INFINITI QX56 2008 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 1841 of 4083

EM-38

< ON-VEHICLE REPAIR >

ROCKER COVER

ROCKER COVER

Removal and InstallationINFOID:0000000001538818

REMOVAL

1. Remove the engine room cover using power tool. Refer to EM-24, "Removal and Installation".

2. Remove the air duct and resonator assembly. Refer to EM-25, "

Removal and Installation" (for LH only).

3. Move the harness on the upper rocker cover and its peripheral aside.

4. Remove the electric throttle control actuat or, loosening the bolts diagonally (for LH only).

5. Remove the ignition coils. Refer to EM-37, "

Removal and Installation".

6. Remove the PCV hose from the PCV control valves.

• ⇐ : Engine front

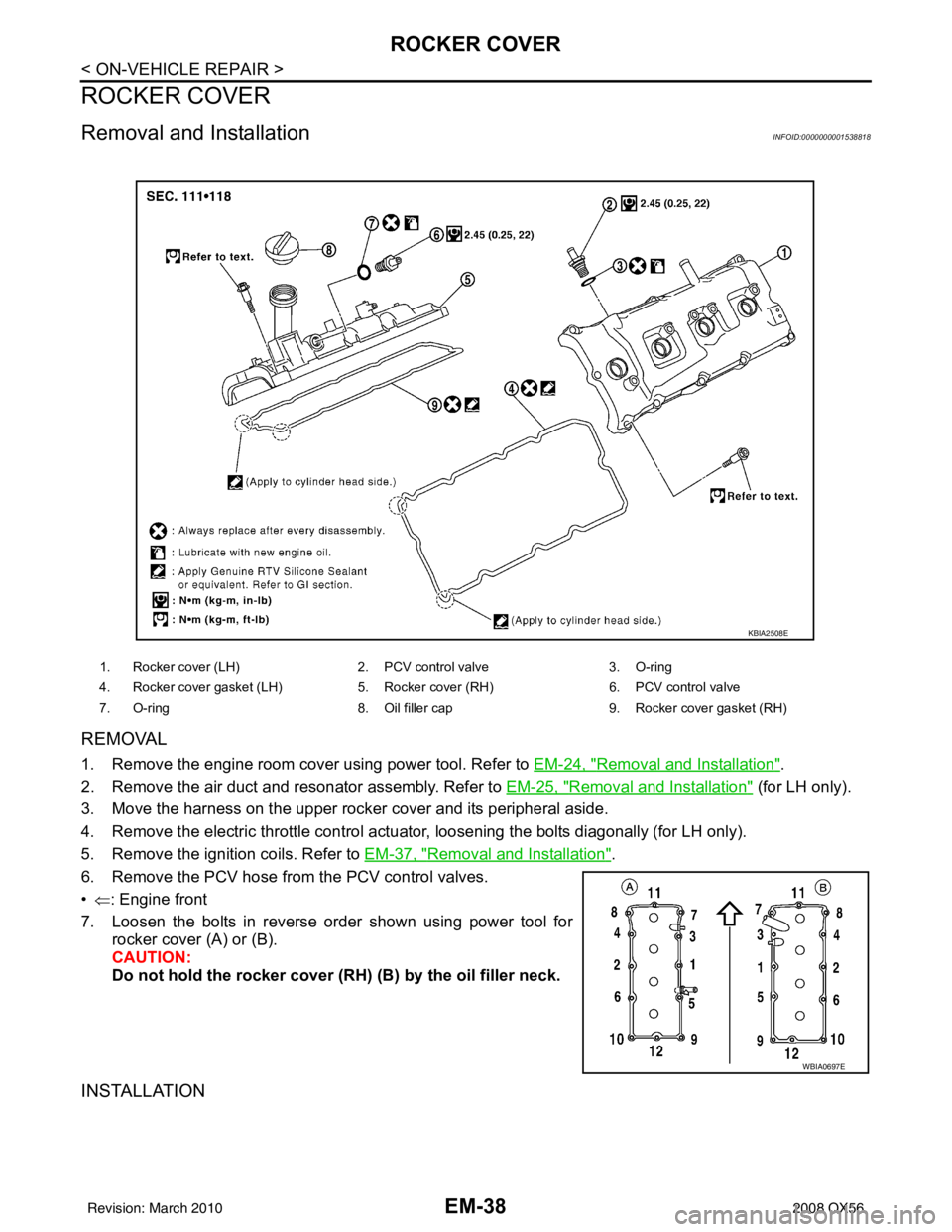

7. Loosen the bolts in reverse order shown using power tool for rocker cover (A) or (B).

CAUTION:

Do not hold the rocker cover ( RH) (B) by the oil filler neck.

INSTALLATION

1. Rocker cover (LH) 2. PCV control valve3. O-ring

4. Rocker cover gasket (LH) 5. Rocker cover (RH)6. PCV control valve

7. O-ring 8. Oil filler cap9. Rocker cover gasket (RH)

KBIA2508E

WBIA0697E

Revision: March 2010 2008 QX56

Page 1842 of 4083

ROCKER COVEREM-39

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

1. Apply liquid gasket to the joint part of the cylinder head and

camshaft bracket following the steps below.

NOTE:

Illustration shows an example of (LH) side (zoomed in shows

No.1 camshaft bracket).

a. Follow illustration ″a ″ to apply liquid gasket to the joint part of

No.1 camshaft bracket and cylinder head.

b. Follow illustration ″b ″ to apply liquid gasket 90 ° to illustration ″ a″.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to

GI-15, "

Recommended Chemical Products and Sealants".

2. Install the rocker cover (A) or (B). • Make sure the new rocker cover gasket is install ed in the groove of the rocker cover (A) or (B).

• Tighten the bolts in two steps in the numerical order shown.

CAUTION:

Do not hold the rocker cover ( RH) (B) by the oil filler neck.

3. Install the PCV hoses. NOTE:

• Remove foreign materials from inside the hose using com-

pressed air.

• The inserted length is within 25 - 30 mm (0.98 - 1.18 in) [Tar-

get: 25 mm (0.98 in)].

4. Installation of the remaining components is in the reverse order of removal.

KBIA2510E

1st step : 2.0 N·m (0.2 kg-m, 18 in-lb)

2nd step : 8.3 N·m (0.85 kg-m, 73 in-lb)

WBIA0697E

Revision: March 2010 2008 QX56

Page 1843 of 4083

EM-40

< ON-VEHICLE REPAIR >

FUEL INJECTOR AND FUEL TUBE

FUEL INJECTOR AND FUEL TUBE

Removal and InstallationINFOID:0000000001538819

CAUTION:

Do not remove or disassemble parts unless instructed as shown.

REMOVAL

1. Remove engine room cover using power tool. Refer to EM-24, "Removal and Installation".

2. Release fuel pressure. Refer to EC-494, "

Fuel Pressure Check".

3. Disconnect the negative battery terminal.

4. Disconnect fuel injector harness connectors.

5. Disconnect fuel hose assembly from fuel tube (RH bank and LH bank). CAUTION:

• While hoses are disconnected, plug th em to prevent fuel from draining.

• Do not separate fuel co nnector and fuel hose.

6. Remove fuel injectors with fuel tube assembly.

1. Fuel tube (RH bank) 2. Cap3. Fuel damper

4. O-ring 5. O-ring (Blue)6. Fuel injector

7. Clip 8. O-ring (Brown)9. O-ring

10. Fuel hose assembly 11. Fuel tube (LH bank)

KBIA2472E

Revision: March 2010 2008 QX56

Page 1844 of 4083

FUEL INJECTOR AND FUEL TUBEEM-41

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

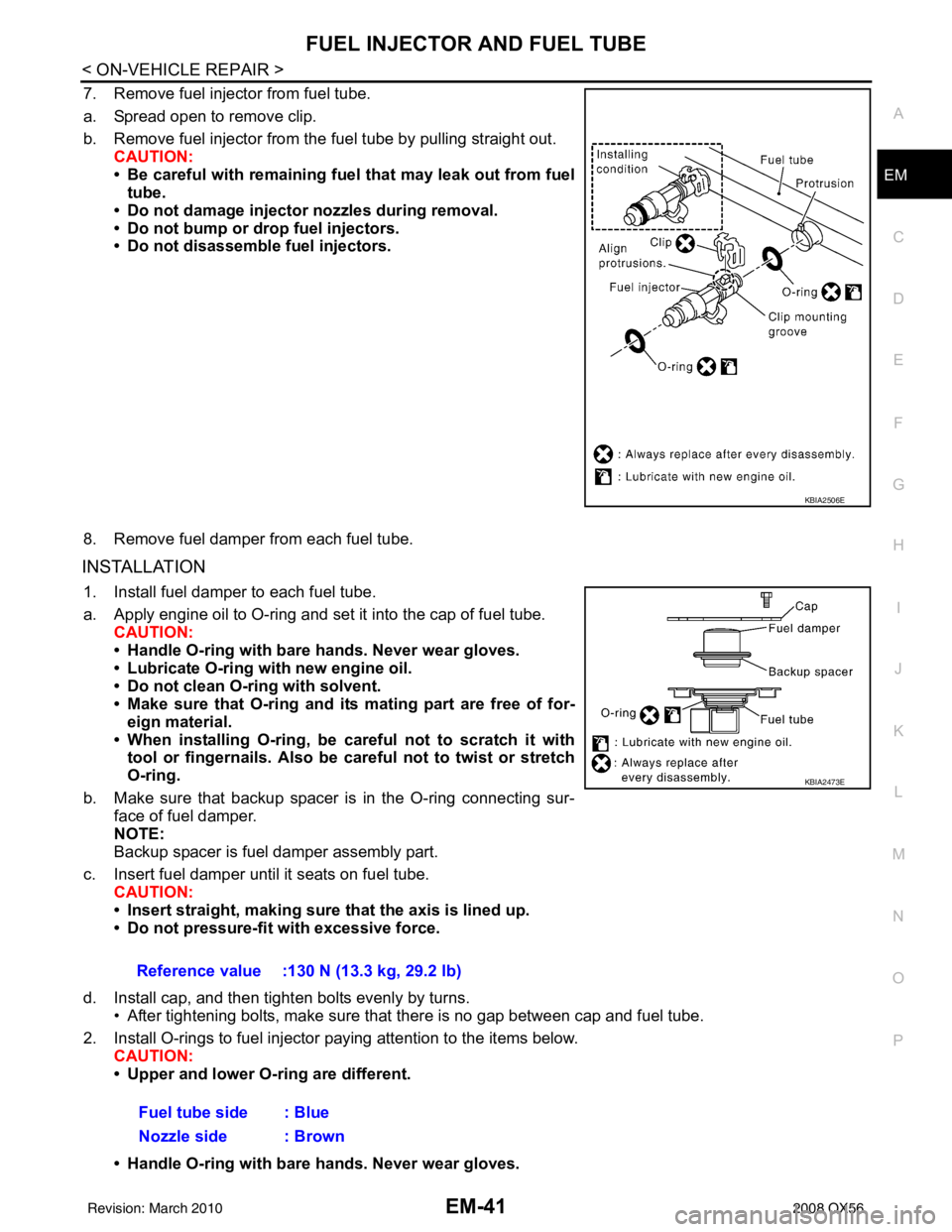

7. Remove fuel injector from fuel tube.

a. Spread open to remove clip.

b. Remove fuel injector from the

fuel tube by pulling straight out.

CAUTION:

• Be careful with remaining fuel that may leak out from fuel

tube.

• Do not damage injector nozzles during removal.

• Do not bump or drop fuel injectors.

• Do not disassemble fuel injectors.

8. Remove fuel damper from each fuel tube.

INSTALLATION

1. Install fuel damper to each fuel tube.

a. Apply engine oil to O-ring and set it into the cap of fuel tube. CAUTION:

• Handle O-ring with bare hands. Never wear gloves.

• Lubricate O-ring with new engine oil.

• Do not clean O-ring with solvent.

• Make sure that O-ring and its mating part are free of for- eign material.

• When installing O-ring, be car eful not to scratch it with

tool or fingernails. Also be careful not to twist or stretch

O-ring.

b. Make sure that backup spacer is in the O-ring connecting sur- face of fuel damper.

NOTE:

Backup spacer is fuel damper assembly part.

c. Insert fuel damper until it seats on fuel tube. CAUTION:

• Insert straight, making sure that the axis is lined up.

• Do not pressure-fit with excessive force.

d. Install cap, and then tighten bolts evenly by turns. • After tightening bolts, make sure that there is no gap between cap and fuel tube.

2. Install O-rings to fuel injector paying attention to the items below. CAUTION:

• Upper and lower O-ring are different.

• Handle O-ring with bare hands. Never wear gloves.

KBIA2506E

Reference value :130 N (13.3 kg, 29.2 lb)

Fuel tube side : Blue

Nozzle side : Brown

KBIA2473E

Revision: March 2010 2008 QX56

Page 1845 of 4083

EM-42

< ON-VEHICLE REPAIR >

FUEL INJECTOR AND FUEL TUBE

• Lubricate O-ring with new engine oil.

• Do not clean O-ring with solvent.

• Make sure that O-ring and its mating part are free of foreign material.

• When installing O-ring, be careful not to scratch it with tool or fingernails. Also be careful not to

twist or stretch O-ring. If O-ring was stretc hed while it was being attached, do not insert it

quickly into fuel tube.

• Insert O-ring straight into fuel tube. Do not angle or twist it.

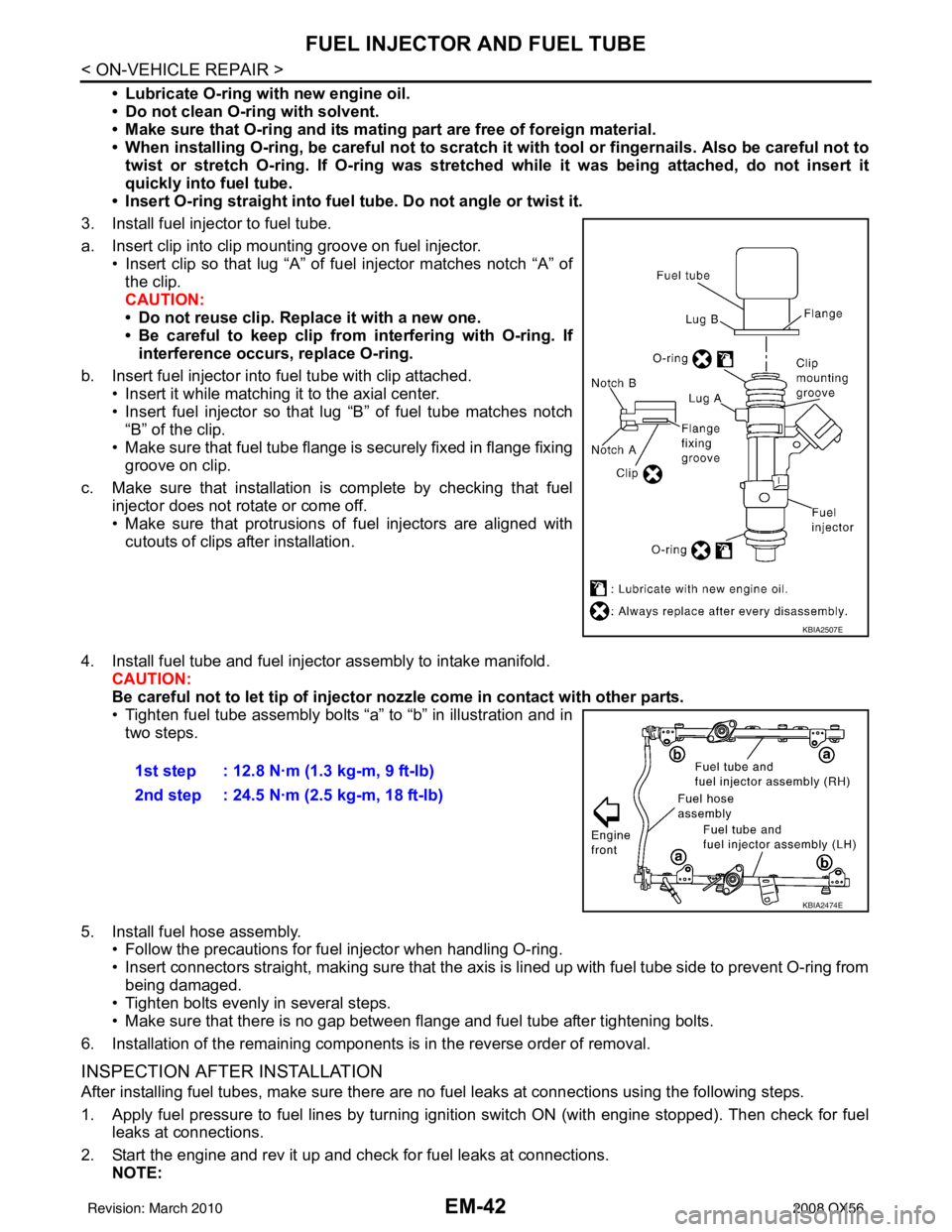

3. Install fuel injector to fuel tube.

a. Insert clip into clip mounting groove on fuel injector. • Insert clip so that lug “A” of fuel injector matches notch “A” ofthe clip.

CAUTION:

• Do not reuse clip. Replace it with a new one.

• Be careful to keep clip from interfering with O-ring. Ifinterference occurs, replace O-ring.

b. Insert fuel injector into fuel tube with clip attached. • Insert it while matching it to the axial center.

• Insert fuel injector so that lug “B” of fuel tube matches notch

“B” of the clip.

• Make sure that fuel tube flange is securely fixed in flange fixing groove on clip.

c. Make sure that installation is complete by checking that fuel injector does not rotate or come off.

• Make sure that protrusions of fuel injectors are aligned withcutouts of clips after installation.

4. Install fuel tube and fuel injector assembly to intake manifold. CAUTION:

Be careful not to let tip of injector nozzle come in contact with other parts.

• Tighten fuel tube assembly bolts “a” to “b” in illustration and in

two steps.

5. Install fuel hose assembly. • Follow the precautions for fuel injector when handling O-ring.

• Insert connectors straight, making sure that the axis is lined up with fuel tube side to prevent O-ring from

being damaged.

• Tighten bolts evenly in several steps.

• Make sure that there is no gap between flange and fuel tube after tightening bolts.

6. Installation of the remaining components is in the reverse order of removal.

INSPECTION AFTER INSTALLATION

After installing fuel tubes, make sure there are no fuel leaks at connections using the following steps.

1. Apply fuel pressure to fuel lines by turning ignition switch ON (with engine stopped). Then check for fuel leaks at connections.

2. Start the engine and rev it up and check for fuel leaks at connections. NOTE:

KBIA2507E

1st step : 12.8 N·m (1.3 kg-m, 9 ft-lb)

2nd step : 24.5 N·m (2.5 kg-m, 18 ft-lb)

KBIA2474E

Revision: March 2010 2008 QX56

Page 1846 of 4083

FUEL INJECTOR AND FUEL TUBEEM-43

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Use mirrors for checking on hidden points.

CAUTION:

Do not touch the engine imme

diately after stopping, as engine becomes extremely hot.

Revision: March 2010 2008 QX56

Page 1847 of 4083

EM-44

< ON-VEHICLE REPAIR >

TIMING CHAIN

TIMING CHAIN

ComponentsINFOID:0000000001538820

AWBIA0100GB

Revision: March 20102008 QX56

Page 1848 of 4083

TIMING CHAINEM-45

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

Removal and InstallationINFOID:0000000001538821

NOTE:

• To remove timing chain and associated parts, start with those on the LH bank. The procedure for removing

parts on the RH bank is omitted because it is t he same as that for removal on the LH bank.

• To install timing chain and associated parts, start with those on the RH bank. The procedure for installing parts on the LH bank is omitted because it is t he same as that for installation on the RH bank.

REMOVAL

1. Remove the engine assembly from the vehicle. Refer to EM-78, "Removal and Installation".

2. Remove the following components and related parts: • Drive belt auto tensioner and idler pulley. Refer to EM-13, "

Removal and Installation".

• Thermostat housing and water hose. Refer to CO-22, "

Removal and Installation".

• Power steering oil pump bracket. Refer to ST-26, "

Removal and Installation".

• Oil pan (lower), (upper) and oil strainer. Refer to EM-33, "

Removal and Installation".

• Ignition coil. Refer to EM-37, "

Removal and Installation".

• Rocker cover. Refer to EM-38, "

Removal and Installation".

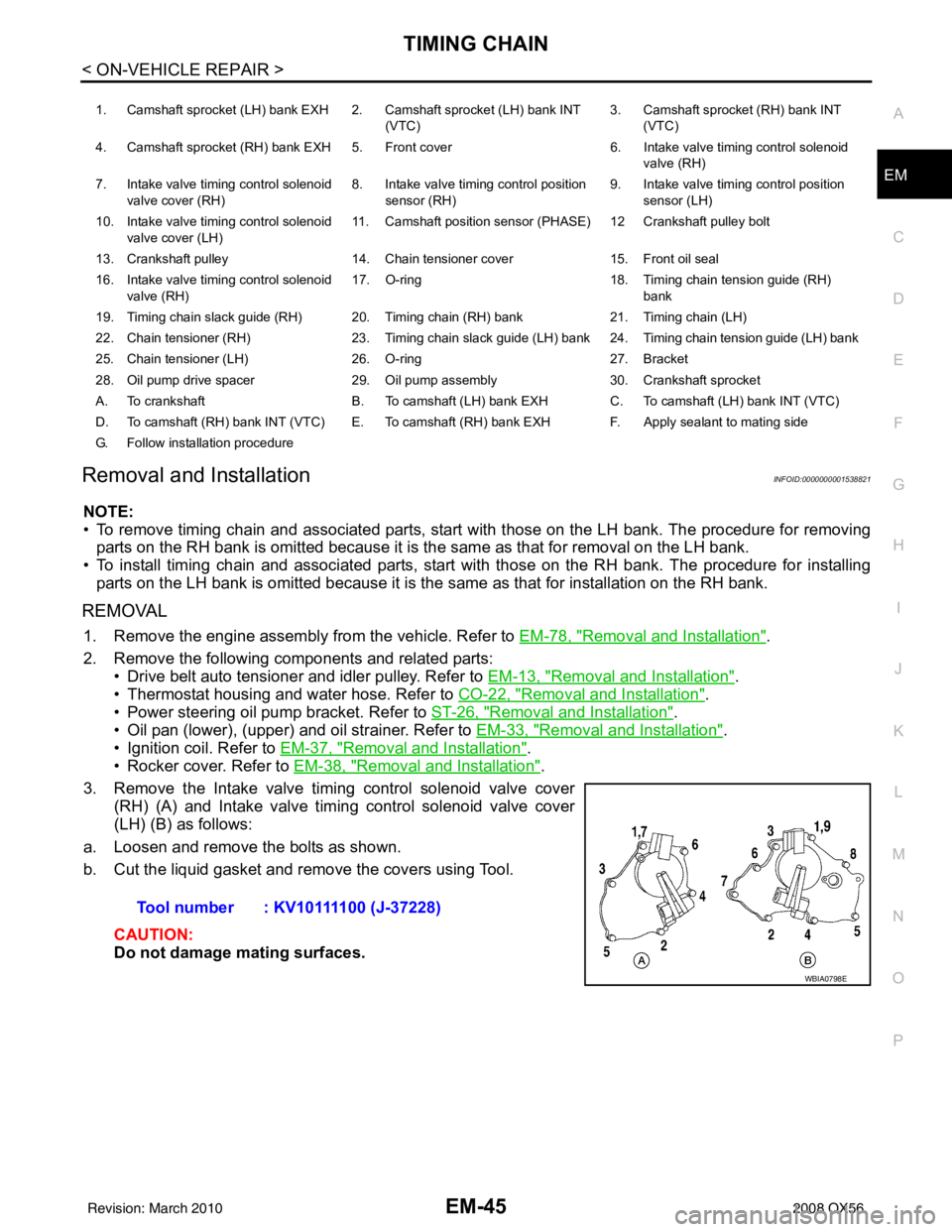

3. Remove the Intake valve timing control solenoid valve cover (RH) (A) and Intake valve timing control solenoid valve cover

(LH) (B) as follows:

a. Loosen and remove the bolts as shown.

b. Cut the liquid gasket and remove the covers using Tool.

CAUTION:

Do not damage mating surfaces.

1. Camshaft sprocket (LH) bank EXH 2. Camshaft sprocket (LH) bank INT (VTC)3. Camshaft sprocket (RH) bank INT

(VTC)

4. Camshaft sprocket (RH) bank EXH 5. Front cover 6. Intake valve timing control solenoid

valve (RH)

7. Intake valve timing control solenoid valve cover (RH) 8. Intake valve timing control position

sensor (RH) 9. Intake valve timing control position

sensor (LH)

10. Intake valve timing control solenoid valve cover (LH) 11. Camshaft position

sensor (PHASE) 12 Cran kshaft pulley bolt

13. Crankshaft pulley 14. Chain tensioner cover 15. Front oil seal

16. Intake valve timing control solenoid valve (RH) 17. O-ring

18. Timing chain tension guide (RH)

bank

19. Timing chain slack guide (RH) 20. Timing chain (RH) bank 21. Timing chain (LH)

22. Chain tensioner (RH) 23. Timing chain slack guide (LH) bank 24. Timing chain tension guide (LH) bank

25. Chain tensioner (LH) 26. O-ring 27. Bracket

28. Oil pump drive spacer 29. Oil pump assembly 30. Crankshaft sprocket

A. To crankshaft B. To camshaft (LH) bank EXH C. To camshaft (LH) bank INT (VTC)

D. To camshaft (RH) bank INT (VTC) E. To camshaft (RH) bank EXH F. Apply sealant to mating side

G. Follow installation procedure

Tool number : KV10111100 (J-37228)

WBIA0798E

Revision: March 2010 2008 QX56

Page 1849 of 4083

EM-46

< ON-VEHICLE REPAIR >

TIMING CHAIN

4. Obtain compression TDC of No. 1 cylinder as follows:

a. Turn the crankshaft pulley clockwise to align the TDC identifica-tion notch (without paint mark) with the timing indicator on the

front cover.

b. At this time, make sure both intake and exhaust cam lobes of No. 1 cylinder (top front on LH bank) point outside.

• If they do not point outside, turn crankshaft pulley once more.

5. Remove the crankshaft pulley.

a. Loosen the crankshaft pulley bolts using a hammer handle to secure the crankshaft.

b. Remove the crankshaft pulley from the crankshaft using tool. • Remove the crankshaft pulley using suitable tool. Set the boltsin the two bolt holes [M6 x 1.0 mm (0.04 in)] on the front sur-

face.

NOTE:

The dimension between the centers of the two bolt holes is 61

mm (2.40 in).

6. Remove the front cover.

a. Loosen and remove the bolts in the reverse of order shown.

b. Cut the liquid gasket and remove the covers using Tool. CAUTION:

Do not damage mating surfaces.

7. Remove the front oil seal using suitable tool. CAUTION:

Do not damage front cover.

KBIA2476E

KBIA0400J

PBIC0053E

KBIA2477E

Tool number : KV10111100 (J-37228)

KBIA2478E

Revision: March 2010 2008 QX56

Page 1850 of 4083

TIMING CHAINEM-47

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

8. Remove the oil pump drive spacer.

• Hold and remove the flat space of the oil pump drive spacer bypulling it forward.

9. Remove the oil pump. Refer to LU-14, "

Removal and Installation".

10. Remove the chain tensioner on the LH bank using the following steps. NOTE:

To remove the timing chain and associated parts, start with those on the LH bank. The procedure for

removing parts on the RH bank is omitted because it is the same as that for the LH bank.

a. Squeeze the return-proof clip ends using suitable tool and push the plunger into the tensioner body.

b. Secure the plunger using stopper pin. • Stopper pin is made from hard wire approximately 1 mm (0.04in) in diameter.

c. Remove the bolts and chain tensioner.

WARNING:

Plunger, spring, an d spring seat pop out when (squeezing)

return-proof clip without holding plunger head. It may

cause serious injuries. Always hold plunger head when

removing.

NOTE:

• Stop the plunger in the fully extended position by using the

return-proof clip (1) if the stopper pin is removed.

• Push the plunger (2) into the tensioner body while squeezing

the return-proof clip (1). Secure it using stopper pin (3).

11. Remove the timing chain tension guide and timing chain slack guide.

12. Remove the timing chain and crankshaft sprocket.

13. Loosen the camshaft sprocket bolts as shown and remove the camshaft sprocket.

CAUTION:

To avoid interference between valves and pistons, do not

turn crankshaft or camshaft wh en timing chain is discon-

nected.

14. Repeat the same procedure to remove the RH timing chain and associated parts.

INSPECTION AFTER REMOVAL

KBIA2512E

KBIA2479E

KBIA2483E

WBIA0799E

Revision: March 2010 2008 QX56