INFINITI QX56 2008 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 1851 of 4083

EM-48

< ON-VEHICLE REPAIR >

TIMING CHAIN

Check for cracks and any excessive wear at link plates. Replace

chain if necessary.

• In the same way as for the LH bank, inspect the timing chain andassociated parts on the RH bank.

INSTALLATION

NOTE:

• The above figure shows the relationship between the ma ting mark on each timing chain and that of the cor-

responding sprocket, with the components installed.

• To install the timing chain and associated parts, start with those on the RH bank. The procedure for installing parts on the LH bank is omitted because it is t he same as that for installation on the RH bank.

PBIC0282E

AWBIA0150ZZ

1. RH bank Camshaft sprocket (INT)

(VTC) 2. RH bank Camshaft sprocket (EXH) 3. RH bank camshaft dowel pin

4. Timing chain 5. RH bank Timing chain slack guide 6. Primary timing chain tensioner

7. Crankshaft sprocket 8. Crankshaft key 9. LH Timing chain tension guide

10. Timing chain 11. LH Camshaft dowel pin 12. LH bank Camshaft sprocket (EXH)

13. LH bank Camshaft sprocket (INT) (VTC) 14. Secondary timing chain tensioner 15. RH bank timing chain tension guide

16. LH timing chain slack guide A. LH bank B. RH bank

C. Alignment mark (Link color: blue) D. Alignment mark (Link color: blue) E. Alignment mark (Identification mark)

F. Alignment mark for LH bank (Notch) G. Alignment mark for LH bank (Link color: copper)H. Alignment mark

for RH bank (Link

color: copper)

J. Alignment mark (Link color: blue) K. Alignment mark (Identification mark) L. Alignment mark (Identification mark)

M Alignment mark (Link color: blue) N. Alignment mark (Identification mark)

Revision: March 2010 2008 QX56

Page 1852 of 4083

TIMING CHAINEM-49

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

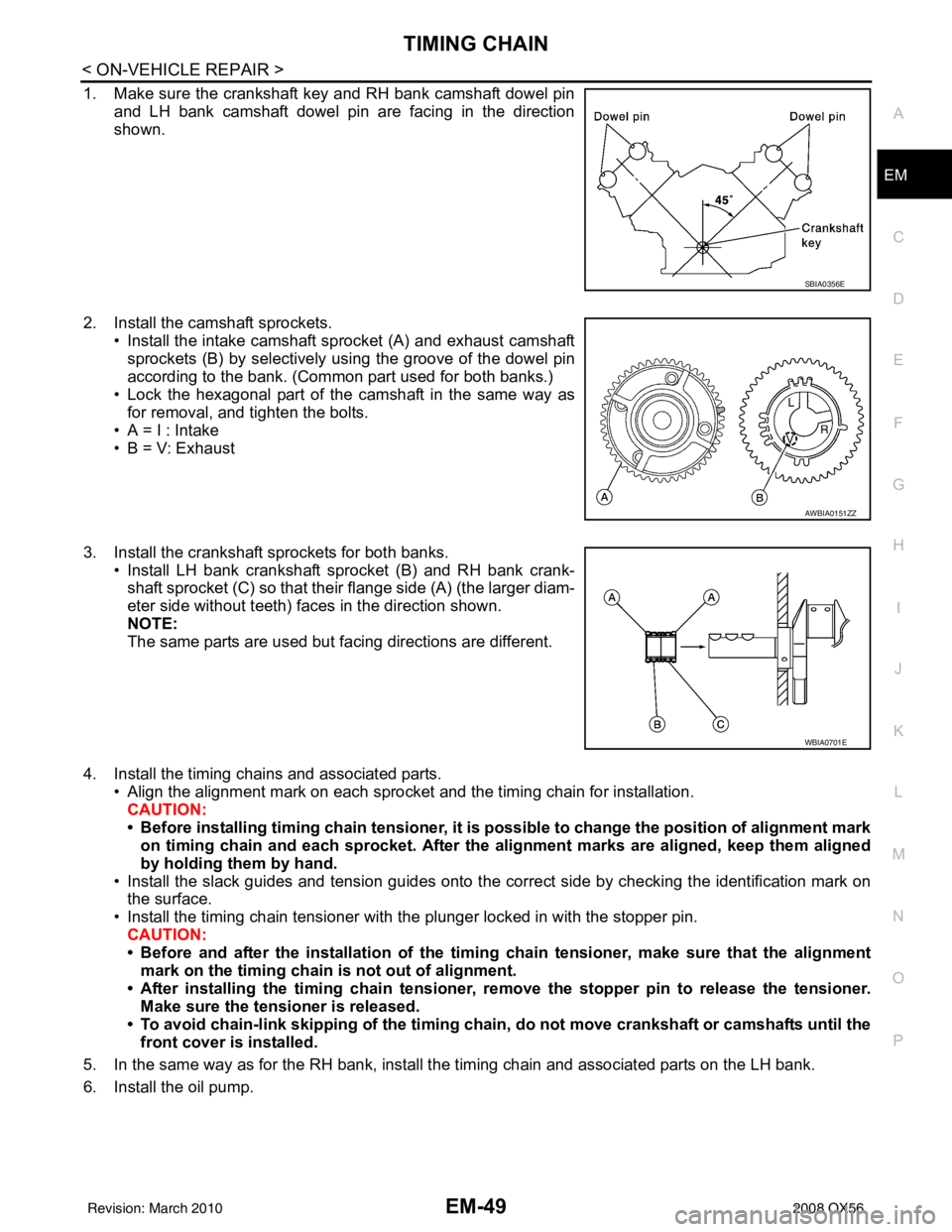

1. Make sure the crankshaft key and RH bank camshaft dowel pin

and LH bank camshaft dowel pin are facing in the direction

shown.

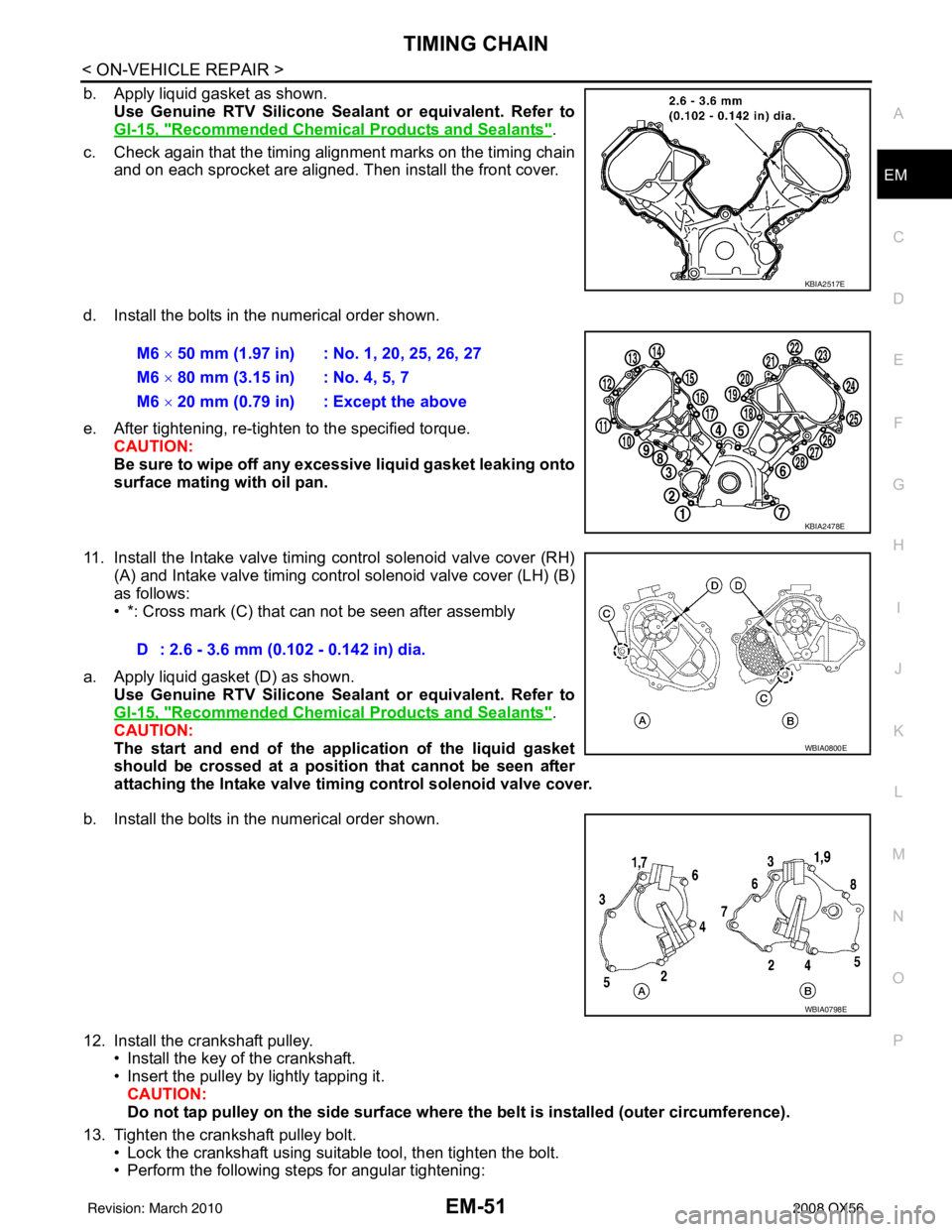

2. Install the camshaft sprockets. • Install the intake camshaft sprocket (A) and exhaust camshaftsprockets (B) by selectively us ing the groove of the dowel pin

according to the bank. (Common part used for both banks.)

• Lock the hexagonal part of the camshaft in the same way as for removal, and tighten the bolts.

• A = I : Intake

• B = V: Exhaust

3. Install the crankshaft sprockets for both banks. • Install LH bank crankshaft sprocket (B) and RH bank crank-shaft sprocket (C) so that their flange side (A) (the larger diam-

eter side without teeth) faces in the direction shown.

NOTE:

The same parts are used but facing directions are different.

4. Install the timing chains and associated parts. • Align the alignment mark on each sprocket and the timing chain for installation.

CAUTION:

• Before installing timing chain tensioner, it is possible to change the position of alignment mark

on timing chain and each sprocket . After the alignment marks are aligned, keep them aligned

by holding them by hand.

• Install the slack guides and tension guides onto the correct side by checking the identification mark on

the surface.

• Install the timing chain tensioner with the plunger locked in with the stopper pin.

CAUTION:

• Before and after the installation of the timing chain tensioner, make sure that the alignment

mark on the timing chain is not out of alignment.

• After installing the timing chain tensioner, remove the stopp er pin to release the tensioner.

Make sure the tensioner is released.

• To avoid chain-link skipping of the timing chain, do not move crankshaft or camshafts until the

front cover is installed.

5. In the same way as for the RH bank, install the timing chain and associated parts on the LH bank.

6. Install the oil pump.

SBIA0356E

AWBIA0151ZZ

WBIA0701E

Revision: March 2010 2008 QX56

Page 1853 of 4083

EM-50

< ON-VEHICLE REPAIR >

TIMING CHAIN

7. Install the oil pump drive spacer as follows:• Install so that the front mark on the front edge of the oil pumpdrive spacer faces the front of the engine.

• Insert the oil pump drive spacer according to the directions of the crankshaft key and the two flat surfaces of the oil pump

inner rotor.

• If the positional relationship does not allow the insertion, rotate the oil pump inner rotor to allow the oil pump drive spacer to

be inserted.

8. Install the front oil seal using suitable tool. CAUTION:

Do not scratch or make burrs on the circumference of the

oil seal.

9. Install the chain tensioner cover. • Apply liquid gasket as shown.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to

GI-15, "

Recommended Chemical Products and Sealants".

10. Install the front cover as follows:

a. Install a new O-ring on the cylinder block.

KBIA2490E

PBIC0059E

KBIA2547E

KBIA2516E

Revision: March 2010 2008 QX56

Page 1854 of 4083

TIMING CHAINEM-51

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

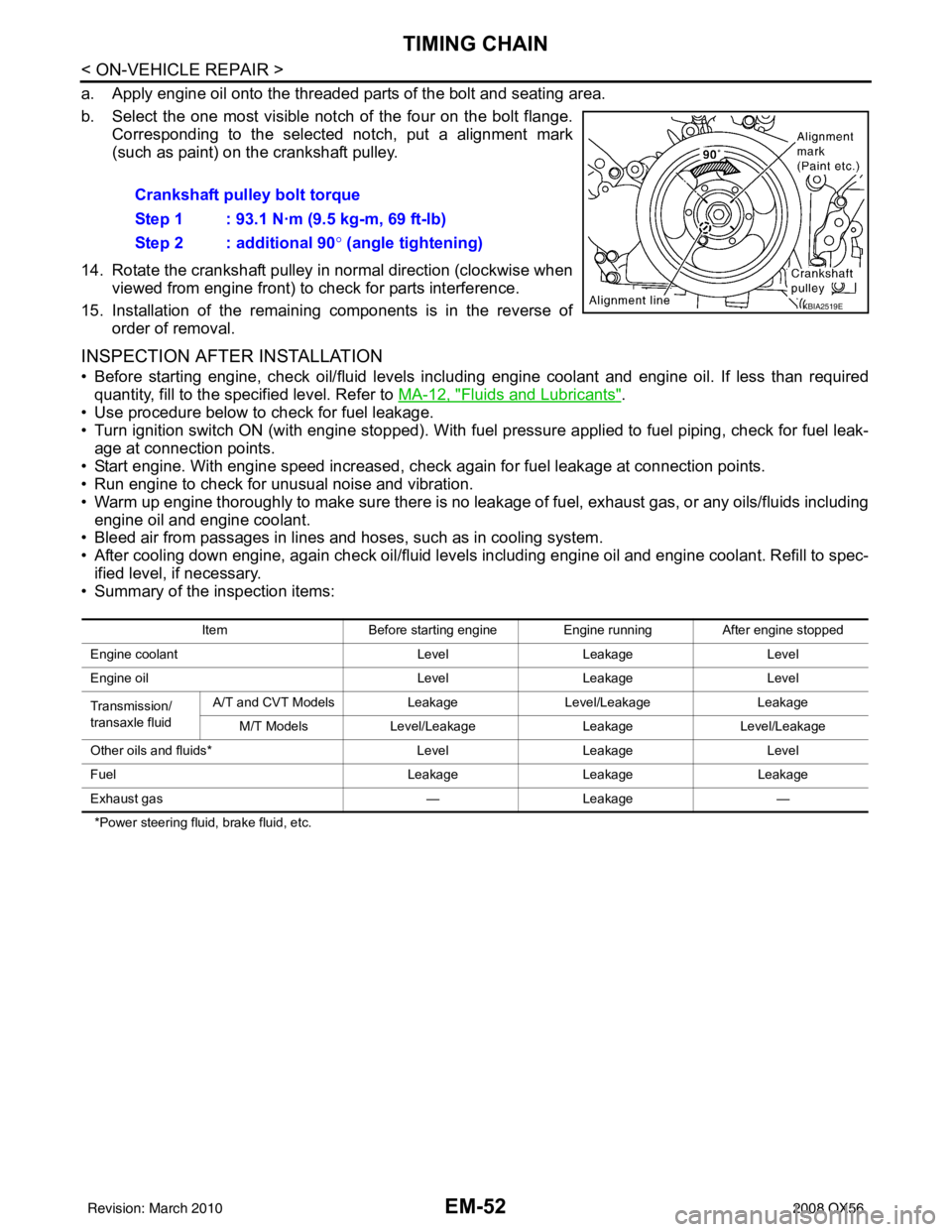

b. Apply liquid gasket as shown.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to

GI-15, "

Recommended Chemical Products and Sealants".

c. Check again that the timing alignment marks on the timing chain and on each sprocket are aligned. Then install the front cover.

d. Install the bolts in the numerical order shown.

e. After tightening, re-tighten to the specified torque. CAUTION:

Be sure to wipe off any excessive liquid gasket leaking onto

surface mating with oil pan.

11. Install the Intake valve timing control solenoid valve cover (RH) (A) and Intake valve timing control solenoid valve cover (LH) (B)

as follows:

• *: Cross mark (C) that can not be seen after assembly

a. Apply liquid gasket (D) as shown. Use Genuine RTV Silicone Seal ant or equivalent. Refer to

GI-15, "

Recommended Chemical Products and Sealants".

CAUTION:

The start and end of the appl ication of the liquid gasket

should be crossed at a positi on that cannot be seen after

attaching the Intake valve timing control solenoid valve cover.

b. Install the bolts in the numerical order shown.

12. Install the crankshaft pulley. • Install the key of the crankshaft.

• Insert the pulley by lightly tapping it.

CAUTION:

Do not tap pulley on the side surface where th e belt is installed (outer circumference).

13. Tighten the crankshaft pulley bolt. • Lock the crankshaft using suitable tool, then tighten the bolt.

• Perform the following steps for angular tightening:

KBIA2517E

M6 × 50 mm (1.97 in) : No. 1, 20, 25, 26, 27

M6 × 80 mm (3.15 in) : No. 4, 5, 7

M6 × 20 mm (0.79 in) : Except the above

KBIA2478E

D : 2.6 - 3.6 mm (0.102 - 0.142 in) dia.

WBIA0800E

WBIA0798E

Revision: March 2010 2008 QX56

Page 1855 of 4083

EM-52

< ON-VEHICLE REPAIR >

TIMING CHAIN

a. Apply engine oil onto the threaded parts of the bolt and seating area.

b. Select the one most visible notch of the four on the bolt flange.Corresponding to the selected notch, put a alignment mark

(such as paint) on the crankshaft pulley.

14. Rotate the crankshaft pulley in normal direction (clockwise when viewed from engine front) to check for parts interference.

15. Installation of the remaining components is in the reverse of order of removal.

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-12, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak- age at connection points.

• Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec-

ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

Crankshaft pulley bolt torque

Step 1 : 93.1 N·m (9.5 kg-m, 69 ft-lb)

Step 2 : additional 90 ° (angle tightening)

KBIA2519E

Item Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakage Leakage

Exhaust gas —Leakage —

Revision: March 2010 2008 QX56

Page 1856 of 4083

CAMSHAFTEM-53

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

CAMSHAFT

ComponentsINFOID:0000000001538822

Removal and InstallationINFOID:0000000001538823

NOTE:

Do not remove the engine assembly to perform this procedure.

REMOVAL

1. Remove the RH bank and LH bank rocker covers. Refer to

EM-38, "Removal and Installation".

AWBIA0101GB

1. Cylinder head RH bank2. Camshaft bracket (No. 2, 3, 4, 5) 3. Valve lifter

4. Camshaft bracket (No. 1) 5. Seal washer6. Camshaft RH bank (EXH)

7. Camshaft RH bank (INT) 8. Camshaft LH bank (INT)9. Camshaft LH bank (EXH)

10. Camshaft sprocket RH bank (EXH) 11. Camshaft sprocket RH bank (INT) (VTC)12. Camshaft sprocket LH bank (INT)

(VTC)

13. Camshaft sprocket LH bank (EXH) 14. Camshaft position sensor (PHASE) 15. O-ring

16. Cylinder head LH bank A. Follow installation procedure

Revision: March 2010 2008 QX56

Page 1857 of 4083

EM-54

< ON-VEHICLE REPAIR >

CAMSHAFT

2. Obtain compression TDC of No. 1 cylinder as follows:

a. Turn the crankshaft pulley clockwise to align the TDC identifica-tion notch (without paint mark) with the timing indicator on the

front cover.

b. At this time, make sure both intake and exhaust cam lobes of No. 1 cylinder (top front on LH bank) point outside.

• If they do not point outside, turn crankshaft pulley once more.

3. Remove the intake valve timing control solenoid cover RH bank (A) and intake valve timing control solenoid cover LH bank (B)

as follows:

a. Loosen and remove the bolts as shown.

b. Cut the liquid gasket and remove the covers using Tool.

CAUTION:

Do not damage mating surfaces.

4. Paint alignment marks on the RH bank (A) timing chain links (C) and LH bank (B) timing chain links (D) and align with the cam-

shaft sprocket alignment marks (E) and (F).

5. Remove the LH bank timing chain tensioner using the following steps. WARNING:

Plunger, spring, and spring seat pop out when squeezing return-proof clip without holding

plunger head. It may cause serious injuries. Always hold plunger head when removing.

KBIA2476E

KBIA0400J

Tool number : KV10111100 (J-37228)

WBIA0798E

AWBIA0154ZZ

Revision: March 2010 2008 QX56

Page 1858 of 4083

CAMSHAFTEM-55

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

a. Squeeze return-proof clip ends using suitable tool and push the

plunger into the tensioner body.

b. Secure plunger using stopper pin. • Stopper pin is made from hard wire approximately 1 mm (0.04in) in diameter.

c. Remove the bolts and the timing chain tensioner.

NOTE:

• Stop plunger in the fully extended position using return-proof clip (1) if stopper pin is removed.

• Push the plunger (2) into the tensioner body while squeezing the return-proof clip (1). Secure it using stopper pin (3).

6. Remove the RH bank timing chain tensioner cover from the front cover using Tool.

CAUTION:

Do not damage mating surfaces.

7. Remove the RH bank timing chain tensioner using the following steps. WARNING:

Plunger, spring, and spring seat pop out when squeezing return -proof clip without holding

plunger head. It may cause serious injuries. Always hold plunger head when removing.

a. Squeeze return-proof clip ends using suitable tool and push the plunger into the tensioner body.

b. Secure plunger using stopper pin. • Stopper pin is made from hard wire approximately 1 mm (0.04in) in diameter.

KBIA2479E

KBIA2483E

Tool number : KV10111100 (J-37228)

KBIA2521E

KBIA2479E

Revision: March 2010 2008 QX56

Page 1859 of 4083

EM-56

< ON-VEHICLE REPAIR >

CAMSHAFT

c. Remove the bolts and the RH bank timing chain tensioner (A).NOTE:

If it is difficult to push plunger on RH bank timing chain tensioner

(A), remove the plunger under extended condition.

8. Loosen camshaft sprocket bolts as shown and remove camshaft sprockets.

CAUTION:

To avoid interference between valves and pistons, do not

turn crankshaft or camshaft with timing chain discon-

nected.

9. Remove the RH front cover bolts (A) and LH front cover bolts (B).

10. Remove RH (A) camshaft bracket bolts and LH (C) camshaft bracket bolts in the reverse of order shown to remove camshaft

brackets.

• Remove No. 1 camshaft bracket.NOTE:

The bottom and front surface of bracket will be stuck because

of liquid gasket.

• ⇐ : Engine front

• B: Exhaust side

• D: Intake side

WBIA0705E

KBIA2485E

WBIA0706E

WBIA0707E

Revision: March 2010 2008 QX56

Page 1860 of 4083

CAMSHAFTEM-57

< ON-VEHICLE REPAIR >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

11. Remove the camshaft.

12. Remove the valve lifters if necessary.

• Correctly identify location where each part is removed from. Keep parts organized to avoid mixing them

up.

INSPECTION AFTER REMOVAL

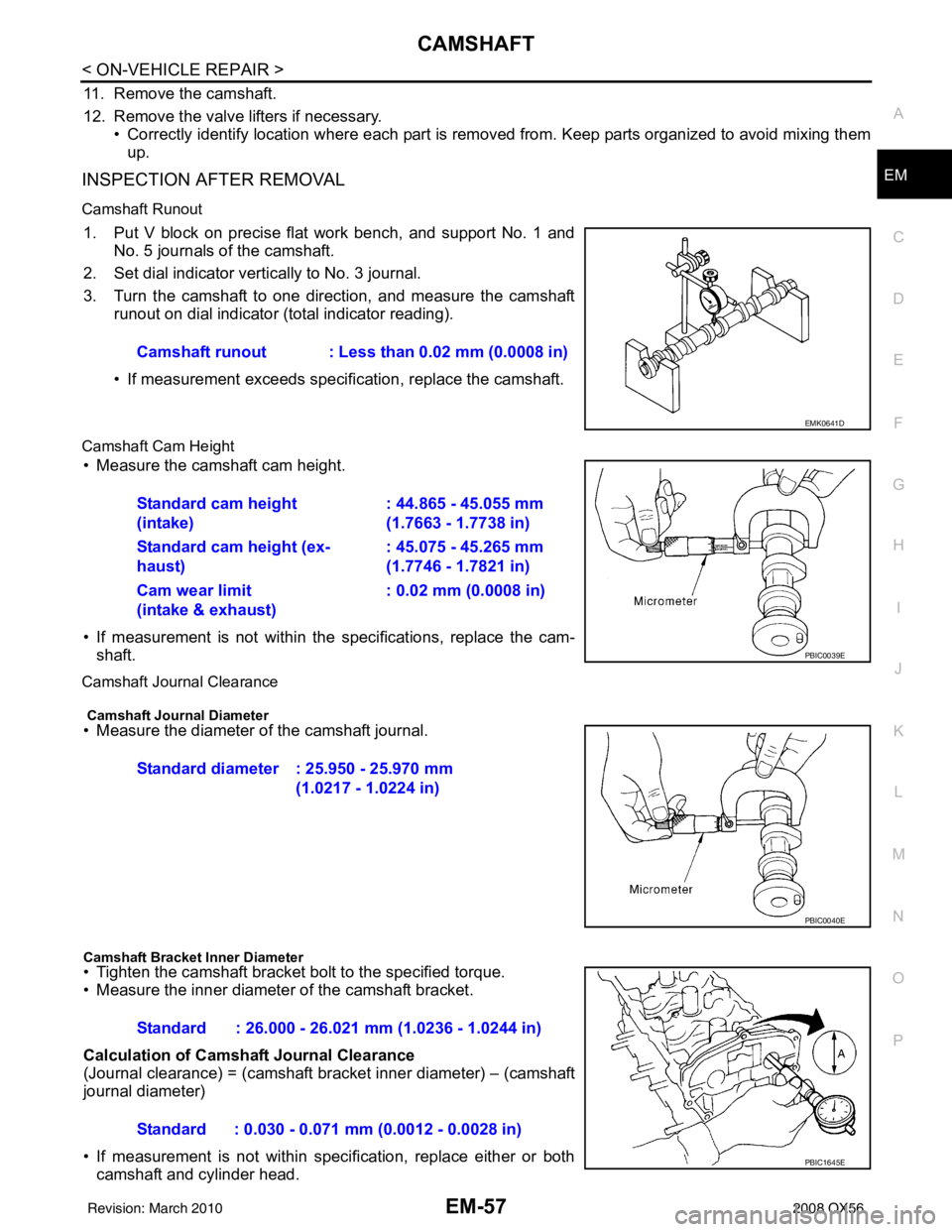

Camshaft Runout

1. Put V block on precise flat work bench, and support No. 1 and No. 5 journals of the camshaft.

2. Set dial indicator vertically to No. 3 journal.

3. Turn the camshaft to one direction, and measure the camshaft runout on dial indicator (total indicator reading).

• If measurement exceeds specif ication, replace the camshaft.

Camshaft Cam Height

• Measure the camshaft cam height.

• If measurement is not within the specifications, replace the cam-

shaft.

Camshaft Journal Clearance

Camshaft Journal Diameter

• Measure the diameter of the camshaft journal.

Camshaft Bracket Inner Diameter

• Tighten the camshaft bracket bolt to the specified torque.

• Measure the inner diameter of the camshaft bracket.

Calculation of Camshaft Journal Clearance

(Journal clearance) = (camshaft bracket inner diameter) – (camshaft

journal diameter)

• If measurement is not within specification, replace either or both

camshaft and cylinder head. Camshaft runout : Less than 0.02 mm (0.0008 in)

EMK0641D

Standard cam height

(intake)

: 44.865 - 45.055 mm

(1.7663 - 1.7738 in)

Standard cam height (ex-

haust) : 45.075 - 45.265 mm

(1.7746 - 1.7821 in)

Cam wear limit

(intake & exhaust) : 0.02 mm (0.0008 in)

PBIC0039E

Standard diameter : 25.950 - 25.970 mm

(1.0217 - 1.0224 in)

PBIC0040E

Standard : 26.000 - 26.021 mm (1.0236 - 1.0244 in)

Standard : 0.030 - 0.071 mm (0.0012 - 0.0028 in)

PBIC1645E

Revision: March 2010 2008 QX56