suspension INFINITI QX56 2007 Factory Owner's Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 2593 of 3061

PREPARATION

RSU-3

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

PREPARATION

Commercial Service ToolINFOID:0000000003532654

Tool nameDescription

Power tool• Removing wheel nuts

• Removing brake caliper assembly

• Removing rear suspension component

parts

PBIC0190E

Page 2594 of 3061

RSU-4

< SERVICE INFORMATION >

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

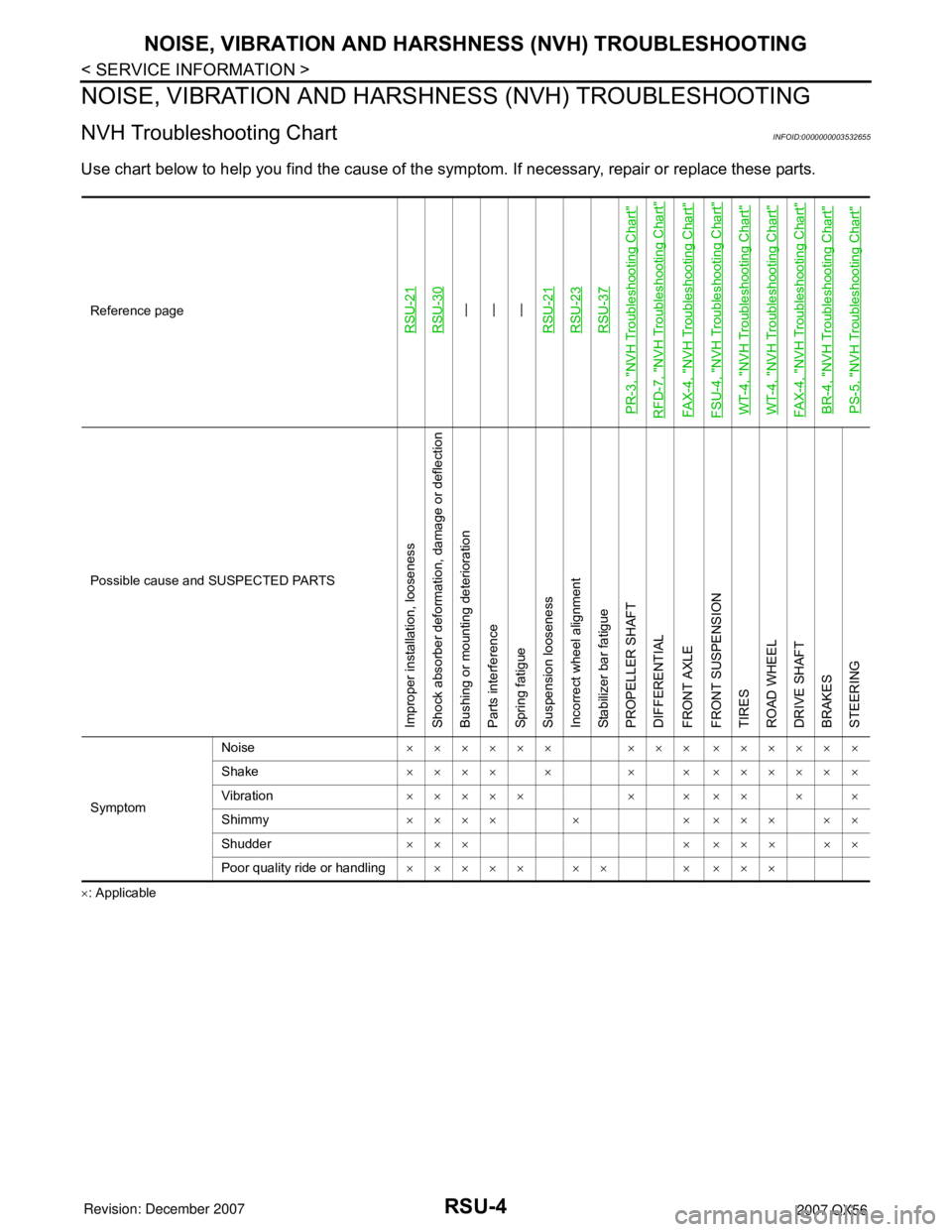

NVH Troubleshooting ChartINFOID:0000000003532655

Use chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

×: ApplicableReference page

RSU-21RSU-30

—

—

—

RSU-21

RSU-23RSU-37

PR-3, "

NVH Troubleshooting Chart

"

RFD-7, "

NVH Troubleshooting Chart

"

FAX-4, "

NVH Troubleshooting Chart

"

FSU-4, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

WT-4, "

NVH Troubleshooting Chart

"

FAX-4, "

NVH Troubleshooting Chart

"

BR-4, "

NVH Troubleshooting Chart

"

PS-5, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Shock absorber deformation, damage or deflection

Bushing or mounting deterioration

Parts interference

Spring fatigue

Suspension looseness

Incorrect wheel alignment

Stabilizer bar fatigue

PROPELLER SHAFT

DIFFERENTIAL

FRONT AXLE

FRONT SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

SymptomNoise×××××× ××× ××××××

Shake×××× × × × ××××××

Vibration××××× × × ×× × ×

Shimmy×××× × × ××× ××

Shudder ××× × ××× ××

Poor quality ride or handling××××× ×× × ×××

Page 2596 of 3061

RSU-6

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

TROUBLE DIAGNOSIS

How to Perform Trouble Diagnosis for Quick and Accurate RepairINFOID:0000000003532657

INTRODUCTION

The rear load leveling air suspension system uses an electronic con-

trol unit to control major functions. The control unit accepts input sig-

nals from the height sensor and controls compressor and exhaust

valve operation.

It is much more difficult to diagnose a rear load leveling air suspen-

sion system problem that occurs intermittently rather than continu-

ously. Most intermittent problems are caused by poor electrical

connections or faulty wiring. In this case, careful checking of suspi-

cious circuits may help prevent the replacement of good parts.

Before undertaking actual checks, take just a few minutes to talk with

a customer who approaches with an air suspension system com-

plaint. The customer is a very good source of information on such

problems, especially intermittent ones. Through discussion with the

customer, find out what symptoms are present and under what con-

ditions they occur.

Start your diagnosis by looking for basic mechanical problems first.

This is one of the best ways to troubleshoot concerns on an air sus-

pension system equipped vehicle. Also check related Service Bulle-

tins for information.

CLARIFY CONCERN

• A customer's description of a vehicle concern may vary depending

on the individual. It is important to clarify the customer's concern.

• Ask the customer about what symptoms are present under what

conditions. Use this information to reproduce the symptom.

SEF233G

SEF234G

SBR339B

Page 2600 of 3061

RSU-10

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

Basic Inspection

INFOID:0000000003532660

AIR HOSES

1. Check for pinched or damaged air hoses between the suspension air reservoir and each load leveling rear

air suspension shock absorber. Reposition, repair or replace hoses as necessary.

2. Check the air hose connections at the suspension air reservoir and at the shock absorbers for leaks. If

connections are leaking, repair or replace hoses as necessary.

WEWA0070E

Page 2601 of 3061

TROUBLE DIAGNOSIS

RSU-11

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

POWER SYSTEM TERMINAL LOOSENESS AND BATTERY INSPECTION

Make sure the battery positive cable, negative cable and ground connection are not loose. In addition, make

sure the battery is sufficiently charged.

CK SUSP INDICATOR LAMP INSPECTION

1. Make sure the CK SUSP indicator lamp turns on for approximately 2 seconds when the ignition switch is

turned ON. If it does not, check the combination meter. Refer to DI-5

.

2. Make sure the lamp turns off approximately 2 seconds after the ignition switch is turned ON. If the lamp

does not turn off, conduct self-diagnosis of the suspension control unit.

3. After conducting the self-diagnosis, be sure to erase the error memory. Refer to RSU-11, "

CONSULT-II

Function (AIR LEVELIZER)" .

Chek Suspension Indicator Lamp TimingINFOID:0000000003532661

X: ON

—: OFF

Control Unit Input/Output Signal StandardINFOID:0000000003532662

CONSULT-II Function (AIR LEVELIZER)INFOID:0000000003532663

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II START PROCEDURE

Refer to GI-36, "CONSULT-II Start Procedure".

ConditionCK SUSP

indicator lampRemarks

Ignition switch OFF – –

Ignition switch ON X Turns off after approximately 2 seconds.

Te r m i n a l

No.Wire color Item ConditionVoltage (V)

(Approx.)

1 V Compressor relay output

Ignition switch ON or STARTBattery voltage

3 W Height sensor signal input 0.2V - 4.8V

5 R Reference voltage 5V

6 G/R Ignition power

Battery voltage

7W/LBattery power —

8 G/W Diagnostic K-line — —

9 SB Exhaust valve output Ignition switch ON or START Battery voltage

10 BR Warning lamp output — —

14 L Height sensor ground — —

15 BR/W Generator L signal input Engine running —

16 B Suspension control unit ground — 0V

AIR LEVELIZER

diagnostic modeDescription

WORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the BCM for setting the status

suitable for required operation, input/output signals are received from the BCM and received data is

displayed.

SELF-DIAG RESULTS Displays suspension control unit self-diagnosis results.

DATA MONITOR Displays suspension control unit input/output data in real time.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

ECU PART NUMBER Suspension control unit part number can be read.

Page 2602 of 3061

RSU-12

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

SELF-DIAGNOSIS

Display Item List

WORK SUPPORT

Display Item List

DATA MONITOR

Display Item List

Self-diagnostic item Malfunction detecting condition Check system

Vehicle height sensor

[C1801]Vehicle height sensor voltage is less than 0.2V or greater than

4.8V for more than 60 seconds.Refer to RSU-14, "

Height

Sensor System Inspection" .

Compressor relay

[C1802]1. Driving transistor for compressor relay is off and monitor

voltage continues high level for more than 10 seconds.

2. Driving transistor for compressor relay is on and monitor

voltage continues low level for more than 5 seconds.Refer to RSU-17, "

Compres-

sor Motor, Compressor Motor

Relay and Circuit Inspection"

.

Exhaust solenoid

[C1803]1. Driving transistor for exhaust solenoid is off and monitor volt-

age continues high level for more than 10 seconds.

2. Driving transistor for exhaust solenoid is on and monitor volt-

age continues low level for more than 5 seconds.Refer to RSU-15, "

Exhaust

Valve Solenoid System In-

spection" .

Vehicle height adjusting trouble

(compressor)

[C1804]Continuous compressor relay ON time is more than 120 seconds.Refer to RSU-17, "

Compres-

sor Motor, Compressor Motor

Relay and Circuit Inspection"

.

Vehicle height adjusting trouble

(exhaust solenoid)

[C1805]Continuous exhaust solenoid ON time is more than 120 seconds.Refer to RSU-15, "

Exhaust

Valve Solenoid System In-

spection" .

Vehicle height sensor locking trou-

ble

[C1806]Output sensor voltage variation ±0.02V is more than 100 hour

when vehicle height range is normal.Refer to RSU-14, "

Height

Sensor System Inspection".

Sensor 5V trouble

[C1807]Sensor reference voltage is less than 0.8V or more than 6V for 20

seconds.Refer to RSU-14, "

Height

Sensor System Inspection".

Integral time trouble by supplying

air

[C1808]Integral discontinuous time on the compressor is more than 180

seconds.Refer to RSU-17, "

Compres-

sor Motor, Compressor Motor

Relay and Circuit Inspec-

tion".

Item Description Condition

STANDARD HEIGHT LEVELResets the vehicle height to the initialization flag set-

ting stored in the suspension control unit.Vehicle unladen RSU-44, "

Wheelarch Height

(Unladen*1)" , set in a horizontal position and

not moving.

NOTE:

Do not take your eyes off the vehicle while

CONSULT-II is processing.

ADJUST HEIGHT INISets the height initialization flag in the suspension

control unit when the control unit has been replaced

or when the initialization flag has been cleared using

the "CLEAR HEIGHT INI" procedure.Vehicle unladen RSU-44, "

Wheelarch Height

(Unladen*1)" . Move vehicle forward and back-

ward approx. 5 m (16.4 ft) and rock vehicle from

side to side.

NOTE:

Do not move vehicle while CONSULT-II is pro-

cessing.

CLEAR HEIGHT INIClears the initialization flag in the suspension control

unit.Vehicle unladen RSU-44, "

Wheelarch Height

(Unladen*1)" .

Page 2603 of 3061

TROUBLE DIAGNOSIS

RSU-13

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

X: Applicable

–: Not applicable

ACTIVE TEST

CAUTION:

• Do not perform active test while driving.

Display Item List

CAUTION:

The "COMPRESSOR" active test will remain ON until it is turned off using CONSULT-II. Allowing the

compressor to run for an extended period of time may cause damage to air suspension system com-

ponents due to excessive pressure in the air suspension system.

NOTE:

• "TEST IS STOPPED" is displayed approximately 10 seconds after operation starts for all active test items

except "COMPRESSOR".

• After "TEST IS STOPPED" is displayed, to perform test again, repeat Step 6.

Test ItemData monitor item selection

ALL

SIGNALSSELECTION

FROM MENU

HEIGT SENXX

HEIGT CALCXX

SEN FIX TIME X X

HEIGT INI VAL X X

COMPRESSOR X X

EXH SOLENOID X X

ACG LXX

Test Item Description

COMPRESSOROFF/ON

EXHAUST SOLENOID OFF/ON

WARNING LAMPOFF/ON

Page 2604 of 3061

RSU-14

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Height Sensor System InspectionINFOID:0000000003532664

INSPECTION PROCEDURE

1.SELF-DIAGNOSIS RESULT CHECK

Check self-diagnosis results.

Is the above displayed in the self-diagnosis display items?

YES >> GO TO 3.

NO >> GO TO 2.

2.DATA MONITOR CHECK

Conduct data monitor of "HEIGT SEN" to check if the status is normal.

OK or NG

OK >> Inspection End.

NG >> GO TO 3.

3.CONNECTOR INSPECTION

1. Disconnect suspension control unit connector B3 and height sensor C8.

2. Check the terminals for deformation, disconnection, looseness or damage.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace as necessary.

4.CHECK HEIGHT SENSOR POWER

1. Reconnect the suspension control unit connector.

2. Turn the ignition switch ON.

3. Check voltage between height sensor connector C8 terminal 1

and ground.

OK or NG

OK >> GO TO 5.

NG >> Check harness or connector for open or short. If OK,

replace suspension control unit. Refer to RSU-42

.

5.CHECK HEIGHT SENSOR GROUND

1. Turn ignition switch OFF.

Self-diagnosis results

C1801

C1806

C1807

HEIGT SEN 0.2V - 4.8V

Voltage : Approx. 5V

WEIA0084E

Page 2605 of 3061

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

RSU-15

< SERVICE INFORMATION >

C

D

F

G

H

I

J

K

L

MA

B

RSU

N

O

P

2. Check continuity between height sensor connector C8 terminal

3 and ground.

OK or NG

OK >> GO TO 6.

NG >> Repair harness or connector.

6.CHECK HEIGHT SENSOR SIGNAL CIRCUIT

1. Disconnect suspension control unit connector.

2. Check continuity between height sensor connector C8 terminal

2 and suspension control unit connector B3 terminal 3.

3. Check continuity between height sensor connector C8 terminal

2 and ground.

OK or NG

OK >> Replace the height sensor. Refer to RSU-40.

NG >> Repair harness or connector.

Exhaust Valve Solenoid System InspectionINFOID:0000000003532665

INSPECTION PROCEDURE

1.SELF-DIAGNOSIS RESULT CHECK

Check self-diagnosis results.

Is the above displayed in the self-diagnosis display items?

YES >> If code C1803 was retrieved during self-diagnosis, GO TO 3. If code C1805 was retrieved during

self-diagnosis, GO TO 2.

NO >> Inspection End.

2.CHECK SYSTEM OPERATION

1. Load vehicle to standard laden condition (with driver, front passenger, 2 passengers in second row seats

and no cargo).

2. Conduct active test of "COMPRESSOR" to raise vehicle ride height to +20mm.

CAUTION:3 - Ground Continuity should exist.

WEIA0085E

2 - 3 Continuity should exist.

WEIA0086E

2 - Ground Continuity should not exist.

WEIA0087E

Self-diagnosis results

C1803

C1805

Page 2606 of 3061

RSU-16

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

The "COMPRESSOR" active test will remain ON until it is turned off using CONSULT-II. Allowing

the compressor to run for an extended period of time may cause damage to air suspension sys-

tem components due to excessive pressure in the air suspension system.

3. Return the rear load leveling air suspension system to normal operating mode.

4. Check self-diagnostic results.

Is code C1805 displayed again?

YES >> GO TO 3.

NO >> Inspection End.

3.CONNECTOR INSPECTION

1. Disconnect suspension control unit connector B3 and suspension air compressor C9.

2. Check the terminals for deformation, disconnection, looseness or damage.

OK or NG

OK >> If code C1805 was retrieved during self-diagnosis, GO TO 4. If code C1803 was retrieved during

self-diagnosis, GO TO 6.

NG >> Repair or replace as necessary.

4.AIR HOSE INSPECTION

Inspect for pinched or damaged air hoses between the suspension air reservoir and each load leveling rear air

suspension shock absorber.

OK or NG

OK >> GO TO 5.

NG >> Repair or replace as necessary.

5.EXHAUST VALVE SOLENOID INSPECTION

Apply 12V to suspension air compressor terminal 2 and ground to

suspension air compressor terminal 1.

OK or NG

OK >> GO TO 6.

NG >> Replace the suspension air compressor. Refer to RSU-

38.

6.CHECK EXHAUST VALVE SOLENOID POWER AND GROUND

1. Reconnect the suspension control unit connector.

2. Turn the ignition switch ON.

3. Check voltage between suspension air compressor connector

C9 terminal 2 and ground.

4. Turn ignition switch OFF.System air pressure should vent.

WEIA0063E

Voltage : Approx. 12V

WEIA0088E