service INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 340 of 3061

AT-270

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

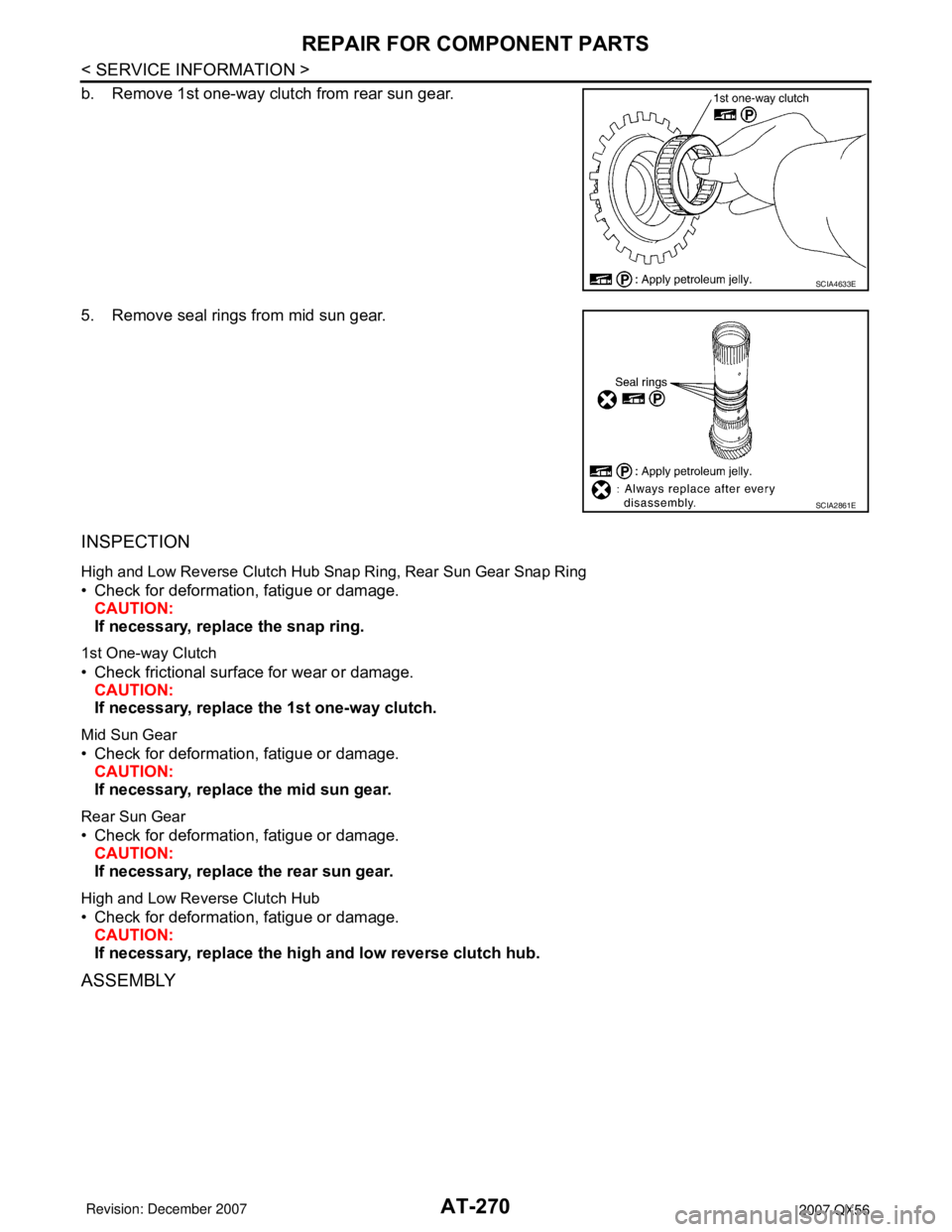

b. Remove 1st one-way clutch from rear sun gear.

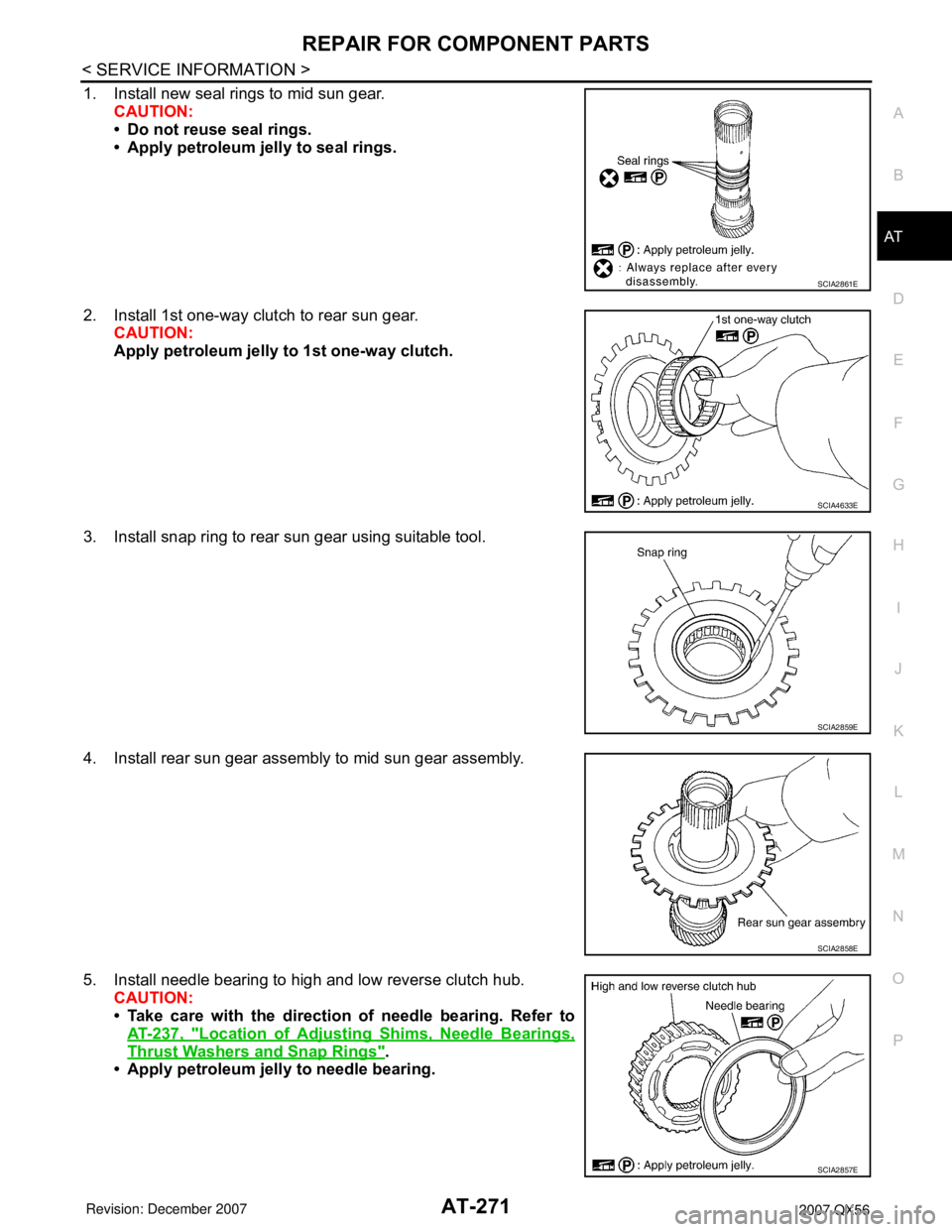

5. Remove seal rings from mid sun gear.

INSPECTION

High and Low Reverse Clutch Hub Snap Ring, Rear Sun Gear Snap Ring

• Check for deformation, fatigue or damage.

CAUTION:

If necessary, replace the snap ring.

1st One-way Clutch

• Check frictional surface for wear or damage.

CAUTION:

If necessary, replace the 1st one-way clutch.

Mid Sun Gear

• Check for deformation, fatigue or damage.

CAUTION:

If necessary, replace the mid sun gear.

Rear Sun Gear

• Check for deformation, fatigue or damage.

CAUTION:

If necessary, replace the rear sun gear.

High and Low Reverse Clutch Hub

• Check for deformation, fatigue or damage.

CAUTION:

If necessary, replace the high and low reverse clutch hub.

ASSEMBLY

SCIA4633E

SCIA2861E

Page 341 of 3061

REPAIR FOR COMPONENT PARTS

AT-271

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

1. Install new seal rings to mid sun gear.

CAUTION:

• Do not reuse seal rings.

• Apply petroleum jelly to seal rings.

2. Install 1st one-way clutch to rear sun gear.

CAUTION:

Apply petroleum jelly to 1st one-way clutch.

3. Install snap ring to rear sun gear using suitable tool.

4. Install rear sun gear assembly to mid sun gear assembly.

5. Install needle bearing to high and low reverse clutch hub.

CAUTION:

• Take care with the direction of needle bearing. Refer to

AT-237, "

Location of Adjusting Shims, Needle Bearings,

Thrust Washers and Snap Rings".

• Apply petroleum jelly to needle bearing.

SCIA2861E

SCIA4633E

SCIA2859E

SCIA2858E

SCIA2857E

Page 342 of 3061

AT-272

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

6. Install high and low reverse clutch hub to mid sun gear assem-

bly.

7. Install snap ring to mid sun gear assembly using suitable tool.

CAUTION:

Do not expand snap ring excessively.

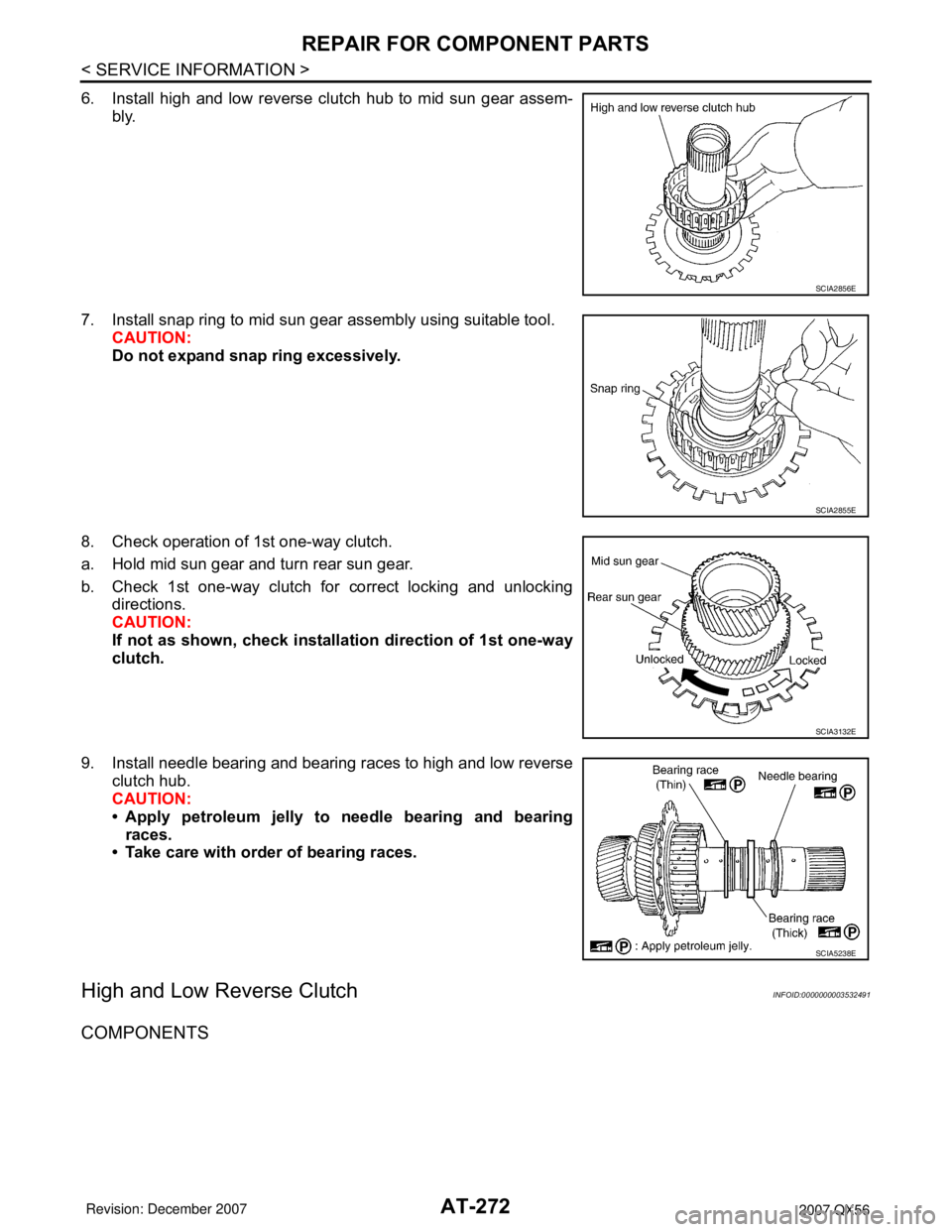

8. Check operation of 1st one-way clutch.

a. Hold mid sun gear and turn rear sun gear.

b. Check 1st one-way clutch for correct locking and unlocking

directions.

CAUTION:

If not as shown, check installation direction of 1st one-way

clutch.

9. Install needle bearing and bearing races to high and low reverse

clutch hub.

CAUTION:

• Apply petroleum jelly to needle bearing and bearing

races.

• Take care with order of bearing races.

High and Low Reverse ClutchINFOID:0000000003532491

COMPONENTS

SCIA2856E

SCIA2855E

SCIA3132E

SCIA5238E

Page 343 of 3061

REPAIR FOR COMPONENT PARTS

AT-273

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

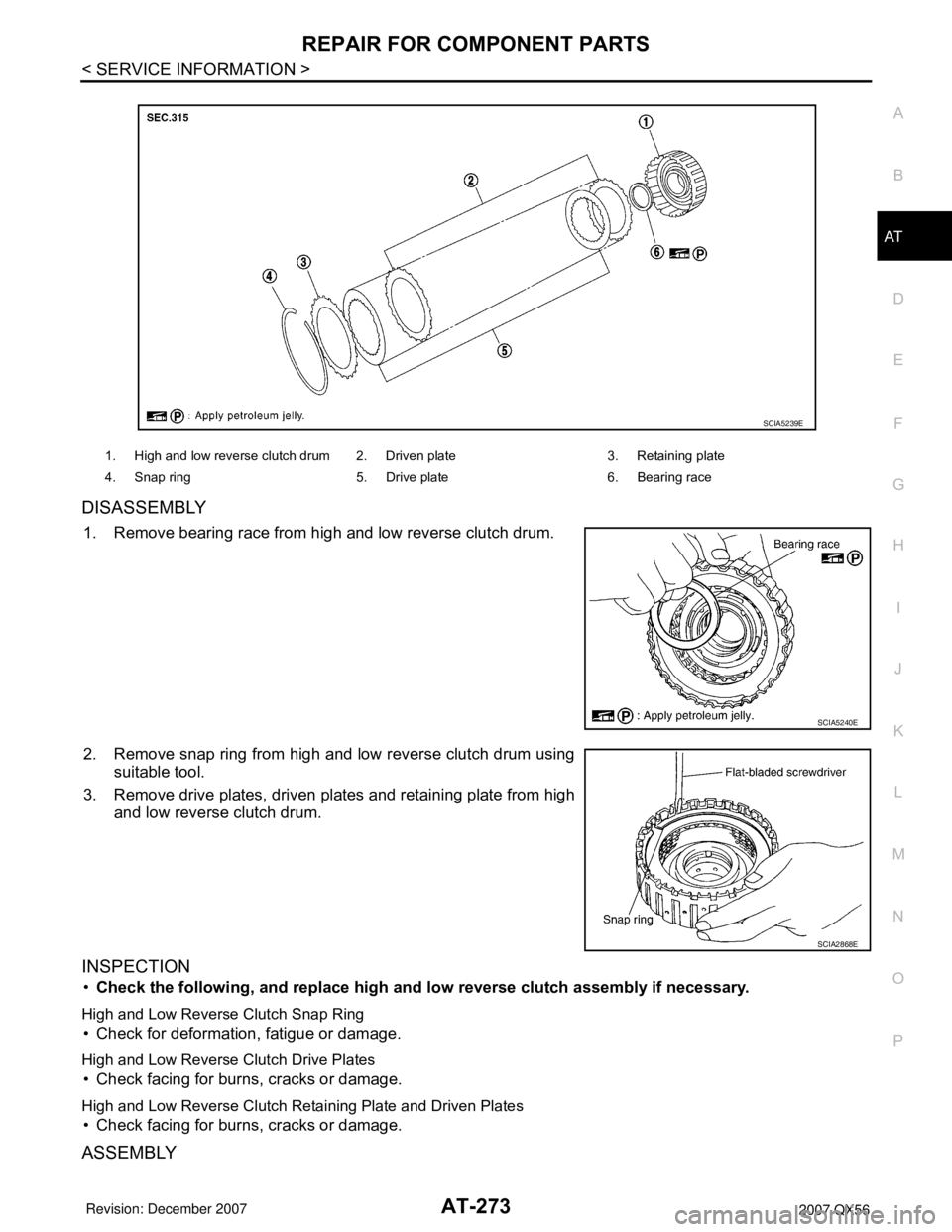

DISASSEMBLY

1. Remove bearing race from high and low reverse clutch drum.

2. Remove snap ring from high and low reverse clutch drum using

suitable tool.

3. Remove drive plates, driven plates and retaining plate from high

and low reverse clutch drum.

INSPECTION

•Check the following, and replace high and low reverse clutch assembly if necessary.

High and Low Reverse Clutch Snap Ring

• Check for deformation, fatigue or damage.

High and Low Reverse Clutch Drive Plates

• Check facing for burns, cracks or damage.

High and Low Reverse Clutch Retaining Plate and Driven Plates

• Check facing for burns, cracks or damage.

ASSEMBLY

1. High and low reverse clutch drum 2. Driven plate 3. Retaining plate

4. Snap ring 5. Drive plate 6. Bearing race

SCIA5239E

SCIA5240E

SCIA2868E

Page 344 of 3061

AT-274

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

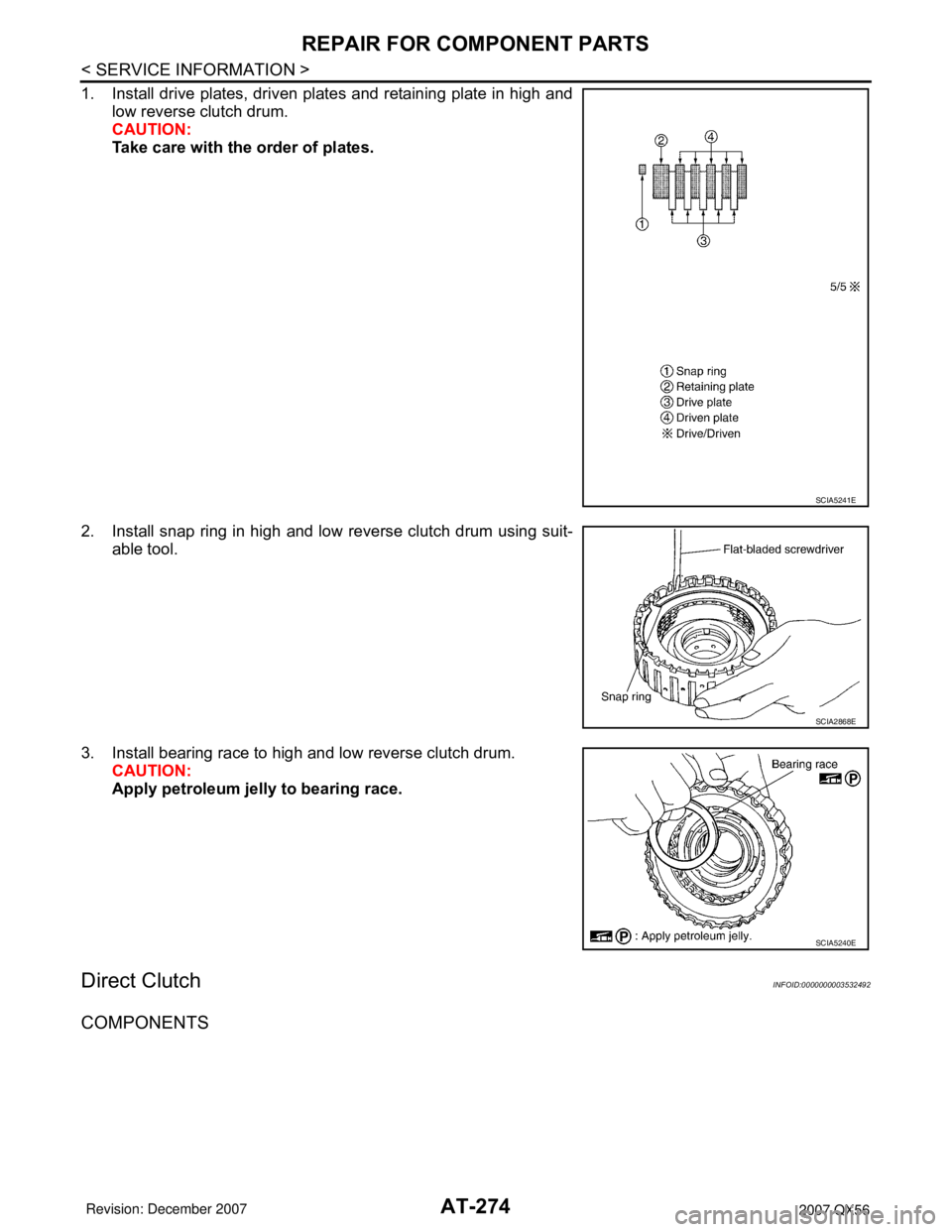

1. Install drive plates, driven plates and retaining plate in high and

low reverse clutch drum.

CAUTION:

Take care with the order of plates.

2. Install snap ring in high and low reverse clutch drum using suit-

able tool.

3. Install bearing race to high and low reverse clutch drum.

CAUTION:

Apply petroleum jelly to bearing race.

Direct ClutchINFOID:0000000003532492

COMPONENTS

SCIA5241E

SCIA2868E

SCIA5240E

Page 345 of 3061

REPAIR FOR COMPONENT PARTS

AT-275

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

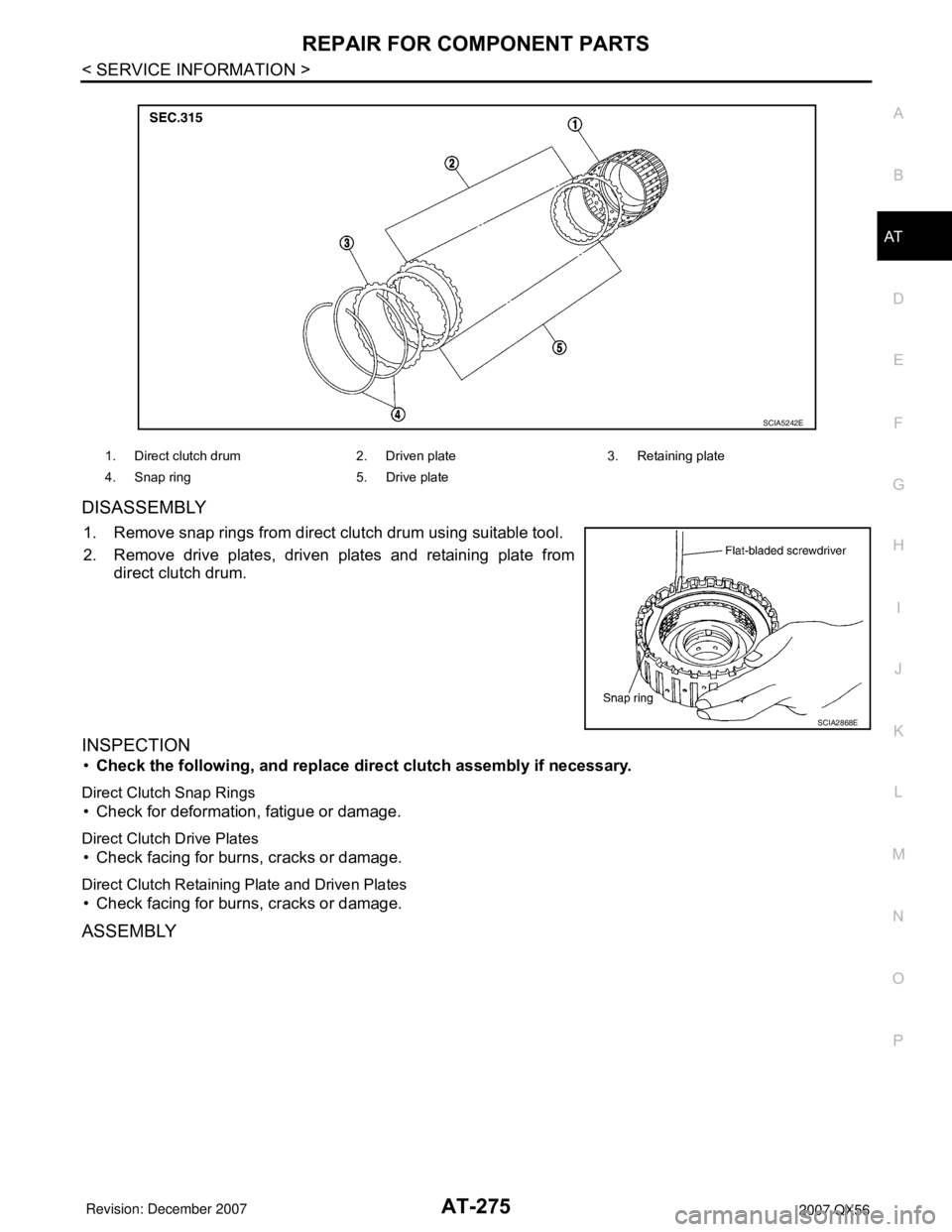

DISASSEMBLY

1. Remove snap rings from direct clutch drum using suitable tool.

2. Remove drive plates, driven plates and retaining plate from

direct clutch drum.

INSPECTION

•Check the following, and replace direct clutch assembly if necessary.

Direct Clutch Snap Rings

• Check for deformation, fatigue or damage.

Direct Clutch Drive Plates

• Check facing for burns, cracks or damage.

Direct Clutch Retaining Plate and Driven Plates

• Check facing for burns, cracks or damage.

ASSEMBLY

1. Direct clutch drum 2. Driven plate 3. Retaining plate

4. Snap ring 5. Drive plate

SCIA5242E

SCIA2868E

Page 346 of 3061

AT-276

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

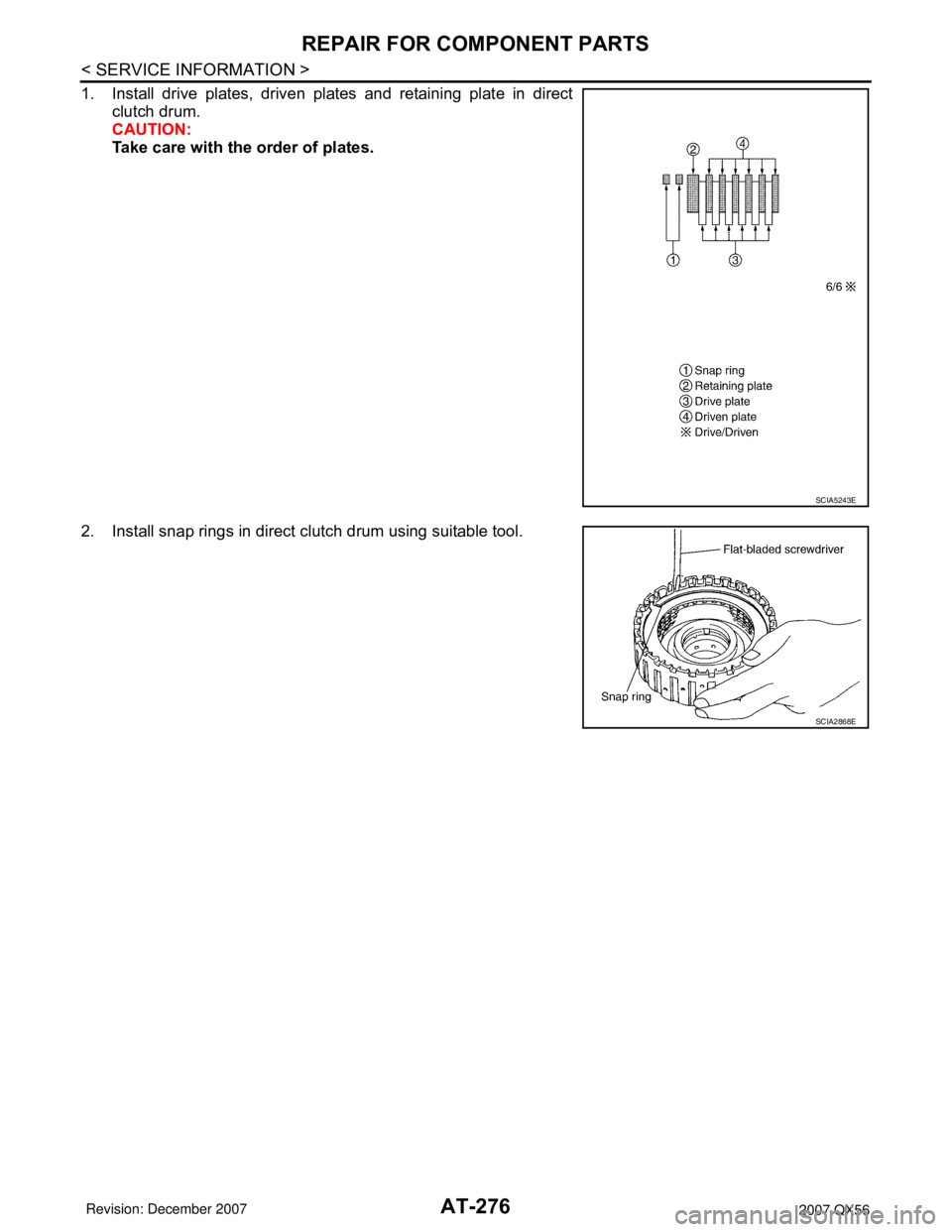

1. Install drive plates, driven plates and retaining plate in direct

clutch drum.

CAUTION:

Take care with the order of plates.

2. Install snap rings in direct clutch drum using suitable tool.

SCIA5243E

SCIA2868E

Page 347 of 3061

ASSEMBLY

AT-277

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

ASSEMBLY

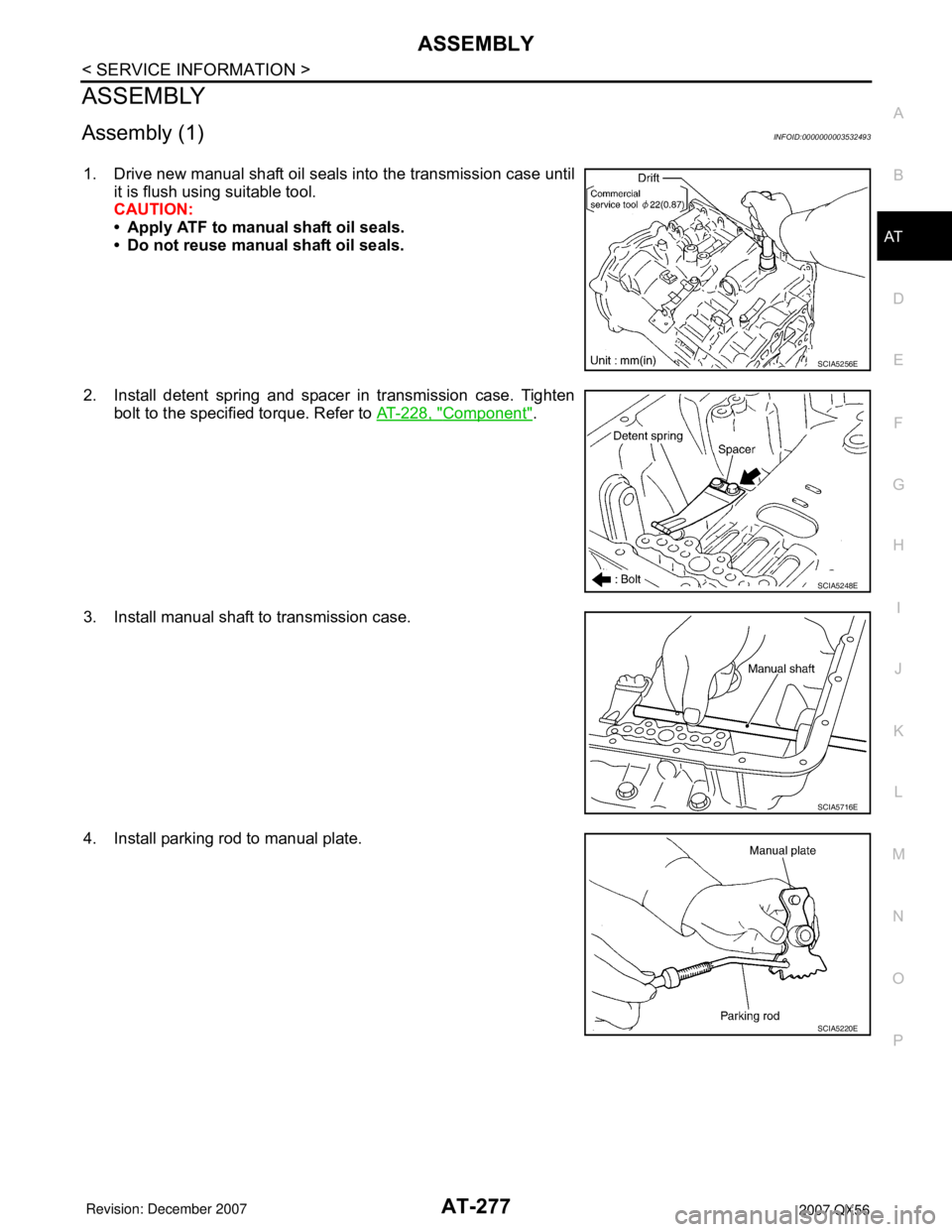

Assembly (1)INFOID:0000000003532493

1. Drive new manual shaft oil seals into the transmission case until

it is flush using suitable tool.

CAUTION:

• Apply ATF to manual shaft oil seals.

• Do not reuse manual shaft oil seals.

2. Install detent spring and spacer in transmission case. Tighten

bolt to the specified torque. Refer to AT-228, "

Component".

3. Install manual shaft to transmission case.

4. Install parking rod to manual plate.

SCIA5256E

SCIA5248E

SCIA5716E

SCIA5220E

Page 348 of 3061

AT-278

< SERVICE INFORMATION >

ASSEMBLY

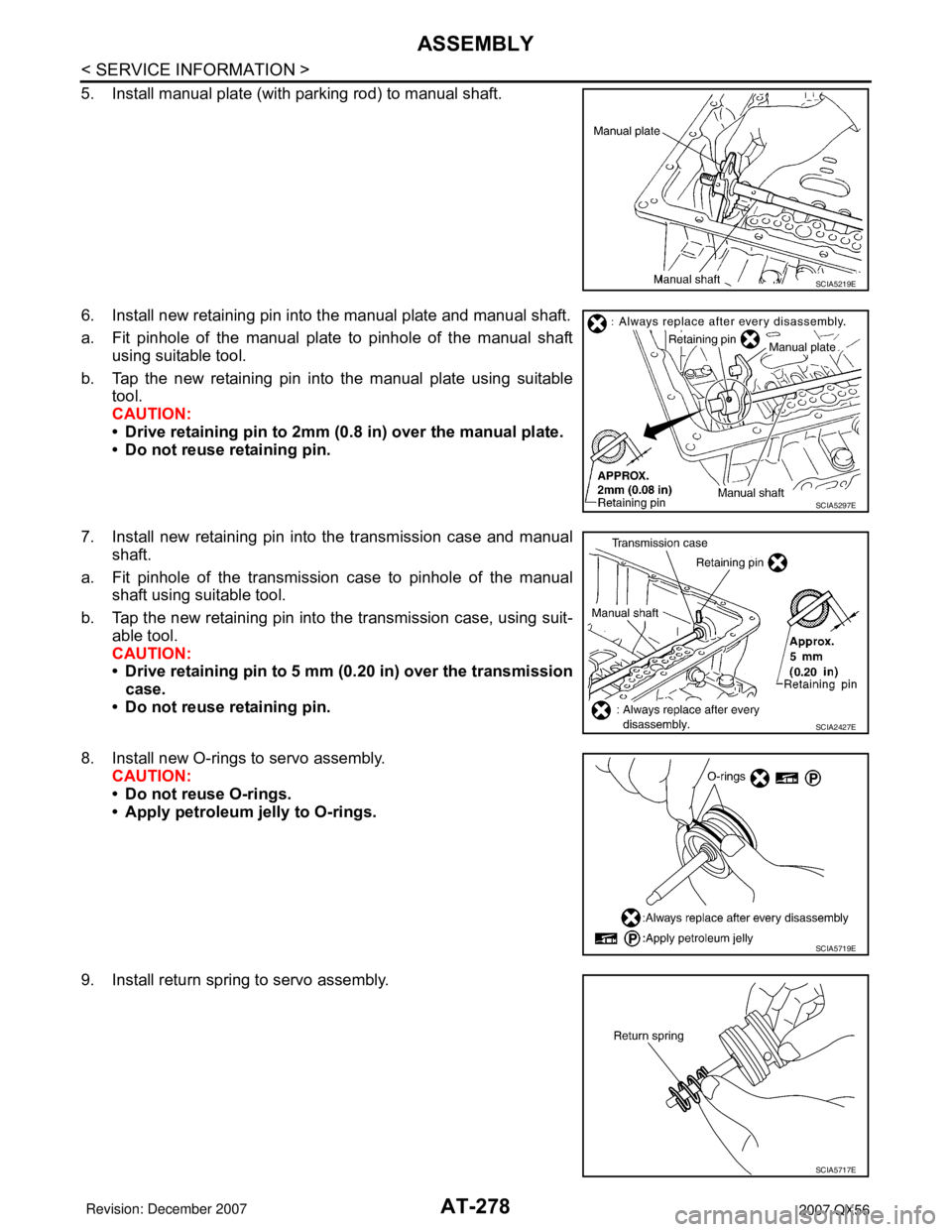

5. Install manual plate (with parking rod) to manual shaft.

6. Install new retaining pin into the manual plate and manual shaft.

a. Fit pinhole of the manual plate to pinhole of the manual shaft

using suitable tool.

b. Tap the new retaining pin into the manual plate using suitable

tool.

CAUTION:

• Drive retaining pin to 2mm (0.8 in) over the manual plate.

• Do not reuse retaining pin.

7. Install new retaining pin into the transmission case and manual

shaft.

a. Fit pinhole of the transmission case to pinhole of the manual

shaft using suitable tool.

b. Tap the new retaining pin into the transmission case, using suit-

able tool.

CAUTION:

• Drive retaining pin to 5 mm (0.20 in) over the transmission

case.

• Do not reuse retaining pin.

8. Install new O-rings to servo assembly.

CAUTION:

• Do not reuse O-rings.

• Apply petroleum jelly to O-rings.

9. Install return spring to servo assembly.

SCIA5219E

SCIA5297E

SCIA2427E

SCIA5719E

SCIA5717E

Page 349 of 3061

ASSEMBLY

AT-279

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

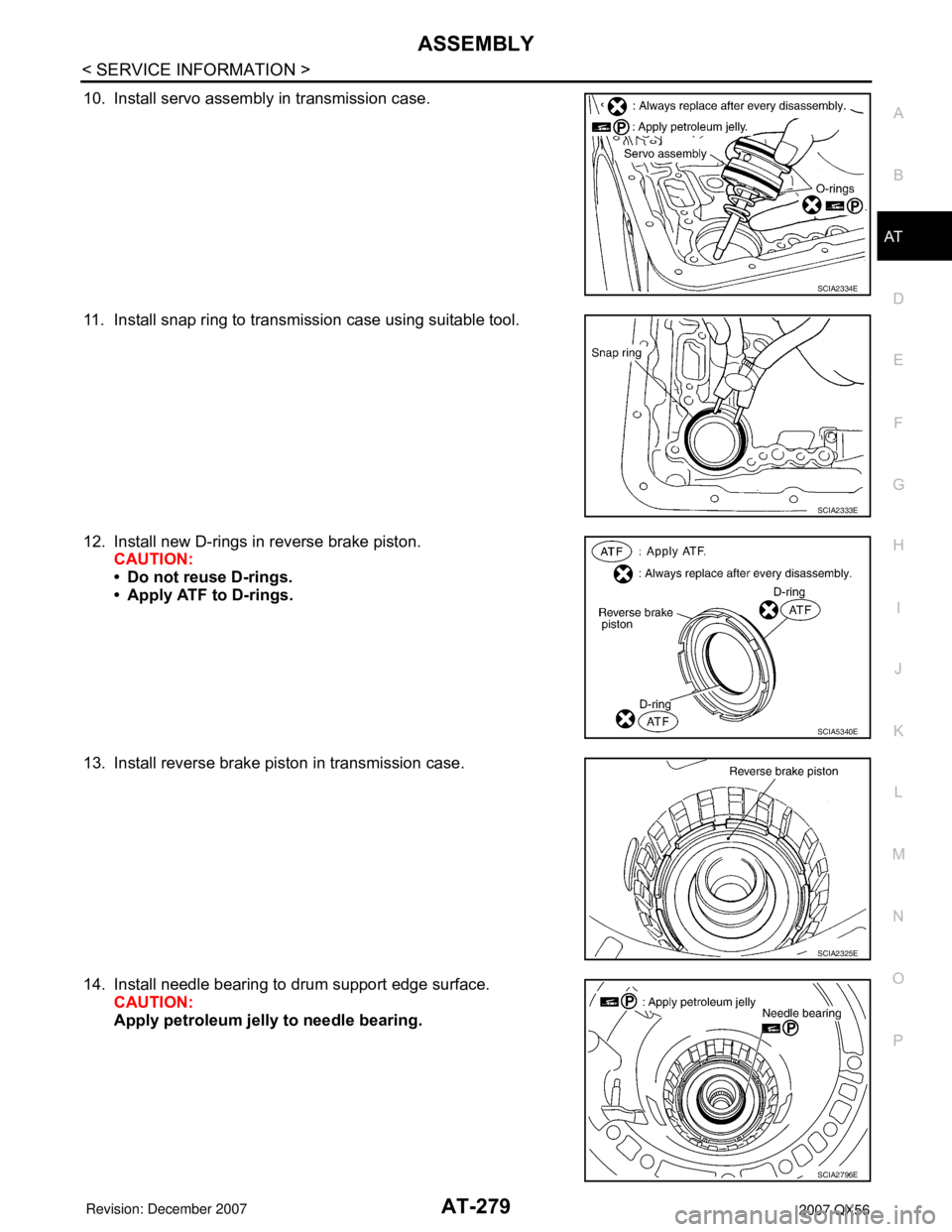

10. Install servo assembly in transmission case.

11. Install snap ring to transmission case using suitable tool.

12. Install new D-rings in reverse brake piston.

CAUTION:

• Do not reuse D-rings.

• Apply ATF to D-rings.

13. Install reverse brake piston in transmission case.

14. Install needle bearing to drum support edge surface.

CAUTION:

Apply petroleum jelly to needle bearing.

SCIA2334E

SCIA2333E

SCIA5340E

SCIA2325E

SCIA2796E