battery INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 734 of 4083

CHG-22

< ON-VEHICLE REPAIR >

GENERATOR

ON-VEHICLE REPAIR

GENERATOR

Removal and InstallationINFOID:0000000001538884

REMOVAL

1. Disconnect the negative battery terminal.

2. Remove the fan shroud. Refer to CO-15, "

Removal and Installation".

3. Remove the drive belt. Refer to EM-13, "

Removal and Installation".

4. Remove lower bracket, using power tools.

5. Remove the generator upper bolt, using power tools.

6. Remove/disconnect the generator harness connectors.

7. Remove the generator.

INSTALLATION

Installation is in the reverse order of removal.

• Install the generator and check the tension of the drive belt. Refer to EM-13, "

Checking Drive Belts".

CAUTION:

Tighten terminal nut carefully.

WKIA1390E

Terminal nut : 10.8 N·m (1.1 kg-m, 8 ft-lb)

Revision: March 2010 2008 QX56

Page 736 of 4083

CO-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION CO

A

CO

N

O P

CONTENTS

ENGINE COOLING SYSTEM

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

Precaution for Liquid Gasket .....................................3

PREPARATION ............................................4

PREPARATION .............................................. .....4

Special Service Tool ........................................... ......4

Commercial Service Tool ..........................................5

FUNCTION DIAGNOSIS ...............................6

COOLING SYSTEM ....................................... .....6

Cooling Circuit ..................................................... ......6

Schematic .................................................................7

OVERHEATING CAUSE ANALYSIS ..................8

Troubleshooting Chart ...............................................8

ON-VEHICLE MAINTENA NCE ....................10

ENGINE COOLANT ....................................... ....10

Inspection ............................................................ ....10

Changing Engine Coolant ........................................11

RADIATOR ........................................................14

Checking Radiator ............................................... ....14

ON-VEHICLE REPAIR .................................15

RADIATOR ....... .................................................15

Removal and Installation ..................................... ....15

ENGINE COOLING FAN ...................................18

Removal and Installation (Crankshaft Driven

Type) .......................................................................

18

Removal and Installation (Motor Driven Type) ........19

WATER PUMP ..................................................20

Removal and Installation .........................................20

THERMOSTAT AND WATER PIPING ..............22

Removal and Installation .........................................22

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

24

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

24

Standard and Limit .............................................. ....24

Revision: March 2010 2008 QX56

Page 737 of 4083

CO-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004857577

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000004857586

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: March 2010 2008 QX56

Page 738 of 4083

PRECAUTIONSCO-3

< PRECAUTION >

C

DE

F

G H

I

J

K L

M A

CO

NP

O

5. When the repair work is completed, return the ignition switch to the

″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Liquid GasketINFOID:0000000001538852

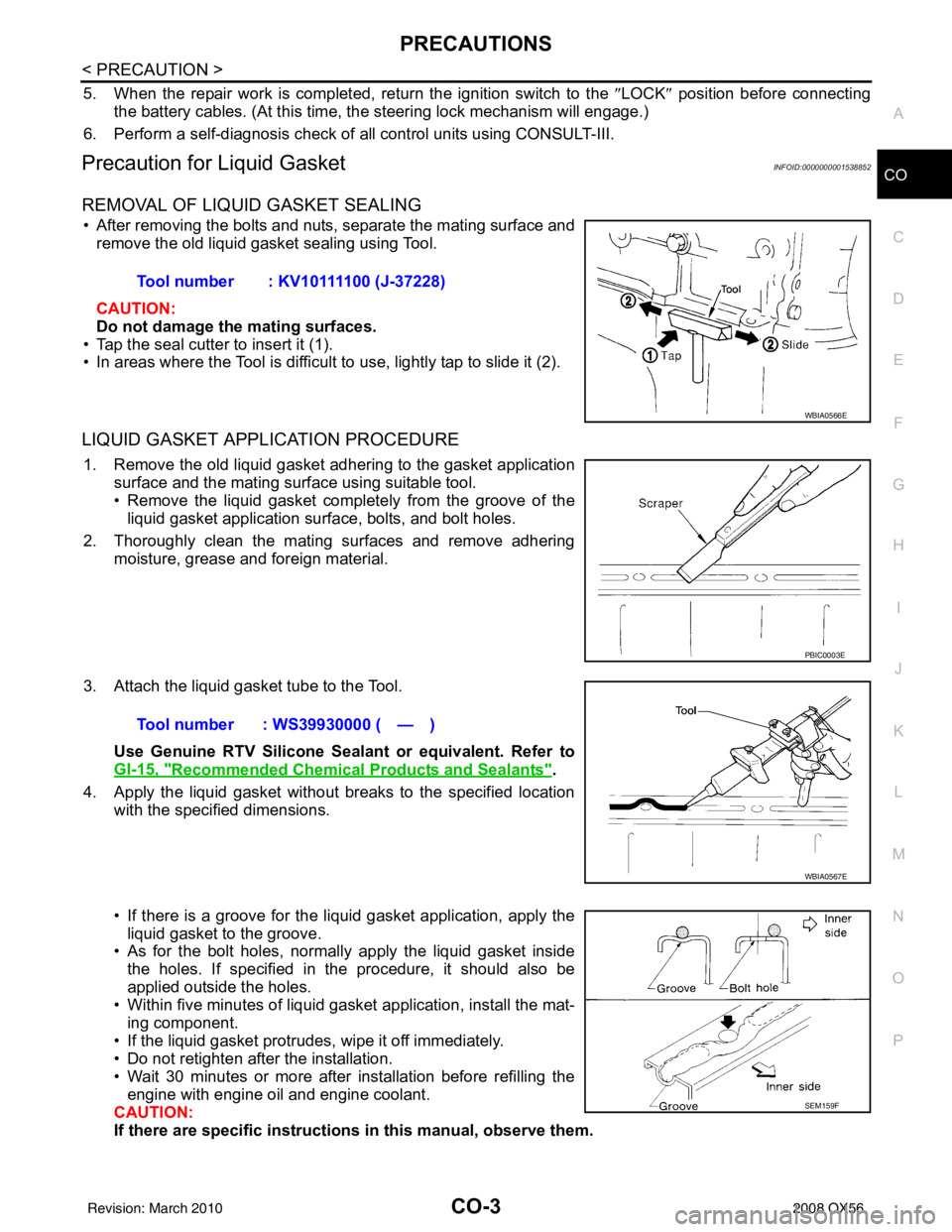

REMOVAL OF LIQUID GASKET SEALING

• After removing the bolts and nuts, separate the mating surface and

remove the old liquid gasket sealing using Tool.

CAUTION:

Do not damage the mating surfaces.

• Tap the seal cutter to insert it (1).

• In areas where the Tool is difficult to use, lightly tap to slide it (2).

LIQUID GASKET APPLICATION PROCEDURE

1. Remove the old liquid gasket adhering to the gasket application surface and the mating surface using suitable tool.

• Remove the liquid gasket completely from the groove of the

liquid gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering moisture, grease and foreign material.

3. Attach the liquid gasket tube to the Tool. Use Genuine RTV Silicone Sealant or equivalent. Refer to

GI-15, "

Recommended Chemical Products and Sealants".

4. Apply the liquid gasket without breaks to the specified location with the specified dimensions.

• If there is a groove for the liquid gasket application, apply theliquid gasket to the groove.

• As for the bolt holes, normally apply the liquid gasket inside

the holes. If specified in the procedure, it should also be

applied outside the holes.

• Within five minutes of liquid gasket application, install the mat-

ing component.

• If the liquid gasket protrudes, wipe it off immediately.

• Do not retighten after the installation.

• Wait 30 minutes or more after installation before refilling the engine with engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

Tool number : KV10111100 (J-37228)

WBIA0566E

PBIC0003E

Tool number : WS39930000 ( — )

WBIA0567E

SEM159F

Revision: March 2010

2008 QX56

Page 761 of 4083

DEF-2

Diagnosis Procedure ..............................................29

REAR WINDOW DEFOGGER SWITCH DOES

NOT LIGHT, BUT REAR WINDOW DEFOG-

GER OPERATES ...............................................

30

Diagnosis Procedure ........................................... ...30

PRECAUTION .............................................31

PRECAUTIONS .............................................. ...31

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. ...

31

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ..................................

31

Handling for Adhesive and Primer ..........................32

ON-VEHICLE REPAIR ...............................33

REAR WINDOW DEFOGGER ........................ ...33

Filament Check .................................................... ...33

Filament Repair .......................................................33

Revision: March 2010 2008 QX56

Page 768 of 4083

REAR WINDOW DEFOGGER RELAYDEF-9

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

REAR WINDOW DEFOGGER RELAY

DescriptionINFOID:0000000001735612

Power is supplied to the rear window defogger with BCM control.

Component Function CheckINFOID:0000000001735613

1. CHECK REAR WINDOW DEFOGGER RELAY POWER SUPPLY CIRCUIT

Check that an operation noise of rear window defogger re lay (located in IPDM E/R) can be heard when turning

the rear window defogger switch ON.

Is the inspection result normal?

YES >> Rear window defogger relay power supply circuit is OK.

NO >> Refer to DEF-9, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001735614

1.CHECK FUSES

Check if any of the following fuses in the IPDM E/R are blown.

Is the inspection result normal?

YES >> GO TO 2

NO >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2. CHECK REAR WINDOW DEFOGGER RELAY POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between IPDM E/R connector and ground.

Is the inspection result normal?

YES >> Replace IPDM E/R. Refer to PCS-34, "Removal and Installation of IPDM E/R".

NO >> GO TO 3

3. CHECK INTERMITTENT INCIDENT

Check intermittent incident.

Refer to GI-38, "

Intermittent Incident"

Is the inspection result normal?

YES >> Check the following.

• Battery power supply circuit.

• IPDM E/R.

NO >> Repair or replace the malfunctioning parts.

COMPONENT PARTS AMPEREFUSE NO.

IPDM E/R 15A46

IPDM E/R 15A47

Te r m i n a l s

Condition of rear

window defogger

switch Voltage (V)

(Approx.)

(+)

(–)

IPDM E/R con-

nector Te r m i n a l

E124 60 Ground ON Battery voltage

OFF 0

LIIA2190E

Revision: March 2010 2008 QX56

Page 769 of 4083

DEF-10

< COMPONENT DIAGNOSIS >

REAR WINDOW DEFOGGER POWER SUPPLY AND GROUND CIRCUIT

REAR WINDOW DEFOGGER POWER SUPPLY AND GROUND CIRCUIT

DescriptionINFOID:0000000001735615

Heats the heating wire with the power supply from the rear window defogger relay to prevent the rear window

from fogging up.

Component Function CheckINFOID:0000000001735616

1. CHECK REAR WINDOW DEFOGGER

Check that the heating wire of rear window defogger is heated when turning the rear window defogger switch

ON.

Is the inspection result normal?

YES >> Rear window defogger is OK.

NO >> Refer to DEF-10, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001735617

1. CHECK POWER SUPPLY CIRCUIT

1. Turn ignition switch ON.

2. Check voltage between rear window defogger connector and ground.

Is the inspection result normal?

YES >> GO TO 2

NO >> GO TO 3

2. CHECK GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect rear window defogger.

3. Check continuity between rear window defogger connector and ground.

Is the inspection result normal?

YES >> GO TO 4

NO >> Repair or replace harness.

3. CHECK HARNESS CONTINUITY

Te r m i n a l s Condition of rear window

defogger switch Voltage (V)

(Approx.)

(+)

(–)

Rear window

defogger

connector Te r m i n a l

D406 1 Ground ON Battery voltage

OFF 0

ALLIA0177ZZ

Rear window defogger connector Terminal

GroundContinuity

D604 2 Yes

ALLIA0178ZZ

Revision: March 2010 2008 QX56

Page 770 of 4083

REAR WINDOW DEFOGGER POWER SUPPLY AND GROUND CIRCUIT

DEF-11

< COMPONENT DIAGNOSIS >

C

D E

F

G H

I

J

K

M A

B

DEF

N

O P

1. Disconnect IPDM E/R.

2. Check continuity between rear window defogger connector (A) and IPDM E/R connector (B).

3. Check continuity between rear window defogger connector (A) and ground.

Is the inspection result normal?

YES >> GO TO 5

NO >> Replace or repair harness.

4. CHECK FILAMENT

Check filament.

Refer to DEF-33, "

Filament Check".

Is the inspection result normal?

YES >> Refer to GI-38, "Intermittent Incident".

NO >> Repair filament. Refer to DEF-33, "

Filament Repair".

5. CHECK INTERMITTENT INCIDENT

Check intermittent incident.

Refer to GI-38, "

Intermittent Incident".

Is the inspection result normal?

YES >> Check the following. • Battery power supply circuit.

• IPDM E/R.

NO >> Repair or replace the malfunctioning parts.

Component InspectionINFOID:0000000001735618

1. CHECK FILAMENT

Check the filament for damage or open circuits.

Refer to DEF-33, "

Filament Check".

Is the inspection result normal?

YES >> Inspection End.

NO >> Repair filament. Refer to DEF-33, "

Filament Repair".

Rear window defog-

ger connector Te r m i n a l

IPDM E/R

connector Terminal Continuity

D406 (A) 1 E124 (B) 60 Yes

Rear window defog- ger connector Te r m i n a l

GroundContinuity

D406 (A) 1 No

LIIA2644E

Revision: March 2010 2008 QX56

Page 771 of 4083

DEF-12

< COMPONENT DIAGNOSIS >

DOOR MIRROR DEFOGGER LH

DOOR MIRROR DEFOGGER LH

DescriptionINFOID:0000000001735623

Heats the heating wire with the power supply from the rear window defogger relay to prevent the door mirror

from fogging up.

Component Function CheckINFOID:0000000001735624

1. CHECK DOOR MIRROR DEFOGGER LH

Check that heating wire of door mirror defogger LH is heated when turning the rear window defogger switch

ON.

Is the inspection result normal?

YES >> Door mirror defogger is OK.

NO >> Refer to DEF-12, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001735625

1. CHECK POWER SUPPLY

Check if the following fuse in the IPDM E/R is blown.

Is the inspection result normal?

YES >> GO TO 2

NO >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

2. CHECK DOOR MIRROR DE FOGGER POWER SUPPLY CIRCUIT

Check voltage between IPDM E/R connector and ground.

Is the inspection result normal?

YES >> GO TO 3

NO >> Replace IPDM E/R. Refer to PCS-34, "

Removal and Installation of IPDM E/R".

3. CHECK DOOR MIRROR DEFOGGER POWER SUPPLY CIRCUIT 2

1. Turn ignition switch OFF.

2. Disconnect door mirror LH.

3. Turn ignition switch ON.

4. Check voltage between door mirror LH connector and ground.

Is the inspection result normal?

YES >> GO TO 4

COMPONENT PARTS AMPEREFUSE NO.

IPDM E/R 15A43

ConnectorTe r m i n a l

ConditionVoltage (V)

(Approx.)

(+) (-)

E120 23 Ground Rear window defogger

switch ON

Battery voltage

Rear window defogger

switch OFF 0

LIIA2049E

ConnectorTe r m i n a l

ConditionVoltage (V)

(Approx.)

(+) (-)

D4 10 Ground Rear window defogger

switch ON

Battery voltage

Rear window defogger

switch OFF 0

LIIA1456E

Revision: March 2010

2008 QX56

Page 772 of 4083

DOOR MIRROR DEFOGGER LHDEF-13

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

DEF

N

O P

NO >> Repair or replace harness.

4. CHECK DOOR MIRROR DEFOGGER CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect IPDM E/R and door mirror LH.

3. Check continuity between IPDM E/R connector E120 terminal 23 and door mirror LH connector D4 terminal 10.

Is the inspection result normal?

YES >> GO TO 5

NO >> Repair or replace harness.

5. CHECK DOOR MIRROR DEFOGGER GROUND CIRCUIT

Check continuity between door mirror LH connector D4 terminal 11

and ground.

Is the inspection result normal?

YES >> GO TO 6

NO >> Repair or replace harness.

6. CHECK DOOR MIRROR DEFOGGER LH

Check door mirror defogger LH.

Refer to DEF-13, "

Component Inspection".

Is the inspection result normal?

YES >> GO TO 7

NO >> Replace door mirror. Refer to MIR-11, "

Door Mirror Assembly".

7. CHECK INTERMITTENT INCIDENT

Check intermittent incident.

Refer to GI-38, "

Intermittent Incident".

Is the inspection result normal?

YES >> Check the following. • Battery power supply circuit.

• IPDM E/R.

NO >> Repair or replace the malfunctioning parts.

Component InspectionINFOID:0000000001735626

1. CHECK DOOR MIRROR DEFOGGER

Check continuity between door mirror LH terminals 10 and 11.

Is the inspection result normal?

YES >> Check the condition of the harness and the connector.

NO >> Replace malfunctioning door mirror LH. Refer to MIR-

11 , "Door Mirror Assembly".

23 - 10

: Continuity should exist.

WIIA0529E

11 - Ground: Continuity should exist.

LIIA1454E

10 - 11 : Continuity should exist.

WIIA0531E

Revision: March 2010 2008 QX56