turn signal INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2702 of 3061

SE-30

< SERVICE INFORMATION >

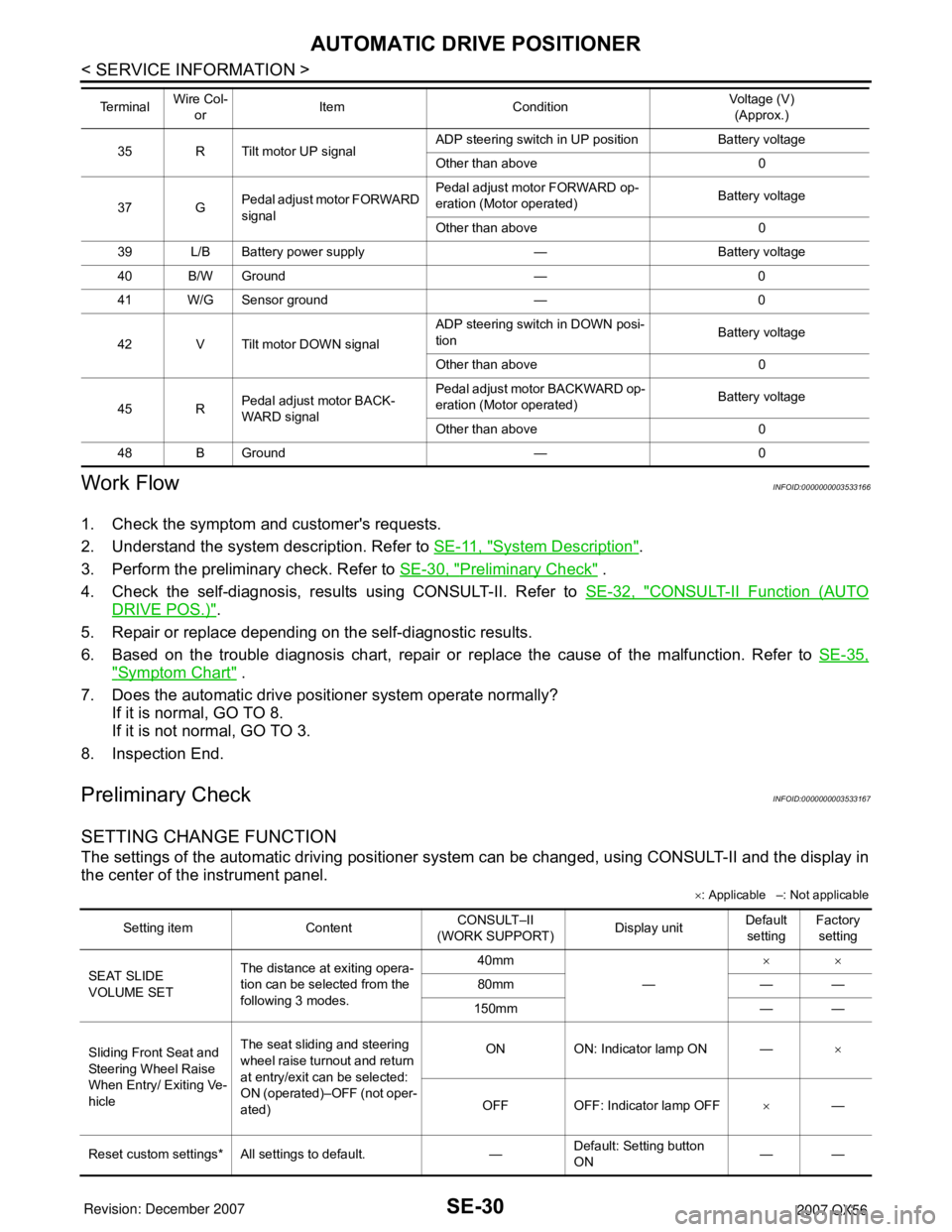

AUTOMATIC DRIVE POSITIONER

Work Flow

INFOID:0000000003533166

1. Check the symptom and customer's requests.

2. Understand the system description. Refer to SE-11, "

System Description".

3. Perform the preliminary check. Refer to SE-30, "

Preliminary Check" .

4. Check the self-diagnosis, results using CONSULT-II. Refer to SE-32, "

CONSULT-II Function (AUTO

DRIVE POS.)".

5. Repair or replace depending on the self-diagnostic results.

6. Based on the trouble diagnosis chart, repair or replace the cause of the malfunction. Refer to SE-35,

"Symptom Chart" .

7. Does the automatic drive positioner system operate normally?

If it is normal, GO TO 8.

If it is not normal, GO TO 3.

8. Inspection End.

Preliminary CheckINFOID:0000000003533167

SETTING CHANGE FUNCTION

The settings of the automatic driving positioner system can be changed, using CONSULT-II and the display in

the center of the instrument panel.

×: Applicable –: Not applicable

35 R Tilt motor UP signalADP steering switch in UP position Battery voltage

Other than above 0

37 GPedal adjust motor FORWARD

signalPedal adjust motor FORWARD op-

eration (Motor operated)Battery voltage

Other than above 0

39 L/B Battery power supply — Battery voltage

40 B/W Ground — 0

41 W/G Sensor ground — 0

42 V Tilt motor DOWN signalADP steering switch in DOWN posi-

tionBattery voltage

Other than above 0

45 RPedal adjust motor BACK-

WARD signalPedal adjust motor BACKWARD op-

eration (Motor operated)Battery voltage

Other than above 0

48 B Ground — 0 Te r m i n a l Wire Col-

orItem ConditionVoltage (V)

(Approx.)

Setting item ContentCONSULT–II

(WORK SUPPORT)Display unitDefault

settingFactory

setting

SEAT SLIDE

VOLUME SETThe distance at exiting opera-

tion can be selected from the

following 3 modes.40mm

—××

80mm — —

150mm — —

Sliding Front Seat and

Steering Wheel Raise

When Entry/ Exiting Ve-

hicleThe seat sliding and steering

wheel raise turnout and return

at entry/exit can be selected:

ON (operated)–OFF (not oper-

ated)ON ON: Indicator lamp ON —×

OFF OFF: Indicator lamp OFF×—

Reset custom settings* All settings to default. —Default: Setting button

ON——

Page 2704 of 3061

SE-32

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

1. Turn ignition switch OFF.

2. Check continuity between the driver seat control unit connector

P2 terminal 32, P3 terminal 48 and ground.

OK or NG

OK >> Driver seat control unit circuit check is OK. Check the

automatic drive positioner control unit. GO TO 4.

NG >> Repair or replace harness.

4.CHECK AUTOMATIC DRIVE POSITIONER CONTROL UNIT POWER SUPPLY CIRCUIT

1. Disconnect automatic drive positioner control unit.

2. Check voltage between automatic drive positioner control unit

connector M34 terminals 34, 39 and ground.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace harness.

5.CHECK AUTOMATIC DRIVE POSITIONER CONTROL UNIT GROUND CIRCUIT

Check continuity between the automatic drive positioner control unit

connector M34 terminals 40, 48 and ground.

OK or NG

OK >> Automatic drive positioner control unit circuit is OK.

NG >> Repair or replace harness.

CONSULT-II Function (AUTO DRIVE POS.)INFOID:0000000003533170

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following. 32 - Ground : Continuity should exist.

48 - Ground : Continuity should exist.

PIIA4542E

ConnectorTe r m i n a l s

Power

sourceConditionVoltage (V)

(Approx.)

(+) (-)

M3434 GroundBattery

power

supplyIgnition

switch

OFFBattery

voltage

39 GroundBattery

power

supplyIgnition

switch

OFFBattery

voltage

PIIA4543E

40 - Ground : Continuity should exist.

48 - Ground : Continuity should exist.

PIIA4544E

AUTO DRIVE POS.

diagnostic modeDescription

WORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the driver seat

control unit for setting the status suitable for required operation, input/output signals

are received from the driver seat control unit and received data is displayed.

SELF-DIAG RESULTS Displays driver seat control unit self-diagnosis results.

DATA MONITOR Displays driver seat control unit input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

ECU PART NUMBER Driver seat control unit part number can be read.

Page 2709 of 3061

AUTOMATIC DRIVE POSITIONER

SE-37

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

SE

N

O

P

Sliding Motor Circuit InspectionINFOID:0000000003533173

1.CHECK SEAT SLIDING MECHANISM

Check the following.

• Operation malfunction caused by sliding rail deformation, pinched harness or other foreign materials

• Operation malfunction caused by foreign materials adhered to the sliding motor LH or sliding rail connector

rod

• Operation malfunction and interference with other parts by poor installation

OK or NG

OK >> GO TO 2.

NG >> Repair or replace the malfunctioning part and check again.

2.CHECK FUNCTION

With CONSULT-II

Check operation with “SEAT SLIDE” in ACTIVE TEST.

Without CONSULT-II

GO TO 3.

OK or NG

OK >> Sliding motor circuit is OK.

NG >> GO TO 3.

3.CHECK SLIDING MOTOR CIRCUIT HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit and sliding motor LH.

3. Check continuity between driver seat control unit connector P3

terminals 35, 42 and sliding motor connector P4 terminals 4, 6.

4. Check continuity between driver seat control unit connector P3

terminals 35, 42 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK DRIVER SEAT CONTROL UNIT OUTPUT SIGNAL

The entry/exiting does not operate when door is opened

and closed.

(The entry/exiting operates with key switch)1. Front door switch circuit inspectionSE-72

2. If all the above systems are normal, replace the BCM.BCS-24

Door mirror system does not operate (only manual oper-

ation).1.Door mirror remote control switch ground circuit inspectionSE-65

Door mirror system does not operate (only automatic op-

eration).1. Door mirror sensor power supply and ground circuit in-

spectionSE-69

Seat system does not operate (only manual operation). 1. Power seat switch ground circuit inspectionSE-60

Symptom Diagnoses / service procedure Refer to page

Test item Description

SEAT SLIDE The sliding motor is activated by receiving the drive signal.

PIIA0265E

35 - 6 : Continuity should exist.

42 - 4 : Continuity should exist.

35 - Ground : Continuity should not exist.

42 - Ground : Continuity should not exist.

LIIA0696E

Page 2710 of 3061

SE-38

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

1. Connect the driver seat control unit and sliding motor LH.

2. Check voltage between driver seat control unit connector and

ground.

OK or NG

OK >> Replace sliding motor. Refer to SE-83.

NG >> Replace driver seat control unit. Refer to SE-83

.

Reclining Motor LH Circuit InspectionINFOID:0000000003533174

1.CHECK SEAT RECLINING MECHANISM

Check the following.

• Operation malfunction caused by an interference with the center pillar or center console

• Operation malfunction and interference with other parts by poor installation

OK or NG

OK >> GO TO 2.

NG >> Repair or replace the malfunctioning part and check again.

2.CHECK FUNCTION

With CONSULT-II

Check operation with “SEAT RECLINING” in ACTIVE TEST.

Without CONSULT-II

GO TO 3.

OK or NG

OK >> Reclining motor LH circuit is OK.

NG >> GO TO 3.

3.CHECK RECLINING MOTOR CIRCUIT HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit and reclining motor LH.

3. Check continuity between driver seat control unit connector P3

terminals 36, 44 and reclining motor LH connector P5 terminals

3, 4.

4. Check continuity between driver seat control unit connector P3

terminals 36, 44 and ground.

OK or NG

ConnectorTe r m i n a l s

ConditionVoltage (V) (Ap-

prox.)

(+) (-)

P335

GroundSliding switch ON

(FORWARD operation)Battery voltage

Other than above 0

42Sliding switch ON

(BACKWARD operation)Battery voltage

Other than above 0

PIIA4801E

Test item Description

SEAT RECLININGThe reclining motor LH is activated by receiving the drive

signal.

PIIA0268E

36 - 4 : Continuity should exist.

44 - 3 : Continuity should exist.

36 - Ground : Continuity should not exist.

44 - Ground : Continuity should not exist.

LIIA0697E

Page 2711 of 3061

AUTOMATIC DRIVE POSITIONER

SE-39

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

SE

N

O

P

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK DRIVER SEAT CONTROL UNIT OUTPUT SIGNAL

1. Connect the driver seat control unit and reclining motor LH.

2. Check voltage between driver seat control unit connector and

ground.

OK or NG

OK >> Replace reclining motor LH. Refer to SE-83.

NG >> Replace driver seat control unit. Refer to SE-83

.

Lifting Motor (Front) Circuit InspectionINFOID:0000000003533175

1.CHECK FRONT END SEAT LIFTING MECHANISM

Check the following.

• Operation malfunction caused by lifter mechanism deformation, pinched harness or other foreign materials

• Operation malfunction caused by foreign materials adhered to the lifting motor (front) or lead screws

• Operation malfunction and interference with other parts by installation

OK or NG

OK >> GO TO 2.

NG >> Repair or replace the malfunctioning part and check again.

2.CHECK FUNCTION

With CONSULT-II

Check operation with “SEAT LIFTER FR” in ACTIVE TEST.

Without CONSULT-II

GO TO 3.

OK or NG

OK >> Lifting motor (front) circuit is OK.

NG >> GO TO 3.

3.CHECK LIFTING MOTOR (FRONT) CIRCUIT HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit and lifting motor (front).

3. Check continuity between driver seat control unit connector P3

terminals 37, 45 and lifting motor (front) connector P6 terminals

4, 6.

4. Check continuity between driver seat control unit connector P3

terminals 37, 45 and ground.

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

P336

GroundReclining switch ON

(FORWARD operation)Battery voltage

Other than above 0

44Reclining switch ON

(BACKWARD operation)Battery voltage

Other than above 0

PIIA4802E

Test item Description

SEAT LIFTER FRThe lifting motor (front) is activated by receiving the drive sig-

nal.

PIIA0271E

37 - 6 : Continuity should exist.

45 - 4 : Continuity should exist.

LIIA0698E

Page 2713 of 3061

AUTOMATIC DRIVE POSITIONER

SE-41

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

SE

N

O

P

1. Turn ignition switch OFF.

2. Disconnect driver seat control unit and lifting motor (rear).

3. Check continuity between driver seat control unit connector P3

terminals 38, 39 and lifting motor (rear) connector P7 terminals

4, 6.

4. Check continuity between driver seat control unit P3 terminals

38, 39 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK DRIVER SEAT CONTROL UNIT OUTPUT SIGNAL

1. Connect the driver seat control unit and lifting motor (rear).

2. Check voltage between driver seat control unit connector and

ground.

OK or NG

OK >> Replace lifting motor (rear). Refer to SE-83.

NG >> Replace driver seat control unit. Refer to SE-83

.

Pedal Adjusting Motor Circuit InspectionINFOID:0000000003533177

1.CHECK PEDAL ADJUSTING MECHANISM

Check the following.

• Operation malfunction caused by pedal adjusting mechanism deformation or pinched harness or other for-

eign materials

• Operation malfunction and interference with other parts by poor installation

OK or NG

OK >> GO TO 2.

NG >> Repair or replace the malfunctioning part and check again.

2.CHECK FUNCTION

With CONSULT-II38 - 6 : Continuity should exist.

39 - 4 : Continuity should exist.

38 - Ground : Continuity should not exist.

39 - Ground : Continuity should not exist.

LIIA0699E

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

P338

GroundLifting switch (rear) ON

(UP operation)Battery voltage

Other than above 0

39Lifting switch (rear) ON

(DOWN operation)Battery voltage

Other than above 0

PIIA4804E

Page 2714 of 3061

SE-42

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

Check operation with “ADJ PEDAL MOTOR” in ACTIVE TEST.

Without CONSULT-II

GO TO 3.

OK or NG

OK >> Pedal adjusting motor circuit is OK.

NG >> GO TO 3.

3.CHECK PEDAL ADJUSTING MOTOR CIRCUIT HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit and pedal

adjusting motor.

3. Check continuity between automatic drive positioner control unit

connector M34 terminals 37, 45 and pedal adjusting motor con-

nector E109 terminals 1, 2.

4. Check continuity between automatic drive positioner control unit

connector M34 terminals 37, 45 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK AUTOMATIC DRIVE POSITIONER CONTROL UNIT OUTPUT SIGNAL

1. Connect the automatic drive positioner control unit and pedal

adjusting motor.

2. Check voltage between automatic drive positioner control unit

connector and ground.

OK or NG

OK >> Replace pedal adjusting motor.

NG >> Replace automatic drive positioner control unit.

Mirror Motor LH Circuit InspectionINFOID:0000000003533178

1.CHECK DOOR MIRROR LH MECHANISM

Check the following items.

Test item Description

ADJ PEDAL MOTORThe pedal adjusting motor is activated by receiving the

drive signal.

PIIA4555E

37 - 1 : Continuity should exist.

45 - 2 : Continuity should exist.

37 - Ground : Continuity should not exist.

45 - Ground : Continuity should not exist.

LIIA1755E

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

M3437

GroundPedal adjusting switch

ON

(FORWARD operation)Battery voltage

Other than above 0

45Pedal adjusting switch

ON

(BACKWARD opera-

tion)Battery voltage

Other than above 0

PIIA4806E

Page 2715 of 3061

AUTOMATIC DRIVE POSITIONER

SE-43

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

SE

N

O

P

Operation malfunction caused by a foreign object caught in door mirror face edge.

OK or NG

OK >> GO TO 2.

NG >> Repair or replace the malfunctioning parts, and check the symptom again.

2.CHECK FUNCTION

With CONSULT-II

Check the operation with “MIRROR MOTOR LH” in the ACTIVE

TEST.

Without CONSULT-II

GO TO 3.

OK or NG

OK >> Mirror motor LH circuit is OK.

NG >> GO TO 3.

3.CHECK DOOR MIRROR MOTOR LH CIRCUIT HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit and door mir-

ror LH.

3. Check continuity between automatic drive positioner control unit

connector M33 terminals 16, 31, 32 and door mirror LH connec-

tor D4 terminals 1, 2, 3.

4. Check continuity between automatic drive positioner control unit

connector M41 terminal 16, 31, 32 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK MIRROR MOTOR SIGNAL

1. Connect automatic drive positioner control unit and door mirror

LH.

2. Turn ignition switch to ACC.

3. Check voltage between door mirror LH connector and ground.

Test item Description

MIRROR MOTOR LHThe mirror motor LH moves the mirror UP/DOWN and

LEFT/RIGHT by receiving the drive signal.

PIIA4784E

16 - 3 : Continuity should exist.

31 - 1 : Continuity should exist.

32 - 2 : Continuity should exist.

16 - Ground : Continuity should not exist.

31 - Ground : Continuity should not exist.

32 - Ground : Continuity should not exist.

LIIA0999E

LIIA1000E

Page 2716 of 3061

SE-44

< SERVICE INFORMATION >

AUTOMATIC DRIVE POSITIONER

OK or NG

OK >> Replace door mirror LH. Refer to GW-84, "Door Mirror Assembly".

NG >> Repair or replace harness.

Mirror Motor RH Circuit InspectionINFOID:0000000003533179

1.CHECK DOOR MIRROR RH MECHANISM

Check the following items.

Operation malfunction caused by a foreign object caught in door mirror face edge.

OK or NG

OK >> GO TO 2.

NG >> Repair or replace the malfunctioning parts, and check the symptom again.

2.CHECK FUNCTION

With CONSULT-II

Check the operation with “MIRROR MOTOR RH” in the ACTIVE

TEST.

Without CONSULT-II

GO TO 3.

OK or NG

OK >> Mirror motor RH circuit is OK.

NG >> GO TO 3.

3.CHECK DOOR MIRROR RH CIRCUIT HARNESS CONTINUITY

1. Turn ignition switch OFF.

2. Disconnect automatic drive positioner control unit and door mir-

ror RH.

3. Check continuity between automatic drive positioner control unit

connector M33 terminals 14, 15, 30 and door mirror RH connec-

tor D107 terminals 1, 2, 3.

4. Check continuity between automatic drive positioner control unit

connector M33 terminal 14, 15, 30 and ground.

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

D41

GroundWhen motor is

operated UP1.5 - Battery voltage

Other than above 0

2When motor is

operated LEFT1.5 - Battery voltage

Other than above 0

3 When motor is

operated DOWN or RIGHT1.5 - Battery voltage

Other than above 0

Test item Description

MIRROR MOTOR RHThe mirror motor RH moves the mirror UP/DOWN and

LEFT/RIGHT by receiving the drive signal.

PIIA0202E

14 - 1 : Continuity should exist.

15 - 2 : Continuity should exist.

30 - 3 : Continuity should exist.

LIIA1001E

Page 2717 of 3061

AUTOMATIC DRIVE POSITIONER

SE-45

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

SE

N

O

P

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

4.CHECK MIRROR MOTOR SIGNAL

1. Connect automatic drive positioner control unit and door mirror

RH.

2. Turn ignition switch to ACC.

3. Check voltage between door mirror RH connector and ground.

OK or NG

OK >> Replace door mirror motor RH. Refer to GW-84, "Door Mirror Assembly".

NG >> Repair or replace harness.

Steering Wheel Tilt Circuit InspectionINFOID:0000000003533180

1.CHECK STEERING WHEEL TILT MECHANISM

Check the following.

• Operation malfunction caused by pedal adjusting mechanism deformation or pinched harness or other for-

eign materials

• Operation malfunction and interference with other parts by poor installation

OK or NG

OK >> GO TO 2.

NG >> Repair or replace the malfunctioning part and check again.

2.CHECK FUNCTION

With CONSULT-II

Check operation with “TILT MOTOR” in ACTIVE TEST.

Without CONSULT-II

GO TO 3.

OK or NG

OK >> Steering wheel tilt motor circuit is OK.

NG >> GO TO 3.

3.CHECK STEERING WHEEL TILT MOTOR HARNESS CONTINUITY 14 - Ground : Continuity should not exist.

15 - Ground : Continuity should not exist.

30 - Ground : Continuity should not exist.

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

D1071

GroundMirror motor is operated

UP1.5 - Battery

voltage

Other than above 0

2Mirror motor is operated

LEFT1.5 - Battery

voltage

Other than above 0

3Mirror motor is operated

DOWN or RIGHT1.5 - Battery

voltage

Other than above 0

LIIA1002E

Test item Description

TILT MOTOR The pedal adjust motor is activated by receiving the drive signal.

PIIA0280E