brake fluid INFINITI QX56 2008 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2008, Model line: QX56, Model: INFINITI QX56 2008Pages: 4083, PDF Size: 81.73 MB

Page 583 of 4083

![INFINITI QX56 2008 Factory Workshop Manual BRC-116

< REMOVAL AND INSTALLATION >[VDC/TCS/ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000001604550

REMOVAL

1. Disconnect the INFINITI QX56 2008 Factory Workshop Manual BRC-116

< REMOVAL AND INSTALLATION >[VDC/TCS/ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000001604550

REMOVAL

1. Disconnect the](/img/42/57030/w960_57030-582.png)

BRC-116

< REMOVAL AND INSTALLATION >[VDC/TCS/ABS]

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)

Removal and InstallationINFOID:0000000001604550

REMOVAL

1. Disconnect the negative battery terminal.

2. Remove the air duct and resonator assembly and air cleaner case. Refer to

EM-25, "

Removal and Instal-

lation".

3. Drain the brake fluid. Refer to BR-17, "

Drain and Refill" .

4. Disconnect the actuator harness from the ABS actuator and electric unit (control unit).

5. Disconnect the brake tubes. CAUTION:

• To remove the brake tubes, use a flare nut wrench to prevent the flare nuts and brake tubes from

being damaged.

• Be careful not to splash brake fluid on painted areas.

6. Remove the three bolts and remove the ABS actuator and electric unit (control unit).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

To install, use a flare nut wr ench (commercial service tool).

1. To rear left caliper

13 N·m (1.3 kg-m, 10 ft-lb) 2. To rear right caliper

13 N·m (1.3 kg-m, 10 ft-lb) 3. To front left caliper

13 N·m (1.3 kg-m, 10 ft-lb)

4. To front right caliper 13 N·m (1.3 kg-m, 10 ft-lb) 5. From the master cylinder secondary side

18.2 N·m (1.9 kg-m, 13 ft-lb) 6. From the master cylinder primary side

18.2 N·m (1.9 kg-m, 13 ft-lb)

7. ABS actuator and electric unit (control unit) 8. Actuator harness connector

WFIA0375E

Revision: March 2010

2008 QX56

Page 584 of 4083

![INFINITI QX56 2008 Factory Workshop Manual ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)BRC-117

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

• Always tighten brake tubes to specifi cation when installing. Refer to BR- INFINITI QX56 2008 Factory Workshop Manual ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)BRC-117

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

• Always tighten brake tubes to specifi cation when installing. Refer to BR-](/img/42/57030/w960_57030-583.png)

ACTUATOR AND ELECTRIC UNIT (ASSEMBLY)BRC-117

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

• Always tighten brake tubes to specifi cation when installing. Refer to BR-21, "Hydraulic Circuit" .

• Never reuse drained brake fluid.

• After installation of the ABS actuator and elect ric unit (control unit), perform the following.

- Refill brake system with new br ake fluid. Then bleed the air from the system. Refer to BR-17, "

Bleed-

ing Brake System" .

- Adjust the steering angle sensor. Refer to BRC-8, "

ADJUSTMENT OF STEERING ANGLE SENSOR

NEUTRAL POSITION : Speci al Repair Requirement" .

- Calibrate the decel G sensor. Refer to BRC-9, "

CALIBRATION OF DECEL G SENSOR : Special Repair

Requirement" .

Revision: March 2010 2008 QX56

Page 656 of 4083

CCS-16

< FUNCTION DIAGNOSIS >

INTELLIGENT CRUISE CONTROL SYSTEM

Component Description

INFOID:0000000001731812

× : Applicable

4. ICC brake hold relay E134 5. ICC sensor E426. ICC brake switch E37

7. Stop lamp switch E38 8. ICC unit B13, B17

(view with luggage side finisher low-

er LH removed)

Component Veh ic le-t o-

vehicle

distance

control mode Conventional

(Fixed speed)

cruise

control mode Brake assist

(With preview function) Description

ICC unit ××× Controls vehicle speed through ECM via CAN commu-

nication.

ICC sensor ××× Measures distance to objects in front of the vehicle and

transmits that information to the ICC unit.

ECM ××× Refer to EC-21, "

System Diagram".

ABS actuator and electric

unit (control unit) ×××

Refer to BRC-18, "

System Description".

Brake pressure sensor ×× Detects brake fluid pressure.

Brake booster ×× Adjusts brake fluid pressure based on command from

ABS actuator and electric unit (control unit).

BCM × Transmits front wiper request signal to ICC sensor inte-

grated unit through CAN communication.

TCM ×× Refer to TM-20, "

TCM Function".

Revision: March 2010 2008 QX56

Page 1110 of 4083

![INFINITI QX56 2008 Factory Workshop Manual DLN-80

< ECU DIAGNOSIS >[ATX14B]

TRANSFER CONTROL UNIT

ECU DIAGNOSIS

TRANSFER CONTROL UNIT

Reference ValueINFOID:0000000001737179

VALUE ON THE DIAGNOSIS TOOL

CONSULT-III data monitor item

Monitored it INFINITI QX56 2008 Factory Workshop Manual DLN-80

< ECU DIAGNOSIS >[ATX14B]

TRANSFER CONTROL UNIT

ECU DIAGNOSIS

TRANSFER CONTROL UNIT

Reference ValueINFOID:0000000001737179

VALUE ON THE DIAGNOSIS TOOL

CONSULT-III data monitor item

Monitored it](/img/42/57030/w960_57030-1109.png)

DLN-80

< ECU DIAGNOSIS >[ATX14B]

TRANSFER CONTROL UNIT

ECU DIAGNOSIS

TRANSFER CONTROL UNIT

Reference ValueINFOID:0000000001737179

VALUE ON THE DIAGNOSIS TOOL

CONSULT-III data monitor item

Monitored item [Unit]

Content ConditionDisplay value

VHCL/S SEN·FR [km/h]

or [mph] Wheel speed (Front

wheel) Vehicle stopped

0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condition. Approximately

equal to the indica-

tion on speedome-

ter (Inside of

±

10%)

VHCL/S SEN·RR [km/h]

or [mph] Wheel speed (Rear

wheel) Vehicle stopped

0 km/h (0 mph)

Vehicle running

CAUTION:

Check air pressure of tire under standard condition. Approximately

equal to the indica-

tion on speedome-

ter (Inside of

±

10%)

ENGINE SPEED [rpm] Engine speed Engine stopped

(Engine speed: Less than 400 rpm)

0 rpm

Engine running

(Engine speed: 400 rpm or more) Approximately

equal to the indica-

tion on tachometer

THRTL POS SEN [V] Accelerator

pedal posi-

tion (APP) sensor signal

voltage Accelerator pedal: Released

Approx. 0.5V

Accelerator pedal: Fully depressed Approx. 4.0V

FLUID TEMP SE [V] Transfer fluid tempera-

ture signal voltage Transfer fluid temperature approx. 20 - 80

°C (68 - 176 °F) Approx. 1.1 - 0.3V

BATTERY VOLT [V] Power supply voltage for

transfer control unit Ignition switch: ON

Battery voltage

2WD SWITCH [ON/OFF] Input condition from 4WD

shift switch 4WD shift switch: 2WD

ON

4WD shift switch: AUTO, 4H or 4LO OFF

AUTO SWITCH [ON/

OFF] Input condition from 4WD

shift switch 4WD shift switch: AUTO

ON

4WD shift switch: 2WD, 4H or 4LO OFF

LOCK SWITCH [ON/

OFF] Input condition from 4WD

shift switch 4WD shift switch: 4H

ON

4WD shift switch: 2WD, AUTO or 4LO OFF

4L SWITCH [ON/OFF] Input condition from 4WD

shift switch 4WD shift switch: 4LO

ON

4WD shift switch: 2WD, AUTO or 4H OFF

N POSI SW TF [ON/

OFF] Condition of neutral-4LO

switch • Vehicle stopped

• Engine running

• A/T selector lever N posi-

tion

• Brake pedal depressed 4WD shift switch: 2WD,

AUTO or 4H

OFF

4WD shift switch: 4H to

4LO (While actuator mo-

tor is operating.) OFF

→ON

4WD shift switch: 4LO to

4H (While actuator motor

is operating.) ON

→OFF

4WD shift switch: 4LO ON

Revision: March 2010 2008 QX56

Page 1116 of 4083

![INFINITI QX56 2008 Factory Workshop Manual DLN-86

< ECU DIAGNOSIS >[ATX14B]

TRANSFER CONTROL UNIT

25 V Neutral-4LO switch• Vehicle stopped

• Engine running

• A/T selector lever

“N” position

• Brake pedal de- pressed 4WD shift swit INFINITI QX56 2008 Factory Workshop Manual DLN-86

< ECU DIAGNOSIS >[ATX14B]

TRANSFER CONTROL UNIT

25 V Neutral-4LO switch• Vehicle stopped

• Engine running

• A/T selector lever

“N” position

• Brake pedal de- pressed 4WD shift swit](/img/42/57030/w960_57030-1115.png)

DLN-86

< ECU DIAGNOSIS >[ATX14B]

TRANSFER CONTROL UNIT

25 V Neutral-4LO switch• Vehicle stopped

• Engine running

• A/T selector lever

“N” position

• Brake pedal de- pressed 4WD shift switch: 2WD, AUTO or 4H Battery voltage

4WD shift switch: 4H to 4LO (While actua-

tor motor is operating.)

Battery voltage

→

0V

4WD shift switch: 4LO to 4H (While actua-

tor motor is operating.) 0V

→ Battery

voltage

4WD shift switch: 4LO 0V

27 W/L Actuator position switch 2

(High) • Vehicle stopped

• Engine running

• A/T selector lever

“N” position

• Brake pedal de-

pressed 4WD shift switch: 4H, AUTO or 2WD 0V

4WD shift switch: 4LO

Battery voltage

28 B/G Sensor ground Always0V

29 L/W Ignition switch monitor Ignition switch: ON

Battery voltage

Ignition switch: OFF 0V

30 SB Shut off relay Ignition switch: ON

0V

Ignition switch: OFF Battery voltage

31 G Transfer fluid temperature

sensor

Ignition switch: ONTransfer fluid temperature approx. 20

°C

(68 °F) 1.1V

Transfer fluid temperature approx. 80 °C

(176 °F) 0.3V

33 R/L Transfer shift high relay

monitor • Vehicle stopped

• Engine running

• A/T selector lever

“N” position

• Brake pedal de- pressed 4WD shift switch: 4H to 4LO (“Wait” func-

tion is operating.)

Battery voltage

Except the above 0V

34 BR Clutch pressure switch • Vehicle stopped

• Engine running

• A/T selector lever

“D” position 4WD shift switch: AUTO or 4H (“Wait” func-

tion is not operating.)

0V

• Vehicle stopped

• Engine running 4WD shift switch: 2WD (“Wait” function is

not operating.)

Battery voltage

35 BR/

W Line pressure switch • Ignition switch: ON

• A/T selector lever “D” position

• 4WD shift switch: AUTO

0V

• After the vehicle has been left at

room temperature

for 5 minutes and

more with ignition

switch in “OFF” po-

sition. • Ignition switch: ON

• A/T selector lever: “P” or "N" position

• 4WD shift switch: other than AUTO

Battery voltage

40 L ATP switch • Vehicle stopped

• Engine running

• A/T selector lever

“N”

• Brak e

pedal de-

pressed 4WD shift switch: 4H to 4LO or 4LO to 4H

(While actuator motor is operating.)

0V

Except the above Battery voltage

Te r m i n a l

Wire

color Item

ConditionData (Approx.)

Revision: March 2010 2008 QX56

Page 1270 of 4083

![INFINITI QX56 2008 Factory Workshop Manual DLN-240

< SYMPTOM DIAGNOSIS >[REAR FINAL DRIVE: R230]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting C INFINITI QX56 2008 Factory Workshop Manual DLN-240

< SYMPTOM DIAGNOSIS >[REAR FINAL DRIVE: R230]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting C](/img/42/57030/w960_57030-1269.png)

DLN-240

< SYMPTOM DIAGNOSIS >[REAR FINAL DRIVE: R230]

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING

SYMPTOM DIAGNOSIS

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000001604455

Use the chart below to help you find the cause of the sy mptom. If necessary, repair or replace these parts.

×: ApplicableReference page

DLN-251, "

Disassembly and Assembly

"

DLN-251, "

Disassembly and Assembly

"

DLN-251, "

Disassembly and Assembly

"

DLN-268, "

Inspection and Adjustment

"

DLN-268, "

Inspection and Adjustment

"

MA-12, "

Fluids and Lubricants

"

DLN-192, "

NVH Troubleshooting Chart

"

DLN-240, "

NVH Troubleshooting Chart

"

RSU-5, "

NVH Troubleshooting Chart

"

WT-41, "

NVH Troubleshooting Chart

"

WT-41, "

NVH Troubleshooting Chart

"

RAX-5, "

NVH Troubleshooting Chart

"

BR-6, "

NVH Troubleshooting Chart

"

ST-12, "

NVH Troubleshooting Chart

"

Possible cause and SUSPECTED PARTS

Gear tooth rough

Gear contact improper

Tooth surfaces worn

Backlash incorrect

Companion flange excessive runout

Gear oil improper

PROPELLER SHAFT

REAR AXLE

REAR SUSPENSION

TIRES

ROAD WHEEL

DRIVE SHAFT

BRAKES

STEERING

Symptom

Noise××××××× ××××××

Revision: March 2010 2008 QX56

Page 1324 of 4083

![INFINITI QX56 2008 Factory Workshop Manual ENGINE CONTROL SYSTEMEC-25

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. EVAP canister purge volume control

solenoid valve (view with engine

cover removed) 2. EVAP service port INFINITI QX56 2008 Factory Workshop Manual ENGINE CONTROL SYSTEMEC-25

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. EVAP canister purge volume control

solenoid valve (view with engine

cover removed) 2. EVAP service port](/img/42/57030/w960_57030-1323.png)

ENGINE CONTROL SYSTEMEC-25

< FUNCTION DIAGNOSIS > [VK56DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. EVAP canister purge volume control

solenoid valve (view with engine

cover removed) 2. EVAP service port (view with engine

cover removed) 3. Crankshaft position sensor (POS)

(view from under the vehicle)

4. Engine oil pan (view from under the vehicle) 5. Condenser-1

6. Brake fluid reservoir

7. EVAP canister (view with fuel tank removed) 8. EVAP control system pressure sen-

sor (view with fuel tank removed) 9. EVAP canister vent control valve

(view with fuel tank removed)

10. Rear suspension member (view with fuel tank removed) 11. Refrigerant pressure sensor (view

with front grille removed) 12. Intake valve timing control position

sensor (bank 2) (view with engine

cover and intake air duct removed)

13. Intake valve timing control position sensor (bank 1) (view with engine

cover and intake air duct removed) 14. Intake valve timing control solenoid

valve (bank 2) (view with engine cov-

er and intake air duct removed) 15. Drive belt (view with engine cover

and intake air duct removed)

16. Radiator hose (view with engine cov- er and intake air duct removed) 17. Intake valve timing control solenoid

valve (bank 1) (view with engine cov-

er and intake air duct removed)

: Vehicle front

BBIA0774E

Revision: March 2010 2008 QX56

Page 1855 of 4083

EM-52

< ON-VEHICLE REPAIR >

TIMING CHAIN

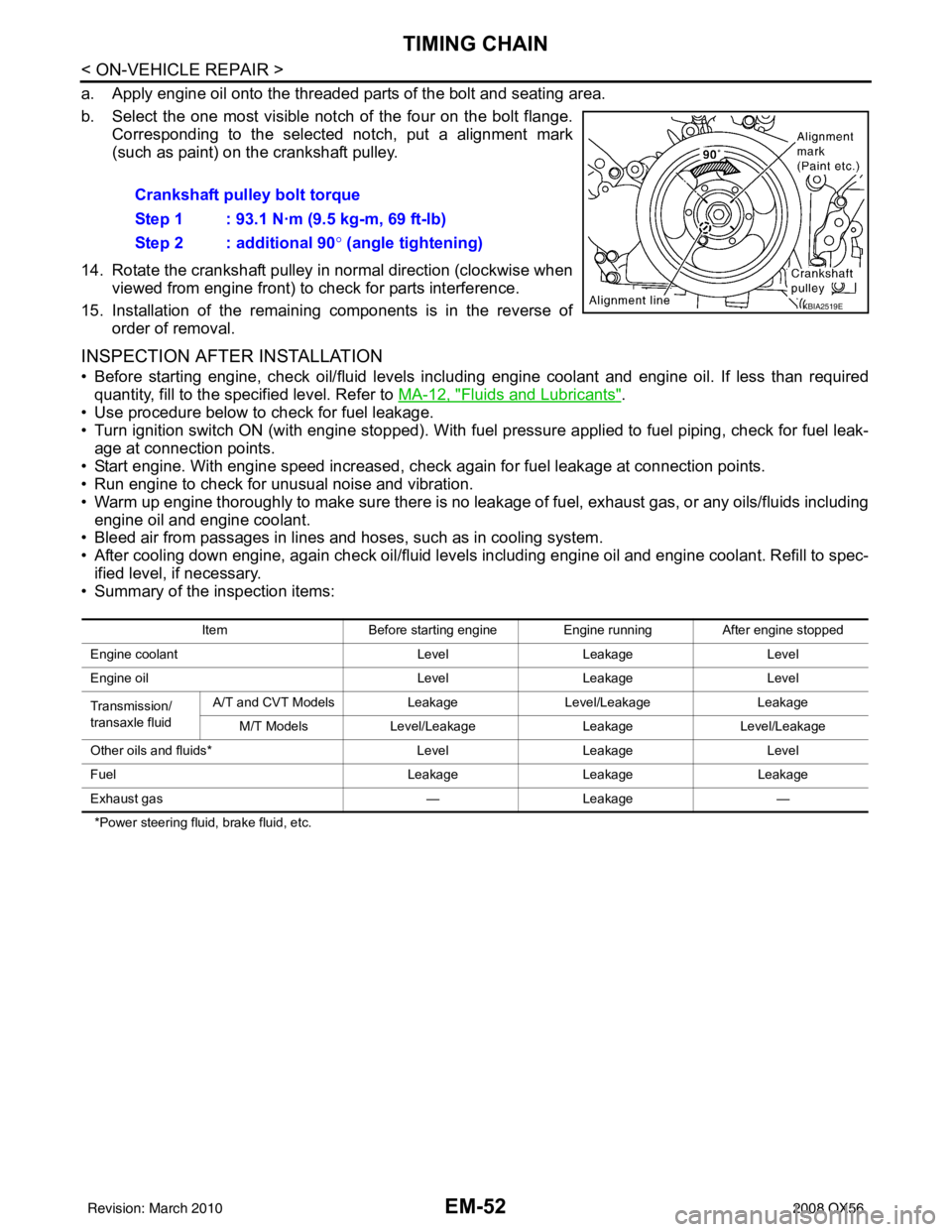

a. Apply engine oil onto the threaded parts of the bolt and seating area.

b. Select the one most visible notch of the four on the bolt flange.Corresponding to the selected notch, put a alignment mark

(such as paint) on the crankshaft pulley.

14. Rotate the crankshaft pulley in normal direction (clockwise when viewed from engine front) to check for parts interference.

15. Installation of the remaining components is in the reverse of order of removal.

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-12, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak- age at connection points.

• Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec-

ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc.

Crankshaft pulley bolt torque

Step 1 : 93.1 N·m (9.5 kg-m, 69 ft-lb)

Step 2 : additional 90 ° (angle tightening)

KBIA2519E

Item Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakage Leakage

Exhaust gas —Leakage —

Revision: March 2010 2008 QX56

Page 1873 of 4083

EM-70

< ON-VEHICLE REPAIR >

CYLINDER HEAD

*Power steering fluid, brake fluid, etc.

Disassembly and AssemblyINFOID:0000000001538829

DISASSEMBLY

1. Remove the spark plug. Refer to EM-16, "Removal and Installation".

2. Remove the valve lifter. • Identify the installation positions, and store them without mixing them up.

Item Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakage Leakage

Exhaust gas —Leakage —

1. Spark plug 2. Valve lifter3. Valve collet

4. Valve spring retainer 5. Valve spring6. Valve spring seat

7. Valve oil seal 8. Valve guide9. Valve seat

10. Valve (INT) 11. Valve (EXH)12. Cylinder head (LH bank)

13. Spark plug tube 14. Cylinder head (RH bank)

WBIA0470E

Revision: March 2010 2008 QX56

Page 1884 of 4083

ENGINE ASSEMBLYEM-81

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EM

NP

O

• Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leak

age of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakageLeakage

Exhaust gas —Leakage —

Revision: March 2010 2008 QX56