tires INFINITI QX56 2007 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2622 of 3061

RSU-32

< SERVICE INFORMATION >

SUSPENSION ARM

• Check the ball joint. Replace the suspension arm assembly if any

of the following conditions exist:

- Ball stud is worn.

- Joint is hard to swing.

- Play in axial direction is excessive.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten the nuts and bolts to specification. Refer to RSU-21, "

Component" .

• Perform the final tightening of the nuts and bolts for the links (rubber bushing) under unladen condition

(unladen condition means that the fuel tank, engine coolant and lubricants are at the full specification, and

the spare tire, jack, hand tools, and mats are in their designated positions) with the tires on level ground.

• Check the wheel alignment. Refer to RSU-23, "

Wheel AlignmentInspection" . Swinging force “A” : Refer to RSU-43, "

Ball Joint" .

Turning force “B” : Refer to RSU-43, "

Ball Joint" .

Vertical end play “C” : Refer to RSU-43, "

Ball Joint" .

SFA858A

Page 2624 of 3061

RSU-34

< SERVICE INFORMATION >

FRONT LOWER LINK

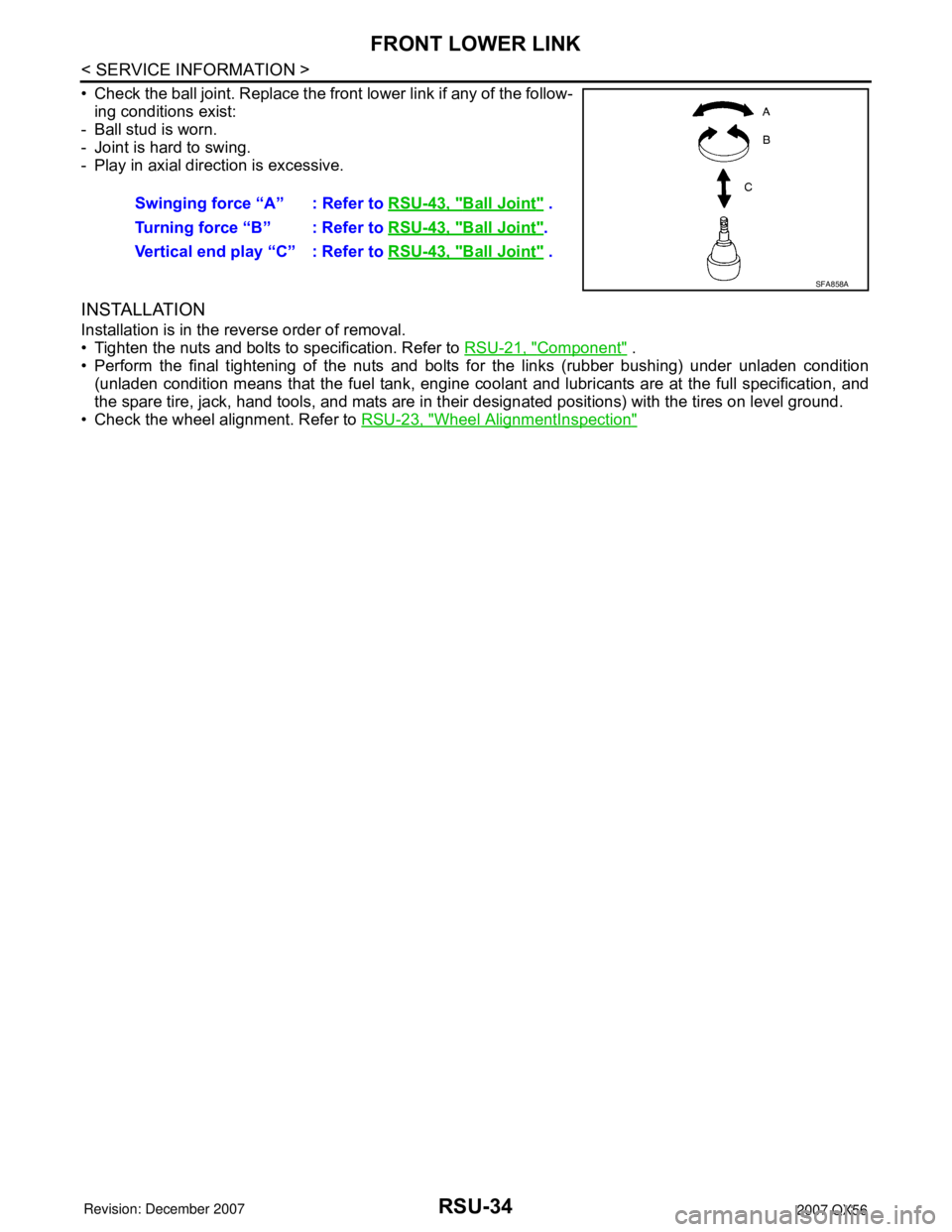

• Check the ball joint. Replace the front lower link if any of the follow-

ing conditions exist:

- Ball stud is worn.

- Joint is hard to swing.

- Play in axial direction is excessive.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten the nuts and bolts to specification. Refer to RSU-21, "

Component" .

• Perform the final tightening of the nuts and bolts for the links (rubber bushing) under unladen condition

(unladen condition means that the fuel tank, engine coolant and lubricants are at the full specification, and

the spare tire, jack, hand tools, and mats are in their designated positions) with the tires on level ground.

• Check the wheel alignment. Refer to RSU-23, "

Wheel AlignmentInspection"

Swinging force “A” : Refer to RSU-43, "Ball Joint" .

Turning force “B” : Refer to RSU-43, "

Ball Joint".

Vertical end play “C” : Refer to RSU-43, "

Ball Joint" .

SFA858A

Page 2840 of 3061

TF-18

< SERVICE INFORMATION >

ALL-MODE 4WD SYSTEM

LINE PRESSURE SWITCH

• With the transfer system design, control of the oil pressure provides the transmission of drive torque to the

front wheels. The main pressure to control the oil pressure is referred to as the line pressure.

• The line pressure switch determines whether or not adequate line pressure has built up under different oper-

ating conditions.

• The line pressure switch turns ON when line pressure is produced.

• The line pressure switch senses line pressure abnormalities and turns the 4WD warning lamp ON.

CLUTCH PRESSURE SWITCH

• The clutch pressure switch determines whether or not adequate clutch pressure has built up under different

operating conditions.

• The clutch pressure switch turns ON when clutch pressure is produced.

• The clutch pressure switch senses clutch pressure abnormalities and turns the 4WD warning lamp ON.

TRANSFER FLUID TEMPERATURE SENSOR

The transfer temperature sensor detects the transfer fluid temperature and sends a signal to the transfer con-

trol unit.

TRANSFER CONTROL UNIT

• Transfer control unit controls transfer control device by input signals of each sensor and each switch.

• Self-diagnosis can be done.

TRANSFER CONTROL DEVICE

The transfer control device changes the state of transfer assembly between 2WD, AUTO, 4H⇔4LO with the

2WD, AUTO, 4H and 4LO signals of 4WD shift switch.

NOTE:

• To shift between 4H⇔4LO, stop the vehicle, depress the brake pedal and shift the transmission selector to

the "N" position. Depress and turn the 4WD shift switch. The shift switch will not shift to the desired mode if

the transmission is not in "N" or the vehicle is moving. The 4LO indicator lamp will be lit when the 4LO is

engaged.

• Actuator motor and actuator position switch are integrated.

4WD SHIFT SWITCH AND INDICATOR LAMP

4WD Shift Switch

The 4WD shift switch allows selection from 2WD, AUTO, 4H or 4LO.

4WD Shift Indicator Lamp

• Displays driving conditions selected by 4WD shift switch with 2WD, AUTO and 4H indicators while engine is

running. (When 4WD warning lamp is turned on, all 4WD shift indicator lamps are turned off.)

• Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4LO Indicator Lamp

• Displays 4LO condition while engine is running. 4LO indicator lamp flashes if transfer gear does not shift

completely under 2WD, AUTO, 4H⇔4LO. (When 4WD warning lamp is turned on, 4LO indicator lamp is

turned off.)

• Turns ON for approximately 1 second when ignition switch is turned ON, for purpose of lamp check.

4WD WARNING LAMP

Turns ON or FLASH when there is a malfunction in 4WD system.

Also turns ON when ignition switch is turned ON, for purpose of lamp check. Turns OFF for approximately 1

second after the engine starts if system is normal.

4WD Warning Lamp Indication

Condition Content 4WD warning lamp

During self-diagnosis Indicates the malfunction position by number of flickers. Flickers at malfunction mode.

Lamp check*Checks the lamp by turning ON during engine starting. After

engine starts, it turns OFF if there are no malfunctions.ON

Malfunction in 4WD system*Turns ON to indicate malfunction. When ignition switch is

turned to “OFF” or the malfunction is corrected, it turns OFF.ON

When vehicle is driven with different

diameters of front and rear tiresFlickers once every 2 seconds.

Turns OFF when ignition switch is “OFF”.Flickers once every 2 sec-

onds.

Page 2933 of 3061

TROUBLE DIAGNOSIS FOR SYMPTOMS

TF-111

< SERVICE INFORMATION >

C

E

F

G

H

I

J

K

L

MA

B

TF

N

O

P

Dose 4WD shift indicator lamp keep flashing?

YES >> GO TO 2.

NO >> Inspection End.

2.CHECK SYSTEM FOR WAIT DETECTION SWITCH

Perform trouble diagnosis for wait detection switch system. Refer to TF-60, "

Wait Detection Switch".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK SYSTEM FOR NEUTRAL-4LO SWITCH

Perform trouble diagnosis for neutral-4LO switch system. Refer to TF-54, "

Neutral-4LO Switch".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.SYMPTOM CHECK

Check again.

OK or NG

OK >> Inspection End.

NG >> GO TO 5.

5.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to TF-35, "

Transfer Control Unit Input/Output Signal Ref-

erence Value".

OK or NG

OK >> GO TO 6.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

6.CHECK TRANSFER INNER PARTS

1. Disassemble transfer assembly. Refer to TF-128, "

Disassembly and Assembly".

2. Check transfer inner parts.

OK or NG

OK >> Inspection End.

NG >> Repair or replace damaged parts.

4WD Warning Lamp Flashes RapidlyINFOID:0000000003532558

SYMPTOM:

While driving, 4WD warning lamp flashes rapidly.

NOTE:

Rapid flashing: 2 times/second

DIAGNOSTIC PROCEDURE

1.CHECK TIRE

Check the following.

• Tire pressure

• Wear condition

• Longitudinal tire size (There is no difference between longitudinal tires.)

OK or NG

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

2.CHECK 4WD WARNING LAMP

Stop the vehicle and allow it to idle for a short period of time.

Does flashing stop?

Page 2934 of 3061

TF-112

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

YES >> Inspection End.

NO >> GO TO 3.

3.CHECK TRANSFER FLUID TEMPERATURE

Perform trouble diagnosis for transfer fluid temperature system. Refer to TF-90, "

Transfer Fluid Temperature".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.SYMPTOM CHECK

Check again.

OK or NG

OK >> Inspection End.

NG >> GO TO 5.

5.CHECK TRANSFER CONTROL UNIT

Check transfer control unit input/output signal. Refer to TF-35, "

Transfer Control Unit Input/Output Signal Ref-

erence Value".

OK or NG

OK >> Inspection End.

NG >> Check transfer control unit pin terminals for damage or loose connection with harness connector.

If any items are damaged, repair or replace damaged parts.

4WD Warning Lamp Flashes SlowlyINFOID:0000000003532559

SYMPTOM:

While driving, 4WD warning lamp flashes slowly. (When continuing to flash until turning ignition

switch OFF.)

NOTE:

Slow flashing: 1 time/2 seconds

DIAGNOSTIC PROCEDURE

1.CHECK TIRE

Check the following.

• Tire pressure

• Wear condition

• Longitudinal tire size (There is no difference between longitudinal tires.)

OK or NG

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

2.CHECK TRANSFER FLUID TEMPERATURE

Perform trouble diagnosis for transfer fluid temperature system. Refer to TF-90, "

Transfer Fluid Temperature".

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.CHECK CLUTCH PRESSURE SWITCH

Perform trouble diagnosis for clutch pressure switch system. Refer to TF-92, "

Clutch Pressure Switch".

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.SYMPTOM CHECK

Check again.

OK or NG

OK >> Inspection End.

Page 2990 of 3061

WT-1

SUSPENSION

C

D

F

G

H

I

J

K

L

M

SECTION WT

A

B

WT

N

O

PCONTENTS

ROAD WHEELS & TIRES

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................3

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING .............................

4

NVH Troubleshooting Chart ......................................4

WHEEL ................................................................5

Inspection ..................................................................5

WHEEL AND TIRE ASSEMBLY .........................6

Balancing Wheels .....................................................6

Rotation .....................................................................7

LOW TIRE PRESSURE WARNING SYSTEM .....8

System Component ...................................................8

System Description ...................................................8

CAN COMMUNICATION ....................................10

System Description .................................................10

TROUBLE DIAGNOSIS .....................................11

Wiring Diagram- T/WARN - .....................................11

Terminal and Reference Value (BCM) ....................12

ID Registration Procedure .......................................12

Transmitter Wake Up Operation .............................14

CONSULT-II Function (BCM) ..................................15

Self-Diagnosis .........................................................15

How to Perform Trouble Diagnosis for Quick and

Accurate Repair .......................................................

17

Preliminary Check ...................................................18

Flash Code/Symptom Chart ....................................18

TROUBLE DIAGNOSIS FOR SELF-DIAG-

NOSTIC ITEMS .................................................

20

Data from Transmitter Not Being Received .............20

Transmitter Malfunction ...........................................20

Transmitter Pressure Malfunction ............................21

Vehicle Speed Signal ..............................................21

Ignition Signal ..........................................................22

TROUBLE DIAGNOSIS FOR SYMPTOMS ......23

Low Tire Pressure Warning Lamp Does Not Come

On When Ignition Switch Is Turned On ...................

23

Low Tire Pressure Warning Lamp Stays On When

Ignition Switch Is Turned On ...................................

23

Low Tire Pressure Warning Lamp Flashes When

Ignition Switch Is Turned On ...................................

24

Hazard Warning Lamps Flash When Ignition

Switch Is Turned On ................................................

25

"TIRE PRESSURE" Information in Display Unit

Does Not Exist .........................................................

25

ID Registration Cannot Be Completed ....................25

REMOVAL AND INSTALLATION .....................26

Transmitter (Pressure Sensor) ................................26

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

28

Road Wheel .............................................................28

Tire ..........................................................................28

Page 2993 of 3061

WT-4

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000003532688

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

WT-5WT-6WT-28WT-7—

—

WT-28

FFD-6, "

NVH Troubleshooting Chart

" (FFD),

RFD-7, "

NVH Troubleshooting Chart

" (RFD)

FA X - 4 , "

NVH Troubleshooting Chart

" (FAX),

FSU-4, "

NVH Troubleshooting Chart

" (FSU)

RAX-4, "

NVH Troubleshooting Chart

" (RAX),

RSU-4, "

NVH Troubleshooting Chart

" (RSU)

Refer to TIRES in this chart.

Refer to ROAD WHEEL in this chart.

BR-4, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Out-of-round

Imbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

DIFFERENTIAL

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEEL

BRAKE

STEERING

SymptomTIRESNoise× ××××× × × × × ××

Shake× ×××× × × × × ××

Vibration××××××

Shimmy× ×××××× × × × ××

Shudder× ×××× × × × × ××

Poor quality ride or

handling× ×××× × × × ×

ROAD

WHEELNoise×× × ××× ×××

Shake×× × ×× ×××

Shimmy, shudder×× × ×× ×××

Poor quality ride or

handling×× × ×× ×

Page 2994 of 3061

WHEEL

WT-5

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

WT

N

O

P

WHEEL

InspectionINFOID:0000000003532689

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If

deformed, remove wheel and check wheel runout.

a. Remove tire from wheel and mount wheel on a tire balance

machine.

b. Set dial indicator as shown. Refer to WT-28, "

Road Wheel" .

3. Check front wheel bearings for looseness.

4. Check front suspension for looseness.

SFA975B

Page 2996 of 3061

WHEEL AND TIRE ASSEMBLY

WT-7

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

WT

N

O

P

c. If calculated balance weight value exceeds 50 g (1.76 oz), install

two balance weight sheets in line with each other as shown.

CAUTION:

Do not install one balance weight sheet on top of another.

3. Start wheel balancer again.

4. Install drive-in balance weight on inner side of road wheel in the

wheel balancer indication position (angle).

CAUTION:

Do not install more than two balance weights.

5. Start wheel balancer. Make sure that inner and outer residual

imbalance values are 5 g (0.18 oz) each or below.

• If either residual imbalance value exceeds 5 g (0.18 oz),

repeat installation procedures.

Wheel balance (Maximum allowable imbalance):

RotationINFOID:0000000003532691

NOTE:

Follow the maintenance schedule for tire rotation service intervals. Refer to MA-6

.

1. Rotate the tires on each side from front to back as shown. Do

not include the spare tire when rotating the tires.

CAUTION:

When installing wheels, tighten them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

2. Adjust the tire pressure to specification. Refer to WT-28, "

Tire" .

3. After the tire rotation, retighten the wheel nuts after the vehicle

has been driven for 1,000 km (600 miles), and also after every

wheel and tire have been installed such as after repairing a flat tire.

Maximum allowable imbalanceDynamic (At rim flange) 5 g (0.18 oz) (one side)

Static 10 g (0.35 oz)

SMA056D

Wheel nut torque : 133 N·m (14 kg-m, 98 ft-lb)

SMA829C

Page 3003 of 3061

WT-14

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

3. Select “WORK SUPPORT” on “SELECT DIAG MODE" screen,

and select "ID REGIST".

4. Adjust the tire pressure to the values shown in the table below

and drive the vehicle at 15 km/h (9.4 MPH) or more for a few

minutes.

5. After completing all ID registrations, press “END” to complete the procedure.

6. Inflate all tires to proper pressure. Refer to WT-28, "

Tire".

Transmitter Wake Up OperationINFOID:0000000003532698

NOTE:

This procedure must be done after replacement of a low tire pressure warning transmitter or BCM.

New replacement transmitters are provided "asleep" and must first be "woken up" using Transmitter

Activation Tool J-45295 before ID registration can be performed.

1. Turn ignition switch ON. Push the transmitter activation tool

against the tire near the front left transmitter. Press the button for

5 seconds. The hazard warning lamps flash per the diagram

below.

2. Repeat this procedure for each tire in the following order: FL, FR, RR, RL.

BCIA0031E

Tire position

Tire pressure kPa (kg/cm2, psi)

Front – Left 250 (2.5, 36)

Front – Right 230 (2.3, 33)

Rear – Right 210 (2.1, 30)

Rear – Left 190 (1.9, 27)

Activation tire position CONSULT-II

Front LH

“YET”

↓

“DONE” Front RH

Rear RH

Rear LH

Tool number : (J-45295)

LEIA0036E