hood open INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 374 of 3061

ATC-4

< SERVICE INFORMATION >

PRECAUTIONS

not have dedicated recovery equipment, you may contact a local refrigerant product retailer for available ser-

vice. This refrigerant must be disposed of in acco rdance with all federal and local regulations. In addition,

replacement of all refrigerant system components on the vehicle is recommended.

• If the vehicle is within the warranty period, the air conditioner warranty is void. Please contact NISSAN Cus-

tomer Affairs for further assistance.

General Refrigerant PrecautionINFOID:0000000003533220

WARNING:

• Do not release refrigerant into th e air. Use approved recovery/recycling equipment to capture the

refrigerant every time an air conditioning system is discharged.

• Always wear eye and hand protection (goggles and gloves) when working with any refrigerant or air

conditioning system.

• Do not store or heat refrigerant containers above 52 °C (125 °F).

• Do not heat a refrigerant container with an open flame; if container warming is required, place the

bottom of the container in a warm pail of water.

• Do not intentionally drop, puncture, or incinerate refrigerant containers.

• Keep refrigerant away from open flames: poisonou s gas will be produced if refrigerant burns.

• Refrigerant will displace oxygen, therefore be certa in to work in well ventilated areas to prevent suf-

focation.

• Do not pressure test or leak test HFC-134a (R-134a) service equipment and/or vehicle air condition-

ing systems with compressed air during repair. Some mixtures of air and HFC-134a (R-134a) have

been shown to be combustible at elevated pressures. These mixtures, if ignited, may cause injury or

property damage. Additional heal th and safety information may be obtained from refrigerant manu-

facturers.

Precaution for Leak Detection DyeINFOID:0000000003533221

• The A/C system contains a fluorescent leak detection dye used for locating refrigerant leaks. An ultraviolet

(UV) lamp is required to illuminate the dye when inspecting for leaks.

• Always wear fluorescence enhancing UV safety goggles to protect your eyes and enhance the visibility of

the fluorescent dye.

• The fluorescent dye leak detector is not a replacement for an electronic refrigerant leak detector. The fluo-

rescent dye leak detector should be used in conjuncti on with an electronic refrigerant leak detector (J-

41995).

• For your safety and the customer's satisfaction, r ead and follow all manufacturer's operating instructions and

precautions prior to performing work.

• A compressor shaft seal should not be repaired because of dye seepage. The compressor shaft seal should only be repaired after confirming the leak with an electronic refrigerant leak detector (J-41995).

• Always remove any dye from the leak area after repairs are complete to avoid a misdiagnosis during a future

service.

• Do not allow dye to come into contact with painted body panels or interior components. If dye is spilled,

clean immediately with the approved dye cleaner. Fluoresc ent dye left on a surface for an extended period of

time cannot be removed .

• Do not spray the fluorescent dye cleaning agent on hot surfaces (engine exhaust manifold, etc.).

• Do not use more than one refrigerant dye bottle (1/4 ounce / 7.4 cc) per A/C system.

• Leak detection dyes for HFC-134a (R-134a) and CFC-12 (R -12) A/C systems are different. Do not use HFC-

134a (R-134a) leak detection dye in CFC-12 (R-12) A/ C systems or CFC-12 (R-12) leak detection dye in

HFC-134a (R-134a) A/C systems or A/C system damage may result.

• The fluorescent properties of the dye will remain for ov er three (3) years unless a compressor failure occurs.

A/C Identification LabelINFOID:0000000003533222

Vehicles with factory installed fluorescent dye have this identification label on the underside of hood.

Precaution for Refrigerant ConnectionINFOID:0000000003533223

A new type refrigerant connection has been introduced to al l refrigerant lines except the following locations.

• Expansion valve to cooling unit

• Evaporator pipes to evaporator (inside cooling unit)

• Refrigerant pressure sensor

FEATURES OF NEW TYPE REFRIGERANT CONNECTION

Page 475 of 3061

TROUBLE DIAGNOSISATC-105

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

AT C

N

O P

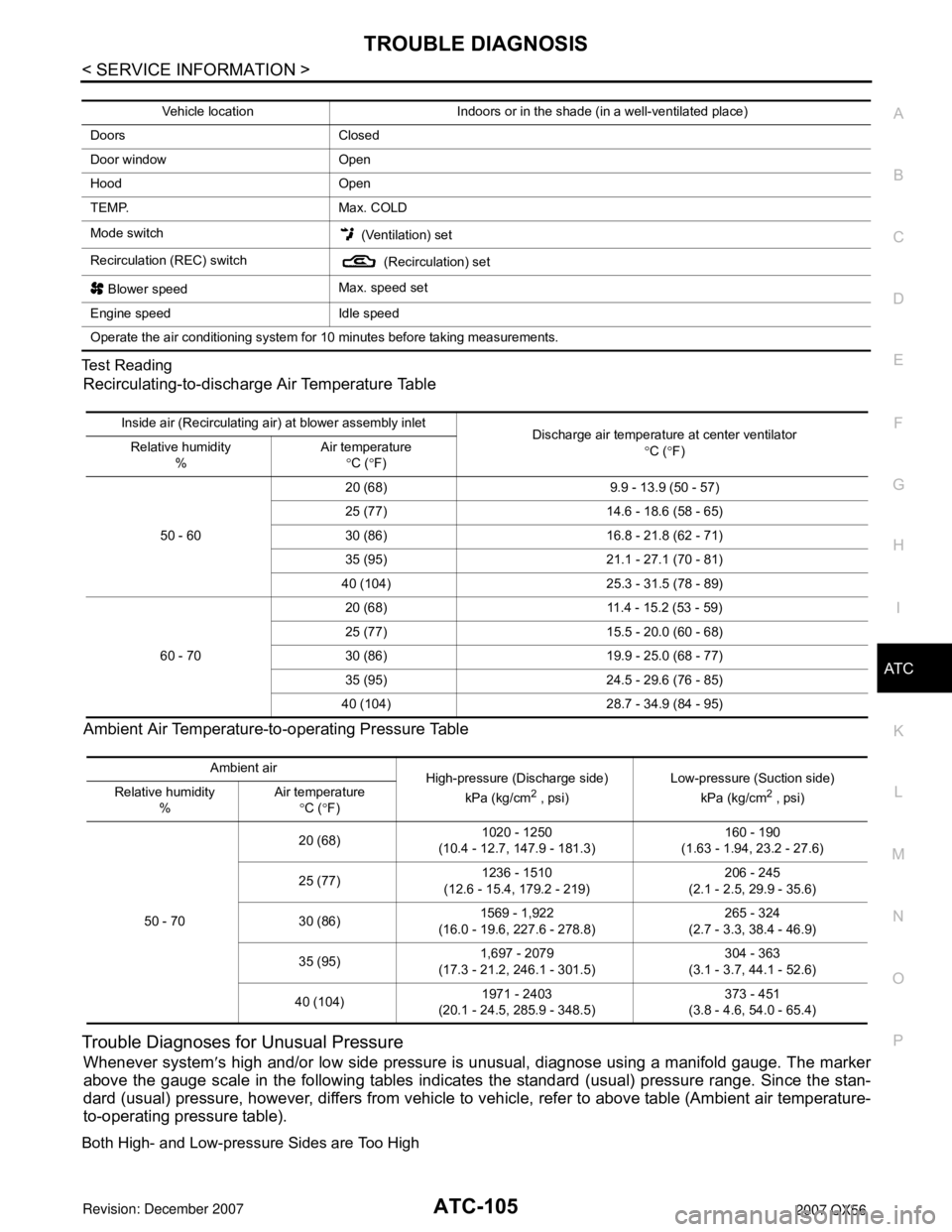

Test Reading

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Trouble Diagnoses for Unusual Pressure

Whenever system

′s high and/or low side pressure is unusual, diagnose using a manifold gauge. The marker

above the gauge scale in the following tables indicate s the standard (usual) pressure range. Since the stan-

dard (usual) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air temperature-

to-operating pressure table).

Both High- and Low-pressure Sides are Too High

Vehicle location Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door window Open

Hood Open

TEMP. Max. COLD

Mode switch (Ventilation) set

Recirculation (REC) switch (Recirculation) set

Blower speed Max. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet Discharge air temperature at center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 - 60 20 (68) 9.9 - 13.9 (50 - 57)

25 (77) 14.6 - 18.6 (58 - 65)

30 (86) 16.8 - 21.8 (62 - 71)

35 (95) 21.1 - 27.1 (70 - 81)

40 (104) 25.3 - 31.5 (78 - 89)

60 - 70 20 (68) 11.4 - 15.2 (53 - 59)

25 (77) 15.5 - 20.0 (60 - 68)

30 (86) 19.9 - 25.0 (68 - 77)

35 (95) 24.5 - 29.6 (76 - 85)

40 (104) 28.7 - 34.9 (84 - 95)

Ambient air High-pressure (Discharge side)

kPa (kg/cm

2 , psi) Low-pressure (Suction side)

kPa (kg/cm2 , psi)

Relative humidity

% Air temperature

°C ( °F)

50 - 70 20 (68)

1020 - 1250

(10.4 - 12.7, 147.9 - 181.3) 160 - 190

(1.63 - 1.94, 23.2 - 27.6)

25 (77) 1236 - 1510

(12.6 - 15.4, 179.2 - 219) 206 - 245

(2.1 - 2.5, 29.9 - 35.6)

30 (86) 1569 - 1,922

(16.0 - 19.6, 227.6 - 278.8) 265 - 324

(2.7 - 3.3, 38.4 - 46.9)

35 (95) 1,697 - 2079

(17.3 - 21.2, 246.1 - 301.5) 304 - 363

(3.1 - 3.7, 44.1 - 52.6)

40 (104) 1971 - 2403

(20.1 - 24.5, 285.9 - 348.5) 373 - 451

(3.8 - 4.6, 54.0 - 65.4)

Page 713 of 3061

BL-2

CAN Communication System Description ..............63

Schematic ...............................................................64

Wiring Diagram - VEHSEC - ...................................65

Terminal and Reference Value for BCM .................69

Terminal and Reference Value for IPDM E/R .........69

CONSULT-II Function (BCM) .................................70

Trouble Diagnosis ...................................................71

Preliminary Check ..................................................72

Symptom Chart .......................................................72

Door Switch Check .................................................73

Hood Switch Check ................................................75

Combination Meter (Security Indicator Lamp)

Check .....................................................................

76

Front Door Lock Assembly LH (Key Cylinder

Switch) Check .........................................................

77

Vehicle Security Horn Alarm Check .......................79

Vehicle Security Headlamp Alarm Check ...............79

Door Lock/Unlock Switch Check ............................79

AUTOMATIC BACK DOOR SYSTEM ...............80

Component Parts and Harness Connector Loca-

tion ..........................................................................

80

System Description .................................................80

Schematic ...............................................................85

Wiring Diagram - B/CLOS - ....................................86

Back Door Control Unit Harness Connector Termi-

nal Layout ...............................................................

91

Terminal and Reference Value for Back Door

Control Unit .............................................................

91

Terminal and Reference Value for BCM .................92

Trouble Diagnosis Procedure .................................92

Self-Diagnosis Procedure .......................................93

Diagnosis Chart ......................................................94

Back Door Power Supply and Ground Circuit In-

spection ..................................................................

95

Power Liftgate Switch System Inspection ...............95

Back Door Close (Close) Switch System Inspec-

tion ..........................................................................

98

Back Door Close (Cancel) Switch System Inspec-

tion ..........................................................................

99

Pinch Strip System Inspection ...............................100

Back Door Warning Chime System Inspection ......101

Half-Latch Switch System Inspection ....................101

Open Switch System Inspection ............................102

Close Switch System Inspection ...........................103

Back Door Handle Switch System Inspection .......104

Cinch Latch Motor System Inspection ...................105

DOOR ...............................................................106

Fitting Adjustment ..................................................106

Removal and Installation .......................................107

FRONT DOOR LOCK .......................................110

Component Structure ............................................110

Removal and Installation .......................................110

Disassembly and Assembly ..................................112

REAR DOOR LOCK .........................................113

Component Structure ............................................113

Removal and Installation .......................................113

BACK DOOR LOCK .........................................114

Power Back Door Opener .....................................114

Door Lock Assembly .............................................115

IVIS (INFINITI VEHICLE IMMOBILIZER SYS-

TEM-NATS) ......................................................

116

Component Parts and Harness Connector Loca-

tion ........................................................................

116

System Description ...............................................116

System Composition .............................................117

ECM Re-communicating Function ........................117

Wiring Diagram - NATS - ......................................119

Terminal and Reference Value for BCM ...............119

CONSULT-II ..........................................................119

Work Flow .............................................................123

Trouble Diagnosis .................................................123

Diagnosis Procedure 1 ..........................................125

Diagnosis Procedure 2 ..........................................126

Diagnosis Procedure 3 ..........................................127

Diagnosis Procedure 4 ..........................................128

Diagnosis Procedure 5 ..........................................129

Diagnosis Procedure 6 ..........................................131

How to Replace NATS Antenna Amp ...................132

HOMELINK UNIVERSAL TRANSCEIVER ......133

Wiring Diagram - TRNSCV - .................................133

Trouble Diagnosis .................................................133

CAB AND REAR BODY ...................................135

Body Mounting ......................................................135

BODY REPAIR .................................................136

Body Exterior Paint Color ......................................136

Body Component Parts .........................................137

Corrosion Protection .............................................142

Body Sealing .........................................................145

Body Construction .................................................149

Body Alignment .....................................................149

Handling Precaution for Plastics ...........................164

Precaution in Repairing High Strength Steel ........167

Foam Repair .........................................................169

Replacement Operation ........................................170

Page 723 of 3061

BL-12

< SERVICE INFORMATION >

HOOD

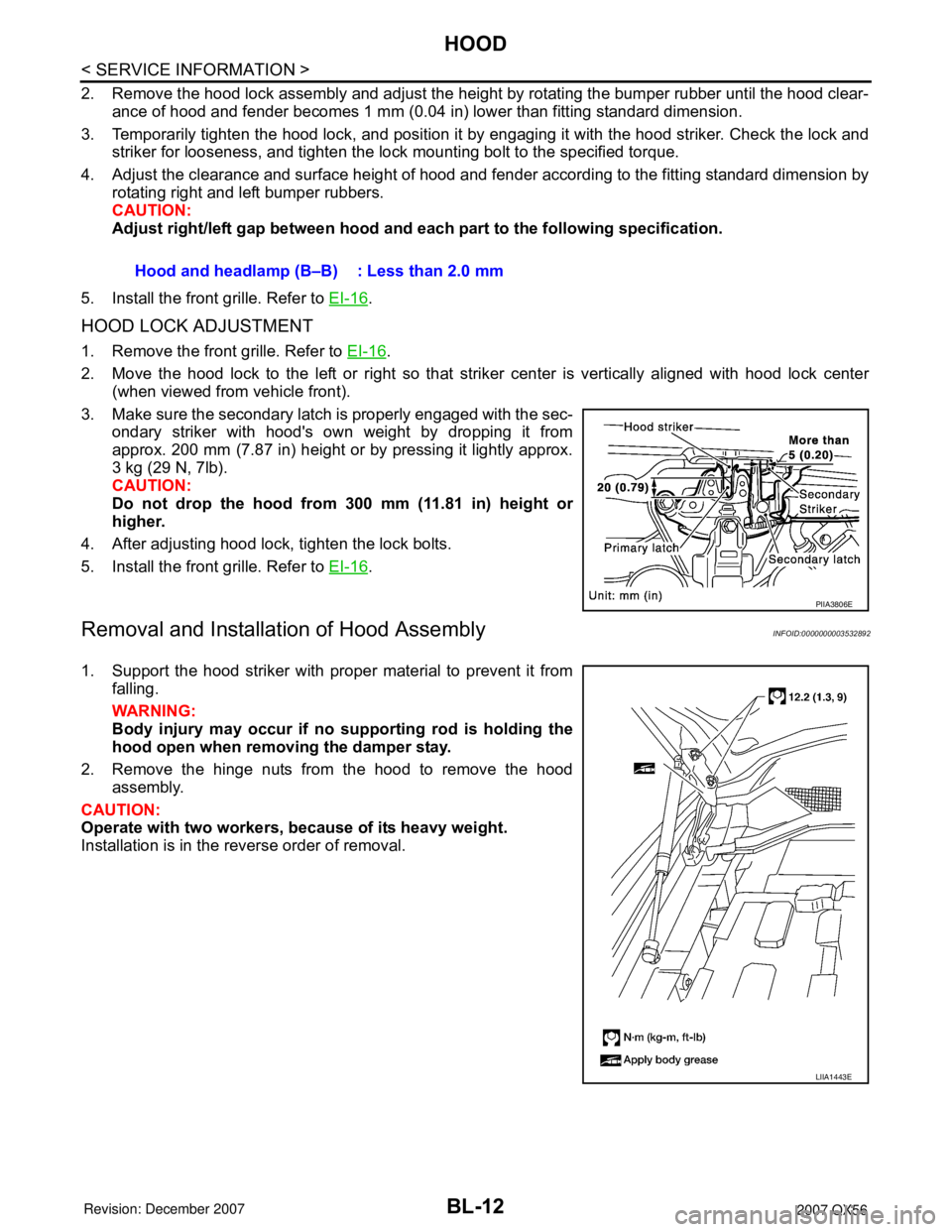

2. Remove the hood lock assembly and adjust the height by rotating the bumper rubber until the hood clear-

ance of hood and fender becomes 1 mm (0.04 in) lower than fitting standard dimension.

3. Temporarily tighten the hood lock, and position it by engaging it with the hood striker. Check the lock and

striker for looseness, and tighten the lock mounting bolt to the specified torque.

4. Adjust the clearance and surface height of hood and fender according to the fitting standard dimension by

rotating right and left bumper rubbers.

CAUTION:

Adjust right/left gap between hood and each part to the following specification.

5. Install the front grille. Refer to EI-16

.

HOOD LOCK ADJUSTMENT

1. Remove the front grille. Refer to EI-16.

2. Move the hood lock to the left or right so that striker center is vertically aligned with hood lock center

(when viewed from vehicle front).

3. Make sure the secondary latch is properly engaged with the sec-

ondary striker with hood's own weight by dropping it from

approx. 200 mm (7.87 in) height or by pressing it lightly approx.

3 kg (29 N, 7lb).

CAUTION:

Do not drop the hood from 300 mm (11.81 in) height or

higher.

4. After adjusting hood lock, tighten the lock bolts.

5. Install the front grille. Refer to EI-16

.

Removal and Installation of Hood AssemblyINFOID:0000000003532892

1. Support the hood striker with proper material to prevent it from

falling.

WARNING:

Body injury may occur if no supporting rod is holding the

hood open when removing the damper stay.

2. Remove the hinge nuts from the hood to remove the hood

assembly.

CAUTION:

Operate with two workers, because of its heavy weight.

Installation is in the reverse order of removal.Hood and headlamp (B–B) : Less than 2.0 mm

PIIA3806E

LIIA1443E

Page 725 of 3061

BL-14

< SERVICE INFORMATION >

HOOD

4. Install the primary and secondary cables securely to the hood

lock.

5. Install the hood lock and the secondary hood lock release

assemblies.

6. Check the hood lock adjustment and hood opener operation.

Refer to BL-11, "

Fitting Adjustment".

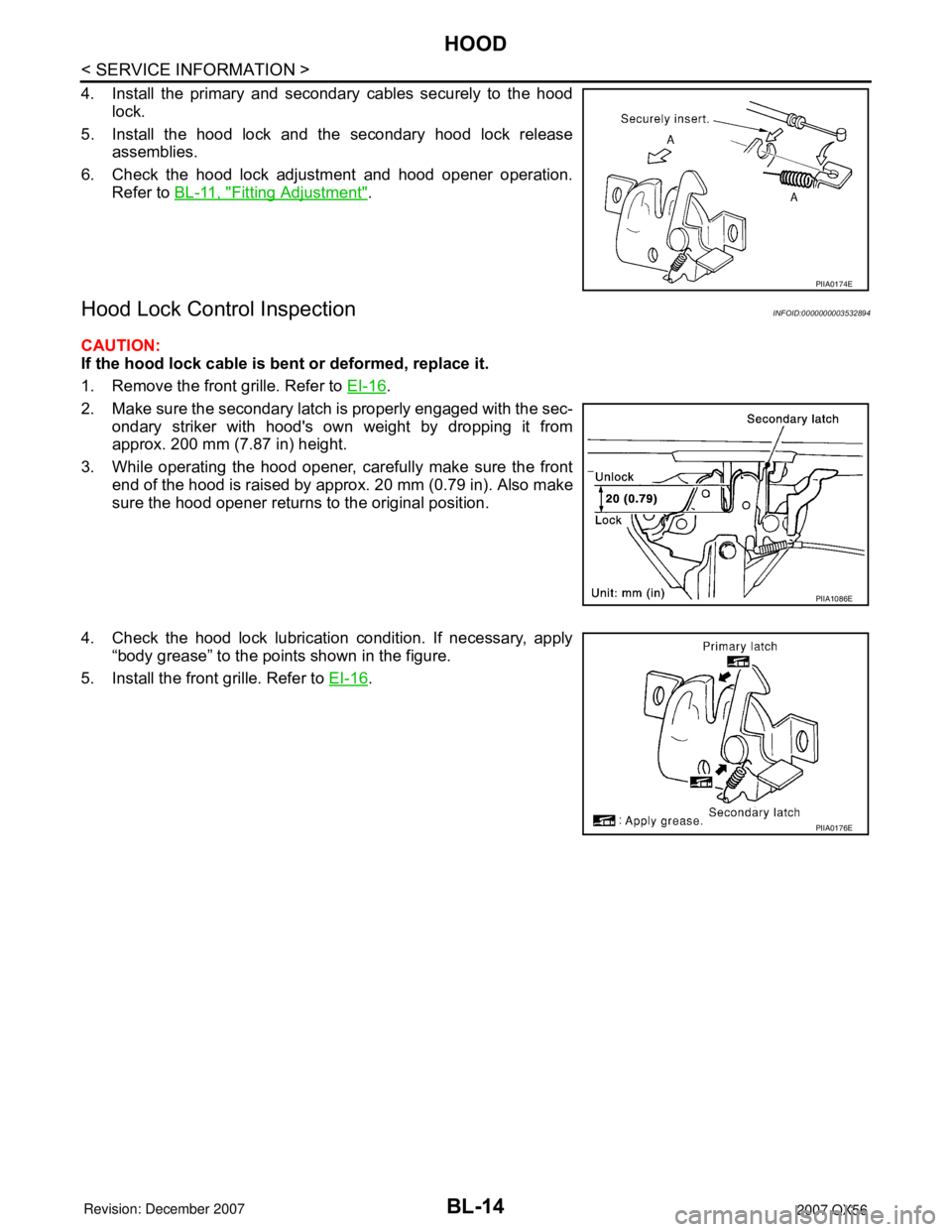

Hood Lock Control InspectionINFOID:0000000003532894

CAUTION:

If the hood lock cable is bent or deformed, replace it.

1. Remove the front grille. Refer to EI-16

.

2. Make sure the secondary latch is properly engaged with the sec-

ondary striker with hood's own weight by dropping it from

approx. 200 mm (7.87 in) height.

3. While operating the hood opener, carefully make sure the front

end of the hood is raised by approx. 20 mm (0.79 in). Also make

sure the hood opener returns to the original position.

4. Check the hood lock lubrication condition. If necessary, apply

“body grease” to the points shown in the figure.

5. Install the front grille. Refer to EI-16

.

PIIA0174E

PIIA1086E

PIIA0176E

Page 772 of 3061

VEHICLE SECURITY (THEFT WARNING) SYSTEM

BL-61

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

System DescriptionINFOID:0000000003532939

DESCRIPTION

Operation Flow

Setting the vehicle security system

Initial condition• Ignition switch is in OFF position.

Disarmed phase

• When the vehicle is being driven or when doors or glass hatch is open, the vehicle security system is set in

the disarmed phase on the assumption that the owner is inside or near the vehicle.

Pre-armed phase and armed phase

• The vehicle security system turns into the "pre-armed" phase when hood, glass hatch and all doors are

closed and locked by keyfob. The security indicator lamp illuminates for 30 seconds, then the system auto-

matically shifts into the "armed" phase.

Canceling the set vehicle security system

When one of the following operations is performed, the armed phase is canceled.

1. Unlock the doors with the key or the keyfob.

2. Open the power back door with the keyfob. When the power back door is closed after opening the power

back door with the keyfob, the system returns to the armed phase.

Activating the alarm operation of the vehicle security system

Make sure the system is in the armed phase.

When one of the following operations is performed, the system sounds the horns and flashes the headlamps

for about 50 seconds.

1. Engine hood, glass hatch or any door is opened before unlocking door with key or keyfob.

2. Door is unlocked without using key or keyfob.

3. Power back door is opened without using the keyfob.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

10. Main power window and door lock/un-

lock switch D7, D8

Power window and door lock/unlock

switch RH D10511. Front door switch

LH B8

RH B10812. Rear door switch

LH B18

RH B116

13. Back door latch (door ajar switch) D503

Glass hatch ajar switch D70714. Combination meter M24 15. Hood switch E8

16. RH headlamp

PIIA1367E

Page 773 of 3061

![INFINITI QX56 2007 Factory Service Manual BL-62

< SERVICE INFORMATION >

VEHICLE SECURITY (THEFT WARNING) SYSTEM

• through 10A fuse [No.19, located in the fuse block (J/B)]

• to combination meter (security indicator lamp) terminal 8 and

� INFINITI QX56 2007 Factory Service Manual BL-62

< SERVICE INFORMATION >

VEHICLE SECURITY (THEFT WARNING) SYSTEM

• through 10A fuse [No.19, located in the fuse block (J/B)]

• to combination meter (security indicator lamp) terminal 8 and

�](/img/42/57029/w960_57029-772.png)

BL-62

< SERVICE INFORMATION >

VEHICLE SECURITY (THEFT WARNING) SYSTEM

• through 10A fuse [No.19, located in the fuse block (J/B)]

• to combination meter (security indicator lamp) terminal 8 and

• through 50A fusible link (letter f , located in the fuse and fusible link box)

• to BCM terminal 70

• through 15A fuse [No. 22, located in the fuse block (J/B)]

• to BCM terminal 57

• through 15A fuse (No. 25, located in the fuse and fusible link box)

• to horn relay terminal 2

• through 20A fuse (No. 52, located in the IPDM E/R) and

• through 20A fuse (No. 53, located in the IPDM E/R),

• to IPDM E/R internal CPU.

With the ignition switch in the ACC or ON position, power is supplied• through 10A fuse [No. 4, located in the fuse block (J/B)]

• to BCM terminal 11.

Ground is supplied

• to BCM terminal 67

• through body grounds M57, M61 and M79 and

• to IPDM E/R terminals 38 and 59

• through body ground E9, E15 and E24.

INITIAL CONDITION TO ACTIVATE THE SYSTEM

The operation of the vehicle security system is controlled by the doors, hood and glass hatch.

To activate the vehicle security system, BCM must receive signals indicating the doors, hood and glass hatch

are closed and the doors are locked.

When a door is open, BCM terminal 12, 13, 42, 47 or 48 receives a ground signal from each door switch.

When front door LH is unlocked, BCM terminal 22 receives a signal from terminal 14 of main power window

and door lock/unlock switch.

When front door RH is unlocked, BCM terminal 22 receives a signal from terminal 16 of power window and

door lock/unlock switch RH or the rear power window switch LH or RH.

When the back door is open, BCM terminal 43 receives a ground signal

• from terminal 7 of the back door latch (door ajar switch)

• through body grounds B7 and B19.

When the glass hatch is open, BCM terminal 42 receives a ground signal

• from terminal + of the glass hatch ajar switch

• through glass hatch ajar switch case ground.

VEHICLE SECURITY SYSTEM ALARM OPERATION

The vehicle security system is triggered by

• opening a door

• opening the hood

• opening the glass hatch

• unlocking door without using the key or keyfob.

The vehicle security system will be triggered once the system is in armed phase,

• when BCM receives a ground signal at terminals 12, 13, 47, 48 (door switch), terminal 42 (glass hatch ajar

switch) or terminal 43 [back door latch (door ajar switch)], or IPDM E/R terminal 41 (hood switch) receives a

ground signal.

Power is supplied at all times

• to horn relay terminal 2

• through 15A fuse (No. 25, located in fuse and fusible link box).

When the vehicle security system is triggered, ground is supplied intermittently

• from IPDM E/R terminal 45

• to headlamp high relay and

• to horn relay terminal 1.

The headlamps flash and the horn sounds intermittently.

The alarm automatically turns off after 50 seconds, but will reactivate if the vehicle is tampered with again.

VEHICLE SECURITY SYSTEM DEACTIVATION

To deactivate the vehicle security system, a door must be unlocked with the key or keyfob.

When the key is used to unlock the front door LH, BCM terminal 22 receives signal

• from terminal 14 of the main power window and door lock/unlock switch.

Page 784 of 3061

VEHICLE SECURITY (THEFT WARNING) SYSTEM

BL-73

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

*1: Make sure the system is in the armed phase.

Door Switch CheckINFOID:0000000003532949

1.CHECK DOOR SWITCHES INPUT SIGNAL

With CONSULT-II

Check door switches ("DOOR SW-DR", "DOOR SW-AS", "DOOR SW-RL", "DOOR SW-RR", "BACK DOOR

SW", "TRNK OPN MNTR") in DATA MONITOR mode with CONSULT–II.Refer to BL-70, "

CONSULT-II Func-

tion (BCM)".

• When doors are open:

• When doors are closed:

Without CONSULT-II

3*1 Vehicle security

system does not

alarm when ····Any door, hood or glass hatch is

opened.Refer to BL-73, "

Door Switch Check".

Refer to BL-75, "

Hood Switch Check".

If the above systems are “OK”, replace BCM. Refer to BCS-24, "

BCM".

4Vehicle security

alarm does not ac-

tivate.Horn alarmRefer to BL-79, "

Vehicle Security Horn Alarm Check" .

If the above systems are “OK”, check horn system.

Refer to WW-43

.

Headlamp alarmRefer to BL-79, "

Vehicle Security Headlamp Alarm Check".

If the above systems are “OK”, replace BCM. Refer to BCS-24, "

BCM".

5Vehicle security

system cannot be

canceled by ····Door outside keyRefer to BL-77, "

Front Door Lock Assembly LH (Key Cylinder Switch)

Check" .

If the above systems are “OK”, check main power window and door lock/

unlock switch.

KeyfobCheck remote keyless entry function. Refer to BL-52, "

Keyfob Battery and

Function Check".

If the above systems are “OK”, replace BCM. Refer to BCS-24, "

BCM" . SYMPTOM PROCEDURE Diagnostic procedure

DOOR SW-DR : ON

DOOR SW-AS : ON

DOOR SW-RL : ON

DOOR SW-RR : ON

BACK DOOR SW : ON

TRNK OPN MNTR : ON

DOOR SW-DR : OFF

DOOR SW-AS : OFF

DOOR SW-RL : OFF

DOOR SW-RR : OFF

BACK DOOR SW : OFF

TRNK OPN MNTR : OFF

WIIA0466E

Page 786 of 3061

VEHICLE SECURITY (THEFT WARNING) SYSTEM

BL-75

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

Check continuity between front or rear door switch terminal 2 and

exposed metal of switch while pressing and releasing switch.

BACK DOOR

Check continuity between back door latch connector (A) D503 termi-

nals 7 and 8 while pressing (closing back door) and releasing (open-

ing back door) switch.

OK or NG

OK >> (Front and rear doors) Switch circuit is OK.

OK >> (Back door) GO TO 4.

NG >> Replace door switch.

4.CHECK BACK DOOR SWITCH GROUND

Check continuity between back door latch connector terminal 8 and

ground.

OK or NG

OK >> Back door switch circuit is OK.

NG >> Repair or replace harness.

Hood Switch CheckINFOID:0000000003532950

1.CHECK HOOD SWITCH

Check hood switch and hood fitting condition.

OK or NG

OK >> GO TO 2.

NG >> Adjust installation of hood switch.

2.CHECK HOOD SWITCH INPUT SIGNAL

With CONSULT-II

Check "HOOD SW" in "DATA MONITOR" mode with CONSULT-II.Door switch is released : Continuity should exist.

Door switch is pushed : Continuity should not exist.

WIIA0644E

When back door is open : Continuity should exist.

When back door is closed : Continuity should not exist.

WIIA0752E

8 - Ground : Continuity should exist.

LIIA0828E

When hood is open : HOOD SW ON

When hood is closed : HOOD SW OFF

LIIA0038E

Page 787 of 3061

BL-76

< SERVICE INFORMATION >

VEHICLE SECURITY (THEFT WARNING) SYSTEM

Without CONSULT-II

Check voltage between IPDM E/R harness connector E122 terminal

41 and ground.

OK or NG

OK >> Hood switch is OK.

NG >> GO TO 3.

3.CHECK HOOD SWITCH

1. Turn ignition switch OFF.

2. Disconnect hood switch connector.

3. Check continuity between hood switch terminals 1 and 2.

OK or NG

OK >> Check the following:

• Hood switch ground circuit.

• Harness for open or short between hood switch and

IPDM E/R

NG >> Replace hood switch.

Combination Meter (Security Indicator Lamp) CheckINFOID:0000000003532951

1.SECURITY INDICATOR LAMP ACTIVE TEST

With CONSULT-II

Check "THEFT IND” in "ACTIVE TEST" mode with CONSULT-II.

Without CONSULT-II

1. Disconnect BCM.

ConnectorTe r m i n a l

Condition of

hoodVoltage (V)

(Approx.)

(+) (-)

E122 41 GroundOpen 0

Closed Battery voltage

WIIA0601E

Terminals Condition Continuity

1- 2Pressed No

Released Yes

LIIA0040E

LIIA0044E