suspension INFINITI QX56 2007 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2617 of 3061

REAR SUSPENSION MEMBER

RSU-27

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

Rear Load Leveling Air Suspension System

REMOVAL

1. Use the CONSULT-II “EXHAUST SOLENOID” active test to release the air pressure from the rear load

leveling air suspension system.

2. Disconnect the electrical connectors for the height sensor and the rear load leveling air suspension com-

pressor assembly.

3. Unclip the rubber cover to access the rear load leveling air suspension compressor assembly.

4. Disconnect the rear load leveling air suspension hoses at the

rear load leveling air suspension compressor assembly.

• To disconnect the hoses, push in on the lock ring using a suit-

able tool and pull the hose out.

5. Remove both of the rear wheel and tire assemblies using power

tool.

6. Remove the brake caliper without disconnecting the brake

hoses, using power tool. Reposition the brake caliper out of the

way using a suitable wire. Refer to BR-25, "

Removal and Instal-

lation of Brake Caliper and Disc Rotor" .

CAUTION:

10. Shock absorber 11. Suspension arm 12. Lower rubber seat

13. Coil spring 14. Upper rubber seat 15. Rear suspension member

16. Spare tire bracket 17. Bound bumper

AWEIA0076ZZ

1. Rear load leveling air suspension

hose, RH2. Shock absorber, RH 3. Height sensor

4. Rear load leveling air suspension

hose, LH5. Shock absorber, LH 6. Rear load leveling air suspension

compressor assembly (includes the

bracket and rubber cover)

⇐Front

LEIA0074E

Page 2618 of 3061

RSU-28

< SERVICE INFORMATION >

REAR SUSPENSION MEMBER

• Do not crimp or stretch the brake hose when repositioning the brake caliper out of the way.

• Do not press brake pedal while the brake caliper is removed.

7. Remove the spare tire.

8. Disconnect the two rear ABS sensor electrical connectors.

9. Remove the two rear drive shafts. Refer to RAX-7, "

Removal and Installation" .

10. Remove the rear final drive. Refer to RFD-14

.

11. Remove the EVAP canister bolt from the top of the rear suspension member.

12. Disconnect the parking brake cables from the brackets on the rear suspension member.

13. Set a suitable jack to support each of the rear lower links and the

coil spring tension.

14. Remove both of the rear lower link outer bolts and lower the jack to remove the rear coil springs.

15. Remove the two bolts to disconnect the seat belt latch anchor

from the rear suspension member.

16. Disconnect both of the connecting rods from the rear stabilizer

bar.

17. Set a suitable jack under the rear suspension member.

18. Remove the six rear suspension member bolts.

19. Slowly lower the jack to remove the rear suspension member,

suspension arm, front and rear lower links and stabilizer bar as

an assembly.

20. If necessary, remove the suspension arm, spare tire bracket,

height sensor, rear load leveling air suspension hoses, stabilizer

bar, knuckle, and front and rear lower links from the rear suspension member.

INSPECTION AFTER REMOVAL

Check the rear suspension member for deformation, cracks, and other damage and replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• When raising the rear suspension member assembly, use the

locating pins to align the rear suspension member to the vehicle

body.

LEIA0077E

LEIA0075E

LEIA0083E

Page 2619 of 3061

REAR SUSPENSION MEMBER

RSU-29

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

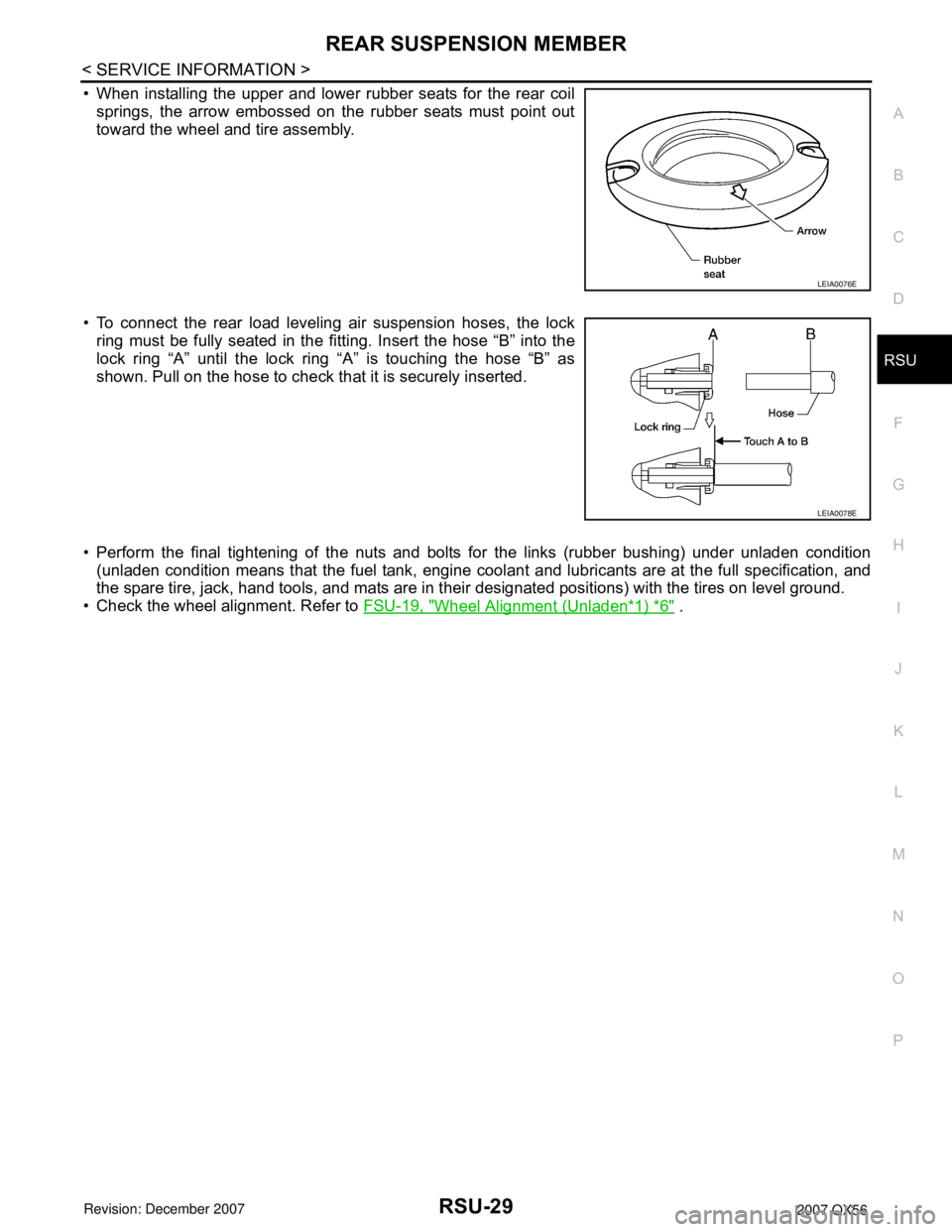

• When installing the upper and lower rubber seats for the rear coil

springs, the arrow embossed on the rubber seats must point out

toward the wheel and tire assembly.

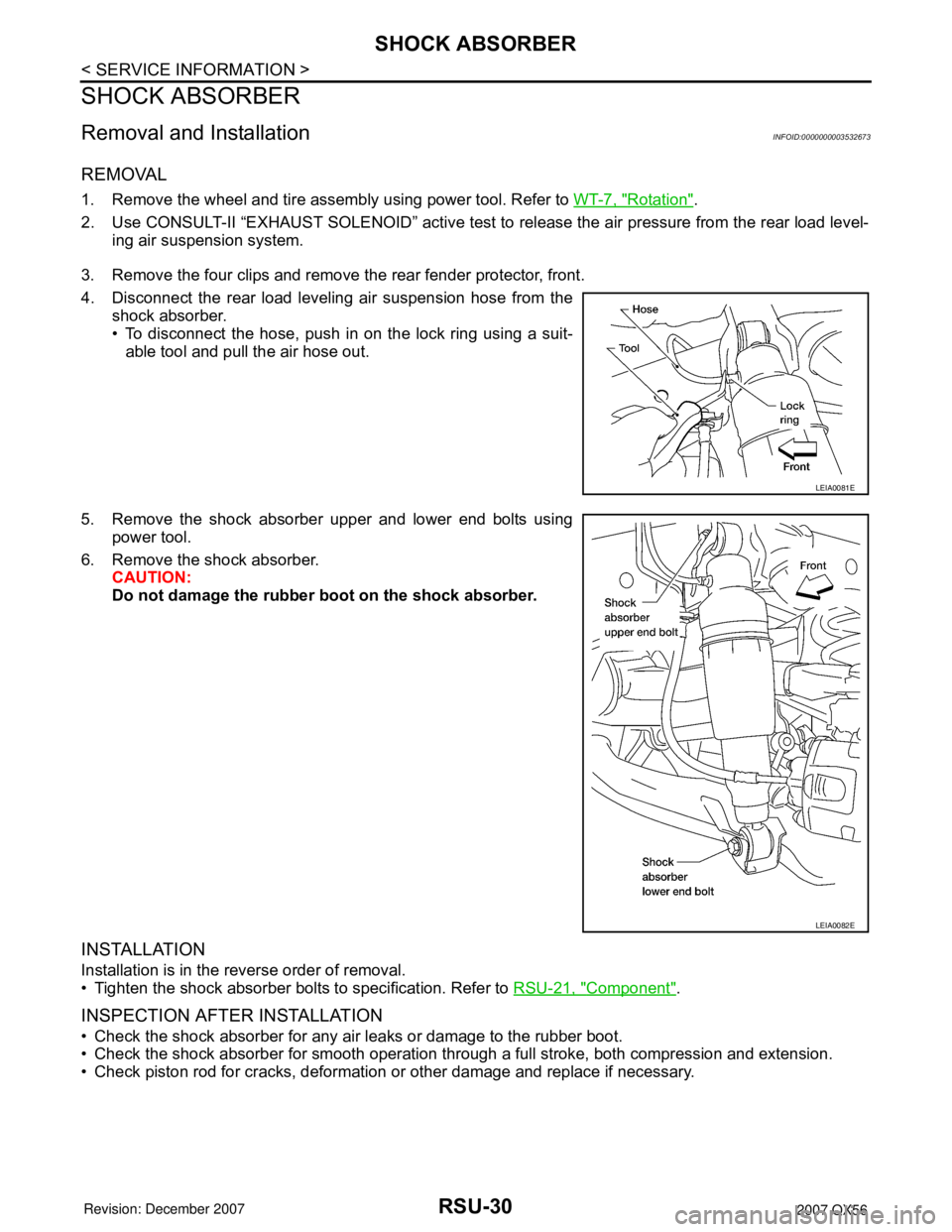

• To connect the rear load leveling air suspension hoses, the lock

ring must be fully seated in the fitting. Insert the hose “B” into the

lock ring “A” until the lock ring “A” is touching the hose “B” as

shown. Pull on the hose to check that it is securely inserted.

• Perform the final tightening of the nuts and bolts for the links (rubber bushing) under unladen condition

(unladen condition means that the fuel tank, engine coolant and lubricants are at the full specification, and

the spare tire, jack, hand tools, and mats are in their designated positions) with the tires on level ground.

• Check the wheel alignment. Refer to FSU-19, "

Wheel Alignment (Unladen*1) *6" .

LEIA0076E

LEIA0078E

Page 2620 of 3061

RSU-30

< SERVICE INFORMATION >

SHOCK ABSORBER

SHOCK ABSORBER

Removal and InstallationINFOID:0000000003532673

REMOVAL

1. Remove the wheel and tire assembly using power tool. Refer to WT-7, "Rotation".

2. Use CONSULT-II “EXHAUST SOLENOID” active test to release the air pressure from the rear load level-

ing air suspension system.

3. Remove the four clips and remove the rear fender protector, front.

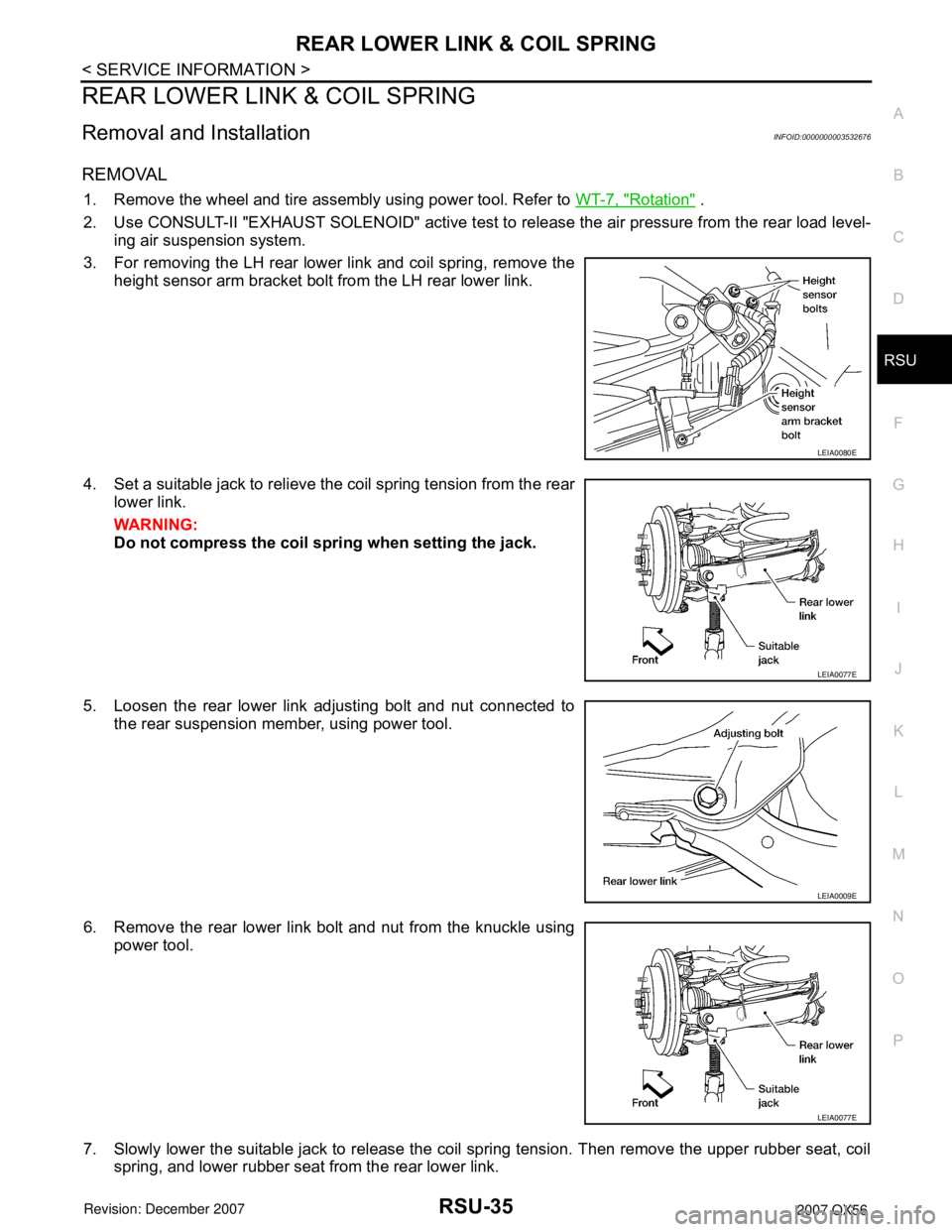

4. Disconnect the rear load leveling air suspension hose from the

shock absorber.

• To disconnect the hose, push in on the lock ring using a suit-

able tool and pull the air hose out.

5. Remove the shock absorber upper and lower end bolts using

power tool.

6. Remove the shock absorber.

CAUTION:

Do not damage the rubber boot on the shock absorber.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten the shock absorber bolts to specification. Refer to RSU-21, "

Component".

INSPECTION AFTER INSTALLATION

• Check the shock absorber for any air leaks or damage to the rubber boot.

• Check the shock absorber for smooth operation through a full stroke, both compression and extension.

• Check piston rod for cracks, deformation or other damage and replace if necessary.

LEIA0081E

LEIA0082E

Page 2621 of 3061

SUSPENSION ARM

RSU-31

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

SUSPENSION ARM

Removal and InstallationINFOID:0000000003532674

REMOVAL

1. Remove the rear suspension member assembly using power tool. Refer to RSU-26, "Removal and Instal-

lation" .

NOTE:

It is necessary to remove the rear suspension member to remove the front upper bolt from the suspension

arm.

2. Remove the shock absorber upper end bolt.

3. Remove the suspension arm upper nuts and bolts on the sus-

pension member side using power tool.

4. Remove the suspension arm pinch bolt and nut on the knuckle

side using power tool.

5. Disconnect the suspension arm from the knuckle using a soft

hammer.

CAUTION:

Do not damage the ball joint with the soft hammer.

6. Remove the suspension arm.

INSPECTION AFTER REMOVAL

• Check the suspension arm for damage, cracks, deformation and replace if necessary.

• Check the rubber bushing for damage, cracks and deformation. Replace suspension arm assembly if neces-

sary.

• Before checking, turn the ball joint at least 10 revolutions so that the ball joint is properly broken in.

LEIA0082E

LEIA0087E

Page 2622 of 3061

RSU-32

< SERVICE INFORMATION >

SUSPENSION ARM

• Check the ball joint. Replace the suspension arm assembly if any

of the following conditions exist:

- Ball stud is worn.

- Joint is hard to swing.

- Play in axial direction is excessive.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten the nuts and bolts to specification. Refer to RSU-21, "

Component" .

• Perform the final tightening of the nuts and bolts for the links (rubber bushing) under unladen condition

(unladen condition means that the fuel tank, engine coolant and lubricants are at the full specification, and

the spare tire, jack, hand tools, and mats are in their designated positions) with the tires on level ground.

• Check the wheel alignment. Refer to RSU-23, "

Wheel AlignmentInspection" . Swinging force “A” : Refer to RSU-43, "

Ball Joint" .

Turning force “B” : Refer to RSU-43, "

Ball Joint" .

Vertical end play “C” : Refer to RSU-43, "

Ball Joint" .

SFA858A

Page 2623 of 3061

FRONT LOWER LINK

RSU-33

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

FRONT LOWER LINK

Removal and InstallationINFOID:0000000003532675

REMOVAL

1. Remove the wheel and tire assembly using power tool.

2. Use CONSULT-II "EXHAUST SOLENOID" active test to release the air pressure from the rear load level-

ing air suspension system.

3. Remove the shock absorber lower end bolt.

4. Remove the adjusting bolt and nut, and the bolt and nut, from

the front lower link and rear suspension member using power

tool.

5. Remove the front lower link pinch bolt and nut on the knuckle

side using power tool.

6. Disconnect the front lower link from the knuckle using a soft

hammer.

CAUTION:

Do not damage the ball joint with the soft hammer.

7. Remove the front lower link.

INSPECTION AFTER REMOVAL

• Check the front lower link and bushing for any deformation, crack, or damage. Replace if necessary.

• Check the rubber bushing for damage, cracks and deformation. Replace the front lower link and bushing if

necessary.

• Before checking, turn the ball joint at least 10 revolutions so that the ball joint is properly broken in.

LEIA0082E

LEIA0086E

Page 2625 of 3061

REAR LOWER LINK & COIL SPRING

RSU-35

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

REAR LOWER LINK & COIL SPRING

Removal and InstallationINFOID:0000000003532676

REMOVAL

1. Remove the wheel and tire assembly using power tool. Refer to WT-7, "Rotation" .

2. Use CONSULT-II "EXHAUST SOLENOID" active test to release the air pressure from the rear load level-

ing air suspension system.

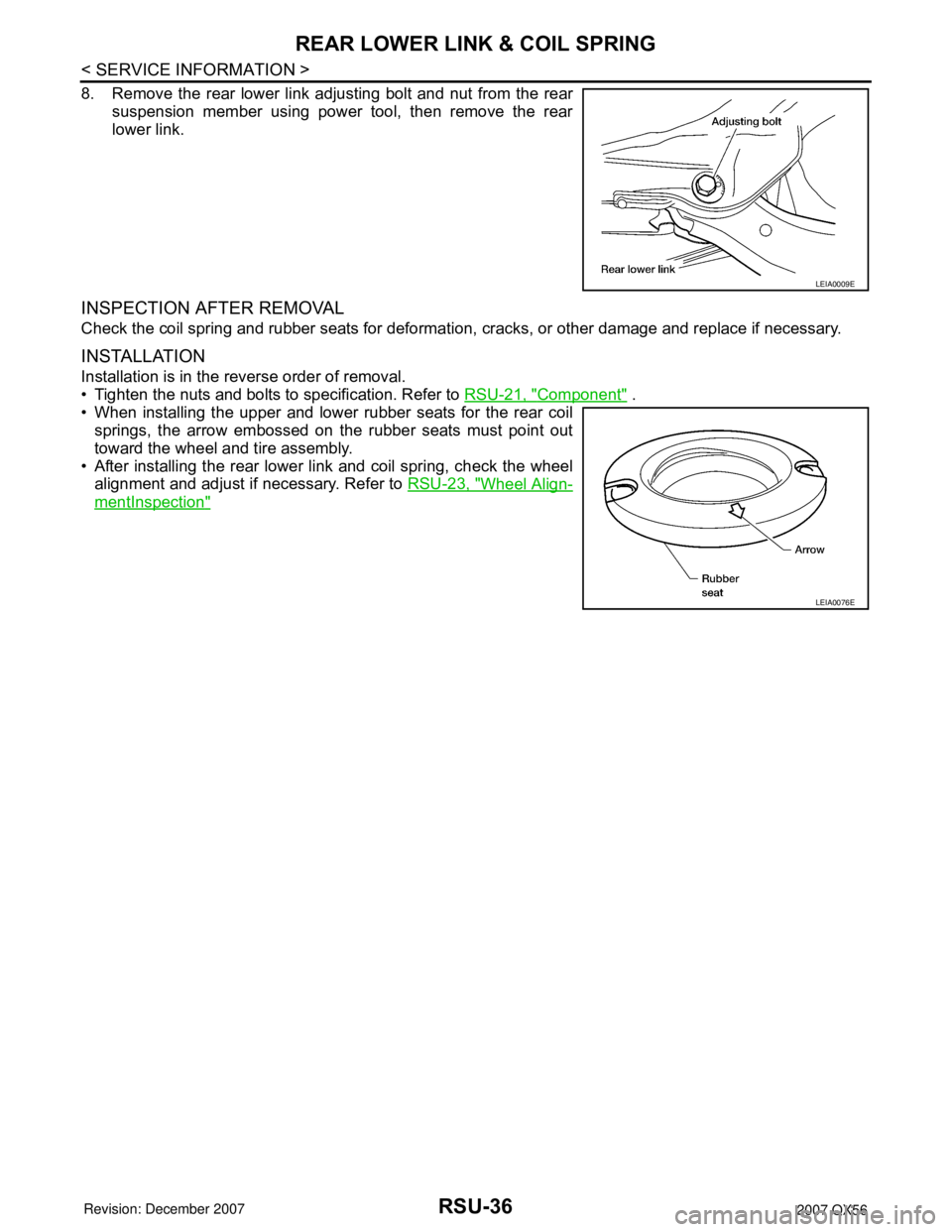

3. For removing the LH rear lower link and coil spring, remove the

height sensor arm bracket bolt from the LH rear lower link.

4. Set a suitable jack to relieve the coil spring tension from the rear

lower link.

WARNING:

Do not compress the coil spring when setting the jack.

5. Loosen the rear lower link adjusting bolt and nut connected to

the rear suspension member, using power tool.

6. Remove the rear lower link bolt and nut from the knuckle using

power tool.

7. Slowly lower the suitable jack to release the coil spring tension. Then remove the upper rubber seat, coil

spring, and lower rubber seat from the rear lower link.

LEIA0080E

LEIA0077E

LEIA0009E

LEIA0077E

Page 2626 of 3061

RSU-36

< SERVICE INFORMATION >

REAR LOWER LINK & COIL SPRING

8. Remove the rear lower link adjusting bolt and nut from the rear

suspension member using power tool, then remove the rear

lower link.

INSPECTION AFTER REMOVAL

Check the coil spring and rubber seats for deformation, cracks, or other damage and replace if necessary.

INSTALLATION

Installation is in the reverse order of removal.

• Tighten the nuts and bolts to specification. Refer to RSU-21, "

Component" .

• When installing the upper and lower rubber seats for the rear coil

springs, the arrow embossed on the rubber seats must point out

toward the wheel and tire assembly.

• After installing the rear lower link and coil spring, check the wheel

alignment and adjust if necessary. Refer to RSU-23, "

Wheel Align-

mentInspection"

LEIA0009E

LEIA0076E

Page 2628 of 3061

RSU-38

< SERVICE INFORMATION >

REAR LOAD LEVELING AIR SUSPENSION COMPRESSOR ASSEMBLY

REAR LOAD LEVELING AIR SUSPENSION COMPRESSOR ASSEMBLY

Removal and InstallationINFOID:0000000003532678

Rear Load Leveling Air Suspension System

REMOVAL

1. Use CONSULT-II "EXHAUST SOLENOID" active test to release the air pressure from the rear load level-

ing air suspension system.

2. Disconnect the electrical connectors for the rear load leveling air suspension compressor assembly.

3. Unclip the rubber cover to access the rear load leveling air suspension compressor assembly.

4. Disconnect the rear load leveling air suspension hoses at the

rear load leveling air suspension compressor assembly.

• To disconnect the hoses, push in on the lock ring using a suit-

able tool and pull the hose out.

AWEIA0076ZZ

1. Rear load leveling air suspension

hose, RH2. Shock absorber, RH 3. Height sensor

4. Rear load leveling air suspension

hose, LH5. Shock absorber, LH 6. Rear load leveling air suspension

compressor assembly

⇐Front

LEIA0074E