coolant INFINITI QX56 2008 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2745 of 4083

![INFINITI QX56 2008 Factory Service Manual PCS-12

< FUNCTION DIAGNOSIS >[IPDM E/R]

DIAGNOSIS SYSTEM (IPDM E/R)

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000001696490

AUTO ACTIVE TEST

Description

In auto active test mode, the INFINITI QX56 2008 Factory Service Manual PCS-12

< FUNCTION DIAGNOSIS >[IPDM E/R]

DIAGNOSIS SYSTEM (IPDM E/R)

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000001696490

AUTO ACTIVE TEST

Description

In auto active test mode, the](/img/42/57030/w960_57030-2744.png)

PCS-12

< FUNCTION DIAGNOSIS >[IPDM E/R]

DIAGNOSIS SYSTEM (IPDM E/R)

DIAGNOSIS SYSTEM (IPDM E/R)

Diagnosis DescriptionINFOID:0000000001696490

AUTO ACTIVE TEST

Description

In auto active test mode, the IPDM

E/R sends a drive signal to the follo wing systems to check their operation.

• Oil pressure low/coolant pressure high warning indicator

• Oil pressure gauge

• Rear window defogger

• Front wipers

• Tail, license and parking lamps

• Front fog lamps

• Headlamps (Hi, Lo)

• A/C compressor (magnetic clutch)

• Cooling fan

Operation Procedure

1. Close the hood and front door RH, and lift the wiper a rms from the windshield (to prevent windshield dam-

age due to wiper operation).

NOTE:

When auto active test is performed with hood opened, sprinkle water on windshield before hand.

2. Turn ignition switch OFF.

3. Turn the ignition switch ON and, within 20 seconds, press the front door switch LH 10 times. Then turn the ignition switch OFF.

4. Turn the ignition switch ON within 10 seconds. Af ter that the horn sounds once and the auto active test

starts.

5. After a series of the following operations is repeated 3 times, auto active test is completed.

NOTE:

When auto active test mode has to be cancelled halfway through test, turn ignition switch OFF.

CAUTION:

• If auto active test mode cannot be actuated, check door switch system. Refer to DLK-67, "

Descrip-

tion".

• Do not start the engine.

Inspection in Auto Active Test Mode

When auto active test mode is actuated, the following 7 steps are repeated 3 times.

Operation

sequence Inspection Location

Operation

1 Rear window defogger 10 seconds

2 Front wipers LO for 5 seconds → HI for 5 seconds

WKIA4655E

Revision: March 2010 2008 QX56

Page 2752 of 4083

![INFINITI QX56 2008 Factory Service Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-19

< ECU DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

ECU DIAGNOSIS

IPDM E/R (INTELLIGENT POWER

DISTRIBUTION MODULE ENGINE INFINITI QX56 2008 Factory Service Manual PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-19

< ECU DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

ECU DIAGNOSIS

IPDM E/R (INTELLIGENT POWER

DISTRIBUTION MODULE ENGINE](/img/42/57030/w960_57030-2751.png)

PCS

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

PCS-19

< ECU DIAGNOSIS > [IPDM E/R]

C

D

E

F

G H

I

J

K L

B A

O P

N

ECU DIAGNOSIS

IPDM E/R (INTELLIGENT POWER

DISTRIBUTION MODULE ENGINE

ROOM)

Reference ValueINFOID:0000000001696496

VALUES ON THE DIAGNOSIS TOOL

Monitor Item ConditionValue/Status

MOTOR FAN REQ Engine idle speed Changes depending on engine

coolant temperature, air conditioner

operation status, vehicle speed,

etc.0 - 100 %

A/C COMP REQ A/C switch OFF

OFF

A/C switch ON ON

TA I L & C L R R E Q Lighting switch OFF

OFF

Lighting switch 1ST, 2ND, HI or AUTO (Light is illuminated) ON

HL LO REQ Lighting switch OFF

OFF

Lighting switch 2ND HI or AUTO (Light is illuminated) ON

HL HI REQ Lighting switch OFF

OFF

Lighting switch HI ON

FR FOG REQ Lighting switch 2ND or AUTO (Light

is illuminated) Front fog lamp switch OFF OFF

• Front fog lamp switch ON

• Daytime light activated (Canada

only) ON

HL WASHER REQ NOTE:

This item is displayed, but cannot be monitored. OFF

FR WIP REQ Ignition switch ON Front wiper switch OFF

STOP

Front wiper switch INT 1LOW

Front wiper switch LO LOW

Front wiper switch HI HI

WIP AUTO STOP Ignition switch ON Front wiper stop position

STOP P

Any position other than front wiper

stop position ACT P

WIP PROT Ignition switch ON Front wiper operates normally OFF

Front wiper stops at fail-safe opera-

tion

BLOCK

ST RLY REQ Ignition switch OFF or ACC

OFF

Ignition switch START ON

IGN RLY Ignition switch OFF or ACC

OFF

Ignition switch ON ON

RR DEF REQ Rear defogger switch OFF

OFF

Rear defogger switch ON ON

OIL P SW Ignition switch OFF, ACC or engine running

OPEN

Ignition switch ON CLOSE

DTRL REQ Daytime light system requested OFF with CONSULT-III.

OFF

Daytime light system reques ted ON with CONSULT-III. ON

Revision: March 2010 2008 QX56

Page 2816 of 4083

PG

HARNESSPG-49

< COMPONENT DIAGNOSIS >

C

DE

F

G H

I

J

K L

B A

O P

N

C3 F7 GR/3

: Ignition coil No. 4 (with power

transistor) F1 F60 GR/2 : Neutral-4LO switch

C3 F8 GR/3 : Ignition coil No. 6 (with power

transistor)

D5 F61 G/2: Intake valve timing control solenoid valve

(bank 1)

E2 F9 G/10 : A/T assembly D5 F62 G/2: Intake valve timing control position sensor

(bank 1)

C3 F10 — : Engine ground C4 F63 G/2: Intake valve timing control solenoid valve

(bank 2)

D3 F11 B/3 : Crankshaft position sensor (POS) C4 F64 G/2 : Intake valve timing control position sensor

(bank 2)

E1 F12 G/4 : Heated oxygen sensor 2 (bank2) E3 F65 GR/4 : Air fuel ratio (A/F) sensor 1 (bank1)

F2 F13 G/4 : Heated oxygen sensor 2 (bank1) C2 F68 B/2 : Water valve

B2 F14 W/24 : To E5 C3 F101 B/6 : To F26

D4 F15 L/2 : EVAP canister purge volume control

solenoid valve C3 F102 B/2 : Knock sensor (bank 1)

E5 F16 — : Engine ground C3 F103 GR/2 : Engine coolant temperature sensor

C4 F18 GR/2 : Fuel injector No. 2 C3 F104 B/2 : Knock sensor (bank 2)

D4 F20 GR/2 : Fuel injector No. 4

F4 F21 W/2 : Condenser-1

D3 F22 GR/2 : Fuel injector No. 6

D4 F23 B/3 : Camshaft position sensor (phase)

D4 F26 B/6 : To F101

E3 F27 B/1 : Starter motor

D4 F30 GR/2 : Fuel injector No. 1

D3 F31 GR/2 : Fuel injector No. 8

B2 F32 W/16 : To E2

C2 F33 W/16 : To E19

C2 F34 W/2 : To E39

B3 F39 — : Fusible link (battery)

D4 F41 GR/2 : Fuel injector No. 3

D4 F42 GR/2 : Fuel injector No. 5

D3 F45 GR/2 : Fuel injector No. 7

B4 F46 B/3 : Power steering pressure sensor

E4 F47 GR/3 : Ignition coil No. 1 (with power

transistor)

E4 F48 GR/3 : Ignition coil No. 3 (with power

transistor)

E4 F49 GR/3 : Ignition coil No. 5 (with power

transistor)

D4 F50 B/6 : Electric throttle control actuator

E4 F51 GR/3 : Ignition coil No. 7 (with power

transistor)

D2 F52 GR/3 : Ignition coil No. 8 (with power

transistor)

E5 F53 B/6 : Mass air flow sensor

B2 F54 B/81 : ECM

F1 F55 B/2 : ATP switch

Revision: March 2010 2008 QX56

Page 3042 of 4083

PRECAUTIONSRSU-3

< PRECAUTION >

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Rear SuspensionINFOID:0000000001534647

• When installing the rubber bushings, the final tightening must be done under unladen condition and with the

tires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immediately.

• Unladen condition means the fuel tank, engine coolant and lubricants are at the full specification. The spare

tire, jack, hand tools, and mats are in their designated positions.

• After installing suspension components, check the wheel alignment.

• Caulking nuts are not reusable. Always use new caulking nuts for installation. New caulking nuts are pre- oiled, do not apply any additional lubrication.

Revision: March 2010 2008 QX56

Page 3045 of 4083

RSU-6

< ON-VEHICLE MAINTENANCE >

REAR SUSPENSION ASSEMBLY

ON-VEHICLE MAINTENANCE

REAR SUSPENSION ASSEMBLY

On-Vehicle Inspection and ServiceINFOID:0000000001534667

Check all of the component mountings for any excessive looseness, or back lash. Check the components for

any excessive wear, damage, or abnormal conditions. Repair or replace the components as necessary.

SHOCK ABSORBER INSPECTION

• Check the shock absorbers for any air leaks or damage, and replace as necessary.

• Check the hoses for any air leaks or damage, and replace as necessary.

Wheel Alignment InspectionINFOID:0000000001534668

Rear Wheel Alignment Adjusting Bolts

PRELIMINARY INSPECTION

WARNING:

Always adjust the alignment with the vehicle on a flat surface. Use CONSULT-III “EXHAUST SOLE-

NOID” active test to release the air pressure from the rear load leveling air suspension system.

NOTE:

If alignment is out of specificat ion, inspect and replace any damaged or worn rear suspension parts before

making any adjustments.

1. Check and adjust the wheel alignment with the vehicle under unladen conditions. “Unladen conditions”

means that the fuel, coolant, and lubricant are full; and that the spare tire, jack, hand tools and mats are in

their designated positions.

2. Check the tires for incorrect air pressure and excessive wear.

3. Check the wheels for runout and damage. Refer to WT-45, "

Inspection" .

4. Check the wheel bearing axial end play.

5. Check the shock absorbers. Refer to RSU-15, "

Removal and Installation" .

6. Check each mounting point of the suspension components for any excessive looseness or damage.

7. Check each link, arm, and the rear suspension member for any damage.

8. Check the vehicle height. Refer to RSU-29, "

Wheelarch Height (Unladen*1)" .

WEIA0102E

1. Rear lower link adjusting bolt, LH 2. Front lower link adjusting bolt, LH 3. Front lower link adjusting bolt, RH

4. Rear lower link adjusting bolt, RH

Axial end play : 0 mm (0 in)

Revision: March 2010 2008 QX56

Page 3068 of 4083

SERVICE DATA AND SPECIFICATIONS (SDS)RSU-29

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DF

G H

I

J

K L

M A

B

RSU

N

O P

Wheelarch Height (Unladen*1)INFOID:0000000004918900

Unit: mm (in)

*1: Fuel, engine coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: Verify the vehicle height. If vehicle height is not within ± 10 mm (0.39 in) of the specification, perform the control unit initialization pro-

cedure. Refer to SCS-7, "

CONSULT-III Function" .

Suspension type

Air leveling*

2

Applied model2WD 4WD

Front wheelarch height (Hf) 920

(36.22) 937

(36.89)

Rear wheelarch height (Hr) 917

(36.10) 937

(36.89)

LEIA0085E

Revision: March 2010 2008 QX56

Page 3122 of 4083

PRECAUTIONSSCS-39

< PRECAUTION >

C

DF

G H

I

J

K L

M A

B

SCS

N

O P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000004900823

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SR and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution for Rear SuspensionINFOID:0000000001732010

• When installing the rubber bushings, the final tightening must be done under unladen condition and with thetires on level ground. Oil will shorten the life of the rubber bushings, so wipe off any spilled oil immediately.

• Unladen condition means the fuel tank, engine coolant and lubricants are at the full specification. The spare tire, jack, hand tools, and mats are in their designated positions.

• After installing suspension components, check the wheel alignment.

• Caulking nuts are not reusable. Always use new caulking nuts for installation. New caulking nuts are pre-

oiled, do not apply any additional lubrication.

Revision: March 2010 2008 QX56

Page 3306 of 4083

![INFINITI QX56 2008 Factory Service Manual SEC-98

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

IPDM E/R (INTELLIGENT POWER DI

STRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Reference ValueINFOID: INFINITI QX56 2008 Factory Service Manual SEC-98

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

IPDM E/R (INTELLIGENT POWER DI

STRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Reference ValueINFOID:](/img/42/57030/w960_57030-3305.png)

SEC-98

< ECU DIAGNOSIS >[WITH INTELLIGENT KEY SYSTEM]

IPDM E/R (INTELLIGENT POWER DI

STRIBUTION MODULE ENGINE ROOM)

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE

ROOM)

Reference ValueINFOID:0000000004807922

VALUES ON THE DIAGNOSIS TOOL

Monitor Item ConditionValue/Status

MOTOR FAN REQ Engine idle speed Changes depending on engine

coolant temperature, air conditioner

operation status, vehicle speed,

etc.0 - 100 %

A/C COMP REQ A/C switch OFF

OFF

A/C switch ON ON

TAIL&CLR REQ Lighting switch OFF

OFF

Lighting switch 1ST, 2ND, HI or AUTO (Light is illuminated) ON

HL LO REQ Lighting switch OFF

OFF

Lighting switch 2ND HI or AUTO (Light is illuminated) ON

HL HI REQ Lighting switch OFF

OFF

Lighting switch HI ON

FR FOG REQ Lighting switch 2ND or AUTO (Light

is illuminated) Front fog lamp switch OFF OFF

• Front fog lamp switch ON

• Daytime light activated (Canada

only) ON

HL WASHER REQ NOTE:

This item is displayed, but cannot be monitored.

OFF

FR WIP REQ Ignition switch ON Front wiper switch OFF

STOP

Front wiper switch INT 1LOW

Front wiper switch LO LOW

Front wiper switch HI HI

WIP AUTO STOP Ignition switch ON Front wiper stop position

STOP P

Any position other than front wiper

stop position ACT P

WIP PROT Ignition switch ON Front wiper operates normally OFF

Front wiper stops at fail-safe opera-

tion

BLOCK

ST RLY REQ Ignition switch OFF or ACC

OFF

Ignition switch START ON

IGN RLY Ignition switch OFF or ACC

OFF

Ignition switch ON ON

RR DEF REQ Rear defogger switch OFF

OFF

Rear defogger switch ON ON

OIL P SW Ignition switch OFF, ACC or engine running

OPEN

Ignition switch ON CLOSE

DTRL REQ Daytime light system requested OFF with CONSULT-III.

OFF

Daytime light system requested ON with CONSULT-III. ON

HOOD SW Hood closed.

OFF

Hood open. ON

Revision: March 2010 2008 QX56

Page 3535 of 4083

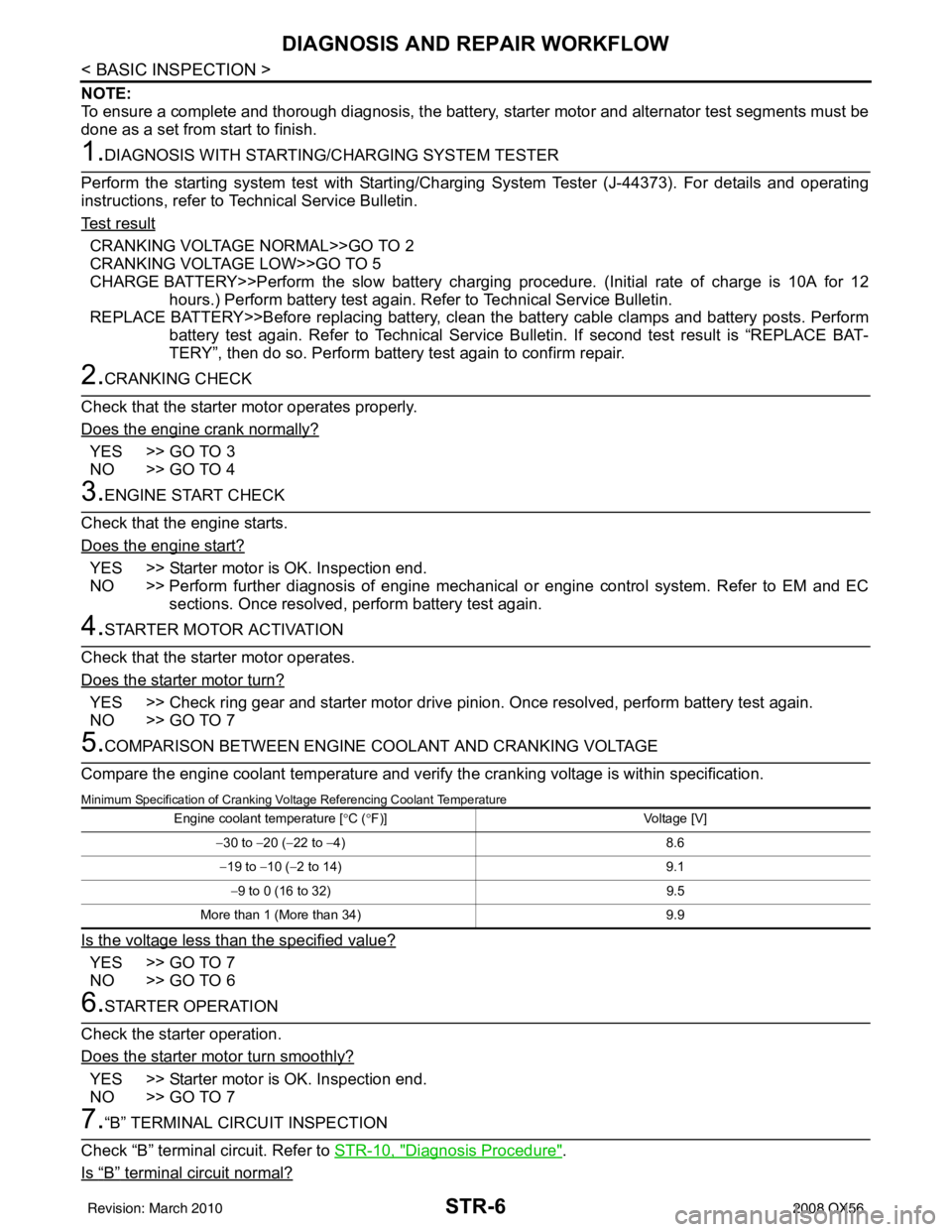

STR-6

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

NOTE:

To ensure a complete and thorough diagnosis, the battery, starter motor and alternator test segments must be

done as a set from start to finish.

1.DIAGNOSIS WITH STARTING/CHARGING SYSTEM TESTER

Perform the starting system test with Starting/Charging System Tester (J-44373). For details and operating

instructions, refer to Technical Service Bulletin.

Te s t r e s u l t

CRANKING VOLTAGE NORMAL>>GO TO 2

CRANKING VOLTAGE LOW>>GO TO 5

CHARGE BATTERY>>Perform the slow battery charging procedure. (Initial rate of charge is 10A for 12

hours.) Perform battery test again. Refer to Technical Service Bulletin.

REPLACE BATTERY>>Before replacing battery, clean t he battery cable clamps and battery posts. Perform

battery test again. Refer to Technical Service Bulletin. If second test result is “REPLACE BAT-

TERY”, then do so. Perform battery test again to confirm repair.

2.CRANKING CHECK

Check that the starter motor operates properly.

Does the engine crank normally?

YES >> GO TO 3

NO >> GO TO 4

3.ENGINE START CHECK

Check that the engine starts.

Does the engine start?

YES >> Starter motor is OK. Inspection end.

NO >> Perform further diagnosis of engine mechanical or engine control system. Refer to EM and EC sections. Once resolved, perform battery test again.

4.STARTER MOTOR ACTIVATION

Check that the starter motor operates.

Does the starter motor turn?

YES >> Check ring gear and starter motor drive pinion. Once resolved, perform battery test again.

NO >> GO TO 7

5.COMPARISON BETWEEN ENGINE COOLANT AND CRANKING VOLTAGE

Compare the engine coolant temperature and verify the cranking voltage is within specification.

Minimum Specification of Cranking Voltage Referencing Coolant Temperature

Is the voltage less than the specified value?

YES >> GO TO 7

NO >> GO TO 6

6.STARTER OPERATION

Check the starter operation.

Does the starter motor turn smoothly?

YES >> Starter motor is OK. Inspection end.

NO >> GO TO 7

7.“B” TERMINAL CIRCUIT INSPECTION

Check “B” terminal circuit. Refer to STR-10, "

Diagnosis Procedure".

Is

“B” terminal circuit normal?

Engine coolant temperature [ °C ( °F)] Voltage [V]

− 30 to − 20 (−22 to − 4) 8.6

− 19 to −10 ( −2 to 14) 9.1

− 9 to 0 (16 to 32) 9.5

More than 1 (More than 34) 9.9

Revision: March 2010 2008 QX56

Page 3577 of 4083

TM-30

< FUNCTION DIAGNOSIS >

ON BOARD DIAGNOSTIC (OBD) SYSTEM

ON BOARD DIAGNOSTIC (OBD) SYSTEM

IntroductionINFOID:0000000001604002

The A/T system has two self-diagnostic systems.

The first is the emission-related on board diagnostic syst em (OBD-II) performed by the TCM in combination

with the ECM. The malfunction is indicated by the MI L (malfunction indicator lamp) and is stored as a DTC in

the ECM memory but not the TCM memory.

The second is the TCM original self-diagnosis indicated by the A/T CHECK indicator lamp. The malfunction is

stored in the TCM memory. The detected items are ov erlapped with OBD-II self-diagnostic items. For detail,

refer to TM-32, "

CONSULT-III Function (TRANSMISSION)".

OBD-II Function for A/T SystemINFOID:0000000001604003

The ECM provides emission-related on board diagnostic (O BD-II) functions for the A/T system. One function

is to receive a signal from the TCM used with OBD-relat ed parts of the A/T system. The signal is sent to the

ECM when a malfunction occurs in the corresponding OBD-re lated part. The other function is to indicate a

diagnostic result by means of the MIL (malfunction indi cator lamp) on the instrument panel. Sensors, switches

and solenoid valves are used as sensing elements.

The MIL automatically illuminates in One or Two Trip Detection Logic when a malfunction is sensed in relation

to A/T system parts.

One or Two Trip Detection Logic of OBD-IIINFOID:0000000001604004

ONE TRIP DETECTION LOGIC

If a malfunction is sensed during the first test drive, the MIL will illuminate and the malfunction will be stored in

the ECM memory as a DTC. The TCM is not provided with such a memory function.

TWO TRIP DETECTION LOGIC

When a malfunction is sensed during the first test drive, it is stored in the ECM memory as a 1st trip DTC

(diagnostic trouble code) or 1st trip freeze frame data. At this point, the MIL will not illuminate. — 1st Trip

If the same malfunction as that experienced during the fi rst test drive is sensed during the second test drive,

the MIL will illuminate. — 2nd Trip

The “Trip” in the “One or Two Trip Detection Logic” means a driving mode in which self-diagnosis is performed

during vehicle operation.

OBD-II Diagnostic Trouble Code (DTC)INFOID:0000000001604005

HOW TO READ DTC AND 1ST TRIP DTC

DTC and 1st trip DTC can be read by the following methods.

( with CONSULT-III or GST) CONSULT-III or GST (Generic Scan Tool) Examples: P0705, P0720 etc.

These DTC are prescribed by SAE J2012.

(CONSULT-III also displays the malfunctioning component or system.)

• 1st trip DTC No. is the same as DTC No.

• Output of the diagnostic troubl e code indicates that the indicated circuit has a malfunction. How-

ever, in case of the Mode II and GST, they do not indicate whether the malfunction is still occurring or

occurred in the past and returned to normal.

CONSULT-III can identify them as shown below, therefore, CONSULT-III (if available) is recom-

mended.

Freeze Frame Data and 1st Trip Freeze Frame Data

The ECM has a memory function, which stores the driv ing condition such as fuel system status, calculated

load value, engine coolant temperatur e, short term fuel trim, long term fuel trim, engine speed and vehicle

speed at the moment the ECM detects a malfunction.

Data which are stored in the ECM memory, along with the 1st trip DTC, are called 1st trip freeze frame data,

and the data, stored together with the DTC data, are called freeze frame data and displayed on CONSULT-III

or GST. The 1st trip freeze frame data can only be disp layed on the CONSULT-III screen, not on the GST. For

detail, refer to TM-30

.

Only one set of freeze frame data (either 1st trip freeze frame data of freeze frame data) can be stored in the

ECM. 1st trip freeze frame data is stored in the ECM memory along with the 1st trip DTC. There is no priority

for 1st trip freeze frame data and it is updated each time a different 1st trip DTC is detected. However, once

freeze frame data (2nd trip detection/MIL on) is stored in the ECM memory, 1st trip freeze frame data is no

Revision: March 2010 2008 QX56