power steering fluid INFINITI QX56 2008 Factory User Guide

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 2629 of 4083

CHASSIS AND BODY MAINTENANCEMA-31

< ON-VEHICLE MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

• Check the steering gear housing for looseness, damage and oil

leakage as shown.

• Check the steering column connections for looseness.

STEERING LINKAGE

• Check the ball joint, dust cover and other component parts for looseness, wear, damage, and grease leak-

age.

Checking Power Steering Fluid and LineINFOID:0000000001606194

CHECKING FLUID LEVEL

• Check the power steering fluid level with the engine off.

• Check fluid level on reservoir. Use “HOT” range at fluid tempera- tures of 50 ° to 80° C (122° to 176° F). Use “COLD” range at fluid

temperatures of 0 ° to 30° C (32° to 86° F).

CAUTION:

• Do not overfill.

• Refer to MA-12, "

Fluids and Lubricants" .

CHECKING LINES

• Check lines for improper attachment, leaks, cracks, damage, loose

connections, chafing, and deterioration.

Checking Axle and Suspension PartsINFOID:0000000001606195

FRONT AND REAR AXLE AND SUSPENSION PARTS

Check front and rear axle and suspension parts for excessive play, cracks, wear or other damage.

• Shake each wheel to check for excessive play.

• Rotate each wheel to check for abnormal noise.

SGIA0506E

LGIA0021E

SGIA0506E

SMA525A

Revision: March 2010 2008 QX56

Page 3492 of 4083

ST-1

STEERING

C

DE

F

H I

J

K L

M

SECTION ST

A

B

ST

N

O P

CONTENTS

STEERING SYSTEM

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution for Steering System .......................... ......4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................6

FUNCTION DIAGNOSIS ...............................7

HEATED STEERING WHEEL ........................ .....7

System Diagram .................................................. ......7

System Description ...................................................7

Component Parts Location ........................................7

Component Description .............................................8

COMPONENT DIAGNOSIS ..........................9

HEATED STEERING WHEEL ........................ .....9

Wiring Diagram ................................................... ......9

SYMPTOM DIAGNOSIS ..............................12

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ ....

12

NVH Troubleshooting Chart ................................ ....12

ON-VEHICLE MAINTENANCE ....................13

POWER STEERING FLUID ........................... ....13

Checking Fluid Level ........................................... ....13

Checking Fluid Leakage ..........................................13

Air Bleeding Hydraulic System ................................13

ON-VEHICLE REPAIR .................................15

STEERING WHEEL ..........................................15

On-Vehicle Inspection and Service ..................... ....15

POWER STEERING OIL PUMP .......................17

On-Vehicle Inspection and Service .........................17

REMOVAL AND INSTALLATION ...............18

STEERING WHEEL ..........................................18

Removal and Installation ..................................... ....18

TILT SYSTEM ...................................................19

Removal and Installation .........................................19

STEERING COLUMN ........................................20

Removal and Installation .........................................20

POWER STEERING GEAR AND LINKAGE ....23

Removal and Installation .........................................23

POWER STEERING OIL PUMP .......................26

Removal and Installation .........................................26

HYDRAULIC LINE ............................................27

Removal and Installation .........................................27

DISASSEMBLY AND ASSEMBLY ..............29

STEERING COLUMN ........................................29

Disassembly and Assembly ................................. ....29

POWER STEERING GEAR AND LINKAGE ....31

Disassembly and Assembly .....................................31

POWER STEERING OIL PUMP .......................35

Disassembly and Assembly .....................................35

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

36

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

36

Steering Wheel .................................................... ....36

Revision: March 2010 2008 QX56

Page 3504 of 4083

POWER STEERING FLUIDST-13

< ON-VEHICLE MAINTENANCE >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

ON-VEHICLE MAINTENANCE

POWER STEERING FLUID

Checking Fluid LevelINFOID:0000000001534691

Check power steering fluid level with engine off, referring to the scale

on reservoir tank.

Use HOT range for fluid temperatures of 50 ° – 80 °C (122 ° – 176 °F).

Use COLD range for fluid temperatures of 0 ° – 30 °C (32° – 86°F).

CAUTION:

• Do not overfill.

• Do not reuse any used power steering fluid.

• Recommended fluid is Genuine NISSAN PSF or equivalent. Refer to MA-12, "

Fluids and Lubricants" .

Checking Fluid LeakageINFOID:0000000001534692

Check the hydraulic piping lines for improper attachment and for

leaks, cracks, damage, loose connec tions, chafing or deterioration.

1. Run engine until fluid temperature reaches 50 ° – 80° C (122° –

176° F) in reservoir tank. Keep engine speed idle.

2. Turn steering wheel right-to-left several times.

3. Hold steering wheel at each “lock” position for five seconds to check fluid leakage.

CAUTION:

Do not hold steering wheel in a locked position for more

than 10 seconds. (There is the possibility that oil pump may

be damaged.)

4. If fluid leakage at connections is noticed, then loosen flare nut and then retighten. Do not over tighten con- nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer to ST-17, "

On-Vehicle Inspection and Ser-

vice".

6. Check steering gear boots for accumulation of fluid indicating a leak from the steering gear.

Air Bleeding Hydraulic SystemINFOID:0000000001534693

Incomplete air bleeding causes the following. When this happens, bleed air again.

• Air bubbles in reservoir tank.

• Clicking noise in oil pump.

• Excessive buzzing in oil pump. NOTE:

When vehicle is stationary or while steering wheel is being turned slowly, some noise may be heard from oil

pump or gear. This noise is normal and does not affect any system.

1. Stop engine, and then turn steering wheel fully to right and left several times. CAUTION:

Do not allow steering fluid reservoir tank to go below the MIN level line. Check tank frequently and

add fluid as needed.

2. Run engine at idle speed. Turn steering wheel fully right and then fully left, hold for about three seconds.

Then check for fluid leakage.

3. Repeat step 2 several times at about three second intervals. CAUTION:

Do not hold steeri ng wheel in the locked position for more than 10 seconds. (There is the possibil-

ity that oil pump may be damaged.)

4. Check for air bubbles or cloudy fluid.

LGIA0021E

SGIA0506E

Revision: March 2010 2008 QX56

Page 3505 of 4083

ST-14

< ON-VEHICLE MAINTENANCE >

POWER STEERING FLUID

5. If air bubbles or cloudiness still exists, stop engine, perform steps 2 and 3 again until air bubbles or cloud-iness does not exist.

6. Stop engine, check fluid level.

Revision: March 2010 2008 QX56

Page 3506 of 4083

STEERING WHEELST-15

< ON-VEHICLE REPAIR >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

ON-VEHICLE REPAIR

STEERING WHEEL

On-Vehicle Inspection and ServiceINFOID:0000000004920096

CHECKING CONDITION OF INSTALLATION

• Check installation condition of steering gear assembly, front suspension, axle and steering column.

• Check if movement exists when steering wheel is mo ved up and down, to the left and right and to the axial

direction.

• Check if the nuts for steering gear assembly are loose. Refer to ST-23, "

Removal and Installation".

CHECKING STEERING WHEEL PLAY

1. Turn tires straight ahead, start engine, then turn steer ing wheel to the left and right lightly, and measure

steering wheel movement on the outer circumference when steering wheel is turned up to the point where

tires start moving.

CHECKING NEUTRAL POSITION ON STEERING WHEEL

• Check neutral position on steering wheel after confirming that front wheel alignment is correct. Refer to FSU-

7, "Front Wheel Alignment".

1. Turn tires straight ahead, check if steering wheel is in the neutral position.

2. If it is not in the neutral position, remo ve steering wheel and reinstall it correctly.

3. If the neutral position cannot be attained by repositi oning the steering wheel two teeth or less on steering

stem, loosen tie-rod lock nuts of steering outer socket s, then adjust tie-rods by the same amount in the

opposite direction.

CHECKING STEERING WHEEL TURNING FORCE

1. Park vehicle on a level, dry surface and set parking brake.

2. Start engine.

3. Bring power steering fluid up to operating temperature of 60 ° – 80 °C (140 ° – 176 °F).

4. Tires need to be inflated to specified pressure. Refer to WT-51, "

Tire".

5. Check steering wheel turning force using Tool when steering wheel has been turned 360 ° from the neutral position.

End play of the axial direction

for steering wheel : 0 mm (0 in)

LGIA0024E

Steering wheel play on the outer circumference : 0 − 35 mm (0 − 1.38 in)

Tool number — (J-44372)

Steering wheel turning force : 39 N (4 kg-f, 9 lb-f) or less

WGIA0035E

Revision: March 2010 2008 QX56

Page 3508 of 4083

POWER STEERING OIL PUMPST-17

< ON-VEHICLE REPAIR >

C

DE

F

H I

J

K L

M A

B

ST

N

O P

POWER STEERING OIL PUMP

On-Vehicle Inspection and ServiceINFOID:0000000004920097

CHECKING RELIEF OIL PRESSURE

CAUTION:

Before starting work, confirm belt tension is proper.

1. Connect Tool between oil pump discharge connector and high pressure hose and then bleed air from the hydraulic circuit.

2. Start engine. Allow engine to run until tank temperature reaches 50 ° – 80 °C (122° – 176°F).

CAUTION:

• Warm up engine with shut-off valve fully opened. If engine is started with shut-off valve closed,

fluid pressure in power steering pump increases to maximum. This will raise fluid temperature

excessively.

• Be careful not to contact hose with belt when engine is started.

3. With engine at idle, close shut-off valve and read the relief oil pressure.

CAUTION:

Do not close shut-off valve of pressure gauge for more than 10 seconds.

4. After measurement, open shut-off valve slowly. • If relief oil pressure is outside the specification, repair or replace oil pump. Refer to ST-35, "

Disassembly

and Assembly" .

5. After inspection, disconnect oil pressure gauge and oil pressure gauge adapter from hydraulic circuit, con-

nect oil pump discharge connector and high pressure hose. Add fluid and bleed air from hydraulic circuit

thoroughly. Refer to ST-13, "

Air Bleeding Hydraulic System" .

Tool number:

Pressure gauge and shut-off valve KV48103500

(J26357 and J26357-10)

Oil pump side Connector A and O-

ring

KV48105300-4 and 5295262U10

(—)

Eye-bolt and O-ring KV48105300-3 and 5295262U00

(—)

High pressure

piping side Connector B and O-

ring

KV48105300-1 and 5295262U00

(—)

Nut KV48105300-2

( — )

SGIA0570E

Relief oil pressure

: 9.0 – 9.8 mPa (91.77 – 99.93 kg/cm2 , 1305.34 – 1421.37 psi)

Revision: March 2010 2008 QX56

Page 3515 of 4083

ST-24

< REMOVAL AND INSTALLATION >

POWER STEERING GEAR AND LINKAGE

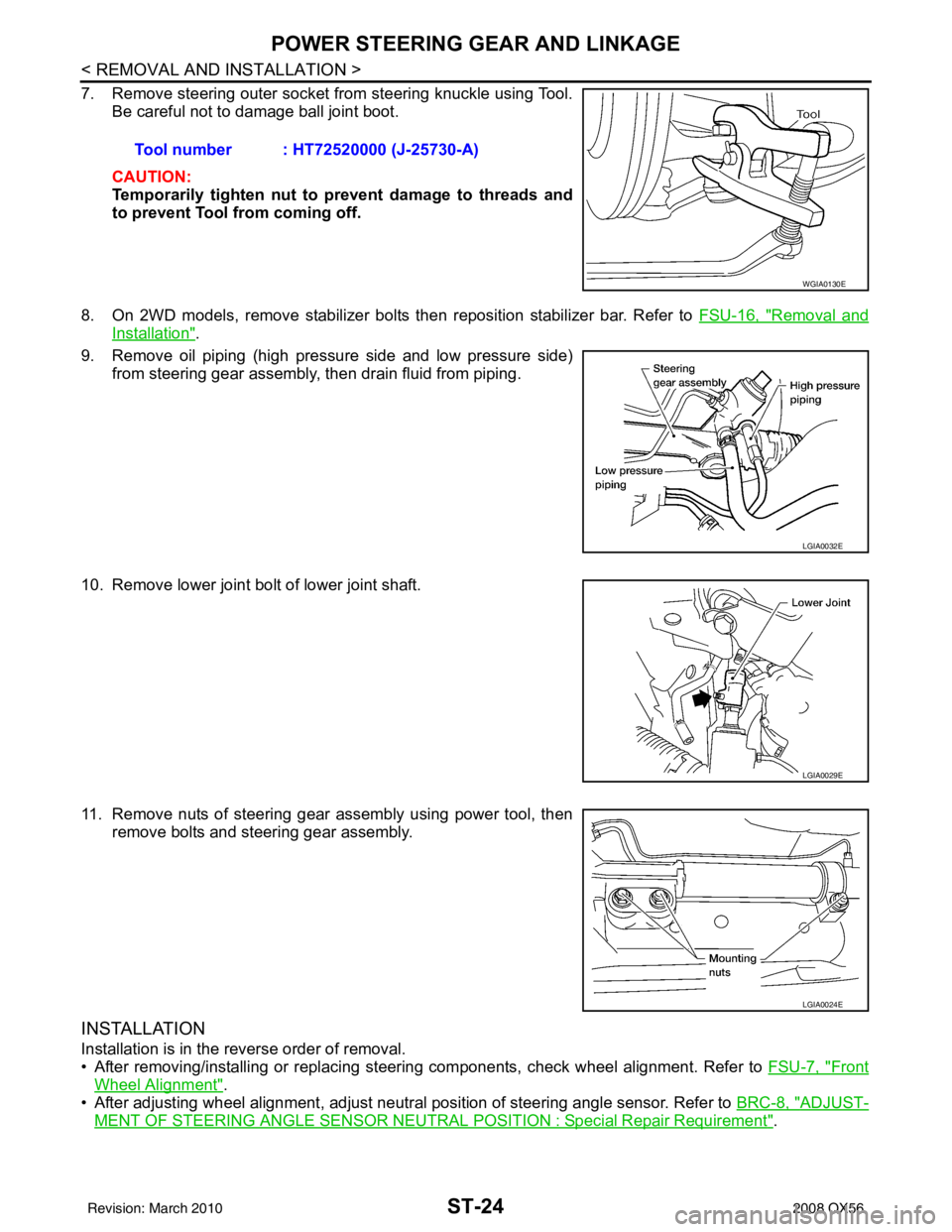

7. Remove steering outer socket from steering knuckle using Tool.Be careful not to damage ball joint boot.

CAUTION:

Temporarily tighten nut to prevent damage to threads and

to prevent Tool from coming off.

8. On 2WD models, remove stabilizer bolts then reposition stabilizer bar. Refer to FSU-16, "

Removal and

Installation".

9. Remove oil piping (high pressure side and low pressure side) from steering gear assembly, then drain fluid from piping.

10. Remove lower joint bolt of lower joint shaft.

11. Remove nuts of steering gear assembly using power tool, then remove bolts and steering gear assembly.

INSTALLATION

Installation is in the reverse order of removal.

• After removing/installing or replacing steering components, check wheel alignment. Refer to FSU-7, "

Front

Wheel Alignment".

• After adjusting wheel alignment, adjust neutral position of steering angle sensor. Refer to BRC-8, "

ADJUST-

MENT OF STEERING ANGLE SENSOR NEUTRAL POSITION : Special Repair Requirement".

Tool number : HT72520000 (J-25730-A)

WGIA0130E

LGIA0032E

LGIA0029E

LGIA0024E

Revision: March 2010

2008 QX56

Page 3517 of 4083

ST-26

< REMOVAL AND INSTALLATION >

POWER STEERING OIL PUMP

POWER STEERING OIL PUMP

Removal and InstallationINFOID:0000000004920102

REMOVAL

1. Drain power steering fluid from reservoir tank.

2. Remove engine room cover. Refer to EM-24, "

Removal and Installation".

3. Remove air duct assembly. Refer to EM-25, "

Removal and Installation".

4. Remove power steering reservoir tank.

5. Remove serpentine drive belt belt from auto tensioner and power steering pump. Refer to EM-13,

"Removal and Installation".

6. Disconnect pressure sensor electrical connector.

7. Remove high pressure and low pressure piping from power steering oil pump. Refer to ST-27

.

8. Remove bolts, then remove power steering pump.

INSTALLATION

Installation is in the reverse order of removal. Refer to ST-27 for tightening torque.

• After installation, bleed air. Refer to ST-13, "

Air Bleeding Hydraulic System".

NOTE:

Belt tension is automatic and requires no adjustment.

Revision: March 2010 2008 QX56

Page 3529 of 4083

ST-38

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Oil Pump

INFOID:0000000001534689

Steering FluidINFOID:0000000001534690

Rack sliding force At the neutral point:

Range within

± 11.5 mm

(± 0.453 in) from the neutral

position

(in power ON) Area average value 147

− 211 N (14.99 − 21.52 kg, 33.1 − 47.52 lb)

Allowable variation 98 N (10 kg, 22 lb) or less

Whole area (in power OFF) Peak value

294 N (30.0 kg, 66 lb) or less

Allowable variation 147 N (16 kg, 35 lb) or less

Steering gear model

PR26AM

Relief oil pressure

9.0 − 9.8 mPa (91.77 − 99.93 kg/cm2, 1305.34 − 1421.37 psi)

Fluid capacity

Approx. 1.0 (1-1/8 US qt, 7/8 Imp qt)

Revision: March 2010 2008 QX56

Page 4007 of 4083

WW-10

< FUNCTION DIAGNOSIS >

REAR WIPER AND WASHER SYSTEM

Component Parts Location

INFOID:0000000001735571

Component DescriptionINFOID:0000000001735572

1. Steering column (v iew with instrument

panel removed) 2. BCM M18, M19, M20

3. Rear washer nozzle

4. Rear wiper motor D704 5. Air cleaner case6. Front and rear washer motor connector

E105

7. Washer fluid reservoir 8. Combination switch M28 9. Glass hatch ajar switch D707

ALLIA0842ZZ

Part Description

BCM • Judges each switch status by the combination switch reading function.

• Supplies power to the rear wiper motor.

• Performs the auto stop control of the rear wiper.

Combination switch

(Wiper and washer switch) Refer to BCS-7, "

System Diagram".

Revision: March 2010

2008 QX56