sensor INFINITI QX56 2007 Factory Repair Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2007, Model line: QX56, Model: INFINITI QX56 2007Pages: 3061, PDF Size: 64.56 MB

Page 153 of 3061

TROUBLE DIAGNOSIS

AT-83

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

PCONSULT-II Function (A/T)INFOID:0000000003532259

CONSULT-II can display each diagnostic item using the diagnostic test modes shown following.

CONSULT-II REFERENCE VALUE

NOTICE:

1. The CONSULT-II electrically displays shift timing and lock-up timing (that is, operation timing of each sole-

noid).

Check for time difference between actual shift timing and the CONSULT-II display. If the difference is

noticeable, mechanical parts (except solenoids, sensors, etc.) may be malfunctioning. Check mechanical

parts using applicable diagnostic procedures.

2. Shift schedule (which implies gear position) displayed on CONSULT-II and that indicated in Service Man-

ual may differ slightly. This occurs because of the following reasons:

- Actual shift schedule has more or less tolerance or allowance,

- Shift schedule indicated in Service Manual refers to the point where shifts start, and

- Gear position displayed on CONSULT-II indicates the point where shifts are completed.

3. Display of solenoid valves on CONSULT-II changes at the start of shifting, while gear position is displayed

upon completion of shifting (which is computed by TCM).

9 B/R Starter relaySelector lever in “N”,“ P” positions. Battery voltage

Selector lever in other positions. 0V

10 B Ground Always 0V Te r m i n a l

No.Wire

colorItem Condition Data (Pyrex.)

TCM diagnostic mode Description

WORK SUPPORTSupports inspections and adjustments. Commands are transmitted to the TCM for setting the status

suitable for required operation, input/output signals are received from the TCM and received data is

displayed.

SELF-DIAG RESULTS Displays TCM self-diagnosis results.

DATA MONITOR Displays TCM input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read.

ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

FUNCTION TEST Conducted by CONSULT-II instead of a technician to determine whether each system is “OK” or “NG”.

ECU PART NUMBER TCM part number can be read.

Item name Condition Display value (Approx.)

ATF TEMP SE 1

0°C (32° F) - 20°C (68°F) - 80°C (176°F)3.3 - 2.7 - 0.9 V

ATF TEMP SE 23.3 - 2.5 - 0.7 V

TCC SOLENOIDWhen perform slip lock-up 0.2 - 0.4 A

When perform lock-up 0.4 - 0.6 A

SLCT LVR POSISelector lever in “N”,“P” position. N/P

Selector lever in “R” position. R

Selector lever in “D” position. D

Selector lever in “4” position. 4

Selector lever in “3” position. 3

Selector lever in “2” position. 2

Selector lever in “1” position. 1

VHCL/S SE·A/T During drivingApproximately matches the

speedometer reading.

ENGINE SPEED Engine runningClosely matches the tachometer

reading.

Page 155 of 3061

TROUBLE DIAGNOSIS

AT-85

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

X: Applicable, —: Not applicable

Items (CONSULT-II

screen terms)Malfunction is detected when...TCM self-di-

agnosisOBD-II (DTC)

“A/T” with

CONSULT-IIMIL indicator

lamp*1, “EN-

GINE” with

CONSULT-II or

GST

CAN COMM CIRCUIT • When a malfunction is detected in CAN communications U1000 U1000

STARTER RELAY/

CIRC• If this signal is ON other than in P or N position, this is judged to be a

malfunction.

(And if it is OFF in P or N position, this too is judged to be a malfunction.)P0615 —

TCM • TCM is malfunctioning. P0700 P0700

PNP SW/CIRC• PNP switch 1-4 signals input with impossible pattern

• “P” position is detected from N position without any other position being

detected in between.P0705 P0705

TURBINE REV S/CIRC• TCM does not receive the proper voltage signal from the sensor.

• TCM detects an irregularity only at position of 4th gear for turbine revo-

lution sensor 2.P0717 P0717

VEH SPD SEN/CIR AT

(Revolution sensor)• Signal from vehicle speed sensor A/T (Revolution sensor) not input due

to cut line or the like

• Unexpected signal input during running

• After ignition switch is turned ON, unexpected signal input from vehicle

speed sensor MTR before the vehicle starts movingP0720 P0720

ENGINE SPEED SIG • TCM does not receive the CAN communication signal from the ECM. P0725 —

TCC SOLENOID/CIRC • Normal voltage not applied to solenoid due to cut line, short, or the like P0740 P0740

A/T TCC S/V FNCTN• A/T cannot perform lock-up even if electrical circuit is good.

• TCM detects as irregular by comparing difference value with slip rota-

tion.P0744 P0744*2

L/PRESS SOL/CIRC• Normal voltage not applied to solenoid due to cut line, short, or the like

• TCM detects as irregular by comparing target value with monitor value.P0745 P0745

TP SEN/CIRC A/T• TCM does not receive the proper accelerator pedal position signals (in-

put by CAN communication) from ECM.P1705 P1705

ATF TEMP SEN/CIRC• During running, the ATF temperature sensor signal voltage is exces-

sively high or lowP1710 P0710

VEH SPD SE/CIR·MTR• Signal (CAN communication) from vehicle speed sensor MTR not input

due to cut line or the like

• Unexpected signal input during runningP1721 —

A/T INTERLOCK• Except during shift change, the gear position and ATF pressure switch

states are monitored and comparative judgement made.P1730 P1730

A/T 1ST E/BRAKING• Each ATF pressure switch and solenoid current is monitored and if a

pattern is detected having engine braking 1st gear other than in the "1"

position, a malfunction is detected.P1731 —

I/C SOLENOID/CIRC• Normal voltage not applied to solenoid due to functional malfunction,

cut line, short, or the like

• TCM detects as irregular by comparing target value with monitor value.P1752 P1752

I/C SOLENOID FNCTN • TCM detects that actual gear ratio is irregular, and relation between

gear position and condition of ATF pressure switch 3 is irregular during

depressing accelerator pedal. (Other than during shift change)

• TCM detects that relation between gear position and condition of ATF

pressure switch 3 is irregular during releasing accelerator pedal. (Other

than during shift change)P1754 P1754*2

FR/B SOLENOID/CIRC• Normal voltage not applied to solenoid due to functional malfunction,

cut line, short, or the like

• TCM detects as irregular by comparing target value with monitor value.P1757 P1757

Page 157 of 3061

TROUBLE DIAGNOSIS

AT-87

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

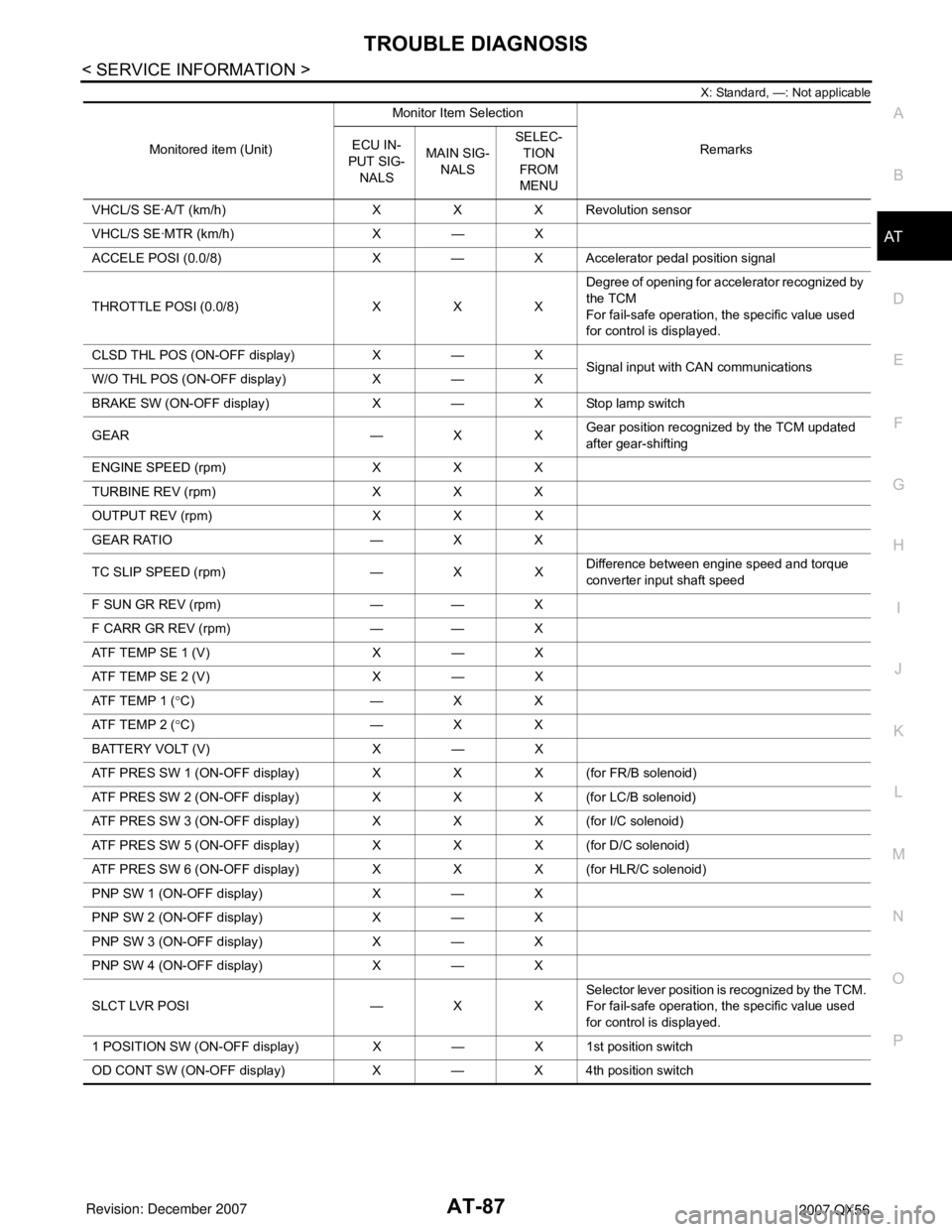

X: Standard, —: Not applicable

Monitored item (Unit)Monitor Item Selection

Remarks ECU IN-

PUT SIG-

NALSMAIN SIG-

NALSSELEC-

TION

FROM

MENU

VHCL/S SE·A/T (km/h) X X X Revolution sensor

VHCL/S SE·MTR (km/h) X — X

ACCELE POSI (0.0/8) X — X Accelerator pedal position signal

THROTTLE POSI (0.0/8) X X XDegree of opening for accelerator recognized by

the TCM

For fail-safe operation, the specific value used

for control is displayed.

CLSD THL POS (ON-OFF display) X — X

Signal input with CAN communications

W/O THL POS (ON-OFF display) X — X

BRAKE SW (ON-OFF display) X — X Stop lamp switch

GEAR — X XGear position recognized by the TCM updated

after gear-shifting

ENGINE SPEED (rpm) X X X

TURBINE REV (rpm) X X X

OUTPUT REV (rpm) X X X

GEAR RATIO — X X

TC SLIP SPEED (rpm) — X XDifference between engine speed and torque

converter input shaft speed

F SUN GR REV (rpm) — — X

F CARR GR REV (rpm) — — X

ATF TEMP SE 1 (V) X — X

ATF TEMP SE 2 (V) X — X

ATF TEMP 1 (°C) — X X

ATF TEMP 2 (°C) — X X

BATTERY VOLT (V) X — X

ATF PRES SW 1 (ON-OFF display) X X X (for FR/B solenoid)

ATF PRES SW 2 (ON-OFF display) X X X (for LC/B solenoid)

ATF PRES SW 3 (ON-OFF display) X X X (for I/C solenoid)

ATF PRES SW 5 (ON-OFF display) X X X (for D/C solenoid)

ATF PRES SW 6 (ON-OFF display) X X X (for HLR/C solenoid)

PNP SW 1 (ON-OFF display) X — X

PNP SW 2 (ON-OFF display) X — X

PNP SW 3 (ON-OFF display) X — X

PNP SW 4 (ON-OFF display) X — X

SLCT LVR POSI — X XSelector lever position is recognized by the TCM.

For fail-safe operation, the specific value used

for control is displayed.

1 POSITION SW (ON-OFF display) X — X 1st position switch

OD CONT SW (ON-OFF display) X — X 4th position switch

Page 166 of 3061

AT-96

< SERVICE INFORMATION >

DTC P0615 START SIGNAL CIRCUIT

With CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “SELECTION FROM MENU” in “DATA MONITOR” mode

for “A/T” with CONSULT-II and check monitor “STARTER

RELAY” ON/OFF.

Without CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Check voltage between the IPDM E/R connector and ground.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK HARNESS BETWEEN A/T ASSEMBLY HARNESS CONNECTOR AND IPDM E/R CONECTOR.

1. Turn ignition switch OFF.

2. Disconnect A/T assembly harness connector and IPDM E/R

connector.

3. Check continuity between A/T assembly harness connector and

IPDM E/R connector.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

OK >> GO TO 3.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

3.CHECK TERMINAL CORD ASSEMBLY

1. Remove control valve with TCM. Refer to AT-210, "

Control Valve with TCM and A/T Fluid Temperature

Sensor 2".

2. Disconnect A/T assembly harness connector and TCM connector.

3. Check continuity between A/T assembly harness connector ter-

minal and TCM connector terminal.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

OK or NG

Item name Condition Display value

STARTER RELAYSelector lever in "N'', "P'' positions. ON

Selector lever in other positions. OFF

PCIA0056E

Item Terminal Shift position Voltage (Approx.)

Starter re-

lay48 Ground"N'' and "P'' Battery voltage

"R'' and "D'' 0V

LCIA0320E

Item Connector Terminal Continuity

A/T assembly harness con-

nectorF9 9

Ye s

IPDM E/R connector E122 48

WCIA0427E

Item Connector Terminal Continuity

A/T assembly harness con-

nectorF9 9

Ye s

TCM connector F502 8

SCIA5440E

Page 167 of 3061

DTC P0615 START SIGNAL CIRCUIT

AT-97

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

OK >> GO TO 4.

NG >> Replace open circuit or short to ground and short to power in harness or connectors.

4.DETECT MALFUNCTIONING ITEM

Check the following items:

• Starter relay, Refer to SC-9

.

• IPDM E/R, Refer to PG-17

.

OK or NG

OK >> Replace the control valve with TCM. Refer to AT-210, "Control Valve with TCM and A/T Fluid Tem-

perature Sensor 2"

G >> Repair or replace damaged parts.

5.CHECK DTC

Perform “DTC Confirmation Procedure”.

• Refer to AT-91, "

DTC Confirmation Procedure".

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

Page 168 of 3061

AT-98

< SERVICE INFORMATION >

DTC P0700 TCM

DTC P0700 TCM

DescriptionINFOID:0000000003532273

The TCM consists of a microcomputer and connectors for signal input and output and for power supply. The

TCM controls the A/T.

On Board Diagnosis LogicINFOID:0000000003532274

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0700 TCM” with CONSULT-II is detected when the TCM is malfunctioning.

Possible CauseINFOID:0000000003532275

TCM.

DTC Confirmation ProcedureINFOID:0000000003532276

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “A/T” with CONSULT-II.

3. Start engine.

4. Run engine for at least 2 consecutive seconds at idle speed.

5. If DTC is detected, go to AT-98, "

Diagnosis Procedure".

WITH GST

Follow the procedure “With CONSULT-II”.

Diagnosis ProcedureINFOID:0000000003532277

1.CHECK DTC

With CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “SELF DIAG RESULTS” mode for “A/T” with CONSULT-

II.

3. Touch “ERASE”.

4. Turn ignition switch “OFF” and wait at least 10 seconds.

5. Perform DTC Confirmation Procedure, AT-98, "

DTC Confirma-

tion Procedure".

Is the

“TCM” displayed again?

YES >> Replace the control valve with TCM. Refer to AT-210,

"Control Valve with TCM and A/T Fluid Temperature

Sensor 2".

NO >>INSPECTION END

BCIA0031E

BCIA0031E

Page 171 of 3061

DTC P0705 PARK/NEUTRAL POSITION SWITCH

AT-101

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “SELECTION FROM MENU” in “DATA MONITOR” mode

for “A/T” with CONSULT-II.

3. Check if correct selector lever position (N/P, R or D) is displayed

as selector lever is moved into each position.

OK or NG

OK >> GO TO 5.

NG >> GO TO 2.

2.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Perform TCM power supply and ground circuit. Refer to AT-158

.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.DETECT MALFUNCTIONING ITEM

Check the following items:

• A/T assembly harness connector pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK SUB-HARNESS

1. Remove control valve with TCM. Refer to AT-210, "

Control Valve

with TCM and A/T Fluid Temperature Sensor 2".

2. Disconnect park/neutral position switch connector and TCM

connector.

3. Check continuity between park/neutral position switch connector

terminals and TCM connector terminals.

4. If OK, check harness for short to ground and short to power.

5. Reinstall any part removed.

Item name Condition Display value

SLCTLVR POSISelector lever in “N”,“P” positions. N/P

Selector lever in “R” position. R

Selector lever in “D” position. D

Selector lever in “4” position. 4

Selector lever in “3” position. 3

Selector lever in “2” position. 2

Selector lever in “1” position. 1

PCIA0034E

Item Connector Terminal Continuity

Park/neutral position

switch connectorF505 1

Ye s

TCM connector F503 13

Park/neutral position

switch connectorF505 2

Ye s

TCM connector F503 11

Park/neutral position

switch connectorF505 3

Ye s

TCM connector F503 12

Park/neutral position

switch connectorF505 5

Ye s

TCM connector F503 14

SCIA5457E

Page 172 of 3061

AT-102

< SERVICE INFORMATION >

DTC P0705 PARK/NEUTRAL POSITION SWITCH

OK or NG

OK >> Replace the control valve with TCM. Refer to AT-210, "Control Valve with TCM and A/T Fluid Tem-

perature Sensor 2".

NG >> Replace open circuit or short to ground and short to power in harness or connectors.

5.CHECK DTC

Perform “DTC Confirmation Procedure”.

• Refer to AT-99, "

DTC Confirmation Procedure".

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

Page 173 of 3061

DTC P0717 TURBINE REVOLUTION SENSOR

AT-103

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

AT

N

O

P

DTC P0717 TURBINE REVOLUTION SENSOR

DescriptionINFOID:0000000003532285

The turbine revolution sensor detects input shaft rpm (revolutions per minute). It is located on the input side of

the automatic transmission. Monitors revolution of sensor 1 and sensor 2 for non-standard conditions.

CONSULT-II Reference Value in Data Monitor ModeINFOID:0000000003532286

On Board Diagnosis LogicINFOID:0000000003532287

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0717 TURBINE REV S/CIRC” with CONSULT-II is detected under the following

conditions.

- When TCM does not receive the proper voltage signal from the sensor.

- When TCM detects an irregularity only at position of 4th gear for turbine revolution sensor 2.

Possible CauseINFOID:0000000003532288

• Harness or connectors

(The sensor circuit is open or shorted.)

• Turbine revolution sensor 1, 2

DTC Confirmation ProcedureINFOID:0000000003532289

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch “OFF”

and wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-II

1. Turn ignition switch “ON”. (Do not start engine.)

2. Select “DATA MONITOR” mode for “A/T” with CONSULT-II.

3. Start engine and maintain the following conditions for at least 5

consecutive seconds.

VHCL SPEED SE: 40 km/h (25 MPH) or more

ENGINE SPEED: 1,500 rpm or more

ACCELE POS: 0.5/8 or more

Selector lever: “D” position

Gear position (Turbine revolution sensor 1): 4th or 5th posi-

tion

Gear position (Turbine revolution sensor 2): All position

Driving location: Driving the vehicle uphill (increased

engine load) will help maintain the driving conditions required for this test.

4. If DTC is detected, go to AT-103, "

Diagnosis Procedure".

WITH GST

Follow the procedure “With CONSULT-II”.

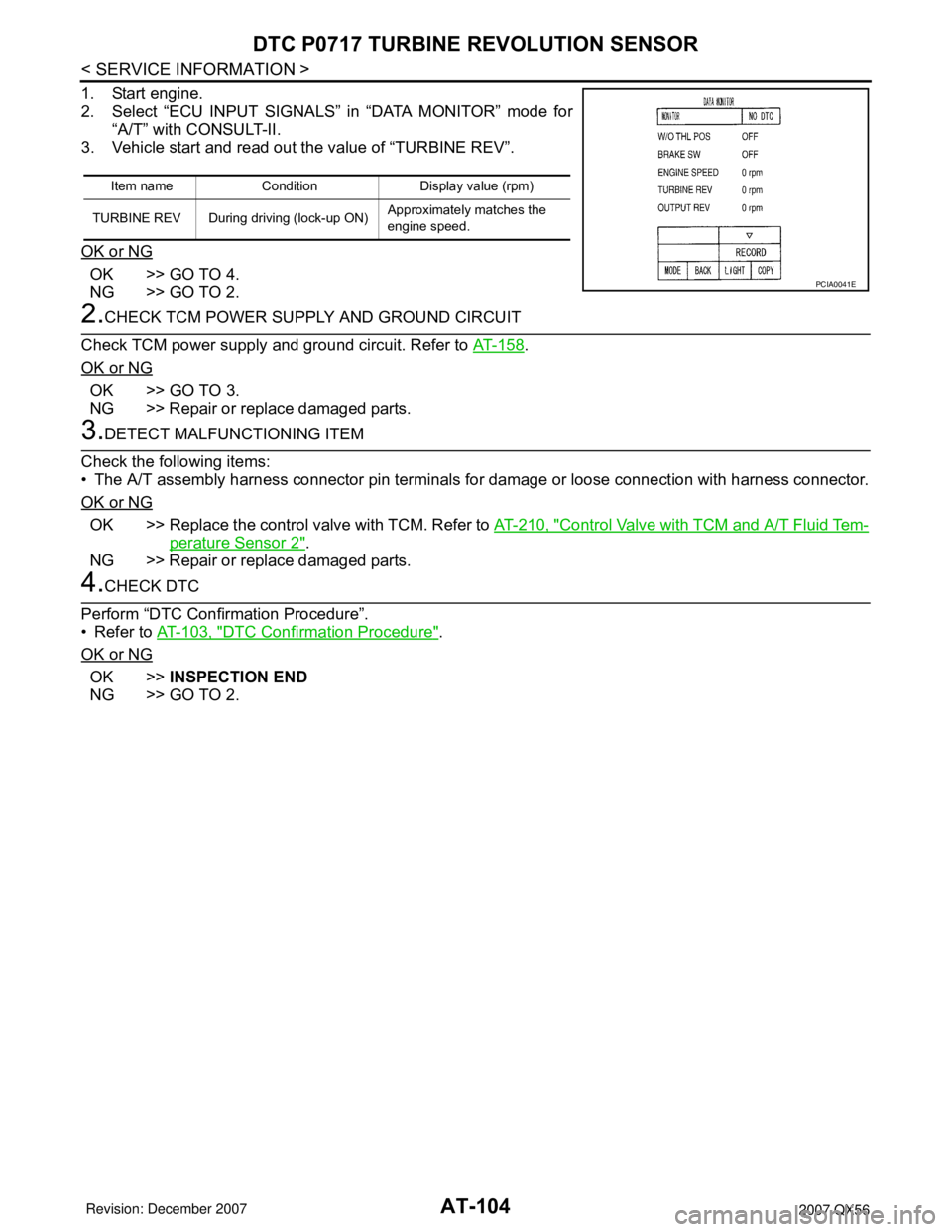

Diagnosis ProcedureINFOID:0000000003532290

1.CHECK INPUT SIGNAL

With CONSULT-II

Item name Condition Display value (rpm)

TURBINE REV During driving (lock-up ON) Approximately matches the engine speed.

BCIA0031E

Page 174 of 3061

AT-104

< SERVICE INFORMATION >

DTC P0717 TURBINE REVOLUTION SENSOR

1. Start engine.

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for

“A/T” with CONSULT-II.

3. Vehicle start and read out the value of “TURBINE REV”.

OK or NG

OK >> GO TO 4.

NG >> GO TO 2.

2.CHECK TCM POWER SUPPLY AND GROUND CIRCUIT

Check TCM power supply and ground circuit. Refer to AT-158

.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace damaged parts.

3.DETECT MALFUNCTIONING ITEM

Check the following items:

• The A/T assembly harness connector pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> Replace the control valve with TCM. Refer to AT-210, "Control Valve with TCM and A/T Fluid Tem-

perature Sensor 2".

NG >> Repair or replace damaged parts.

4.CHECK DTC

Perform “DTC Confirmation Procedure”.

• Refer to AT-103, "

DTC Confirmation Procedure".

OK or NG

OK >>INSPECTION END

NG >> GO TO 2.

Item name Condition Display value (rpm)

TURBINE REV During driving (lock-up ON)Approximately matches the

engine speed.

PCIA0041E