length INFINITI QX56 2007 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 6 of 3061

QUICK REFERENCE CHART: QX56

2007

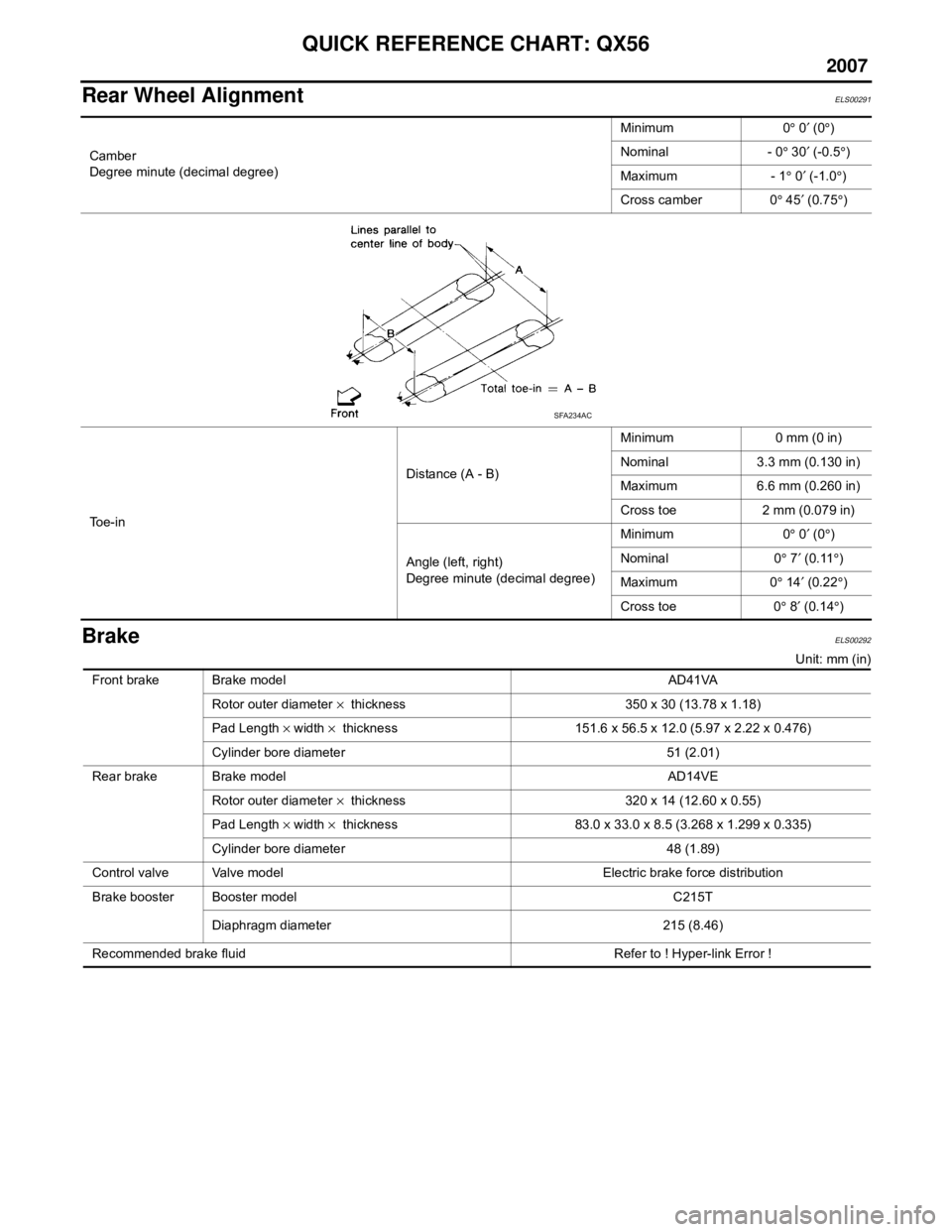

Rear Wheel AlignmentELS00291

BrakeELS00292

Unit: mm (in)

Camber

Degree minute (decimal degree)

Minimum 0

° 0 ′ (0 °)

Nominal - 0 ° 30 ′ (-0.5 °)

Maximum - 1 ° 0 ′ (-1.0 °)

Cross camber 0 ° 45 ′ (0.75 °)

To e - i n Distance (A - B)

Minimum 0 mm (0 in)

Nominal 3.3 mm (0.130 in)

Maximum 6.6 mm (0.260 in)

Cross toe 2 mm (0.079 in)

Angle (left, right)

Degree minute (decimal degree) Minimum 0

° 0 ′ (0 °)

Nominal 0 ° 7 ′ (0.11 °)

Maximum 0 ° 14 ′ (0.22 °)

Cross toe 0 ° 8 ′ (0.14 °)

SFA234AC

Front brake Brake model AD41VA

Rotor outer diameter × thickness 350 x 30 (13.78 x 1.18)

Pad Length × width × thickness 151.6 x 56.5 x 12.0 (5.97 x 2.22 x 0.476)

Cylinder bore diameter 51 (2.01)

Rear brake Brake model AD14VE Rotor outer diameter × thickness 320 x 14 (12.60 x 0.55)

Pad Length × width × thickness 83.0 x 33.0 x 8.5 (3.268 x 1.299 x 0.335)

Cylinder bore diameter 48 (1.89)

Control valve Valve model Electric brake force distribution

Brake booster Booster model C215T

Diaphragm diameter 215 (8.46)

Recommended brake fluid Refer to ! Hyper-link Error !

Page 283 of 3061

ON-VEHICLE SERVICE

AT-213

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

11. Remove bolts (A), (B) and (C) from control valve with TCM.

• : Front

12. Remove control valve with TCM from transmission case.

CAUTION:

Be careful with the manual valve notch and manual plate

height. Remove it vertically.

13. Remove A/T fluid temperature sensor 2 with bracket from con-

trol valve with TCM.

14. Remove bracket from A/T fluid temperature sensor 2.

15. Remove O-ring from A/T assembly harness connector.

Bolt symbol Length mm (in) Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA8074E

SCIA5142E

SCIA5253E

SCIA5264E

SCIA5155E

Page 286 of 3061

AT-216

< SERVICE INFORMATION >

ON-VEHICLE SERVICE

7. Install control valve with TCM in transmission case.

CAUTION:

• Make sure that turbine revolution sensor securely installs

turbine revolution sensor hole.

• Hang down revolution sensor harness toward outside so

as not to disturb installation of control valve with TCM.

• Adjust A/T assembly harness connector of control valve

with TCM to terminal hole of transmission case.

• Assemble it so that manual valve cutout is engaged with

manual plate projection.

8. Install bolts (A), (B) and (C) in control valve with TCM.

• : Front

9. Tighten bolt (1), (2) and (3) temporarily to prevent dislocation. Then tighten them in order (1 → 2 → 3),

and then tighten other bolts.

• : Front

10. Tighten control valve with TCM bolts to the specified torque.

Refer to AT-228, "

Component".

SCIA5034E

SCIA5142E

Bolt symbol Length mm (in) Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA8074E

SCIA8075E

Page 316 of 3061

AT-246

< SERVICE INFORMATION >

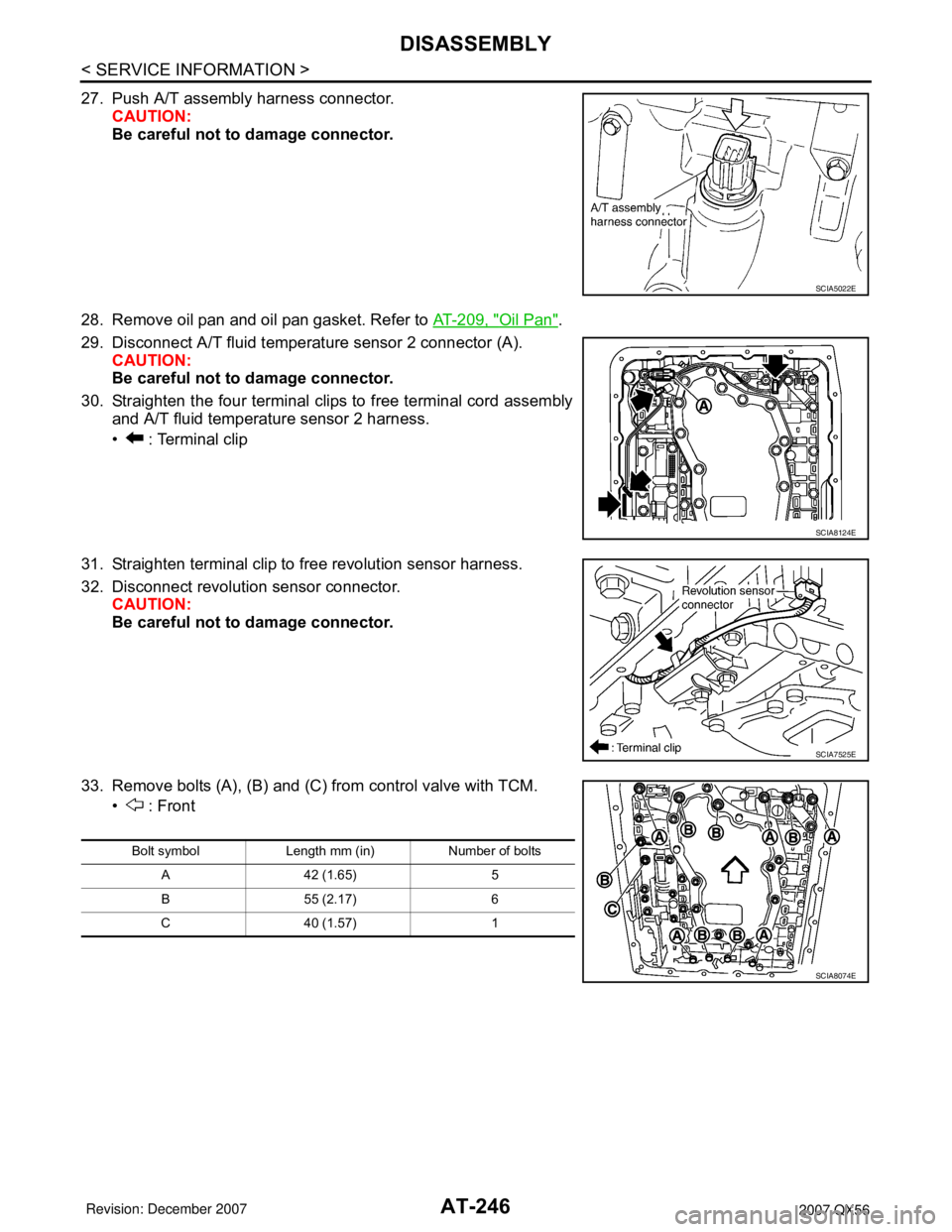

DISASSEMBLY

27. Push A/T assembly harness connector.

CAUTION:

Be careful not to damage connector.

28. Remove oil pan and oil pan gasket. Refer to AT-209, "

Oil Pan".

29. Disconnect A/T fluid temperature sensor 2 connector (A).

CAUTION:

Be careful not to damage connector.

30. Straighten the four terminal clips to free terminal cord assembly

and A/T fluid temperature sensor 2 harness.

• : Terminal clip

31. Straighten terminal clip to free revolution sensor harness.

32. Disconnect revolution sensor connector.

CAUTION:

Be careful not to damage connector.

33. Remove bolts (A), (B) and (C) from control valve with TCM.

• : Front

SCIA5022E

SCIA8124E

SCIA7525E

Bolt symbol Length mm (in) Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA8074E

Page 365 of 3061

ASSEMBLY

AT-295

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

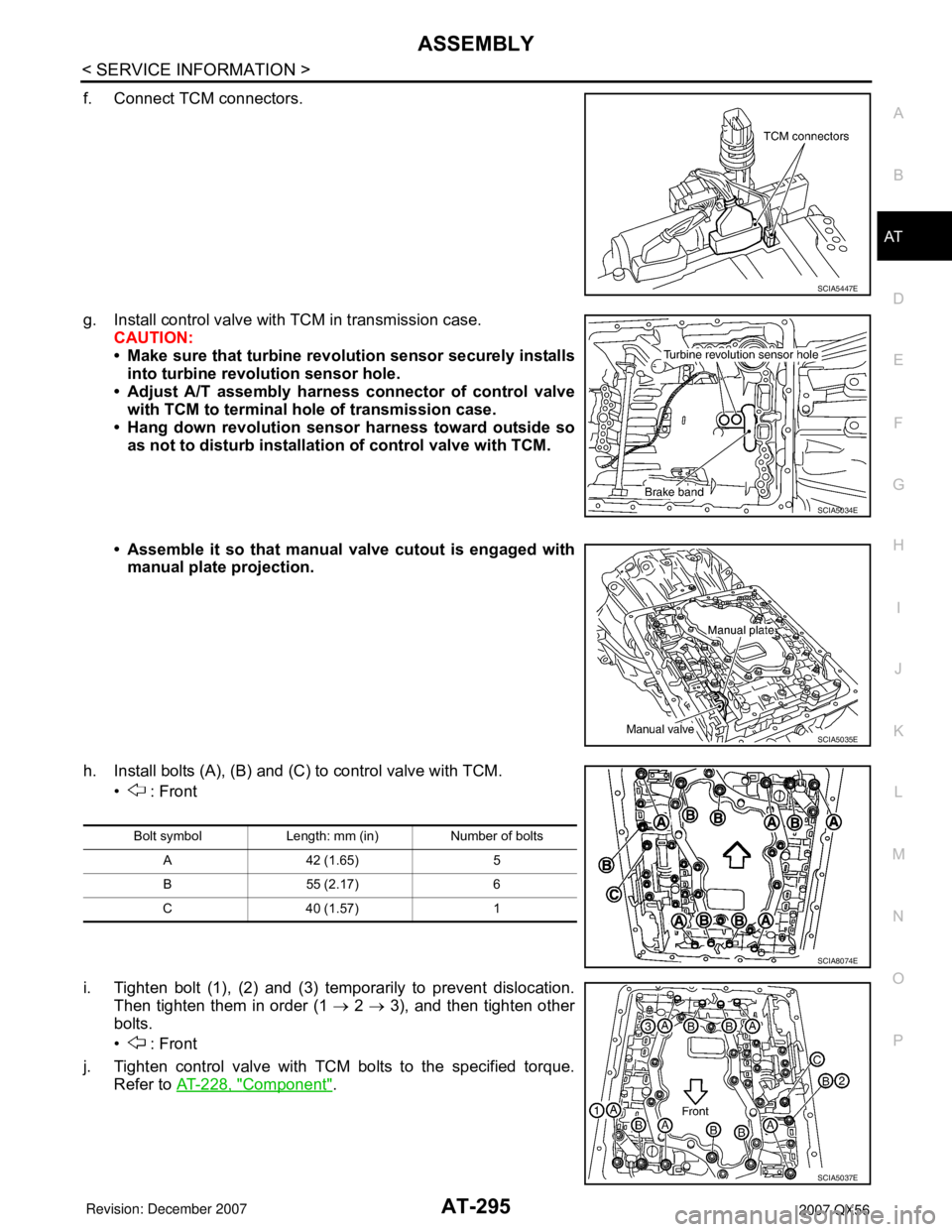

f. Connect TCM connectors.

g. Install control valve with TCM in transmission case.

CAUTION:

• Make sure that turbine revolution sensor securely installs

into turbine revolution sensor hole.

• Adjust A/T assembly harness connector of control valve

with TCM to terminal hole of transmission case.

• Hang down revolution sensor harness toward outside so

as not to disturb installation of control valve with TCM.

• Assemble it so that manual valve cutout is engaged with

manual plate projection.

h. Install bolts (A), (B) and (C) to control valve with TCM.

• : Front

i. Tighten bolt (1), (2) and (3) temporarily to prevent dislocation.

Then tighten them in order (1 → 2 → 3), and then tighten other

bolts.

• : Front

j. Tighten control valve with TCM bolts to the specified torque.

Refer to AT-228, "

Component".

SCIA5447E

SCIA5034E

SCIA5035E

Bolt symbol Length: mm (in) Number of bolts

A 42 (1.65) 5

B 55 (2.17) 6

C 40 (1.57) 1

SCIA8074E

SCIA5037E

Page 805 of 3061

BL-94

< SERVICE INFORMATION >

AUTOMATIC BACK DOOR SYSTEM

10. After approximately 5 seconds, the back door warning chime will sound for 1 second.

11. Release the power liftgate switch.

12. Immediately close the back door manually.

13. Press and release the power liftgate switch to activate operating check mode.

Self-diagnosis results are indicated by the back door warning chime.

Turn ignition switch OFF to end input signal check mode.

Diagnosis ChartINFOID:0000000003532965

Back door warning chime order Back door warning chime length

Start self-diagnosis1.5 seconds

OK NG

1. Operating conditions diagnosis 0.5 seconds 0.2 seconds

2. Back door encoder diagnosis 0.5 seconds 0.2 seconds

3. Back door clutch diagnosis 0.5 seconds 0.2 seconds

4. Back door motor diagnosis 0.5 seconds 0.2 seconds

5. Cinch latch motor diagnosis 0.5 seconds 0.2 seconds

Restart self-diagnosis 1.5 seconds

Item NG Result Refer to

1. Operating conditions diagnosis resultOne of the following operating conditions no

longer met: ignition switch ON, back door close

switch (CANCEL) ON, A/T selector lever in P

position—

2. Back door encoder diagnosis resultSensor diagnosis/short, pulse signal, pulse

signal directionBL-114

3. Back door clutch diagnosis result Back door clutch does not operateBL-114

4. Back door motor diagnosis resultBack door motor does not operate (no operat-

ing current)BL-114

5. Cinch latch motor diagnosis resultCinch latch motor does not operate (no operat-

ing current)BL-114

Symptom Suspect systems Refer to

Automatic operations are not executed from the back door fully

closed or fully open position.

(Auto closure operates normally.)Power liftgate switch system inspectionBL-95

Park switch —

Power window serial linkBL-92

Pinch strip system inspectionBL-100

Automatic operations are not carried out together with open/close

operations.

(Manual operations are normal.)Power liftgate switch system inspectionBL-95Back door close switch system inspectionBL-98

Auto back door power supply and ground cir-

cuit system inspection.BL-95

The auto closure function does not operate.

(Stops at the halfway position for auto closing operations.)Pinch strip system inspectionBL-100

During auto closing operations, if obstruction is detected, the door

does not operate in reverse.Back door motor assembly —

During close or cinch operations, the door does not operate in re-

verse if the back door handle is operated.Handle switch systemBL-104

Page 862 of 3061

BODY REPAIR

BL-151

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

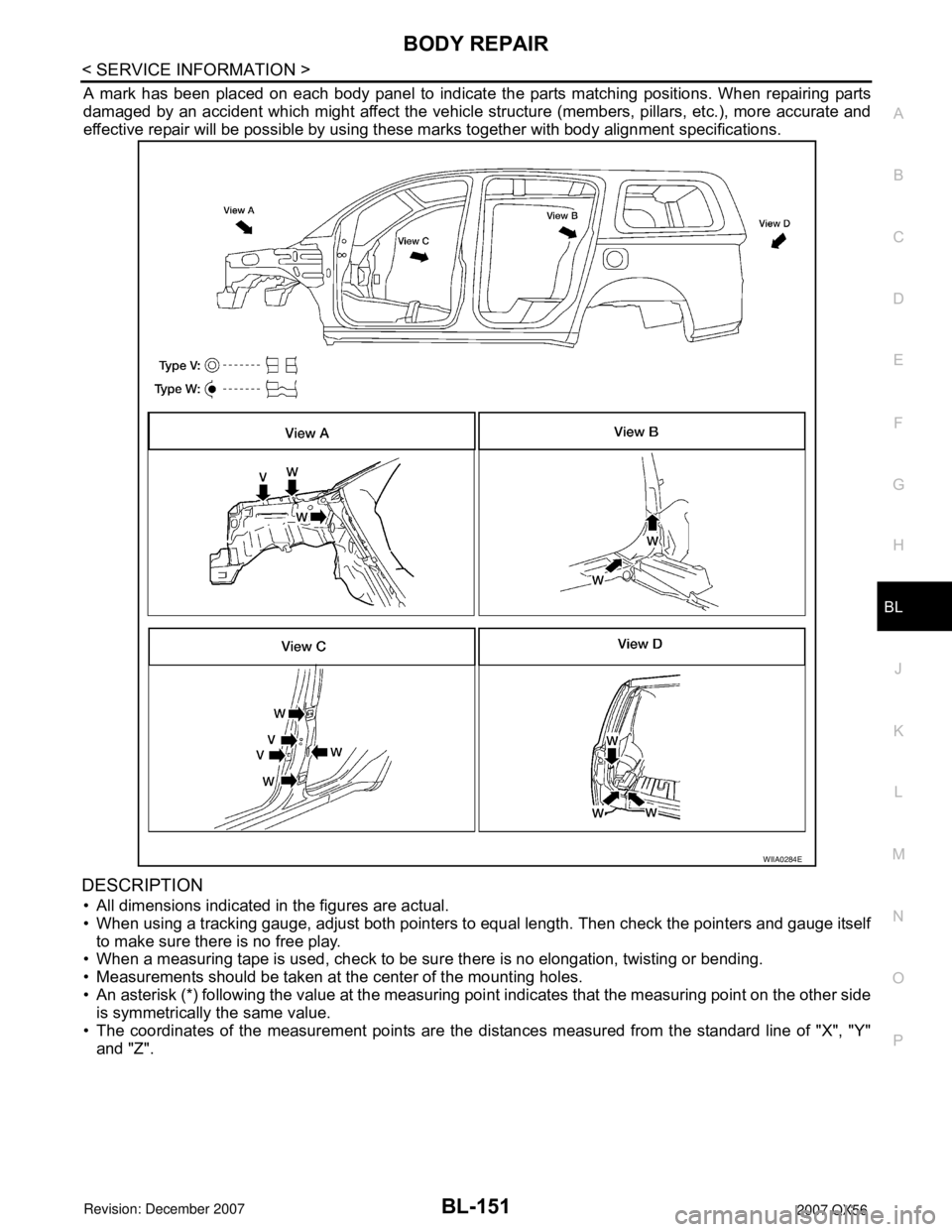

A mark has been placed on each body panel to indicate the parts matching positions. When repairing parts

damaged by an accident which might affect the vehicle structure (members, pillars, etc.), more accurate and

effective repair will be possible by using these marks together with body alignment specifications.

DESCRIPTION

• All dimensions indicated in the figures are actual.

• When using a tracking gauge, adjust both pointers to equal length. Then check the pointers and gauge itself

to make sure there is no free play.

• When a measuring tape is used, check to be sure there is no elongation, twisting or bending.

• Measurements should be taken at the center of the mounting holes.

• An asterisk (*) following the value at the measuring point indicates that the measuring point on the other side

is symmetrically the same value.

• The coordinates of the measurement points are the distances measured from the standard line of "X", "Y"

and "Z".

WIIA0284E

Page 914 of 3061

BR-16

< SERVICE INFORMATION >

BRAKE BOOSTER

• Be careful not to damage brake booster stud bolt threads. If brake booster is tilted or inclined during

installation, dash panel may damage the threads.

• Attach the check valve in the correct direction.

1. Remove engine room cover with power tool. Refer to EM-12, "

Removal and Installation" .

2. Remove engine air duct assembly. Refer to EM-15, "

Removal and Installation" .

3. Remove brake piping from brake master cylinder.

4. Remove brake master cylinder. Refer to BR-13, "

Removal and Installation" .

5. Remove vacuum hose from brake booster. Refer to BR-17

.

6. Disconnect active boost and delta stroke sensor harness connectors from brake booster assembly.

7. Remove brake pedal attachment snap pin and clevis pin from inside the vehicle.

8. Remove nuts on brake booster and brake pedal assembly.

9. Remove brake booster assembly from dash panel.

INSPECTION AFTER REMOVAL

Output Rod Length Inspection

1. Using a handy vacuum pump, apply a vacuum of – 66.7 kPa (–

500 mmHg, –19.69 inHg) to brake booster.

2. Check output rod length.

INSTALLATION

1. Loosen lock nut to adjust input rod length so that the length B (in

the figure) satisfies the specified value.

2. After adjusting “B”, temporarily tighten lock nut and install

booster assembly to the vehicle.

• Install a gaskets and spacer block between booster assembly

and the dash panel.

3. Connect brake pedal with clevis of input rod.

4. Install pedal bracket mounting nuts and tighten them to the

specified torque.

5. Install brake piping from brake master cylinder to ABS actuator. Refer to BR-10, "

Hydraulic Circuit".

6. Connect active boost and delta stroke sensor harness connectors to brake booster assembly.

7. Connect vacuum hose to brake booster.

8. Install master cylinder to booster assembly. Refer to BR-13, "

Removal and Installation" .

9. Adjust the height and play of brake pedal.

10. Tighten lock nut of input rod to specification.

11. Install engine air duct assembly. Refer to EM-15, "

Removal and Installation" .

12. Install engine room cover with power tool. Refer to EM-12, "

Removal and Installation" .

13. Refill with new brake fluid and bleed air. Refer to BR-8, "

Bleeding Brake System" .

SBR208E

Standard dimension : 15.6 − 15.9 mm (0.614 − 0.626 in)

[when vacuum is – 66.7 kPa (– 500 mmHg, – 19.69 inHg)]

Length “B” : 151 mm (5.94 in)

WFIA0382E

Page 927 of 3061

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-29

< SERVICE INFORMATION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

SERVICE DATA AND SPECIFICATIONS (SDS)

General SpecificationINFOID:0000000003532748

Unit: mm (in)

Brake PedalINFOID:0000000003532749

Unit: mm (in)

Front brake Brake model AD41VA

Rotor outer diameter × thickness 350 x 30 (13.78 x 1.18)

Pad Length × width × thickness 151.6 x 56.5 x 12.0 (5.97 x 2.22 x 0.476)

Cylinder bore diameter 51 (2.01)

Rear brake Brake model AD14VE

Rotor outer diameter × thickness 320 x 14 (12.60 x 0.551)

Pad Length × width × thickness 83.0 x 33.0 x 12.13 (3.268 x 1.299 x 0.478)

Cylinder bore diameter 48 (1.89)

Control valve Valve model Electric brake force distribution

Brake booster Booster model C215T

Diaphragm diameter 215 (8.46)

Recommended brake fluid Refer to MA-10

Free height "H"182.3 - 192.3 mm (7.18 - 7.57 in)

Depressed pedal height "D" [under a force of 490 N (50 kg-f, 110 lb-f) with engine

running]More than 90.3 mm (3.55 in)

Clearance between pedal stopper and threaded end of stop lamp switch and

ASCD switch "C

1 " or “C2 ”0.74 - 1.96 mm (0.029 - 0.077 in)

Pedal play "A"3 - 11 mm (0.12 - 0.43 in)

WFIA0160E

Page 1108 of 3061

ENGINE CONTROL SYSTEM

EC-25

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

K

L

MA

EC

N

P O

*1: This sensor is not used to control the engine system. This is used only for the on board diagnosis.

*2: This signal is sent to the ECM through CAN communication line.

*3: ECM determines the start signal status by the signals of engine speed and battery voltage.

SYSTEM DESCRIPTION

The amount of fuel injected from the fuel injector is determined by the ECM. The ECM controls the length of

time the valve remains open (injection pulse duration). The amount of fuel injected is a program value in the

ECM memory. The program value is preset by engine operating conditions. These conditions are determined

by input signals (for engine speed and intake air) from both the crankshaft position sensor and the mass air

flow sensor.

VARIOUS FUEL INJECTION INCREASE/DECREASE COMPENSATION

In addition, the amount of fuel injected is compensated to improve engine performance under various operat-

ing conditions as listed below.

• When starting the engine

• During acceleration

• Hot-engine operation

• When selector lever is changed from N to D

• High-load, high-speed operation

• During deceleration

• During high engine speed operation

MIXTURE RATIO FEEDBACK CONTROL (CLOSED LOOP CONTROL)

Sensor Input signal to ECM ECM function Actuator

Crankshaft position sensor (POS)

Engine speed*

3

Piston position

Fuel injection

& mixture ratio

controlFuel injector Camshaft position sensor (PHASE)

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Air fuel ratio (A/F) sensor 1 Density of oxygen in exhaust gas

Throttle position sensor Throttle position

Accelerator pedal position sensor Accelerator pedal position

Park/neutral position (PNP) switch Gear position

Knock sensor Engine knocking condition

Battery

Battery voltage*

3

Power steering pressure sensor Power steering operation

Heated oxygen sensor 2*

1Density of oxygen in exhaust gas

ABS actuator and electric unit (control unit)

VDC/TCS operation command*

2

Air conditioner switch

Air conditioner operation*2

Wheel sensor

Vehicle speed*2

PBIB3020E