INFINITI QX56 2008 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 581 of 4083

![INFINITI QX56 2008 Factory Service Manual BRC-114

< REMOVAL AND INSTALLATION >[VDC/TCS/ABS]

WHEEL SENSORS

REMOVAL AND INSTALLATION

WHEEL SENSORS

Removal and InstallationINFOID:0000000001604548

REMOVAL

1. Remove wheel sensor bolt.

• When rem INFINITI QX56 2008 Factory Service Manual BRC-114

< REMOVAL AND INSTALLATION >[VDC/TCS/ABS]

WHEEL SENSORS

REMOVAL AND INSTALLATION

WHEEL SENSORS

Removal and InstallationINFOID:0000000001604548

REMOVAL

1. Remove wheel sensor bolt.

• When rem](/img/42/57030/w960_57030-580.png)

BRC-114

< REMOVAL AND INSTALLATION >[VDC/TCS/ABS]

WHEEL SENSORS

REMOVAL AND INSTALLATION

WHEEL SENSORS

Removal and InstallationINFOID:0000000001604548

REMOVAL

1. Remove wheel sensor bolt.

• When removing the front wheel sensor, first remove t he disc rotor to gain access to the front wheel sen-

sor bolt. Refer to BR-31, "

Removal and Installation of Brake Caliper and Rotor" .

• When removing the rear wheel sensor, first remove the rear hub and bearing assembly to gain access to

the rear wheel sensor bolt. Refer to RAX-8, "

Removal and Installation".

2. Pull out the sensor, being careful to turn it as little as possible. CAUTION:

• Do not pull on the sensor harness.

3. Disconnect wheel sensor harness electrical connec tor, then remove harness from attaching points.

INSTALLATION

Installation is in the reverse order of removal. Tighten wheel sensor bolt to specification.

CAUTION:

• Inspect wheel sensor O-ring, replace sensor assembly if damaged.

• Before installing wheel sensor, make sure no foreign materials (such as iron fragments) are adhered

to the pick-up part of the sensor, to the inside of the sensor hole or on the rotor mating surface.

• Apply a coat of suitable grease to the wheel sensor O-ring and hole. Refer to MA-12, "

Fluids and

Lubricants" .

WFIA0376E

Revision: March 2010 2008 QX56

Page 582 of 4083

![INFINITI QX56 2008 Factory Service Manual SENSOR ROTORBRC-115

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SENSOR ROTOR

Removal and InstallationINFOID:0000000001604549

NOTE:

The wheel sensor rotors are built in INFINITI QX56 2008 Factory Service Manual SENSOR ROTORBRC-115

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SENSOR ROTOR

Removal and InstallationINFOID:0000000001604549

NOTE:

The wheel sensor rotors are built in](/img/42/57030/w960_57030-581.png)

SENSOR ROTORBRC-115

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

SENSOR ROTOR

Removal and InstallationINFOID:0000000001604549

NOTE:

The wheel sensor rotors are built into the wheel hubs and are not removable. If damaged, replace wheel hub

and bearing assembly. Refer to FAX-7, "

Removal and Installation" (front), RAX-8, "Removal and Installation"

(rear).

Revision: March 2010 2008 QX56

Page 583 of 4083

![INFINITI QX56 2008 Factory Service Manual BRC-116

< REMOVAL AND INSTALLATION >[VDC/TCS/ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000001604550

REMOVAL

1. Disconnect the INFINITI QX56 2008 Factory Service Manual BRC-116

< REMOVAL AND INSTALLATION >[VDC/TCS/ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000001604550

REMOVAL

1. Disconnect the](/img/42/57030/w960_57030-582.png)

BRC-116

< REMOVAL AND INSTALLATION >[VDC/TCS/ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000001604550

REMOVAL

1. Disconnect the negative battery terminal.

2. Remove the air duct and resonator assembly and air cleaner case. Refer to

EM-25, "

Removal and Instal-

lation".

3. Drain the brake fluid. Refer to BR-17, "

Drain and Refill" .

4. Disconnect the actuator harness from the ABS actuator and electric unit (control unit).

5. Disconnect the brake tubes. CAUTION:

• To remove the brake tubes, use a flare nut wrench to prevent the flare nuts and brake tubes from

being damaged.

• Be careful not to splash brake fluid on painted areas.

6. Remove the three bolts and remove the ABS actuator and electric unit (control unit).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

To install, use a flare nut wr ench (commercial service tool).

1. To rear left caliper

13 N·m (1.3 kg-m, 10 ft-lb) 2. To rear right caliper

13 N·m (1.3 kg-m, 10 ft-lb) 3. To front left caliper

13 N·m (1.3 kg-m, 10 ft-lb)

4. To front right caliper 13 N·m (1.3 kg-m, 10 ft-lb) 5. From the master cylinder secondary side

18.2 N·m (1.9 kg-m, 13 ft-lb) 6. From the master cylinder primary side

18.2 N·m (1.9 kg-m, 13 ft-lb)

7. ABS actuator and electric unit (control unit) 8. Actuator harness connector

WFIA0375E

Revision: March 2010

2008 QX56

Page 584 of 4083

![INFINITI QX56 2008 Factory Service Manual ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)BRC-117

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

• Always tighten brake tubes to specifi cation when installing. Refer to BR- INFINITI QX56 2008 Factory Service Manual ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)BRC-117

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

• Always tighten brake tubes to specifi cation when installing. Refer to BR-](/img/42/57030/w960_57030-583.png)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)BRC-117

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

• Always tighten brake tubes to specifi cation when installing. Refer to BR-21, "Hydraulic Circuit" .

• Never reuse drained brake fluid.

• After installation of the ABS actuator and elect ric unit (control unit), perform the following.

- Refill brake system with new br ake fluid. Then bleed the air from the system. Refer to BR-17, "

Bleed-

ing Brake System" .

- Adjust the steering angle sensor. Refer to BRC-8, "

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION : Speci al Repair Requirement" .

- Calibrate the decel G sensor. Refer to BRC-9, "

CALIBRATION OF DECEL G SENSOR : Special Repair

Requirement" .

Revision: March 2010 2008 QX56

Page 585 of 4083

![INFINITI QX56 2008 Factory Service Manual BRC-118

< REMOVAL AND INSTALLATION >[VDC/TCS/ABS]

STEERING ANGLE SENSOR

STEERING ANGLE SENSOR

Removal and InstallationINFOID:0000000001836943

REMOVAL

1. Remove spiral cable. Refer to

SR-7, "Removal a INFINITI QX56 2008 Factory Service Manual BRC-118

< REMOVAL AND INSTALLATION >[VDC/TCS/ABS]

STEERING ANGLE SENSOR

STEERING ANGLE SENSOR

Removal and InstallationINFOID:0000000001836943

REMOVAL

1. Remove spiral cable. Refer to

SR-7, "Removal a](/img/42/57030/w960_57030-584.png)

BRC-118

< REMOVAL AND INSTALLATION >[VDC/TCS/ABS]

STEERING ANGLE SENSOR

STEERING ANGLE SENSOR

Removal and InstallationINFOID:0000000001836943

REMOVAL

1. Remove spiral cable. Refer to

SR-7, "Removal and Installation".

2. Remove the screws and remove the steering angle sensor.

CAUTION:

In the case that the ABS actuator and electronic unit (control unit) is replaced, make sure to adjust

position of steering angle sensor. Refer to BRC-8, "

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION : Special Repair Requirement".

INSTALLATION

1. Installation is in the reverse order of removal.

Revision: March 2010 2008 QX56

Page 586 of 4083

![INFINITI QX56 2008 Factory Service Manual G SENSORBRC-119

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

G SENSOR

Removal and InstallationINFOID:0000000001604552

REMOVAL

1. Remove center console. Refer to IP-20, INFINITI QX56 2008 Factory Service Manual G SENSORBRC-119

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

G SENSOR

Removal and InstallationINFOID:0000000001604552

REMOVAL

1. Remove center console. Refer to IP-20,](/img/42/57030/w960_57030-585.png)

G SENSORBRC-119

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

G SENSOR

Removal and InstallationINFOID:0000000001604552

REMOVAL

1. Remove center console. Refer to IP-20, "Removal and Installa-

tion".

2. Remove yaw rate/side/decel G sensor attaching nuts. CAUTION:

• Do not use power tools to re move or install yaw rate/side/

decel G sensor.

• Do not drop or strike the yaw rate/side/decel G sensor.

3. Disconnect harness connector and remove the yaw rate/side/ decel G sensor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not drop or strike the yaw rate/side/decel G sensor.

• After installation, calibrate the yaw rate/side/decel G sensor. Refer to BRC-9, "

CALIBRATION OF

DECEL G SENSOR : Special Repair Requirement".

WFIA0202E

Revision: March 2010 2008 QX56

Page 587 of 4083

BRM-1

BODY EXTERIOR, DOORS, ROOF & VEHICLE SECURITY

C

DE

F

G H

I

J

L

M

SECTION BRM

A

B

BRM

N

O P

CONTENTS

BODY REPAIR

SERVICE INFORMATION .. ..........................2

BODY REPAIR ....................................................2

Body Mounting .................................................... ......2

Body Exterior Paint Color ..........................................3

Body Component Parts .............................................4

Corrosion Protection .................................................9

Body Sealing ....................................................... ....12

Body Construction ...................................................16

Body Alignment .......................................................16

Handling Precaution for Plastics ..............................31

Precaution in Repairing High Strength Steel ...........34

Foam Repair ............................................................36

Replacement Operation ...........................................37

Revision: March 2010 2008 QX56

Page 588 of 4083

BRM-2

< SERVICE INFORMATION >

BODY REPAIR

SERVICE INFORMATION

BODY REPAIR

Body MountingINFOID:0000000003243373

When removing, be sure to replace bolts and nuts (sealant applied bolts or self-lock nuts are used for all

mounting).

LIIA1564E

Revision: March 20102008 QX56

Page 589 of 4083

BODY REPAIRBRM-3

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

BRM

N

O P

Body Exterior Paint ColorINFOID:0000000001609797

M: Metallic; 2S: 2-Coat Solid, 2P: 2-Coat Pearl; 3P: 3-Coat Pearl; t: Primerless Diamond Coat Clear

LIIA1437E

Component Color code B30 K32 G10 K11 K12 Q11

Description

Lake-

shore

Slate Serengeti

Sand Liquid

Onyx Silver

Graphite Silver

Indulgence Tuscan

Pearl

Typ e m m m m mm

Clear coat t tt t tt

1 Outside

mirror Body

Chromium

plate Cr2P Cr2P Cr2P Cr2P Cr2P Cr2P

Base Black KH3 KH3 KH3 KH3 KH3 KH3

2 Radiator grille Center and

emblemChromium

plate

Cr2P Cr2P Cr2P Cr2P Cr2P Cr2P

3 Bumpers Fascias Body color B30 K32 G10 K11 K12 Q11

4 Valance BlackKH3 KH3 KH3 KH3 KH3 KH3

5 Running

Boards Body

Body color B30 K32 G10 K11 K12 Q11

Step pad Black KH3 KH3 KH3 KH3 KH3 KH3

6 Outside han-

dles Front

Chromium

plate

Cr2P Cr2P Cr2P Cr2P Cr2P Cr2P

Rear Body color B30 K32 G10 K11 BK12 BQ10

7 Side Guard

Molding Base

Body color B30 K32 G10 K11 BK12 BQ10

To p T r i m Chromium

plate Cr2P Cr2P Cr2P Cr2P Cr2P Cr2P

8 License plate

finisher Base

Body color B30 K32 G10 K11 K12 Q11

Top and bot-

tom trim Chromium

plate

Cr2P Cr2P Cr2P Cr2P Cr2P Cr2P

9 Cowl top cover Body color B30 K32 G10 K11 K12 Q11

10 Rear spoiler Body color B30 K32 G10 K11 K12 Q11

Revision: March 2010 2008 QX56

Page 590 of 4083

BRM-4

< SERVICE INFORMATION >

BODY REPAIR

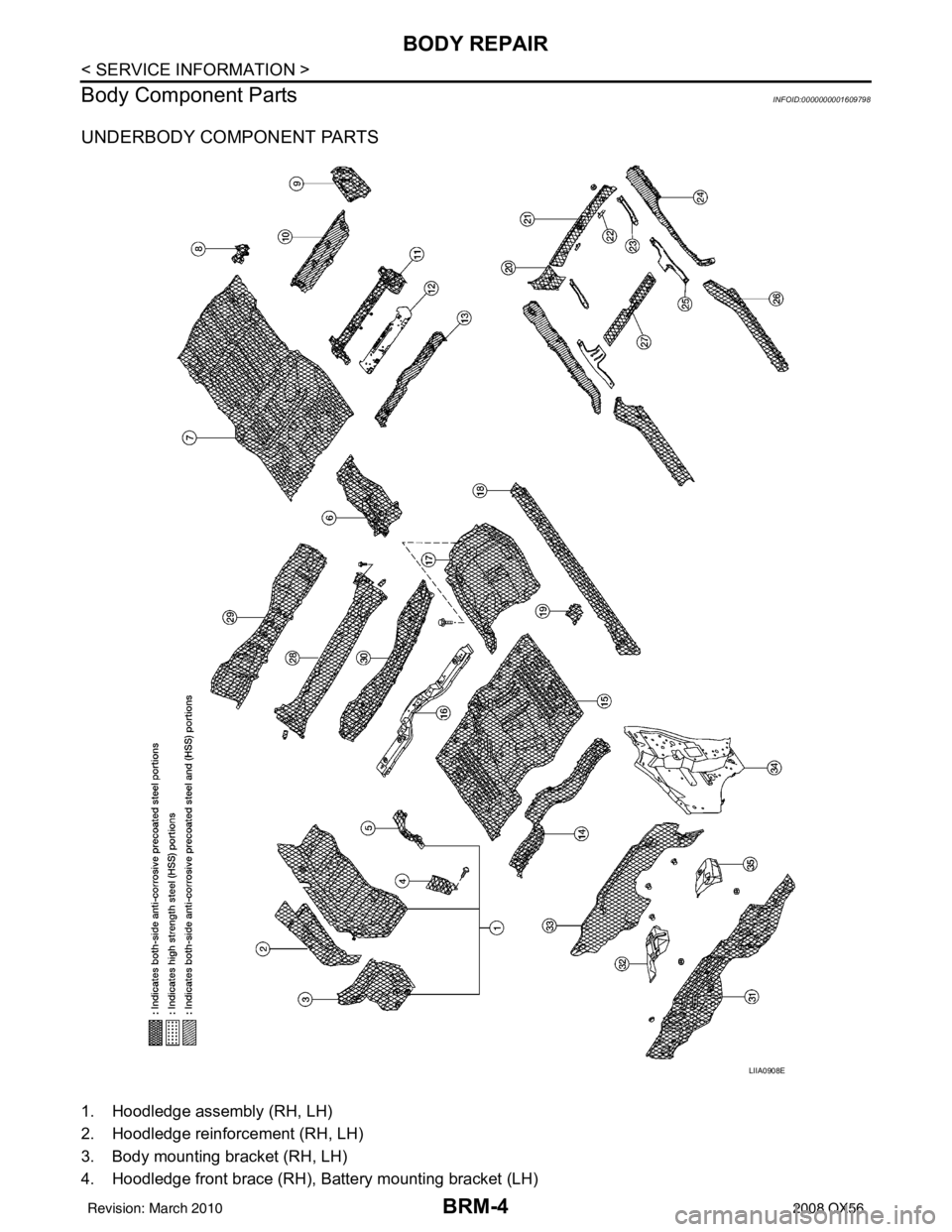

Body Component Parts

INFOID:0000000001609798

UNDERBODY COMPONENT PARTS

1. Hoodledge assembly (RH, LH)

2. Hoodledge reinforcement (RH, LH)

3. Body mounting bracket (RH, LH)

4. Hoodledge front brace (RH), Battery mounting bracket (LH)

LIIA0908E

Revision: March 2010 2008 QX56