turn signal INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2736 of 3061

SE-64

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

Check continuity between door mirror remote control switch termi-

nals as follows.

OK or NG

OK >> Check the condition of the harness and the connector.

NG >> Replace door mirror remote control switch.

Door Mirror Remote Control Switch (Mirror Switch) Circuit InspectionINFOID:0000000003533196

1.CHECK DOOR MIRROR REMOTE CONTROL SWITCH (MIRROR SWITCH) SIGNAL

With CONSULT-II

Check the operation on “MIR CON SW-UP/DN” and

“MIR CON SW-RH/LH” in the DATA MONITOR.

Without CONSULT-II

1. Turn ignition switch to ACC.

2. Check voltage between automatic drive positioner control unit

connector and ground.

OK or NG

OK >> Door mirror remote control switch (mirror switch) circuit is OK.

NG >> GO TO 2.

2.CHECK HARNESS CONTINUITY

Terminals Condition Continuity

3

13Changeover switch RIGHT position Yes

Other than above No

2Changeover switch LEFT position Yes

Other than above No

LIIA2052E

Monitor item [OPERATION or

UNIT]Contents

MIR CON SW-UP “ON/OFF”ON/OFF status judged from the door mirror

switch (UP) signal is displayed.

MIR CON SW-DN “ON/OFF”ON/OFF status judged from the door mirror

switch (DOWN) signal is displayed.

MIR CON SW-RH “ON/OFF”ON/OFF status judged from the door mirror

switch (RIGHT) signal is displayed.

MIR CON SW-LH “ON/OFF”ON/OFF status judged from the door mirror

switch (LEFT) signal is displayed.

PIIA0199E

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

M333

GroundMirror switch UP operation 0

Other than above 5

4Mirror switch LEFT operation 0

Other than above 5

19Mirror switch DOWN operation 0

Other than above 5

20Mirror switch RIGHT operation 0

Other than above 5

PIIA4771E

Page 2738 of 3061

SE-66

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

2.CHECK DOOR MIRROR REMOTE CONTROL SWITCH (CHANGEOVER SWITCH)

Check continuity between door mirror remote control switch termi-

nals as follows.

OK or NG

OK >> Check the condition of the harness and the connector.

NG >> Replace door mirror remote control switch.

Seat Memory Switch Circuit InspectionINFOID:0000000003533198

1.CHECK FUNCTION

With CONSULT-II

With “SET SW, MEMORY SW1, MEMORY SW2” on the DATA

MONITOR, operate the switch to check ON/OFF operation.

Without CONSULT-II

GO TO 2.

OK or NG

OK >> Seat memory switch circuit is OK.

NG >> GO TO 2.

2.CHECK SEAT MEMORY SWITCH

1. Turn ignition switch OFF.

2. Disconnect seat memory switch.

3. Operate the setting switch and seat memory switch.

4. Check continuity between seat memory switch terminals as fol-

lows.

Terminals Condition Continuity

3

13Changeover switch RIGHT position Yes

Other than above No

2Changeover switch LEFT position Yes

Other than above No

LIIA2052E

Monitor item [OPERATION or

UNIT]Contents

MEMORY SW1 “ON/OFF”ON/OFF status judged from the seat

memory switch 1 signal is displayed.

MEMORY SW2 “ON/OFF”ON/OFF status judged from the seat

memory switch 2 signal is displayed.

SET SW “ON/OFF”ON/OFF status judged from the setting

switch signal is displayed.

PIIA0309E

LIIA1020E

Page 2740 of 3061

SE-68

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

With “MEMORY SW INDCTR” in ACTIVE TEST, check operation.

Without CONSULT-II

GO TO 2.

OK or NG

OK >> Seat memory switch indicator lamp circuit is OK.

NG >> GO TO 2.

2.CHECK SEAT MEMORY SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect seat memory switch.

3. Check voltage between seat memory switch connector D5 ter-

minal 5 and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK SEAT MEMORY INDICATOR CIRCUIT HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit.

3. Check continuity between automatic drive positioner control unit

connector M33 terminals 12, 13 and seat memory switch con-

nector D5 terminals 6, 7.

4. Check continuity between automatic drive positioner control unit

connector M33 terminals 12, 13 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK SEAT MEMORY SWITCH INDICATOR SIGNAL

1. Connect seat memory switch.

2. Turn ignition switch ON.

3. Check voltage between automatic drive positioner control unit

connector M33 terminals 12, 13 and ground.

OK or NG

OK >> Replace automatic drive positioner control unit.

NG >> Replace seat memory switch.

Te s t i t e m D e s c r i p t i o n

MEMORY SW INDCTRThe memory switch indicator is lit by receiving the

drive signal.

PIIA0319E

5 - Ground : Battery voltage

PIIA4595E

12 - 6 : Continuity should exist.

13 - 7 : Continuity should exist.

12 - Ground : Continuity should not exist.

13 - Ground : Continuity should not exist.

LIIA1022E

12 - Ground : Battery voltage

13 - Ground : Battery voltage

LIIA1134E

Page 2742 of 3061

SE-70

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

Check that when the A/T selector lever is in P position, “DETENT

SW” on the DATA MONITOR becomes OFF.

Without CONSULT-II

GO TO 2.

OK or NG

OK >> A/T device (park position switch) circuit is OK.

NG >> GO TO 2.

2.CHECK A/T DEVICE (PARK POSITION SWITCH) HARNESS

1. Turn ignition switch OFF.

2. Disconnect A/T device and driver seat control unit.

3. Check continuity between A/T device connector M203 terminal 6

and driver seat control unit connector P2 terminal 21.

4. Check continuity between A/T device connector M203 terminal 6

and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

3.CHECK PARK POSITION SWITCH

Check continuity between A/T device (park position switch) terminals

as follows.

OK or NG

OK >> A/T device is OK.

NG >> Replace A/T device.

Steering Wheel Tilt Switch Circuit InspectionINFOID:0000000003533202

1.CHECK FUNCTION

With CONSULT-II

With “TILT SW-UP, TILT SW-DOWN” on the DATA MONITOR, oper-

ate the ADP steering wheel tilt switch to check ON/OFF operation.

Monitor item

[OPERATION or UNIT]Contents

DETENT SW“ON/

OFF”The A/T selector lever position “P position (OFF)/other

than P position (ON)” judged from the park position switch

signal is displayed.

PIIA0291E

6 - 21 : Continuity should exist.

6 - Ground : Continuity should not exist.

LIIA1024E

Terminals Condition Continuity

56P position No

Other than P position Yes

LIIA1491E

Monitor item [OPERATION or

UNIT]Contents

TILT SW-UP “ON/OFF”Operation (ON)/open (OFF) status

judged from the tilt switch (FR) signal is

displayed.

TILT SW-DOWN “ON/OFF”Operation (ON)/open (OFF) status

judged from the tilt switch (RR) signal is

displayed.

PIIA0315E

Page 2745 of 3061

AUTOMATIC DRIVE POSITIONER

SE-73

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

SE

N

O

P

UART Communication Line Circuit InspectionINFOID:0000000003533204

1.CHECK UART LINE INPUT/OUTPUT SIGNAL 1

1. Turn ignition switch OFF.

2. Check signal between driver seat control unit connector and

ground, with oscilloscope.

OK or NG

OK >> GO TO 2.

NG >> Check the following.

• When voltage wave form does not appear with a constant voltage (approx. 5V), replace driver

seat control unit.

• When voltage wave form does not appear with a constant voltage (approx. 0V), replace auto-

matic driver seat control unit.

2.CHECK UART LINE INPUT/OUTPUT SIGNAL 2

Check signal between automatic drive positioner control unit con-

nector ground, with oscilloscope.

OK or NG

OK >> GO TO 3.

NG >> Check the following.

• When voltage wave form does not appear with a constant voltage (approx. 5V), replace auto-

matic drive positioner control unit.

• When voltage wave form does not appear with a constant voltage (approx. 0V), replace driver

seat control unit.

3.CHECK UART LINE HARNESS

ConnectorTe r m i n a l s

Condition Signal

(+) (-)

P2 17 GroundPedal ad-

justing

switch ON

(FOR-

WARD or

BACK-

WARD op-

eration)

PIIA4599E

PIIA4814E

ConnectorTe r m i n a l s

Condition Signal

(+) (-)

M33 10 GroundPedal ad-

justing

switch ON

(FOR-

WARD or

BACK-

WARD op-

eration)

PIIA4816E

PIIA4813E

Page 2788 of 3061

SRS-18

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

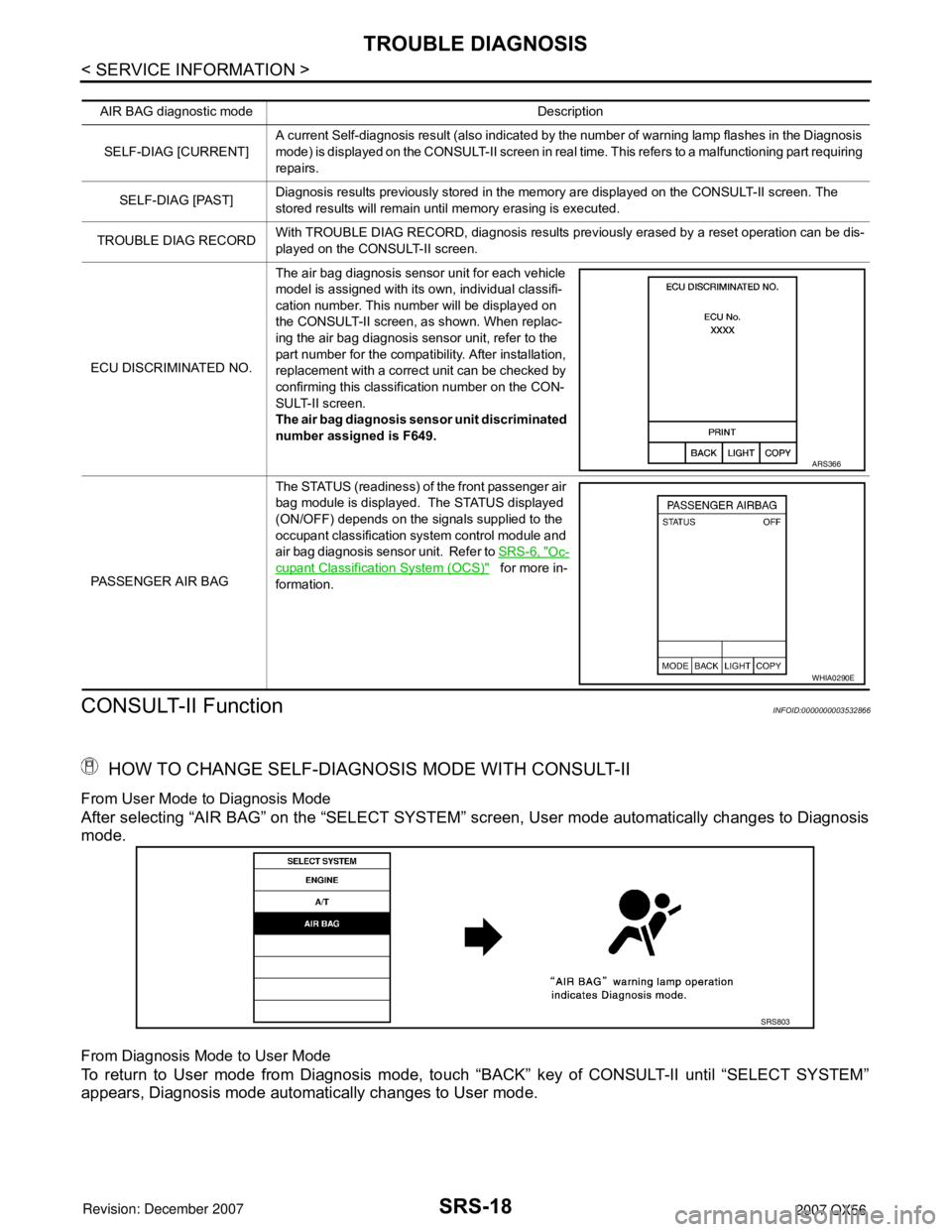

CONSULT-II Function

INFOID:0000000003532866

HOW TO CHANGE SELF-DIAGNOSIS MODE WITH CONSULT-II

From User Mode to Diagnosis Mode

After selecting “AIR BAG” on the “SELECT SYSTEM” screen, User mode automatically changes to Diagnosis

mode.

From Diagnosis Mode to User Mode

To return to User mode from Diagnosis mode, touch “BACK” key of CONSULT-II until “SELECT SYSTEM”

appears, Diagnosis mode automatically changes to User mode.

AIR BAG diagnostic mode Description

SELF-DIAG [CURRENT]A current Self-diagnosis result (also indicated by the number of warning lamp flashes in the Diagnosis

mode) is displayed on the CONSULT-II screen in real time. This refers to a malfunctioning part requiring

repairs.

SELF-DIAG [PAST]Diagnosis results previously stored in the memory are displayed on the CONSULT-II screen. The

stored results will remain until memory erasing is executed.

TROUBLE DIAG RECORDWith TROUBLE DIAG RECORD, diagnosis results previously erased by a reset operation can be dis-

played on the CONSULT-II screen.

ECU DISCRIMINATED NO.The air bag diagnosis sensor unit for each vehicle

model is assigned with its own, individual classifi-

cation number. This number will be displayed on

the CONSULT-II screen, as shown. When replac-

ing the air bag diagnosis sensor unit, refer to the

part number for the compatibility. After installation,

replacement with a correct unit can be checked by

confirming this classification number on the CON-

SULT-II screen.

The air bag diagnosis sensor unit discriminated

number assigned is F649.

PASSENGER AIR BAGThe STATUS (readiness) of the front passenger air

bag module is displayed. The STATUS displayed

(ON/OFF) depends on the signals supplied to the

occupant classification system control module and

air bag diagnosis sensor unit. Refer to SRS-6, "

Oc-

cupant Classification System (OCS)" for more in-

formation.

ARS366

WHIA0290E

SRS803

Page 2807 of 3061

SPIRAL CABLE

SRS-37

< SERVICE INFORMATION >

C

D

E

F

G

I

J

K

L

MA

B

SRS

N

O

P

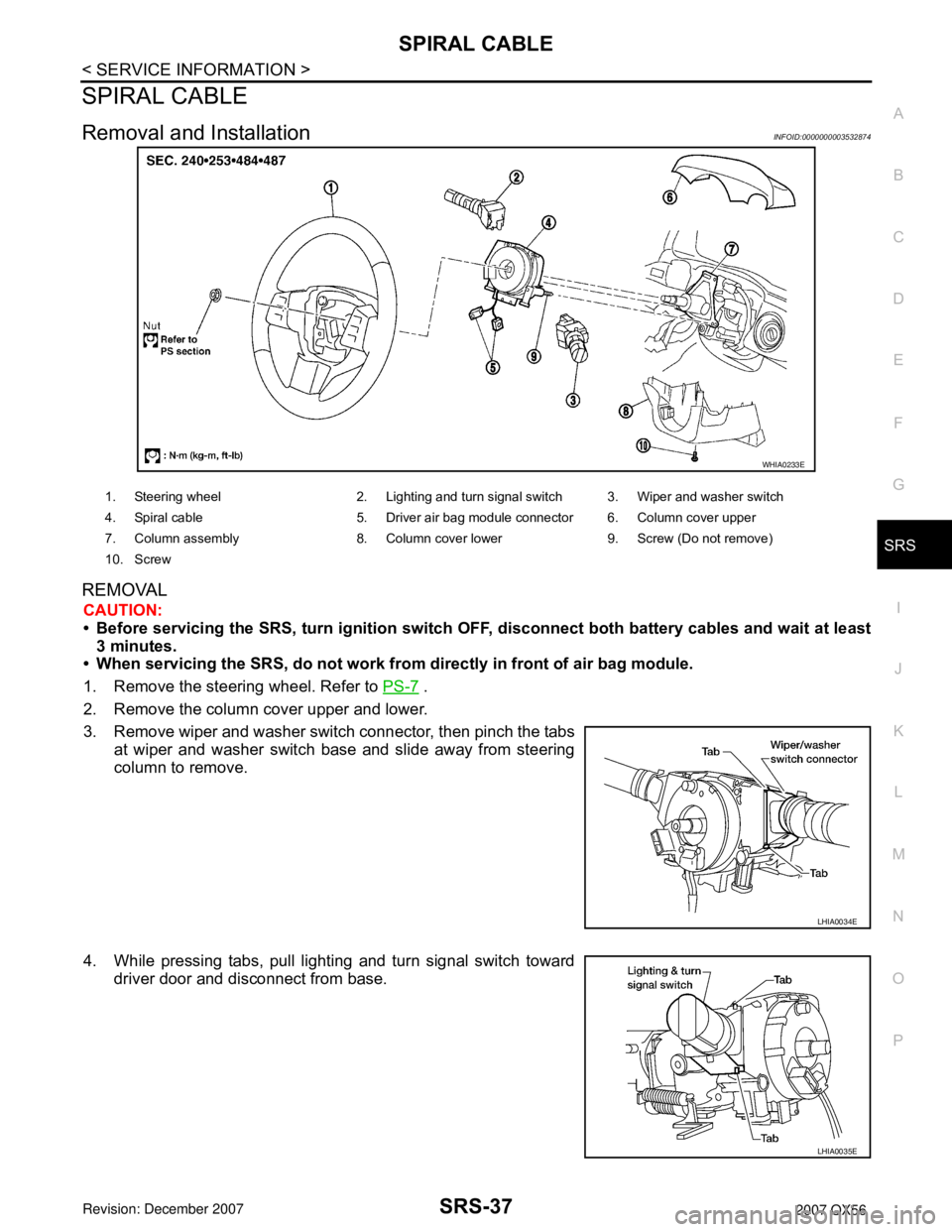

SPIRAL CABLE

Removal and InstallationINFOID:0000000003532874

REMOVAL

CAUTION:

• Before servicing the SRS, turn ignition switch OFF, disconnect both battery cables and wait at least

3 minutes.

• When servicing the SRS, do not work from directly in front of air bag module.

1. Remove the steering wheel. Refer to PS-7

.

2. Remove the column cover upper and lower.

3. Remove wiper and washer switch connector, then pinch the tabs

at wiper and washer switch base and slide away from steering

column to remove.

4. While pressing tabs, pull lighting and turn signal switch toward

driver door and disconnect from base.

WHIA0233E

1. Steering wheel 2. Lighting and turn signal switch 3. Wiper and washer switch

4. Spiral cable 5. Driver air bag module connector 6. Column cover upper

7. Column assembly 8. Column cover lower 9. Screw (Do not remove)

10. Screw

LHIA0034E

LHIA0035E

Page 2823 of 3061

TF-1

DRIVELINE/AXLE

C

E

F

G

H

I

J

K

L

M

SECTION TF

A

B

TF

N

O

P

CONTENTS

TRANSFER

SERVICE INFORMATION ............................3

PRECAUTIONS ...................................................3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

3

Precaution for Transfer Assembly and Transfer

Control Unit Replacement .........................................

3

Precaution .................................................................4

Service Notice ...........................................................4

PREPARATION ...................................................6

Special Service Tool .................................................6

Commercial Service Tool ..........................................9

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ............................

10

NVH Troubleshooting Chart ....................................10

TRANSFER FLUID .............................................11

Replacement ...........................................................11

Inspection ................................................................11

ALL-MODE 4WD SYSTEM ................................12

Cross-Sectional View ..............................................12

Power Transfer ........................................................12

System Description .................................................14

Schematic ...............................................................19

CAN Communication ...............................................20

TROUBLE DIAGNOSIS .....................................21

How to Perform Trouble Diagnosis .........................21

Location of Electrical Parts ......................................22

Circuit Diagram .......................................................23

Wiring Diagram - T/F - .............................................24

Inspections Before Trouble Diagnosis ....................31

Trouble Diagnosis Chart by Symptom ....................34

Transfer Control Unit Input/Output Signal Refer-

ence Value ..............................................................

35

CONSULT-II Function (ALL MODE AWD/4WD) .....42

Self-Diagnosis Procedure .......................................48

TROUBLE DIAGNOSIS FOR SYSTEM ............51

Power Supply Circuit for Transfer Control Unit ........51

Transfer Control Unit ...............................................53

Output Shaft Revolution Signal (TCM) ....................53

Vehicle Speed Sensor (ABS) ..................................54

Neutral-4LO Switch .................................................54

4WD Shift Switch .....................................................57

Wait Detection Switch ..............................................60

PNP Switch Signal (TCM) .......................................63

Actuator Motor .........................................................64

Actuator Position Switch ..........................................69

Transfer Control Device ...........................................72

Engine Speed Signal (ECM) ....................................76

Clutch Pressure Solenoid ........................................76

2-4WD Solenoid ......................................................80

Transfer Motor .........................................................84

Transfer Fluid Temperature .....................................90

Clutch Pressure Switch ...........................................92

Line Pressure Switch ...............................................94

Throttle Position Signal (ECM) ................................97

ABS Operation Signal (ABS) ...................................97

VDC Operation Signal (ABS) ...................................98

TCS Operation Signal (ABS) ...................................98

CAN Communication Line .......................................99

ATP Switch ..............................................................99

TROUBLE DIAGNOSIS FOR SYMPTOMS ....102

4WD Shift Indicator Lamp and 4LO Indicator

Lamp Do Not Turn ON ...........................................

102

4WD Warning Lamp Does Not Turn ON ...............104

4WD Shift Indicator Lamp or 4LO Indicator Lamp

Does Not Change ..................................................

107

ATP Warning Lamp Turns ON ...............................109

4LO Indicator Lamp Repeats Flashing ..................110

4WD Warning Lamp Flashes Rapidly ....................111

4WD Warning Lamp Flashes Slowly .....................112

Heavy Tight-corner Braking Symptom Occurs ......113

4WD System Does Not Operate ............................114

TRANSFER CONTROL UNIT .........................115

Removal and Installation .......................................115

Page 2826 of 3061

TF-4

< SERVICE INFORMATION >

PRECAUTIONS

Precaution

INFOID:0000000003532508

•Before connecting or disconnecting the transfer control unit

harness connector, turn ignition switch “OFF” and disconnect

battery ground cable. Failure to do so may damage the trans-

fer control unit. Battery voltage is applied to transfer control

unit even if ignition switch is turned “OFF”.

•When connecting or disconnecting pin connectors into or

from transfer control unit, take care not to damage pin termi-

nals (bend or break).

When connecting pin connectors make sure that there are not

any bends or breaks on transfer control unit pin terminals.

•Before replacing transfer control unit, perform transfer con-

trol unit input/output signal inspection and make sure transfer

control unit functions properly. Refer to TF-35, "

Transfer Con-

trol Unit Input/Output Signal Reference Value".

Service NoticeINFOID:0000000003532509

• After overhaul refill the transfer with new transfer fluid.

• Check the fluid level or replace the fluid only with the vehicle parked on level ground.

• During removal or installation, keep inside of transfer clear of dust or dirt.

• Disassembly should be done in a clean work area.

• Before proceeding with disassembly, thoroughly clean the transfer. It is important to prevent the internal

parts from becoming contaminated by dirt or other foreign matter.

• Check for the correct installation status prior to removal or disassembly. If matchmarks are required, be cer-

tain they do not interfere with the function of the parts when applied.

• All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or

reassembly.

• Check appearance of the disassembled parts for damage, deformation, and unusual wear. Replace them

with new ones if necessary.

• Gaskets, seals and O-rings should replaced any time the transfer is disassembled.

• In principle, tighten bolts or nuts gradually in several steps working diagonally from inside to outside. If tight-

ening sequence is specified, use it.

• Observe the specified torque when assembling.

• Clean and flush the parts sufficiently and blow-dry them.

• Be careful not to damage sliding surfaces and mating surfaces.

SEF289H

SEF291H

MEF040DB

Page 2840 of 3061

TF-18

< SERVICE INFORMATION >

ALL-MODE 4WD SYSTEM

LINE PRESSURE SWITCH

• With the transfer system design, control of the oil pressure provides the transmission of drive torque to the

front wheels. The main pressure to control the oil pressure is referred to as the line pressure.

• The line pressure switch determines whether or not adequate line pressure has built up under different oper-

ating conditions.

• The line pressure switch turns ON when line pressure is produced.

• The line pressure switch senses line pressure abnormalities and turns the 4WD warning lamp ON.

CLUTCH PRESSURE SWITCH

• The clutch pressure switch determines whether or not adequate clutch pressure has built up under different

operating conditions.

• The clutch pressure switch turns ON when clutch pressure is produced.

• The clutch pressure switch senses clutch pressure abnormalities and turns the 4WD warning lamp ON.

TRANSFER FLUID TEMPERATURE SENSOR

The transfer temperature sensor detects the transfer fluid temperature and sends a signal to the transfer con-

trol unit.

TRANSFER CONTROL UNIT

• Transfer control unit controls transfer control device by input signals of each sensor and each switch.

• Self-diagnosis can be done.

TRANSFER CONTROL DEVICE

The transfer control device changes the state of transfer assembly between 2WD, AUTO, 4H⇔4LO with the

2WD, AUTO, 4H and 4LO signals of 4WD shift switch.

NOTE:

• To shift between 4H⇔4LO, stop the vehicle, depress the brake pedal and shift the transmission selector to

the "N" position. Depress and turn the 4WD shift switch. The shift switch will not shift to the desired mode if

the transmission is not in "N" or the vehicle is moving. The 4LO indicator lamp will be lit when the 4LO is

engaged.

• Actuator motor and actuator position switch are integrated.

4WD SHIFT SWITCH AND INDICATOR LAMP

4WD Shift Switch

The 4WD shift switch allows selection from 2WD, AUTO, 4H or 4LO.

4WD Shift Indicator Lamp

• Displays driving conditions selected by 4WD shift switch with 2WD, AUTO and 4H indicators while engine is

running. (When 4WD warning lamp is turned on, all 4WD shift indicator lamps are turned off.)

• Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4LO Indicator Lamp

• Displays 4LO condition while engine is running. 4LO indicator lamp flashes if transfer gear does not shift

completely under 2WD, AUTO, 4H⇔4LO. (When 4WD warning lamp is turned on, 4LO indicator lamp is

turned off.)

• Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4WD WARNING LAMP

Turns ON or FLASH when there is a malfunction in 4WD system.

Also turns ON when ignition switch is turned ON, for purpose of lamp check. Turns OFF for approximately 1

second after the engine starts if system is normal.

4WD Warning Lamp Indication

Condition Content 4WD warning lamp

During self-diagnosis Indicates the malfunction position by number of flickers. Flickers at malfunction mode.

Lamp check*Checks the lamp by turning ON during engine starting. After

engine starts, it turns OFF if there are no malfunctions.ON

Malfunction in 4WD system*Turns ON to indicate malfunction. When ignition switch is

turned to “OFF” or the malfunction is corrected, it turns OFF.ON

When vehicle is driven with different

diameters of front and rear tiresFlickers once every 2 seconds.

Turns OFF when ignition switch is “OFF”.Flickers once every 2 sec-

onds.