boot INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 916 of 3061

BR-18

< SERVICE INFORMATION >

FRONT DISC BRAKE

FRONT DISC BRAKE

On-vehicle InspectionINFOID:0000000003532738

PAD WEAR INSPECTION

• Inspect the thickness of pad through cylinder body inspection hole.

Use a scale for inspection if necessary. Refer to BR-30, "

Front Disc

Brake".

ComponentINFOID:0000000003532739

BRA0010D

1. Upper sliding pin 2. Sliding pin boot 3. Torque member bolt

4. Torque member 5. Piston seal 6. Piston

7. Inner pad 8. Pad retainer 9. Outer pad

10. Piston boot 11. Union bolt 12. Copper washer

13. Sliding pin bolt 14. Bleed valve 15. Cylinder body

16. Cap 17. Brake hose 18. Lower sliding pin

19. Outer shim 20. Inner shim A. Wear indicator

WFIA0451E

Page 917 of 3061

FRONT DISC BRAKE

BR-19

< SERVICE INFORMATION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

WARNING:

Clean dust on cylinder body and brake pads with a vacuum dust collector to minimize the hazard of

airborne particles or other materials.

CAUTION:

• While removing cylinder body never depress brake pedal because piston will pop out.

• It is not necessary to remove bolts on torque member and brake hose except for disassembly or

replacement of cylinder body. In this case, hang cylinder body with a wire so as not to stretch brake

hose.

• Do not damage piston boot.

• Burnish brake contact surface after refinishing or replacing rotors, after replacing pads, or if a soft

pedal occurs at very low mileage. Refer to BR-20, "

Disassembly and Assembly of Brake Caliper".

Removal and Installation of Brake PadINFOID:0000000003532740

REMOVAL

1. Remove tires from vehicle using power tool.

2. Remove lower sliding pin bolt.

3. Suspend cylinder body with a wire and remove pads, shims and pad retainers from torque member.

INSTALLATION

1. Push pistons in so that pad is firmly installed and mount cylinder body to torque member.

CAUTION:

By pushing in piston, brake fluid returns to master cylinder reservoir tank. Watch the level of the

surface of reservoir tank.

NOTE:

Using a disc brake piston tool (commercial service tool), makes it easier to push in piston.

2. Attach pad retainers, pads and shims to torque member.

• Apply Molykote M-77 grease to pad retainer where brake pad

contacts and between pad and shim.

CAUTION:

• When attaching pad retainer, attach it firmly so that it is

seated fully in the torque member as shown.

• Do not get grease on the brake rotor friction surface.

3. Install lower sliding pin bolt and tighten it to the specified torque. Refer to BR-18, "

Component" .

4. Check brake for drag.

5. Install tires to the vehicle. Refer to WT-7, "

Rotation".

Removal and Installation of Brake Caliper and Disc RotorINFOID:0000000003532741

REMOVAL

1. Remove tires from vehicle using power tool.

2. Drain brake fluid as necessary. Refer to BR-8, "

Drain and Refill".

NOTE:

Do not remove union bolt unless removing cylinder body from vehicle.

3. Remove torque member bolts.

NOTE:

Position cylinder body aside using suitable wire, as necessary.

NOTE:

When servicing cylinder body, remove sliding pin bolts and torque member from cylinder body.

B. Brake fluid M. Molykote M-77 grease R. Rubber grease

⇐Vehicle front

PFIA0273E

Page 918 of 3061

BR-20

< SERVICE INFORMATION >

FRONT DISC BRAKE

4. Remove disc rotor.

INSTALLATION

CAUTION:

• Refill with new brake fluid. Refer to MA-10

.

• Do not reuse drained brake fluid.

1. Install disc rotor.

2. Install sliding pin bolts and torque member to caliper, if removed. Refer to BR-18, "

Component" .

3. Install caliper assembly to the vehicle, then tighten the torque

member bolts to the specified torque. Refer to BR-18, "

Compo-

nent" .

CAUTION:

• When attaching caliper assembly to the vehicle, wipe any

oil off knuckle spindle, washers and caliper assembly

attachment surfaces.

• Do not reuse caliper torque member bolts.

4. Install brake hose to cylinder body, then tighten union bolt to

specification, as necessary. Refer to BR-18, "

Component" .

CAUTION:

• Do not reuse copper washer.

• Install brake hose to caliper assembly together with union

bolt and washers.

5. Refill with new brake fluid and bleed air. Refer to BR-8, "

Bleeding Brake System" .

6. Install tires to the vehicle. Refer to WT-7, "

Rotation" .

Disassembly and Assembly of Brake CaliperINFOID:0000000003532742

DISASSEMBLY

1. Remove sliding pin bolt, and then remove the pad, shim, shim cover, and pad retainer from the torque

member.

2. Remove sliding pins and sliding pin boots from torque member.

3. Place a wooden block as shown, and blow air from union bolt

mounting hole to remove pistons and piston boots.

CAUTION:

Keep hands away from piston.

LFIA0209E

LFIA0214E

BRB0032D

Page 919 of 3061

FRONT DISC BRAKE

BR-21

< SERVICE INFORMATION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

4. Using a flat-bladed screwdriver, remove piston seal from cylin-

der body.

CAUTION:

Be careful not to damage cylinder inner wall.

CALIPER INSPECTION

Cylinder Body

CAUTION:

• Use new brake fluid for cleaning. Do not use mineral oils such as gasoline or kerosene. Refer to MA-

10.

• Check inside surface of cylinder body for score, rust, wear, damage or foreign materials. If any of the

above conditions are observed, replace cylinder body.

• Minor damage from rust or foreign materials may be eliminated by polishing surface with a fine

emery paper. Replace cylinder body if necessary.

Torque Member

Check for wear, cracks, and damage. If damage or deformation is present, replace the affected part.

Piston

Check piston for score, rust, wear, damage or presence of foreign materials. Replace if any of the above con-

ditions are observed.

CAUTION:

Piston sliding surface is plated, do not polish with emery paper even if rust or foreign materials are

stuck to sliding surface.

Sliding Pins, and Sliding Pin Boots

Check sliding pin and sliding pin boot for wear, damage, and cracks. If damage or deformation is present,

replace the affected part.

CAUTION:

Trailing/upper sliding pin must be replaced at each service.

ASSEMBLY

CAUTION:

Do not use NISSAN Rubber Grease (KRE00 00010, KRE00 00010 01) when assembling.

1. Apply clean brake fluid to new piston seal and insert seal in to

groove on cylinder body.

CAUTION:

Do not reuse piston seal.

SFIA0141E

SFIA2399E

Page 920 of 3061

BR-22

< SERVICE INFORMATION >

FRONT DISC BRAKE

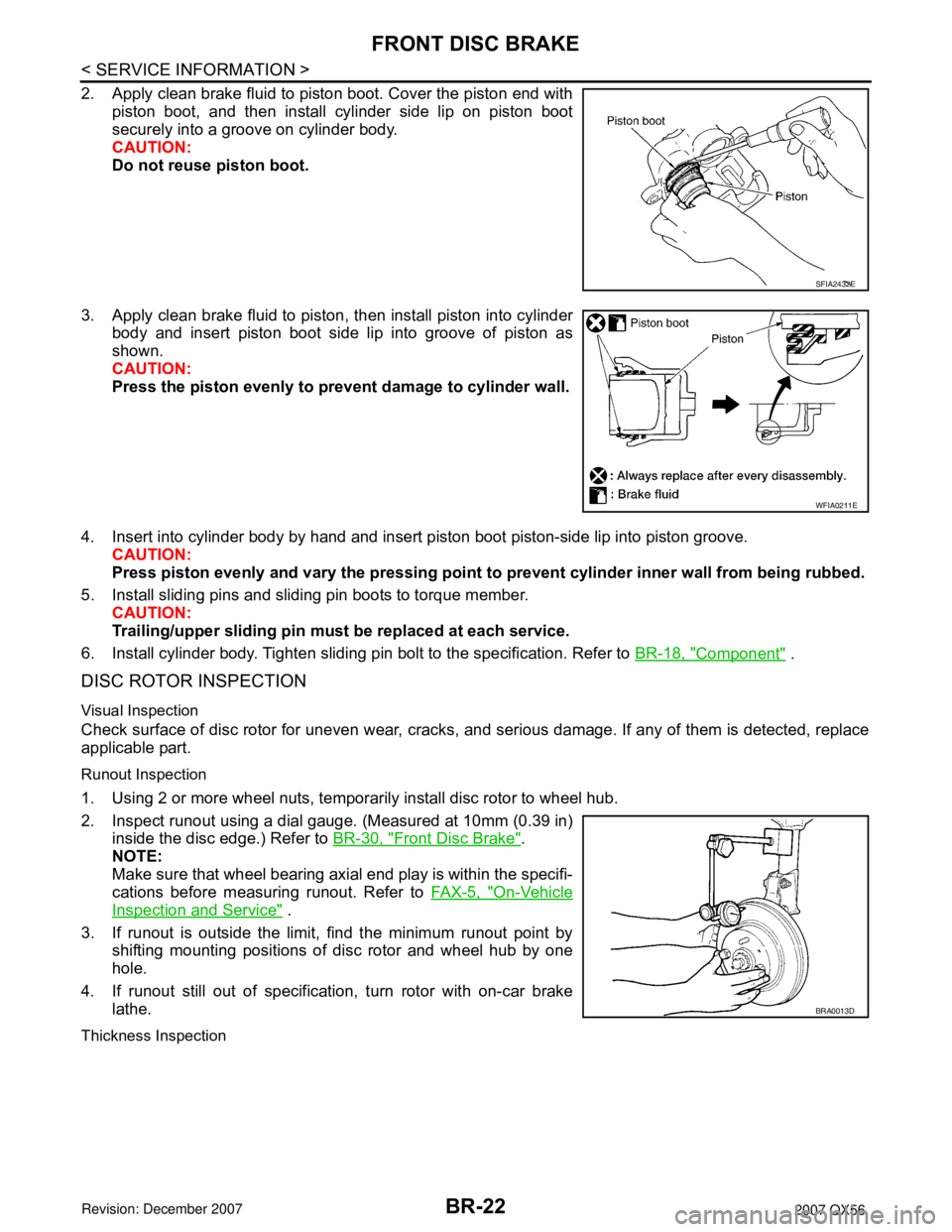

2. Apply clean brake fluid to piston boot. Cover the piston end with

piston boot, and then install cylinder side lip on piston boot

securely into a groove on cylinder body.

CAUTION:

Do not reuse piston boot.

3. Apply clean brake fluid to piston, then install piston into cylinder

body and insert piston boot side lip into groove of piston as

shown.

CAUTION:

Press the piston evenly to prevent damage to cylinder wall.

4. Insert into cylinder body by hand and insert piston boot piston-side lip into piston groove.

CAUTION:

Press piston evenly and vary the pressing point to prevent cylinder inner wall from being rubbed.

5. Install sliding pins and sliding pin boots to torque member.

CAUTION:

Trailing/upper sliding pin must be replaced at each service.

6. Install cylinder body. Tighten sliding pin bolt to the specification. Refer to BR-18, "

Component" .

DISC ROTOR INSPECTION

Visual Inspection

Check surface of disc rotor for uneven wear, cracks, and serious damage. If any of them is detected, replace

applicable part.

Runout Inspection

1. Using 2 or more wheel nuts, temporarily install disc rotor to wheel hub.

2. Inspect runout using a dial gauge. (Measured at 10mm (0.39 in)

inside the disc edge.) Refer to BR-30, "

Front Disc Brake".

NOTE:

Make sure that wheel bearing axial end play is within the specifi-

cations before measuring runout. Refer to FAX-5, "

On-Vehicle

Inspection and Service" .

3. If runout is outside the limit, find the minimum runout point by

shifting mounting positions of disc rotor and wheel hub by one

hole.

4. If runout still out of specification, turn rotor with on-car brake

lathe.

Thickness Inspection

SFIA2432E

WFIA0211E

BRA0013D

Page 922 of 3061

BR-24

< SERVICE INFORMATION >

REAR DISC BRAKE

REAR DISC BRAKE

On-vehicle InspectionINFOID:0000000003532743

PAD WEAR INSPECTION

• Inspect the thickness of pad through cylinder body inspection hole.

Use a scale for inspection if necessary.

Exploded ViewINFOID:0000000003532744

Standard thickness : 12.13 mm (0.478 in)

Repair limit thickness : 1.0 mm (0.039 in)

BRA0010D

1. Union bolt 2. Brake hose 3. Copper washer

4. Cap 5. Bleed valve 6. Bolt

7. Cylinder body 8. Piston seal 9. Piston

10. Piston boot 11. Knuckle slide 12. Sliding sleeve boot

13. Sliding sleeve 14. Inner pad 15. Outer pad

(B) : Brake fluid (R) : Rubber grease (M) : Molykote M-77

⇐: Front

WFIA0453E

Page 923 of 3061

REAR DISC BRAKE

BR-25

< SERVICE INFORMATION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector to minimize the hazard of airborne

particles or other materials.

CAUTION:

• While removing cylinder body, never depress brake pedal because piston will pop out.

• It is not necessary to remove bolts on torque member and brake hose except for disassembly or

replacement of cylinder body. In this case, hang cylinder body with a wire so as not to stretch brake

hose.

• Do not damage piston boot.

• Burnish brake contact surface after refinishing or replacing rotors, after replacing pads, or it a soft

pedal occurs at very low mileage. Refer to BR-26, "

Brake Caliper" .

Removal and Installation of Brake PadINFOID:0000000003532745

REMOVAL

1. Remove tires from vehicle with power tool.

2. Remove the top bolt from the cylinder body.

3. Swing cylinder body open, and remove pads.

INSTALLATION

1. Push piston in so that pad is firmly attached and install cylinder body to torque member.

NOTE:

Using a disc brake piston tool (commercial service tool), makes it easier to push in the piston.

CAUTION:

By pushing in piston, brake fluid returns to master cylinder reservoir tank. Watch the level of the

surface of reservoir tank.

2. Apply Molykote M-77 grease to knuckle slide where brake pad contacts.

CAUTION:

Do not get grease on the brake rotor friction surface.

3. Install pads to cylinder body.

4. Install cylinder body top bolt and tighten to specification.

5. Check brake for drag.

6. Install tires to the vehicle. Refer to WT-7, "

Rotation" .

Removal and Installation of Brake Caliper and Disc RotorINFOID:0000000003532746

REMOVAL

1. Remove tires from vehicle with power tool.

2. Drain brake fluid as necessary. Refer to BR-8, "

Drain and Refill" .

NOTE:

Do not remove union bolt unless removing cylinder body from vehicle.

3. Remove mounting bolts and cylinder body.

NOTE:

Position cylinder body aside using suitable wire, as necessary.

4. Remove disc rotor.

INSTALLATION

CAUTION:

• Refill with new brake fluid. Refer to MA-10

.

• Do not reuse drained brake fluid.

1. Install disc rotor.

LFIA0211E

Page 924 of 3061

BR-26

< SERVICE INFORMATION >

REAR DISC BRAKE

2. Install cylinder body and tighten bolts to specification. Refer to BR-24, "Exploded View" .

CAUTION:

Before installing cylinder body to the vehicle, wipe off mating surface of cylinder body.

3. Install brake hose to cylinder body and tighten union bolt to specification as necessary. Refer to BR-24,

"Exploded View".

CAUTION:

• Do not reuse copper washers.

• Securely attach brake hose to protrusion on cylinder body.

4. Refill new brake fluid and bleed air as necessary. Refer to BR-8, "

Bleeding Brake System" .

5. Install tires to the vehicle. Refer to WT-7, "

Rotation" .

Brake CaliperINFOID:0000000003532747

DISASSEMBLY

1. Remove pads from cylinder body.

2. Remove sliding sleeve and boot from cylinder body.

3. Place a wooden block as shown, and blow air into union bolt

hole to remove piston and piston boot.

CAUTION:

Do not get your fingers caught in piston.

4. Using a suitable tool, remove piston seal from cylinder body as

shown.

CAUTION:

Be careful not to damage cylinder body inner wall.

CALIPER INSPECTION

Cylinder Body

CAUTION:

• Use new brake fluid to clean. Do not use mineral oils such as gasoline or kerosene. Refer to MA-10

.

• Check inside surface of cylinder body for score, rust wear, damage or foreign materials. If any of the

above conditions are observed, replace cylinder body.

• Minor damage from rust or foreign materials may be eliminated by polishing surface with a fine

emery paper. Replace cylinder body if necessary.

Torque Member

Check for wear, cracks, and damage. If damage or deformation is present, replace the affected part.

Piston

CAUTION:

• Piston sliding surface is plated, do not polish with emery paper even if rust of foreign materials are

stuck to sliding surface.

• Check piston for score, rust, wear, damage or presence of foreign materials. Replace if any of the

above conditions are observed.

Sliding Pin Bolts and Sliding Pin Boots

BRD0041D

PFIA0269E

Page 925 of 3061

REAR DISC BRAKE

BR-27

< SERVICE INFORMATION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

Make sure there is no wear, damage, or cracks in sliding sleeve and sliding sleeve boots, and if there are,

replace them.

ASSEMBLY

CAUTION:

Do not use NISSAN Rubber Grease (KRE00 00010, KRE00 00010 01) when assembling.

1. Apply clean brake fluid to new piston seal and insert in to

groove on cylinder body. Refer to MA-10

.

CAUTION:

Do not reuse piston seal.

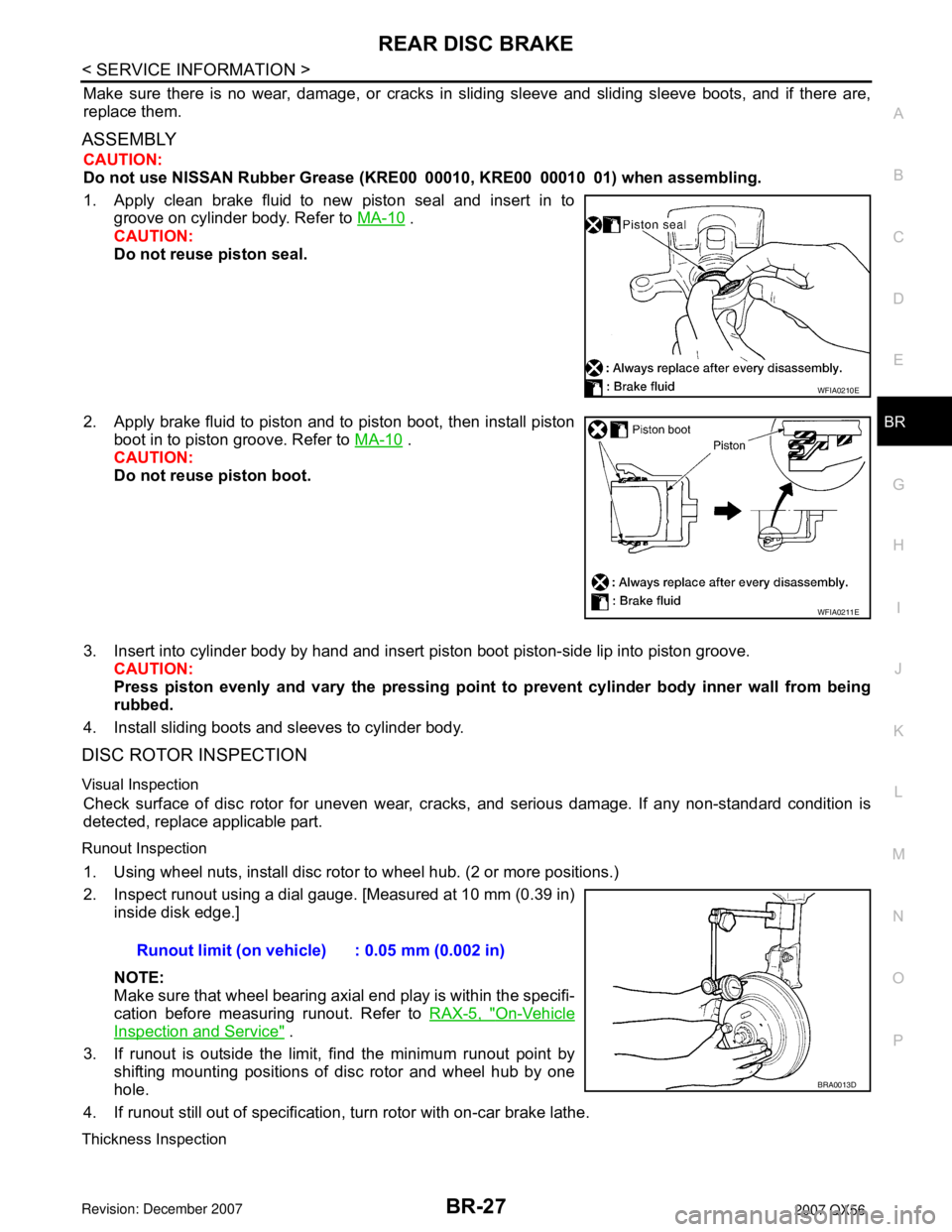

2. Apply brake fluid to piston and to piston boot, then install piston

boot in to piston groove. Refer to MA-10

.

CAUTION:

Do not reuse piston boot.

3. Insert into cylinder body by hand and insert piston boot piston-side lip into piston groove.

CAUTION:

Press piston evenly and vary the pressing point to prevent cylinder body inner wall from being

rubbed.

4. Install sliding boots and sleeves to cylinder body.

DISC ROTOR INSPECTION

Visual Inspection

Check surface of disc rotor for uneven wear, cracks, and serious damage. If any non-standard condition is

detected, replace applicable part.

Runout Inspection

1. Using wheel nuts, install disc rotor to wheel hub. (2 or more positions.)

2. Inspect runout using a dial gauge. [Measured at 10 mm (0.39 in)

inside disk edge.]

NOTE:

Make sure that wheel bearing axial end play is within the specifi-

cation before measuring runout. Refer to RAX-5, "

On-Vehicle

Inspection and Service" .

3. If runout is outside the limit, find the minimum runout point by

shifting mounting positions of disc rotor and wheel hub by one

hole.

4. If runout still out of specification, turn rotor with on-car brake lathe.

Thickness Inspection

WFIA0210E

WFIA0211E

Runout limit (on vehicle) : 0.05 mm (0.002 in)

BRA0013D

Page 1889 of 3061

PREPARATION

FAX-3

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

PREPARATION

Special Service ToolINFOID:0000000003532611

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000003532612

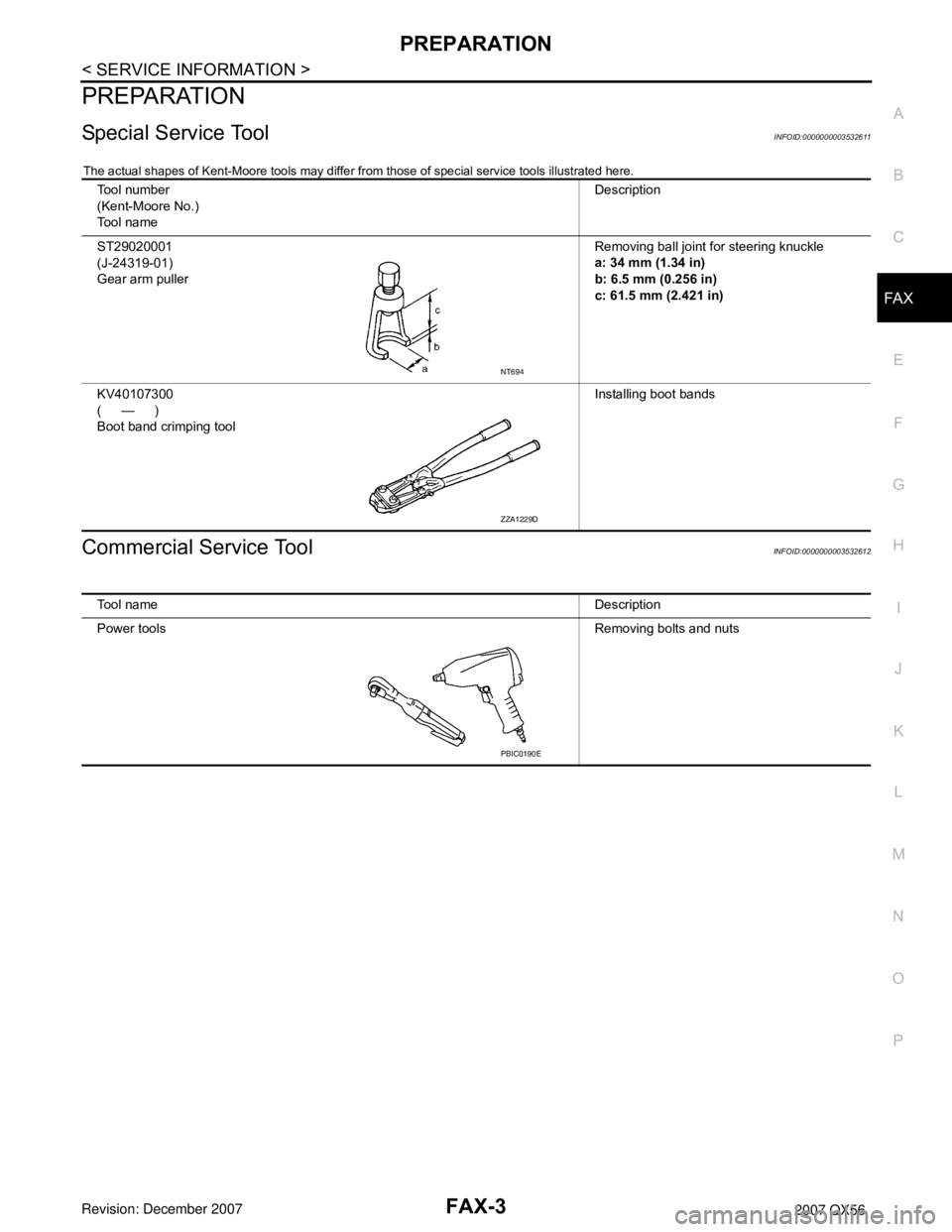

Tool number

(Kent-Moore No.)

Tool nameDescription

ST29020001

(J-24319-01)

Gear arm pullerRemoving ball joint for steering knuckle

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

KV40107300

(—)

Boot band crimping toolInstalling boot bands

NT694

ZZA1229D

Tool nameDescription

Power toolsRemoving bolts and nuts

PBIC0190E