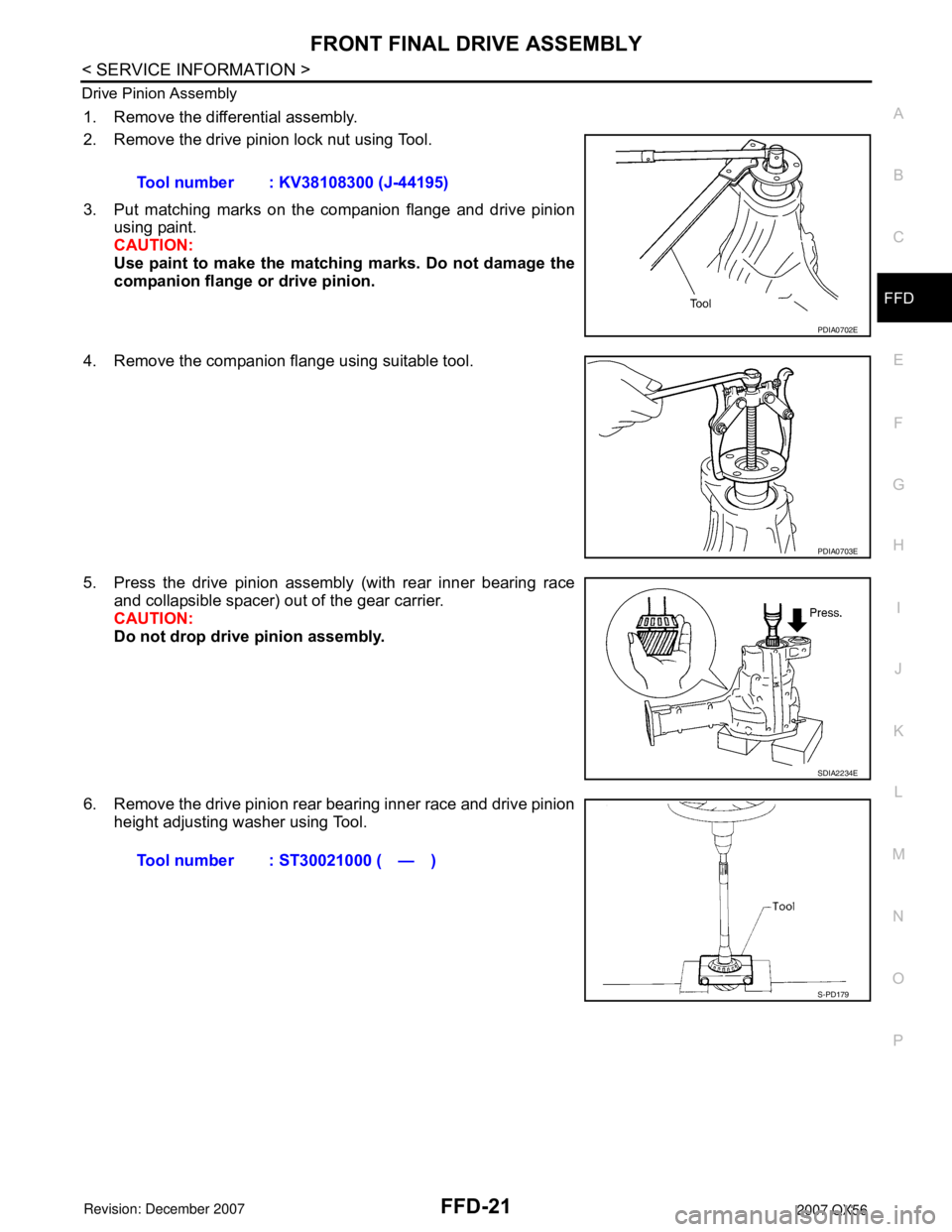

P Drive Pinion Assembly

1. Remove the differential assembly.

2. Remove the drive pinion lock nut using Tool.

3. Put matching marks on the companion flange and drive pinion

using paint.

CAUTION:

Use paint to make the matching marks. Do not damage the

companion flange or drive pinion.

4. Remove the companion flange using suitable tool.

5. Press the drive pinion assembly (with rear inner bearing race

and collapsible spacer) out of the gear carrier.

CAUTION:

Do not drop drive pinion assembly.

6. Remove the drive pinion rear bearing inner race and drive pinion

height adjusting washer using Tool.Tool number : KV38108300 (J-44195)

PDIA0702E

PDIA0703E

SDIA2234E

Tool number : ST30021000 ( — )

S-PD179

Page 1926 of 3061

FRONT FINAL DRIVE ASSEMBLY

FFD-27

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FFD

N

O

P

10. Apply anti-corrosive oil to the threads of the drive pinion and the

seating surface of the new drive pinion lock nut. Then adjust the

drive pinion lock nut tightening torque using Tool A, and check

the drive pinion bearing preload torque using Tool B.

CAUTION:

• Do not reuse drive pinion lock nut.

• Apply anti-corrosive oil to the threads of the drive pinion

and the seating surface of the new drive pinion lock nut.

• Adjust the drive pinion lock nut tightening torque to the

lower limit first. Do not exceed the drive pinion lock nut

specified torque.

• If the drive pinion bearing preload torque exceeds the

specified value, replace collapsible spacer and tighten it

again to adjust. Do not loosen drive pinion lock nut to

adjust the drive pinion bearing preload torque.

• After adjustment, rotate drive pinion back and forth 2 to 3

times to check for unusual noise, rotation malfunction,

and other malfunctions.

11. Check companion flange runout.

12. Install the differential case assembly.

Differential Assembly

1. Install side gear thrust washers with the same thickness as the

ones installed prior to disassembly, or reinstall the old ones on

the side gears.

2. Install the side gears and side gear thrust washers into the dif-

ferential case.

3. Install the pinion mate thrust washers to the two pinion mate

gears. Then install the pinion mate gears with the pinion mate

thrust washers by aligning them in diagonally opposite positions

and rotating them into the differential case.Tool number A: KV38108300 (J-44195)

B: ST3127S000 (J-25765-A)

Drive pinion bearing preload torque:

2.3 - 3.4 N·m (24 - 34 kg-cm, 21 - 30 in-lb)

WDIA0382E

SDIA0193J

SDIA2025E

Page 1927 of 3061

FFD-28

< SERVICE INFORMATION >

FRONT FINAL DRIVE ASSEMBLY

4. Install the pinion mate shaft and align the lock pin hole on the

pinion mate shaft with the lock pin hole on the differential case.

5. Measure the side gear end play. If necessary, select the appro-

priate side gear thrust washers.

6. Drive a new lock pin into the pinion mate shaft until it is flush

with the differential case using suitable tool.

CAUTION:

Do not reuse lock pin.

7. Align the matching mark of the differential case with the mark of

the drive gear, then place the drive gear onto the differential

case.

8. Install and tighten the new drive gear bolts to the specified

torque.

CAUTION:

• Make sure the drive gear back and threaded holes are

clean.

• Do not reuse drive gear bolts.

• Tighten new drive gear bolts in a crisscross pattern.

9. Press the new side bearing inner races to the differential case

using Tools.

CAUTION:

Do not reuse side bearing inner races.

SDIA0195J

SPD030

SDIA2593E

SDIA2239E

Tool number A: KV38100300 (J-25523)

B: ST33081000

SPD353

Page 1934 of 3061

PREPARATION

FL-3

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

FL

N

P O

PREPARATION

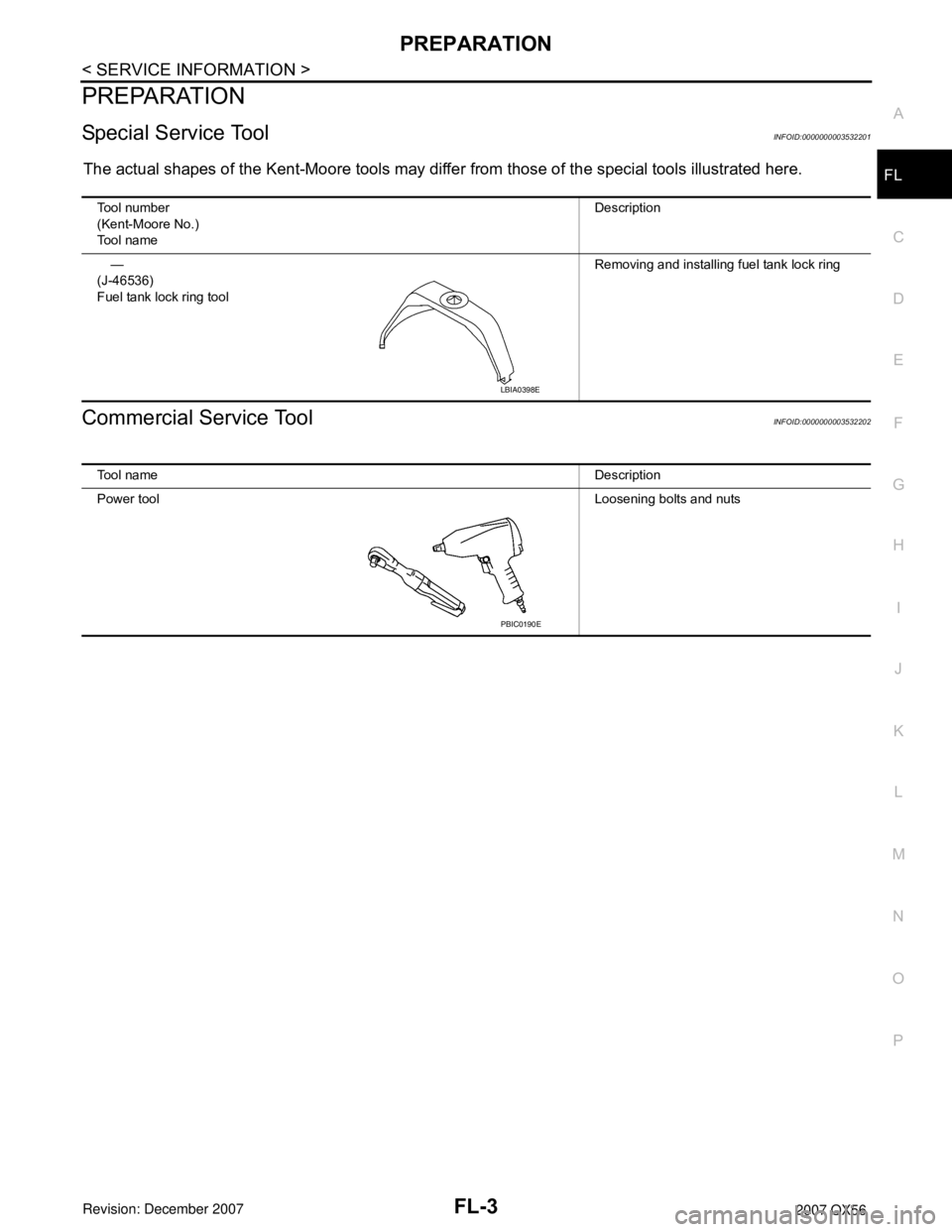

Special Service ToolINFOID:0000000003532201

The actual shapes of the Kent-Moore tools may differ from those of the special tools illustrated here.

Commercial Service ToolINFOID:0000000003532202

Tool number

(Kent-Moore No.)

Tool nameDescription

—

(J-46536)

Fuel tank lock ring toolRemoving and installing fuel tank lock ring

LBIA0398E

Tool nameDescription

Power toolLoosening bolts and nuts

PBIC0190E

Page 1936 of 3061

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-5

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

FL

N

P O

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

Removal and InstallationINFOID:0000000003532205

REMOVAL

WARNING:

Follow the “General Precautions” before working on the fuel system. Refer to GI-3, "

General Precau-

tion" .

1. Remove the fuel filler cap to release the pressure from inside the fuel tank.

2. Check the fuel level on level gauge. If the fuel gauge indicates

more than the level as shown (full or almost full), drain the fuel

from the fuel tank until the fuel gauge indicates the level as

shown, or less.

• If the fuel pump does not operate, use the following procedure

to drain the fuel to the specified level.

a. Insert a suitable hose of less than 15 mm (0.59 in) diameter into

the fuel filler pipe through the fuel filler opening to drain the fuel

from fuel filler pipe.

b. Remove the LH rear wheel and tire. Refer to WT-7, "

Rotation" .

c. Remove the four clips and remove the rear fender protector,

front.

1. Inspection hole cover 2. Inspection hole cover O-ring 3. Lock ring

4. Fuel level sensor, fuel filter, and fuel

pump assembly5. Fuel tank 6. Fuel level sensor, fuel filter, and fuel

pump assembly O-ring

LBIA0381E

WBIA0390E

Page 1937 of 3061

FL-6

< SERVICE INFORMATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

d. Disconnect the fuel filler hose from the fuel filler pipe.

e. Insert a suitable hose into the fuel tank through the fuel filler hose to drain the fuel from the fuel tank.

• As a guide, the fuel level reaches the fuel gauge position as shown, or less, when approximately 14

liters (3 3/4 US gal, 3 1/8 Imp gal) of fuel are drained from the fuel tank.

3. Release the fuel pressure from the fuel lines. Refer to EC-80, "

Fuel Pressure Check" .

4. Disconnect the battery negative terminal.

5. Remove the second row LH seat and the third row LH seat. Refer to SE-89, "

Removal and Installation"

(second row), SE-95, "LH Side Seat" (third row).

6. Remove the second and third row rear seat belt buckles mounted on the floor. Refer to SB-3

.

7. Remove the LH center pillar trim, the LH rear trim panel, and the LH rear side door kick plate and weather

stripping. Refer to EI-34

.

8. Remove the second row rear center console and base, if equipped. Refer to EI-36

.

9. Reposition the floor carpet out of the way to access the inspection hole cover, located under the center LH

rear seat.

10. Remove the inspection hole cover by turning the retainers 90°

degrees clockwise.

• Remove the O-ring.

11. Disconnect the fuel level sensor, fuel filter, and fuel pump

assembly electrical connector, the EVAP hose, and the fuel feed

hose.

LBIA0386E

LBIA0382E

LBIA0383E

Page 1939 of 3061

FL-8

< SERVICE INFORMATION >

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

12. Remove the lock ring using Tool.

13. Remove the fuel level sensor, fuel filter, and fuel pump assem-

bly. Remove and discard the fuel level sensor, fuel filter, and fuel

pump assembly O-ring.

CAUTION:

• Do not bend the float arm during removal.

• Avoid impacts such as dropping when handling the com-

ponents.

INSTALLATION

Installation is in the reverse order of removal.

• For installation, use a new fuel level sensor, fuel filter, and fuel pump assembly O-ring.

• Connect the quick connector as follows:

- Check the connection for any damage or foreign materials.

- Align the connector with the pipe, then insert the connector straight into the pipe until a click is heard.

- After connecting the quick connector, make sure that the connec-

tion is secure by checking as follows:

- Pull the tube and the connector to make sure they are securely

connected.

- Visually inspect the connector to make sure the two retainer tabs

are securely connected.

INSPECTION AFTER INSTALLATION

1. Turn the ignition switch ON but do not start engine, then check the fuel pipes and hose connections for

leaks while applying fuel pressure to the system.

2. Start the engine and rev it above idle speed, then check that there are no fuel leaks at any of the fuel pipe

and hose connections.Tool number : — (J-46536)

LBIA0389E

PBIC1653E

Page 1941 of 3061

FL-10

< SERVICE INFORMATION >

FUEL TANK

FUEL TANK

Removal and InstallationINFOID:0000000003532207

1. Inspection hole cover 2. Inspection hole cover O-ring 3. Lock ring

4. Fuel level sensor, fuel filter, and fuel

pump assembly5. Fuel tank 6. Fuel tank protector

7. Fuel tank protector clips 8. Fuel tank straps 9. Fuel level sensor, fuel filter, and fuel

pump assembly O-ring

10. Fuel filler hose 11. Fuel filler pipe 12. Fuel filler cup

13. Fuel filler hose grommet 14. Fuel filler cap 15. Fuel tank shield

AWBIA0522GB